Unlocking the Power of Neodymium: Your Complete Guide to Custom Neodymium Magnets

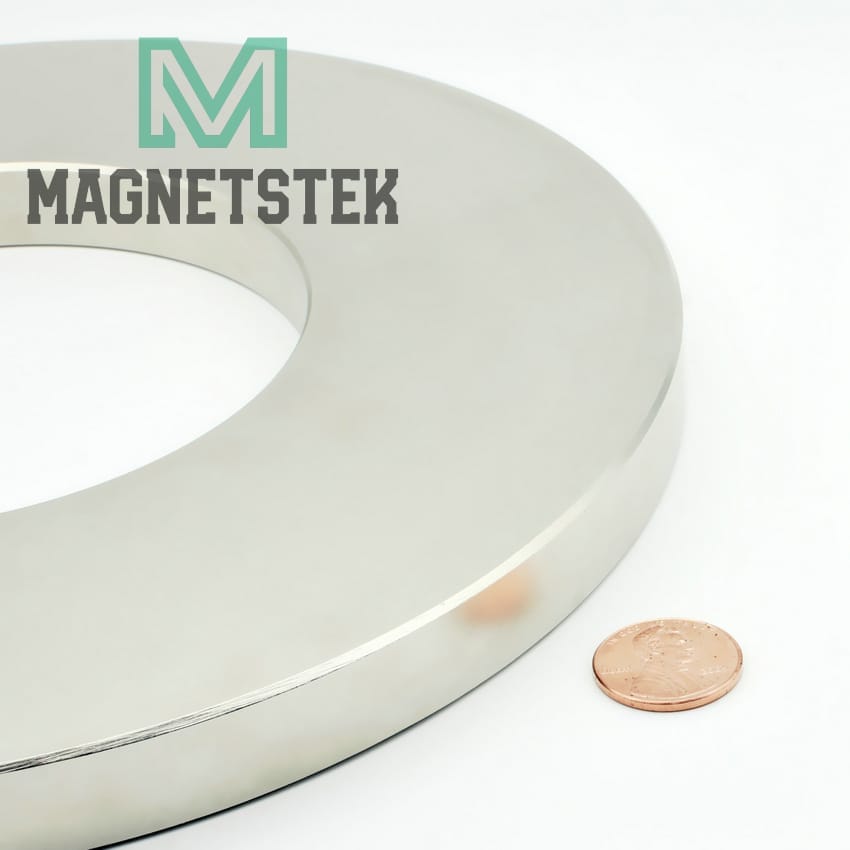

Custom neodymium magnets are revolutionizing the world of magnets. These compact and powerful magnetic marvels have the potential to unlock countless possibilities in various industries. Whether it’s in electronics, automotive, renewable energy, or medical equipment, custom neodymium magnets offer exceptional strength and reliability.

With their magnetic strength, these magnets can be crafted into various shapes and sizes to fit specific applications. Their versatility allows them to be used in a wide range of products, from consumer electronics to high-tech industrial equipment.

What sets custom neodymium magnets apart is their superior performance. They possess a significantly higher magnetic energy density compared to other magnets, making them more efficient for various applications. Their strength allows them to hold heavier loads, ensuring optimum performance in different settings.

Moreover, custom neodymium magnets are known for their durability. They can withstand extreme temperatures, making them suitable for both indoor and outdoor use. They also have excellent resistance to corrosion, ensuring a longer lifespan.

In conclusion, custom neodymium magnets are the future of magnet technology. Their compact yet powerful design, versatility, and exceptional performance make them a game-changer in multiple industries.

Table of Contents

I. What Set Neodymium Magnets Apart?

Neodymium magnets, also known as rare earth magnets, offer several advantages that set them apart from other types of magnets. One of the key advantages is their exceptionally high magnetic energy density. This means that they can generate a stronger magnetic field compared to other magnets of similar size, making them ideal for applications that require a compact yet powerful magnetic solution.

Another advantage of neodymium magnets is their high coercivity, which allows them to maintain their magnetization in the presence of external magnetic fields. This makes them highly reliable and ensures consistent performance in various settings.

Additionally, neodymium magnets have excellent temperature stability. They can withstand extreme temperatures, making them suitable for applications in environments with high heat or cold. This temperature stability also contributes to their long lifespan and durability.

Furthermore, neodymium magnets have excellent resistance to corrosion. This is due to their composition, which includes a protective coating to prevent oxidation. This resistance to corrosion ensures that the magnets maintain their performance and reliability over time, even in harsh environments.

II. Understanding the Composition of Neodymium Magnets

Neodymium magnets are made from an alloy of neodymium, iron, and boron, commonly referred to as NdFeB. This composition gives the magnets their exceptional magnetic properties, including their high magnetic energy density and coercivity.

