Samarium Cobalt Magnets

Samarium Cobalt (SmCo) magnets are highly resistant to corrosion and oxidation. They are a type of rare earth magnet known for their strong magnetic properties and resistance to high temperatures. Depending on the grades, the maximum operating temperature can reach 250°C to 600°C, with no limit on negative temperatures. At working temperatures above 180°C, SmCo magnets’ temperature and chemical stability exceed those of Neodymium magnets.

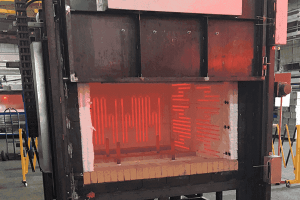

Our R&D abilities set us apart. MagnetsTek made SmCo magnets that can work at temperatures up to 600°C. Our production time is as short as 4 days!

Custom Samarium Cobalt Magnets for Your Needs!

Your Trusted Source of Samarium Cobalt Magnets

Grades/Strength

The range of SmCo magnet grade ranged from 16 MGOe to 32 MGOe. There are two types of SmCo magnets: Sm₁Co₅ and Sm₂Co₁₇.

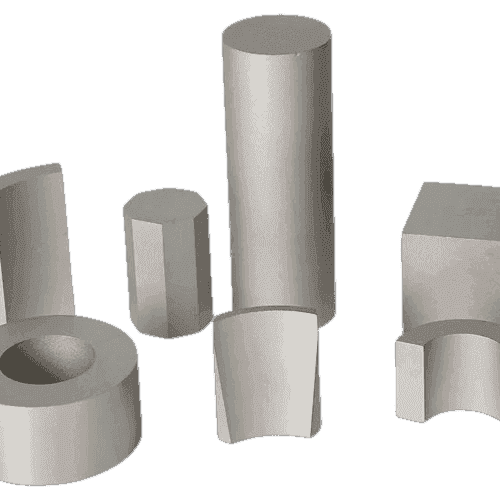

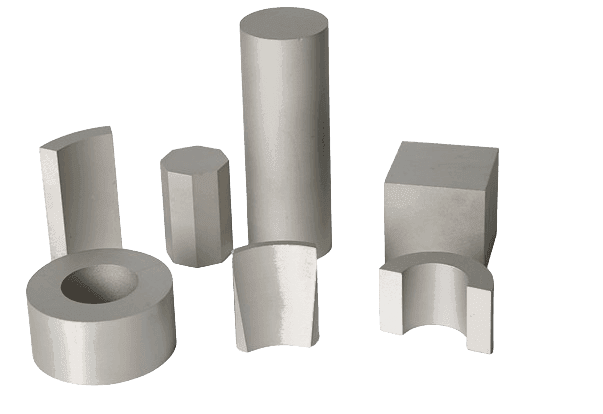

Shape and Dimension

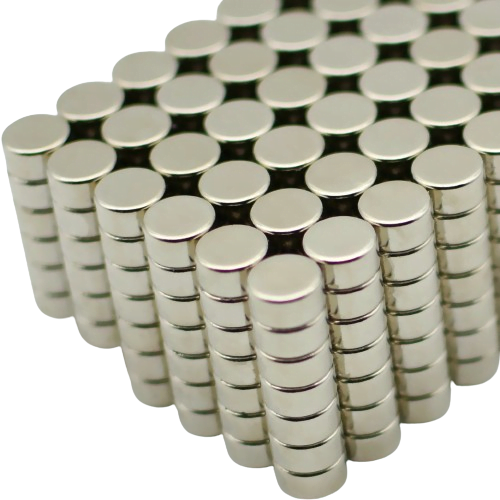

Samarium Cobalt magnets are available in various shapes and sizes, including discs, cylinders, blocks, cubes, rings, tubes, arcs, balls and custom shapes.

Magnetizing Direction

Magnetizing directions refer to the orientation of the magnetic field within a magnet. Magnetstek can magnetize magnets with thicknesses up to 115mm for MRI.

Temperature Effects

The maximum operating temperature can reach 250°C to 600°C depending on the grades, with no limit on negative temperatures.

Advantages

Samarium Cobalt Magnets are highly resistant to corrosion and oxidation; it has strong magnetic properties and resistance to high temperatures.

What Set Us Apart

Strong Capabilities

Eco-friendly facilities, 4,500 tons of magnets yearly. Our company has more than 700 processing and precision machining equipment that can handle a variety of complex shapes and high-precision magnet products.

Most Experienced

With a large expert team, Magnetstek offers a range of technical solutions covering the entire process, from the design and development of customer products to their validation and mass production.

Quality Controls

Magnetstek strictly adheres to ISO 9001:2015, IATF 16949:2016 Quality Management System, and ISO 14001:2015 Environmental Management System. Products RoHS certified.

Fast Services

We offer custom samarium cobalt magnets for as short as 4 days and multiple customer service channels (calls, emails, and WhatsApp). We provide various document options, and we conduct regular customer satisfaction surveys.

Custom Per Requests

At MagnetsTek, we can produce magnets per request. Magnets can be made in various materials, grades, shapes, sizes, coatings, and magnetizing directions. All you need to do is send a message.

Magnet Assemblies

MagnetsTek Engineering specializes in customizing magnets and magnetic assemblies, serving as your comprehensive magnet solution provider. We are your one-stop supplier for all magnet needs.

Large Inventory

We understand the importance of convenience and quick solutions. MagnetsTek offers a variety of ready-made magnet options, including some with quantities in the millions that can be tailored to your specific needs.

Happy Customers

Customer satisfaction is our top priority. We ensure timely responses and solutions for all inquiries, backed by regular satisfaction surveys. Whether regarding production or service inquiries, we consistently deliver excellent results.

- Sm₁Co₅

- Sm₂Co₁₇

Sm₁Co₅-Samarium Cobalt Magnets

Samarium and cobalt with atomic ratio of 1:5

The 1:5 samarium cobalt magnets, also known as SmCo₅, are made from a combination of rare earth metals such as samarium, cobalt, gadolinium, and praseodymium. Magnetstek Engineering supplies custom SmCo5 magnets.

The 1:5 samarium cobalt magnets offer a maximum magnetic energy range of 10-25 and can withstand temperatures up to 250℃. Meanwhile, the total magnetic energy product is lower than that of 2:17 samarium cobalt magnets. Moreover, the mechanical properties and flexibility are superior. This makes it easier to machine into complex shapes such as thin disks, squares, rings, and custom shapes.

Sintered Sm₁Co₅ Magnet Magnetic Properties Standard

| Grade | Remanence/Br. | Coercivity Force/HcB. | Intrinsic Coercivity/HcJ. | Maximun Energy/(BH)max | Curie Temperature | Max. Operating Temperature | Temperature Coefficient of Br α(Br) | Temperature Coefficient of Hcj β(Hcj) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T | KGs | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ℃ | ℃ | %/℃ | %/℃ | |

| YX-16s | 0.79-0.84 | 7.9-8.4 | 620-660 | 7.8-8.3 | ≥1830 | ≥23 | 118-135 | 15-17 | 750 | 250 | -0.035 | -0.28 |

| YX-18s | 0.84-0.89 | 8.4-8.9 | 660-700 | 8.3-8.8 | ≥1830 | ≥23 | 135-151 | 17-19 | 750 | 250 | -0.04 | -0.28 |

| YX-20s | 0.89-0.93 | 8.9-9.3 | 684-732 | 8.6-9.2 | ≥1830 | ≥23 | 150-167 | 19-21 | 750 | 250 | -0.045 | -0.28 |

| YX-22s | 0.92-0.96 | 9.2-9.6 | 710-756 | 8.9-9.5 | ≥1830 | ≥23 | 167-183 | 21-23 | 750 | 250 | -0.045 | -0.28 |

| YX-24s | 0.96-1.00 | 9.6-10.0 | 740-788 | 9.3-9.9 | ≥1830 | ≥23 | 183-199 | 23-25 | 750 | 250 | -0.045 | -0.28 |