The neodymium component, which is a rare earth element, is responsible for the magnets’ strong magnetic field. It provides the magnets with the magnetic strength needed for various applications. The iron component enhances the magnetic properties of the magnets, while the boron component helps to stabilize the crystal structure of the alloy, improving its magnetic performance.

To protect the magnets from corrosion, they are typically coated with a layer of nickel. This nickel coating provides a barrier between the magnets and the surrounding environment, preventing oxidation and ensuring long-term performance.

III. Applications of Neodymium Magnets in Various Industries

Neodymium magnets have found applications in a wide range of industries due to their exceptional strength and versatility. Here are some examples of how these magnets are being used:

Electronics

In the electronics industry, neodymium magnets are used in various devices, including speakers, headphones, and hard disk drives. Their compact size and strong magnetic field make them ideal for miniaturized electronic components. They help to improve the performance of audio devices by providing clear and powerful sound reproduction. In hard disk drives, neodymium magnets are used to precisely position the read and write heads, allowing for faster and more accurate data access.

Automotive

The automotive industry also benefits from the use of neodymium magnets. These magnets are used in electric vehicle motors, hybrid vehicle systems, and various sensors. In electric vehicles, neodymium magnets help to generate the torque required for propulsion, ensuring efficient and powerful performance. They are also used in regenerative braking systems, where they convert kinetic energy into electrical energy, improving overall energy efficiency.

Renewable Energy

Neodymium magnets play a crucial role in renewable energy systems, particularly in wind turbines and solar power systems. In wind turbines, these magnets are used in the generator to convert the rotational energy of the blades into electrical energy. The strong magnetic field of neodymium magnets enables efficient power generation. In solar power systems, neodymium magnets are used in the motors that track the movement of solar panels, ensuring maximum exposure to sunlight.

Medical Equipment

In the medical industry, neodymium magnets find applications in equipment such as magnetic resonance imaging (MRI) machines and magnetic therapy devices. In MRI machines, neodymium magnets are used to generate the strong magnetic field required for imaging. The magnets help to produce detailed and accurate images of internal body structures. In magnetic therapy devices, neodymium magnets are used to provide pain relief and improve blood circulation.

Other Industries

Neodymium magnets are also used in a variety of other industries, including aerospace, defense, and telecommunications. In aerospace applications, these magnets are used in actuators, sensors, and navigation systems. In defense applications, neodymium magnets are used in radar systems, missile guidance systems, and magnetic levitation systems. In telecommunications, these magnets are used in high-frequency antennas and magnetic sensors.

IV. Factors to Consider When Selecting Neodymium Magnets

When choosing neodymium magnets for your applications, several critical factors must be considered to ensure optimal performance and suitability. Here’s a detailed look at the key factors:

1. Magnetic Strength and Grade

Neodymium magnets are available in various grades, which indicate the strength of the magnet. The grade of a neodymium magnet typically ranges from N35 to N52; the higher the number, the stronger the magnet. Choosing the right grade depends on the required magnetic force for your specific application.

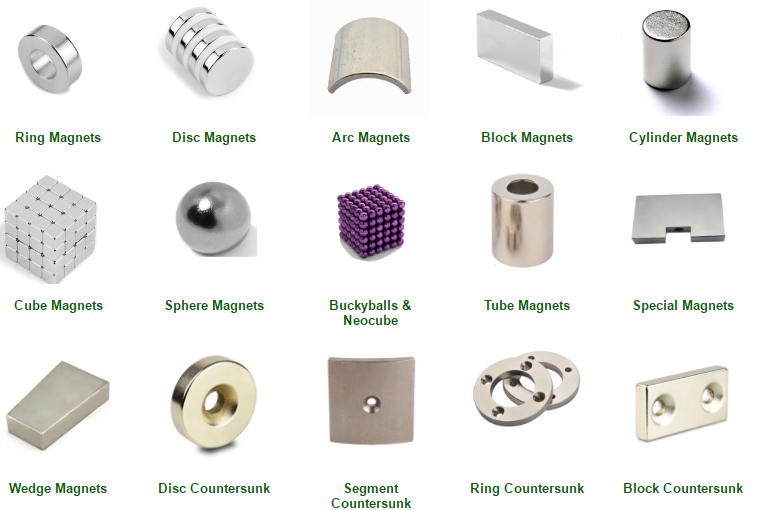

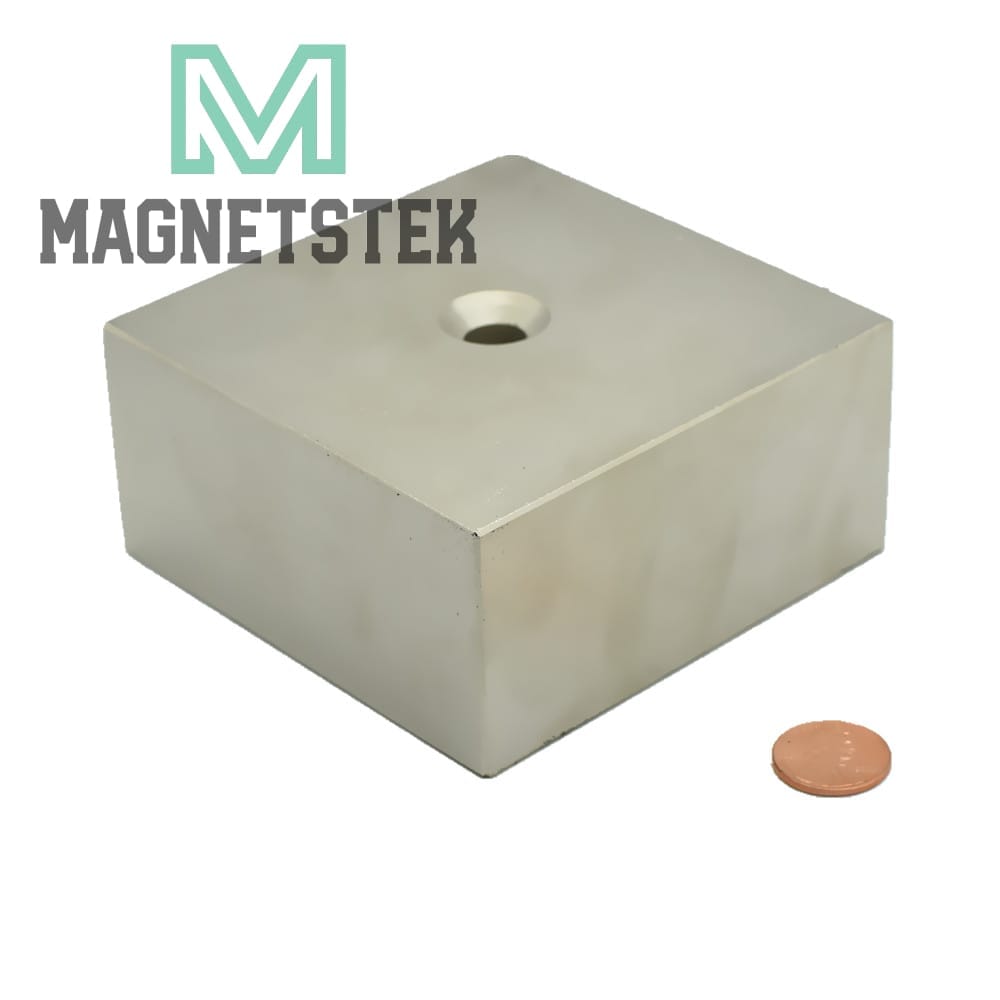

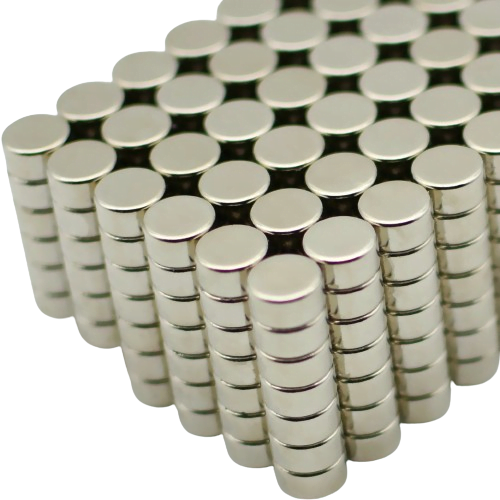

2. Size and Shape

The size and shape of the magnet affect its strength and how it can be used. Neodymium magnets come in various forms, such as discs, rings, blocks, and spheres. The choice of size and shape will largely depend on the space available and the magnetic field configuration required for the application.

3. Coating

Neodymium magnets are prone to corrosion, especially in humid or wet environments. To prevent corrosion, these magnets are usually coated with materials such as nickel, zinc, gold, or epoxy. The choice of coating affects the magnet’s resistance to corrosion and its appearance.

4. Temperature Tolerance

The performance of neodymium magnets decreases at high temperatures. Each magnet is rated for a maximum operating temperature, and exceeding this temperature can lead to a permanent loss in magnetic strength. If your application involves high temperatures, consider a high-temperature grade magnet.

5. Environmental Factors

Environmental exposure such as moisture, chemicals, and abrasive conditions can degrade neodymium magnets. It’s crucial to consider the environmental conditions the magnet will face and choose a magnet with appropriate protective coatings or housings.