| LTC (YX-10) (SmGd)Co5 | 0.62-0.66 | 6.2-6.6 | 485-517 | 6.1-6.5 | ≥1830 | ≥23 | 75-88 | 9.5-11 | 750 | 300 | Temp. Range 20-100℃ 100-200℃ 200-300℃ | α(Br) +0.0156+0.0087 +0.0007 |

| The temperature coefficients of remanence Br and intrinsic coercivity Hcj are measured at 20°C to 150°C, only for reference. | ||||||||||||

| Theoretical calculation formula (T1 = room temperature (usually 20℃), T2=high temperature): | ||||||||||||

| Br@T2=Br@T1-[(T2-T1)*α(Br)*Br@T1] | ||||||||||||

| Hcj@T2=Hcj@T1-[(T2-T1)*β(Hcj)*Hcj@T1] | ||||||||||||

| Taking YX-20s,Br=0.9T, Hcj=1830KA/m as an example, the theoretical value at 150℃ is calculated as follows: | ||||||||||||

| Br@150℃=0.9-[(150-20)*0.045%*0.9]=0.8473T | ||||||||||||

| Hcj@150℃=1830-[(150-20)*0.28%*1830]=1163.88KA/m | ||||||||||||

Physical Properties of Sm₁Co₅ Magnets

| Sm₁Co₅ | Unit | SmCo5 Magnet |

|---|---|---|

| Density (D) | G/Cm3 | 8.3 |

| Curie Temperature (Tc) | K | 1000 |

| Vickers Hardness (Hv) | MPa | 450-500 |

| Compressive Strength (δc) | MPa | 1000 |

| Resistivity (ρ) | Ω.Cm | 5~6×10⁻⁵ |

| Bending Strength (δb) | Mpa | 150-180 |

| Tensile Strength (δt) | Mpa | 40 |

| Coeff. of Thermal Expansion (α) | (10⁻⁶/℃) | ∥ 6 |

Sm₂Co₁₇-Samarium Cobalt Magnets

Samarium and cobalt with atomic ratio of 2:17

The 2:17 samarium cobalt magnets, also known as Sm₂Co₁₇ magnets, are a high-performance magnetic material made of samarium, cobalt, copper, iron, and zirconium through melting, grinding, pressing, sintering, and aging processes. With a maximum energy product ranging from 17-35 MGOe and a high working temperature between 250℃-500℃, Sm₂Co₁₇ magnets have excellent corrosion resistance and low-temperature coefficient, making them ideal for various applications in aerospace, military, high-temperature motors, automotive sensors, magnetic drives, pumps, and microwave devices.

Although Sm2Co17 has excellent properties, it is brittle and not easily shaped into complex shapes or thin-walled structures like round disks or rings. Please handle this with care to avoid breakage or injury.

The material for Sm2Co17 magnets is Sm2(CoFeCuZr)17. The grade is coded with YXG. When there is LTC in front of the grade, it means low-temperature coefficient, while HT means high-temperature type. You can quickly tell the difference from the grade table below:

Sintered Sm₂Co₁₇ Magnet Magnetic Properties Standard

| Grade | Remanence/Br | Coercivity Force/HcB | Intrinsic Coercivity/HcJ | (BH)max Maximun Energy | Curie Temperature | Max. Operating Temperature | Temperature Coefficient of Br α(Br) | Temperature Coefficient of Hcj β(Hcj) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T | KGs | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ℃ | ℃ | %/℃ | %/℃ | |

| YXG-24H | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥1990 | ≥25 | 175-191 | 22-24 | 800 | 350 | -0.035 | -0.2 |

| YXG-26H | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥1990 | ≥25 | 191-207 | 24-26 | 800 | 350 | -0.035 | -0.2 |

| YXG-28H | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥1990 | ≥25 | 207-223 | 26-28 | 800 | 350 | -0.035 | -0.2 |

| YXG-30H | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1990 | ≥25 | 223-239 | 28-30 | 800 | 350 | -0.035 | -0.2 |

| YXG-32H | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥1990 | ≥25 | 231-255 | 29-32 | 800 | 350 | -0.035 | -0.2 |

| YXG-33H | 1.12-1.16 | 11.2-11.6 | 845-890 | 10.6-11.2 | ≥1990 | ≥25 | 239-263 | 30-33 | 800 | 350 | -0.035 | -0.2 |

| YXG-22 | 0.93-0.97 | 9.3-9.7 | 676-740 | 8.5-9.3 | ≥1433 | ≥18 | 160-183 | 20-23 | 800 | 300 | -0.035 | -0.2 |

| YXG-24 | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥1433 | ≥18 | 175-191 | 22-24 | 800 | 300 | -0.035 | -0.2 |

| YXG-26 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥1433 | ≥18 | 191-207 | 24-26 | 800 | 300 | -0.035 | -0.2 |

| YXG-28 | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥1433 | ≥18 | 207-223 | 26-28 | 800 | 300 | -0.035 | -0.2 |

| YXG-30 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1433 | ≥18 | 223-239 | 28-30 | 800 | 300 | -0.035 | -0.2 |

| YXG-32 | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥1433 | ≥18 | 231-255 | 29-32 | 800 | 300 | -0.035 | -0.2 |

| YXG-33 | 1.12-1.16 | 11.2-11.6 | 845-890 | 10.6-11.2 | ≥1433 | ≥18 | 239-263 | 30-33 | 800 | 300 | -0.035 | -0.2 |

| YXG-35 | 1.16-1.2 | 11.6-12.0 | 868-908 | 10.9-11.4 | ≥1433 | ≥18 | 255-278 | 32-35 | 800 | 300 | -0.035 | -0.25 |

| YXG-26M | 1.02-1.05 | 10.2-10.5 | 676-780 | 8.5-9.8 | 955-1433 | 45278 | 199-215 | 25-27 | 800 | 300 | -0.035 | -0.2 |

| YXG-28M | 1.03-1.08 | 10.3-10.8 | 676-796 | 8.5-10.0 | 955-1433 | 45278 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.2 |

| YXG-30M | 1.08-1.10 | 10.8-11.0 | 676-835 | 8.5-10.5 | 955-1433 | 45278 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.2 |

| YXG-32M | 1.10-1.13 | 11.0-11.3 | 676-852 | 8.5-10.7 | 955-1433 | 45278 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.2 |

| YXG-24L | 0.95-1.02 | 9.5-10.2 | 541-716 | 6.8-9.0 | 636-955 | 45150 | 183-199 | 23-25 | 800 | 250 | -0.035 | -0.2 |

| YXG-26L | 1.02-1.05 | 10.2-10.5 | 541-748 | 6.8-9.4 | 636-955 | 45150 | 199-215 | 25-27 | 800 | 250 | -0.035 | -0.2 |

| YXG-28L | 1.03-1.08 | 10.3-10.8 | 541-764 | 6.8-9.6 | 636-955 | 45150 | 207-220 | 26-28 | 800 | 250 | -0.035 | -0.2 |

| YXG-30L | 1.08-1.15 | 10.8-11.5 | 541-796 | 6.8-10.0 | 636-955 | 45150 | 220-240 | 28-30 | 800 | 250 | -0.035 | -0.2 |

| YXG-32L | 1.10-1.15 | 11.0-11.5 | 541-812 | 6.8-10.2 | 636-955 | 45150 | 230-255 | 29-32 | 800 | 250 | -0.035 | -0.2 |

| LTC(YXG-18) | 0.84-0.89 | 8.4-8.9 | 629-668 | 7.9-8.4 | ≥1433 | ≥18 | 135-151 | 17-19 | 840 | 300 | -0.001 | -0.25 |

| LTC(YXG-20) | 0.89-0.94 | 8.9-9.4 | 660-708 | 8.3-8.9 | ≥1433 | ≥18 | 151-167 | 19-21 | 840 | 300 | -0.007 | -0.25 |

| LTC(YXG-22) | 0.94-0.98 | 9.4-9.8 | 692-740 | 8.7-9.3 | ≥1433 | ≥18 | 167-183 | 21-23 | 840 | 300 | -0.01 | -0.25 |

| HT400(YXG-26) | 0.99-1.04 | 9.9-10.4 | 740-812 | 9.3-10.2 | ≥1830 | ≥23 | 191-215 | 24-27 | 850 | 400 | -0.035 | -0.12 |