6. Magnetic Field Requirements

Depending on the application, the configuration of the magnetic field can be crucial. Factors such as the polarity, the intensity of the magnetic field, and the direction of magnetization need to be considered to match your specific needs.

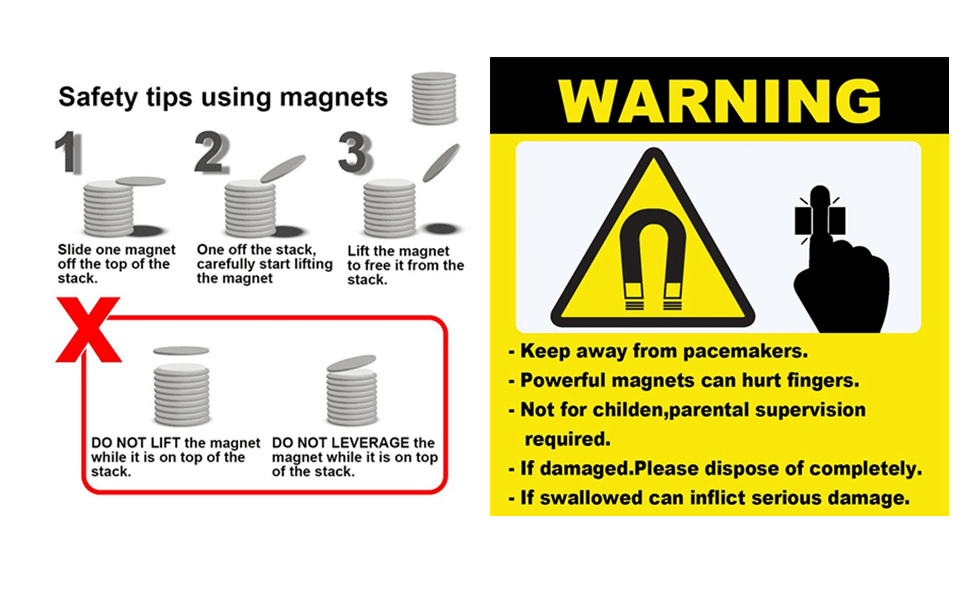

7. Regulatory and Safety Concerns

Neodymium magnets are extremely powerful and can pose hazards if not handled correctly. Safety concerns such as pinching injuries or hazards due to unintended attraction to metal objects need consideration. Furthermore, compliance with regulatory standards for magnetic emissions and safety is essential.

8. Cost Considerations

The cost of neodymium magnets varies based on the grade, size, coating, and quantity ordered. Higher grades and specialized coatings can increase the cost, so it’s important to balance performance requirements with budget constraints.

9. Supplier Reliability

Choosing a reputable supplier is crucial as it affects the quality of the magnets, the consistency of the supply, and the support services available. A reliable supplier will ensure that the magnets meet the specified grades and tolerances and provide assistance in selecting the right magnet for your applications.

By thoroughly evaluating these factors, you can select the most appropriate neodymium magnets for your needs, ensuring performance, durability, and cost-effectiveness.

V. How to Properly Handle and Store Neodymium Magnets

Proper handling and storage of neodymium magnets are crucial to maintain their strength and integrity, as well as to ensure safety due to their powerful magnetic properties. Here are some guidelines to help you manage neodymium magnets effectively:

Handling Neodymium Magnets

Use Protective Gloves: Always wear protective gloves when handling larger magnets to avoid pinching your fingers between magnets or between a magnet and a metal surface.

Avoid Impact: Neodymium magnets are brittle and can crack or chip if they snap together or slam against a hard surface. Handle them gently to prevent collisions.

Keep Away from Electronics: The strong magnetic fields of neodymium magnets can damage electronic devices and magnetic media. Keep magnets away from computers, smartphones, credit cards, watches, and other sensitive equipment.

Secure During Transport: When transporting larger magnets, secure them firmly to prevent movement. The magnetic force can cause them to shift abruptly, which could be dangerous.

Use Spacers: If storing multiple magnets together, place a non-magnetic spacer between them to prevent them from snapping together and causing injury or damage.

Storing Neodymium Magnets

Controlled Environment: Store magnets in a dry, mild temperature environment to prevent corrosion. High humidity and extreme temperatures can degrade the magnet’s protective coating, leading to corrosion.

Separate and Shielded Storage: Store strong magnets separately or in a way that their magnetic fields do not interfere with each other. For extremely powerful magnets, consider using steel sheeting or other magnetic shields to contain the magnetic field.

Avoid Mechanical Stress: Do not stack heavy objects on top of neodymium magnets. The mechanical stress can alter the magnet’s properties or cause physical damage.

Label Storage Areas: Clearly label the storage areas for magnets to warn people who might not be familiar with the strength of neodymium magnets about the potential hazards.