| HT450(YXG-24) | 0.96-0.99 | 9.6-9.9 | 724-772 | 9.1-9.7 | ≥1830 | ≥23 | 175-199 | 22-25 | 850 | 450 | -0.035 | -0.12 |

| HT500(YXG-22) | 0.93-0.97 | 9.3-9.7 | 708-756 | 8.9-9.5 | ≥1830 | ≥23 | 160-183 | 20-23 | 850 | 500 | -0.035 | -0.12 |

| The temperature coefficients of remanence Br and intrinsic coercivity Hcj are measured at 20°C to 150°C, only for reference. | ||||||||||||

| Theoretical calculation formula (T1 = room temperature (usually 20℃), T2=high temperature): | ||||||||||||

| Br@T2=Br@T1-[(T2-T1)*α(Br)*Br@T1] | ||||||||||||

| Hcj@T2=Hcj@T1-[(T2-T1)*β(Hcj)*Hcj@T1] | ||||||||||||

| Taking YXG-28H, Br=1.03T, Hcj=1990KA/m as an example, the theoretical value at 150℃ is calculated as follows: | ||||||||||||

| Br@150℃=1.03-[(150-20)*0.035%*1.03]=0.9831T | ||||||||||||

| Hcj@150℃=1990-[(150-20)*0.2%*1990]=1472KA/m | ||||||||||||

Physical Properties of Sm₂Co₁₇ Magnets

| Sm₂Co₁₇ Magnet | Unit | Result |

|---|---|---|

| Density (D) | G/Cm3 | 8.4 |

| Curie Temperature (Tc) | K | 1100 |

| Vickers Hardness (Hv) | MPa | 550-600 |

| Compressive Strength (δc) | MPa | 800 |

| Resistivity (ρ) | Ω.Cm | 8~9× 10⁻⁵ |

| Bending Strength (δb) | Mpa | 130-150 |

| Tensile Strength (δt) | Mpa | 35 |

| Coeff. of Thermal Expansion (α) | ( 10⁻⁶/℃) | ∥ 8 |

| ⊥11 |

Introduction to Samarium Cobalt Magnets

Samarium Cobalt magnets provided by Magnetstek Engineering are highly resistant to corrosion and oxidation, with high energy products and an extremely low temperature coefficient. The maximum operating temperature can reach 250°C to 600°C depending on the grades, with no limit on negative temperatures. At working temperatures above 180°C, SmCo magnets’ temperature and chemical stability exceed those of NdFeB magnets.

With over ten years of industry experience, Magnetstek Engineering can supply a wide range of customized Samarium Cobalt (SmCo) Magnets according to requests.

Samarium Cobalt Magnets Grade

The range of SmCo magnet grade ranged from 16 MGOe to 32 MGOe. The various grades can support industrial and commercial applications with operational temperature resistance, magnetic performance, and budget balance.

There are two types of SmCo magnets with different samarium and cobalt atomic ratios: Sm₁Co₅ and Sm₂Co₁₇.

Advantages of Samarium Cobalt:

- When compared to Neo, SmCo offers unique capabilities such as higher energy density at elevated temperatures.

- Maximum operating temperature for samarium cobalt is more than 2x neodymium iron boron.

- SmCo flux output varies much less with respect to temperature, meaning the device performance can truly be optimized.

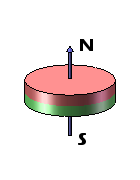

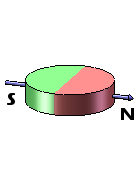

Magnetizing Direction

Magnetstek Engineering has been supplying rare earth magnets for over two decades. We offer competitive prices for magnets with multiple magnetizing directions. Newly introduced technology makes Magnetstek’s magnetized thickness up to 90mm, almost twice that of our competitors. Magnetizing directions refer to the orientation of the magnetic field within a magnet. The direction in which a magnet is magnetized influences its performance and application. For rare earth magnets, the magnetizing direction plays a crucial role in determining their magnetic properties.

Here are the common magnetizing directions for rare earth magnets:

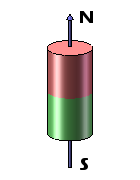

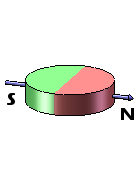

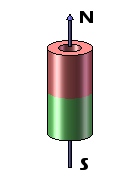

Discs & Cylinders

Disc and Cylinder magnets can be axially or diametrically magnetized.

Axially Magnetization

Diametrically Magnetization

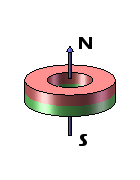

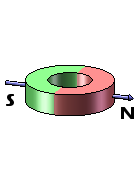

Rings&Tubes

Rings and tubes like discs and cylinders can be axially or diametrically magnetized.

Axially Magnetization

Diametrically Magnetization

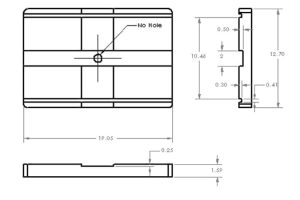

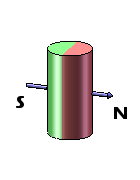

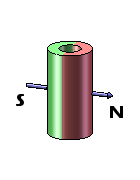

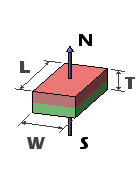

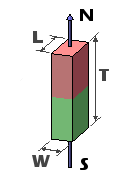

Blocks&Cubes

Block magnets are characterized by their three dimensions: length, width, and thickness. We are occasionally asked if we can provide magnetized block magnets through their length or width. The answer is yes; some long “bar” magnets are magnetized in their longest dimension.

Thickness Magnetization

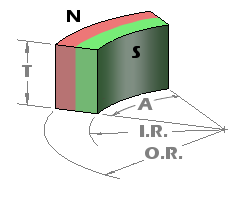

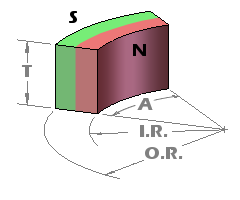

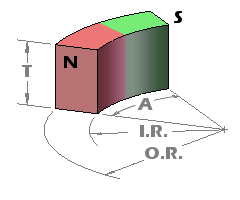

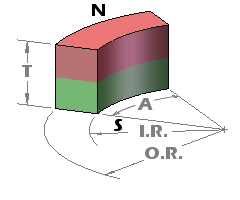

Arc Segments

Arc segments have usually been magnetized in pairs, SN-NS. So that they can be assembled to one ring on a rotor, there are two other possible magnetization directions.

North on the Outside Curve

South on the Outside Curve

Magnetized through Circumference

Magnetized through Thickness

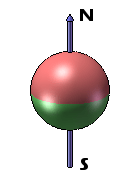

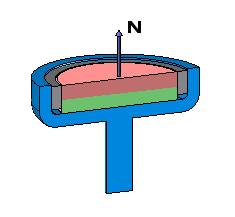

Special Magnetization

Spheres can be only axially magnetized, and mounting magnets usually have one North pole towards the outside (can be customized).