Safety Precautions

Pacemakers and Medical Devices: Keep neodymium magnets away from individuals with pacemakers or other medical devices. Magnets can interfere with the operation of such devices.

Children’s Safety: Keep neodymium magnets out of reach of children. Small magnets can pose a serious choking hazard, and if ingested, they can cause significant internal injury.

Eye Protection: Wear safety goggles when handling large magnets to protect your eyes from potential shrapnel if a magnet chips or shatters.

By following these guidelines for handling and storing neodymium magnets, you can prevent injuries, protect your equipment, and extend the life of the magnets.

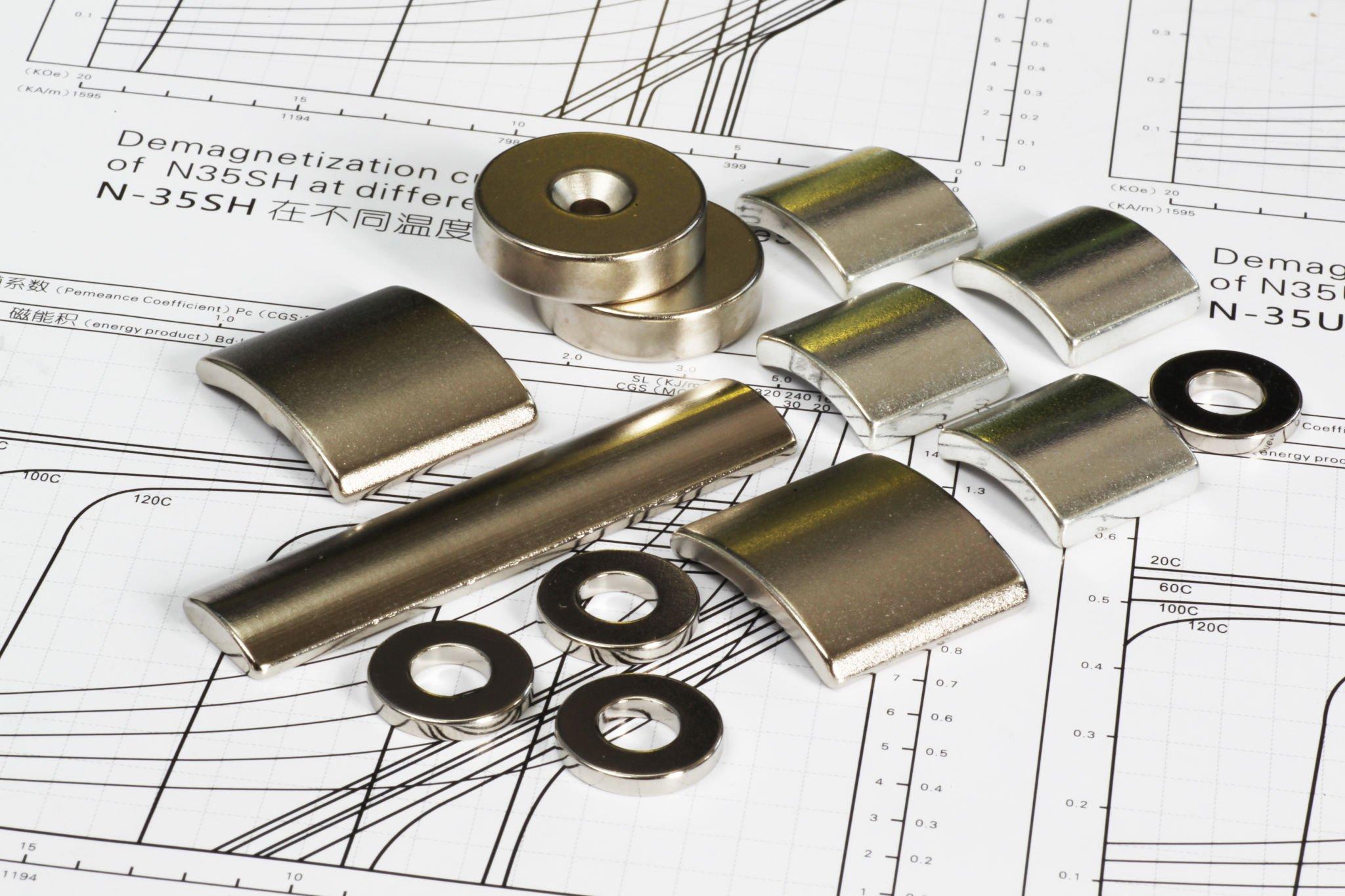

VI. Customization Options for Neodymium Magnets

Customization plays a critical role in maximizing the utility of neodymium magnets across various applications. Customizing neodymium magnets involves altering their properties, dimensions, and other specifications to fit specific requirements. Here’s a detailed overview of the main customization options available for neodymium magnets:

1. Size and Shape

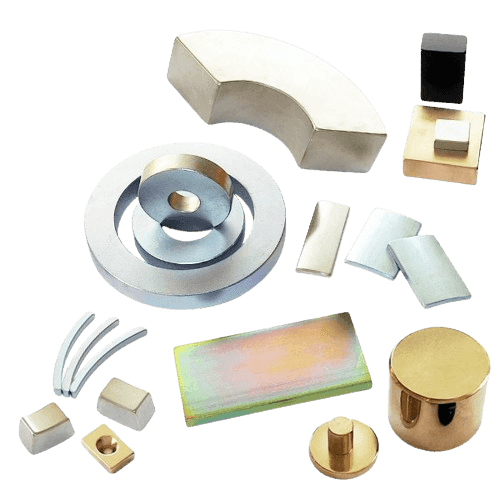

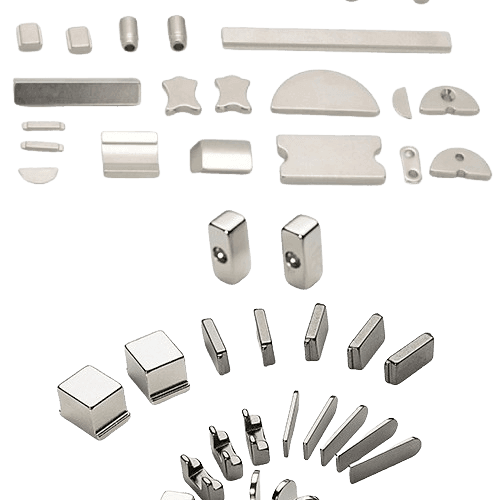

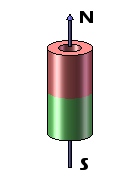

Neodymium magnets can be manufactured in virtually any shape and size, depending on the application’s demands. Common shapes include:

- Discs

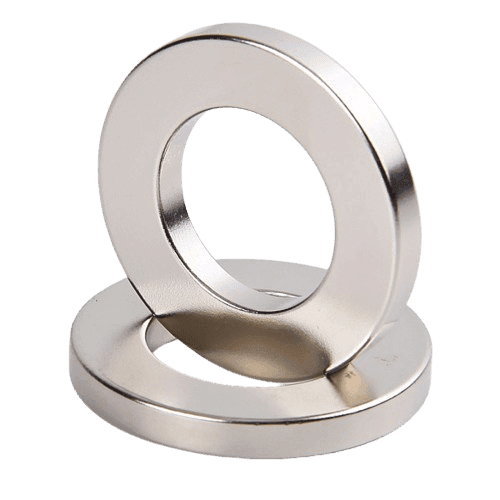

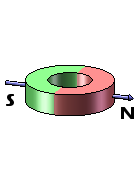

- Rings

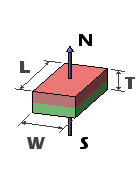

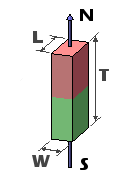

- Blocks

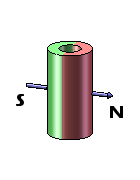

- Cylinders

- Spheres

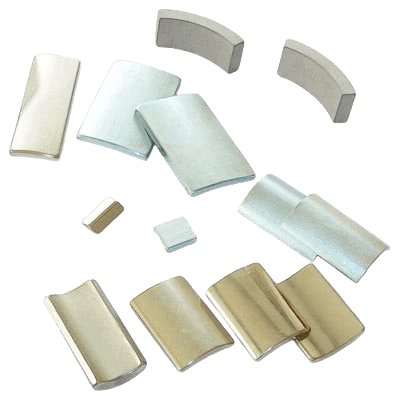

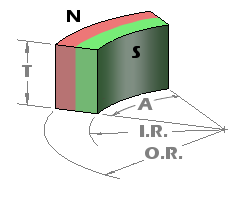

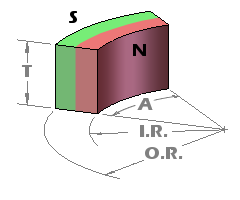

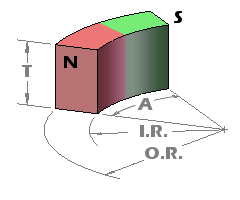

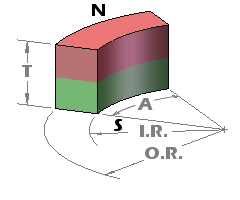

- Arcs (common in motors)

- Custom shapes designed according to specific customer drawings or requirements, such as complex geometric shapes for advanced engineering projects.