Spheres Magnetization

Mounting Magnets Magnetization

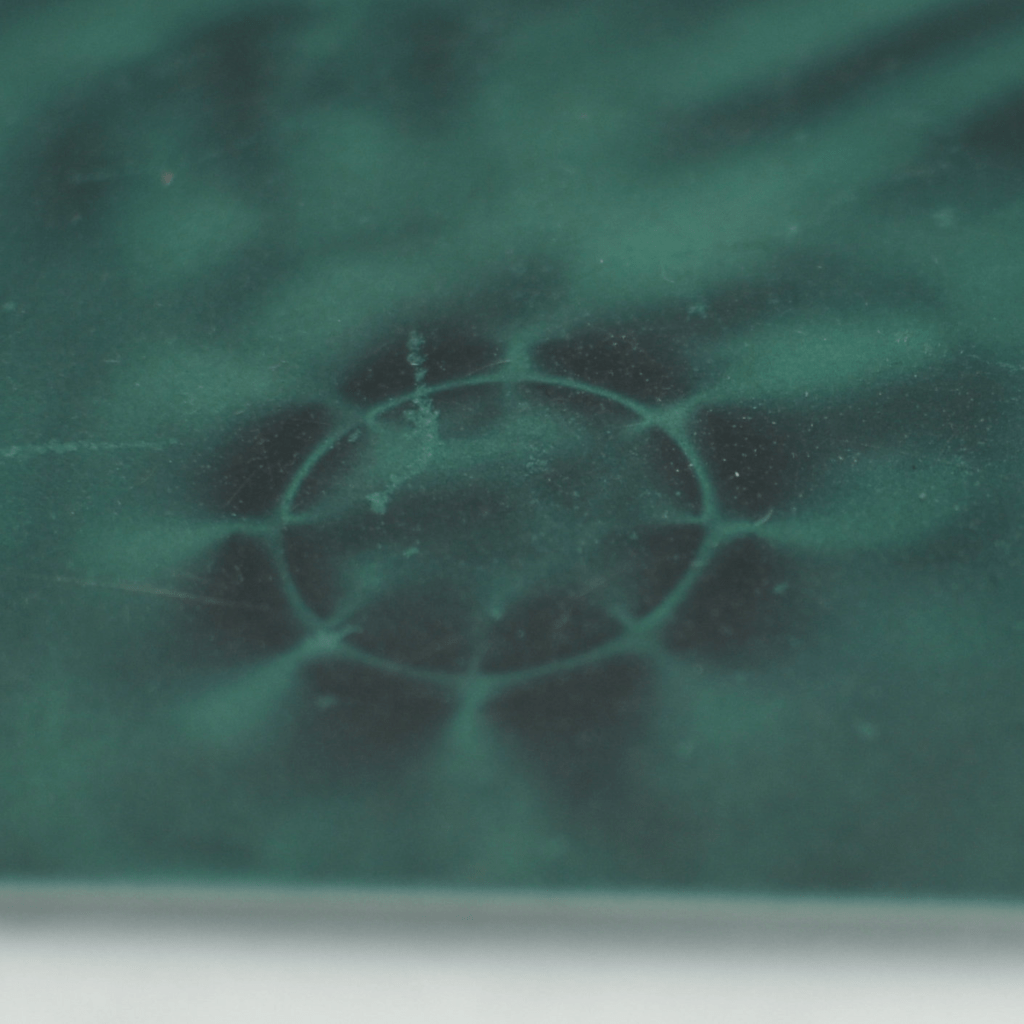

Multi-Pole Magnetization

Multi-pole magnetization involves creating multiple poles on the surface of the magnet. This can be achieved by magnetizing the magnet with alternating poles along its length or diameter. Multi-pole magnetization is often used in applications requiring a specific magnetic field pattern, especially on Bonded Magnets.

Radial Magnetization

Radial magnetization is also an ordinary ring magnet, with North and South poles in a circle form on the curves.

It’s important to note that the magnetizing direction significantly affects the magnet’s performance in a specific application. When working with neodymium magnets, manufacturers carefully consider the magnetizing direction to meet the intended use requirements.

Feel free to talk to an expert for more information.

Magnetizing directions refer to the orientation of the magnetic field within a magnet. The direction in which a magnet is magnetized influences its performance and application. For neodymium magnets, the magnetizing direction plays a crucial role in determining their magnetic properties. Generally speaking, to obtain the most vital pulling force, we magnetize through thickness and make the poles on the most prominent faces of the magnet.

Coatings

Generally speaking, SmCo magnets do not require any coating or plating. That is because, unlike neodymium magnets, they contain little or no iron and have excellent corrosion resistance. But when SmCo magnets are used in acidic or highly humid environments, we should still consider coatings.

Low environmental reactivity makes Samarium Cobalt (SmCo) magnets good candidates for Medical and Aerospace applications. It is always advisable to empirically evaluate the magnet alloy in the operational environment before deciding on a design path.

Typically, SmCo magnets used in medical applications will be coated with perylene and clad in an application-appropriate material.

We at Magnetstek Engineering can do the coating on SmCo magnets.