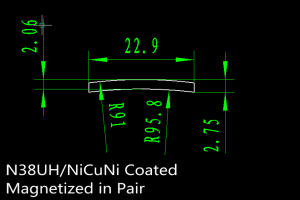

2. Magnetic Grade

Choosing the appropriate grade of neodymium magnet is crucial for achieving the desired magnetic performance. Grades typically range from N35 to N52, indicating the strength and resistance to demagnetization. Higher grades are stronger but more expensive. For extreme environments or specialized applications, grades like N42SH or N52M might be selected for their high-temperature resistance or increased magnetic strength.

3. Coating and Plating

The susceptibility of neodymium magnets to corrosion necessitates the application of protective coatings. The choice of coating can also influence the magnet’s appearance and performance in various environments. Common coatings include:

- Nickel (Ni-Cu-Ni) – The most common coating due to its effectiveness in resistance against corrosion.

- Zinc – A cost-effective alternative that provides good protection.

- Epoxy – Used for superior corrosion resistance, especially in marine or harsh environments.

- Gold – Provides both aesthetic appeal and corrosion resistance.

- Teflon – Often used where the magnet needs to be non-stick or in medical applications.

- Parylene – Used for applications requiring biocompatibility and high corrosion resistance.

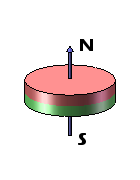

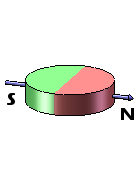

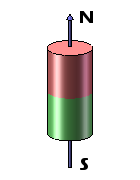

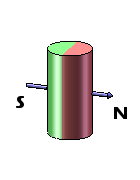

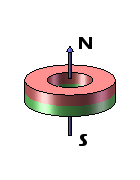

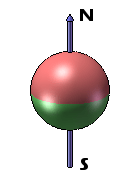

4. Magnetization Direction

The direction in which a magnet is magnetized affects how it interacts with other components in an assembly. Common magnetization directions include:

- Axially magnetized (through thickness)

- Diametrically magnetized (through diameter)

- Radially magnetized (for ring magnets)

- Multi-poles on one face (common in sensory and holding applications)

5. Temperature Ratings

Neodymium magnets have different maximum operating temperatures depending on their material composition. Custom magnets can be designed to withstand specific temperatures, with options available for applications requiring stability under elevated temperatures.

6. Tolerance

Custom tolerance levels can be specified for dimensions and strength, ensuring the magnets perfectly fit into precise mechanical assemblies without additional modification.

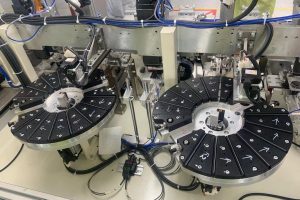

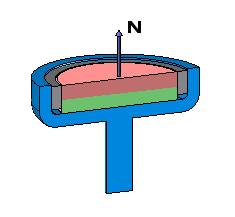

7. Assembly Integration

Magnets can be integrated into assemblies with other components, such as metal pieces, plastic molds, or other materials. This might include embedding magnets into parts or creating magnetic assemblies that are ready for installation.

8. Certifications and Testing

For certain industries, like aerospace or medical devices, magnets might need to meet specific standards or undergo rigorous testing to confirm their performance under expected conditions.

By exploring these customization options, customers can tailor neodymium magnets to their specific needs, enhancing both the functionality and the efficiency of their applications. This flexibility is crucial in industries where precision and reliability are paramount.

VII. Tips for maximizing the performance and lifespan of neodymium magnets

Maximizing the performance and lifespan of neodymium magnets involves proper handling, usage, and storage. Here are key tips to ensure you get the most out of your neodymium magnets:

1. Handle with Care

Neodymium magnets are brittle and can chip or break if they collide with a hard surface. Always handle magnets with care, especially larger ones, as they can snap together with significant force. Using padding and protective gear, like gloves and safety glasses, can prevent injury and damage to the magnets.

2. Use Appropriate Coatings

To protect neodymium magnets from corrosion, which can lead to a deterioration in magnetic performance, ensure they are coated. Common coatings include nickel, zinc, epoxy, and more specialized coatings like parylene for specific environments. Regularly check the integrity of the coating and replace or re-coat the magnets if you see signs of wear or corrosion.

3. Maintain Optimal Temperature Conditions

Neodymium magnets lose their magnetic properties if heated above their maximum operating temperature. Different grades have different temperature limits, typically ranging from 80°C to 200°C. Keep magnets away from heat sources and consider using higher grade magnets if operating in high-temperature environments.

4. Minimize Impact and Pressure

Physical stress, such as impact from dropping or striking, and excessive pressure from clamping or mechanical stress, can physically damage the magnet or alter its magnetic properties. Store and use magnets in a way that minimizes these risks.