Handling and Storage

While strong rare earth magnets, such as NdFeB and SmCo magnets, are widely used for various applications due to their strong magnetic properties, it is essential to be aware of safety considerations when handling these magnets.

Here are some essential safety guidelines:

Avoiding Pinching

Rare earth magnets, such as neodymium and samarium cobalt magnets, are powerful, and if they come together suddenly, they can cause injuries. Be cautious of fingers or other body parts getting caught between attracting magnets.

With large magnets, severe injuries can be caused.

Children and Pets

Rare earth magnets are not toys. Children should not be allowed to handle strong magnets. Choking small magnets or playing with large magnets are equally dangerous to children. If multiple magnets are swallowed, they can attach through intestine walls. This can cause a severe health risk, requiring immediate, emergency surgery if correctly diagnosed.

Keeping Away from Pacemakers

The strong magnetic fields near a neodymium or samarium cobalt magnet can affect pacemakers, ICDs, and other implanted medical devices. Therefore, you must take care to avoid inadvertently deactivating such devices.

Nickel-Allergic

Some people may have a nickel allergy, where an allergic reaction can cause redness and a skin rash. These people should avoid prolonged contact with nickel-coated magnets.

Magnetic Media

Strong magnets can interfere with electronic devices like credit cards, magnetic I.D. cards, VCRs, cassette tapes, floppy disks, and hard drives. Keep strong magnets away from these devices to prevent potential damage.

Navigation and Compasses

Magnetic fields can influence compasses or magnetometers used in air transport. They can also affect the internal compasses of smartphones and GPS devices. IATA (International Air Transport Association) and US Federal rules and regulations cover shipping magnets by air and ground delivery.

Magnets are Brittle and Fragile

Rare earth magnets are made of hard and brittle material. They are not as durable as steel, even if they look like steel. Magnets can chip, peel, crack, or shatter if they are slammed together. Eye protection should be worn when handling magnets.

Rare earth magnets can not easily be re-machined.

Avoiding High Temperatures

Rare earth magnets, especially Neodymium magnets, can become demagnetized at high temperatures. You should know the magnet grade and the maximum operating temperature. A magnet should be stored and used below the maximum temperature.

Magnets are not Waterproof

Though most magnets are coated and protected, they are still not waterproof. In humid environments or even water, neodymium magnets can rust or corrode and lose magnetic strength.

*The icons used on this page are derivative works based on icons by Freepik from www.flaticon.com, licensed by CC BY 3.0.

Handling SmCo magnets carefully is essential, as they are brittle and break easily. Additionally, precautions should be taken to avoid situations where the magnets could pose a danger, such as swallowing, as they can be hazardous if ingested.

Always keep away from pacemakers and children.

SmCo Magnets Applications

SmCo magnets find wide-ranging applications in various industries, including aerospace, defense, transportation, and communication, specifically:

- Automotive industry, for electronic throttle pedals, ignition coils, engine intake sensors, position sensors, seatbelt sensors, ABS, and DCT shift forks.

- Medical equipment, for magnetic resonance imaging (MRI) machines and small medical motors.

- Aerospace industry, for various sensors and small motors.

- Defense and military, for armored vehicles, special motors, generators, and ship propulsion motors.

- Mechanical transmission, for magnetic pumps, high-temperature reaction vessels, magnetic stirrers, and magnetic bearings.

- Microwave communication, for microwave isolators and traveling wave tubes.

- Railway transportation, for traction motors and generator rotors.

SmCo Magnets Applications

High-Temp. Environment

Mechanical Engineering

Medical Equipment

Defence&Aerospace Industry

Railway Industry

Transportations

Why MagnetsTek Engineering - What Set Us Apart

MagnetsTek invests heavily in product development annually, distinguishing us from other suppliers in the industry.

- Fully magnetize up to 120mm thickness

- Grade N56 for Neodymium magnets

- Up to 600°C SmCo operation temperature

- Over 20 years industry experience

- Professional expert team including Ph.Ds for your R&D assistance

- ISO9001, ISO/TS16949 standard, RoHS compliant

- Down to 4 days for SmCo and 2 weeks for NdFeB production time