5. Avoid Demagnetizing Influences

Keep neodymium magnets away from electrical currents, other magnets with opposing fields, and any equipment generating significant electromagnetic fields. Exposure to opposing magnetic fields can partially demagnetize your magnets.

6. Proper Storage

Store neodymium magnets in an organized manner:

- Place a soft material like foam or rubber between individual magnets to prevent them from attracting each other and breaking.

- If possible, store magnets in a closed container to protect them from environmental factors and reduce the risk of accidental contact with other metal objects.

- Avoid storing magnets near electronic devices and magnetic media, as their strong fields can cause damage or data loss.

7. Regular Testing and Inspection

Regularly test the strength and integrity of your magnets. This can be especially important in critical applications where a decrease in magnetic performance could lead to failures or safety issues. Inspect for physical and chemical wear, especially around the coatings.

8. Compliance with Handling Guidelines

Educate all users on the proper handling and storage practices for neodymium magnets. This includes safety training to avoid injuries from pinching and proper procedures for assembling and disassembling magnetic assemblies.

By following these tips, you can ensure that your neodymium magnets perform at their best for the longest possible time, supporting efficient operations in any application where they are used.

VIII. Common misconceptions about neodymium magnets

Neodymium magnets, being among the strongest permanent magnets available, are often surrounded by misconceptions due to their powerful magnetic properties and wide range of applications. Here are some common misconceptions about neodymium magnets:

1. Neodymium Magnets are Indestructible

One common myth is that neodymium magnets are indestructible due to their high strength. In reality, while neodymium magnets are very strong magnetically, they are quite brittle and prone to chipping, cracking, or breaking if mishandled, dropped, or allowed to snap together.

2. Higher Grade Means Better for All Applications

Higher grade neodymium magnets (e.g., N52) are often thought to be superior in all aspects because they have a higher magnetic strength. However, higher grades are not always the best choice; they are more sensitive to temperature and can demagnetize more easily at elevated temperatures compared to lower grades. The choice of grade should depend on the specific requirements of the application, including environmental conditions.

3. Neodymium Magnets Can Be Easily Remagnetized

It’s a common belief that if a neodymium magnet becomes demagnetized, it can be easily remagnetized. However, remagnetizing a neodymium magnet to its original strength requires precise control over the magnetic field and temperature, which is not feasible outside of a professional manufacturing or laboratory setting.

4. They Are Safe Around All Electronic Devices

There’s a misconception that small neodymium magnets won’t harm electronics due to their size. Even small neodymium magnets can generate fields strong enough to damage electronic components, erase magnetic media, and affect the operation of medical devices like pacemakers. Caution should always be exercised when using magnets near any electronic devices.

5. All Neodymium Magnets Are the Same

Many people think all neodymium magnets are the same, but they can vary greatly in terms of magnetic strength, size, shape, coating, and temperature tolerance. These factors can dramatically affect their suitability for different applications.

6. Magnets Never Lose Their Magnetism

There is a notion that once magnetized, neodymium magnets will retain their magnetism indefinitely. While it’s true they are permanent magnets, they can lose their magnetism over time if exposed to adverse conditions such as high temperatures, strong opposing magnetic fields, or physical damage.

7. Magnetic Therapy Myths

Magnetic therapy often uses neodymium magnets with claims of health benefits, such as pain relief and enhanced healing. However, there is little scientific evidence to support these health claims, and reliance on magnet therapy for serious conditions can lead to delays in seeking effective medical treatment.

8. Magnets Can be Drilled or Remachined

Can neodymium magnets be drilled or machined? It’s neither easy nor safe. Neodymium sintered magnets have properties similar to ceramics, which makes them prone to cracking and chipping if subjected to drilling. Furthermore, the powder generated during the machining process is highly flammable. Additionally, machining can cause heat to accumulate within the magnet, potentially leading to demagnetization. In most cases, attempting to drill or machine a neodymium magnet will render it unusable due to breakage, cracking, or heat damage.

Understanding these misconceptions can help users better appreciate the real properties of neodymium magnets and employ them more effectively and safely in their specific applications.

IX. Conclusion: Harnessing the power of neodymium magnets for innovation and efficiency

In conclusion, neodymium magnets offer unparalleled strength and versatility, making them invaluable in pushing the boundaries of innovation and efficiency across various industries. By understanding their unique properties and capabilities, businesses can harness the power of these magnets to enhance product performance, streamline manufacturing processes, and develop new, cutting-edge applications.

Whether used in electronics, automotive, healthcare, or renewable energy sectors, neodymium magnets contribute significantly to advancements that shape our modern world. It is essential, however, to handle and integrate these powerful magnets properly to maximize their performance and lifespan, ensuring they deliver the best possible outcomes in every application. With careful consideration and appropriate customization, neodymium magnets continue to be at the forefront of technological innovation, driving efficiency and progress in countless projects and products.