- Custom Magnets

- Standard Magnets

- Mounting Magnets

- Magnetic Assemblies

- About Us

- Knowledge

Magnetstek Engineering is one of the largest manufacturers of rare earth magnets, covering most of the grades available worldwide. Our range comprises a comprehensive array of magnetic materials of various grades, and we produce around 4,500 tons annually.

Magnetstek Engineering has advanced processing equipment and technology that allows us to produce 4,500 tons of magnets every year. We have devoted over two decades to researching and developing a unique production process that ensures the creation of top-quality magnet products. Our company has more than 700 processing and precision machining equipment that can handle a variety of complex shapes and high-precision magnet products.

Precise proportioning according to grade specifications

Key controls include vacuum pressure, voltage, argon filling capacity, refining time, and cooling temperature and time

Coarse, medium, and fine crushing with control over rotational speed, nitrogen pressure, oxygen content, and particle size

Main controls include mold dimensions, powder weight, temperature, humidity, pressure, and time

Key control points are vacuum pressure, argon pressure, sintering and aging temperatures, and duration

Inspection of external dimensions and observation of Max demagnetization curves

Main controls include dimensional tolerances, positional tolerances, coatings, and appearance

Inspection of appearance, dimensions, positional tolerances, and quantity

Comprehensive inspection of appearance, dimensions (full or sampling), positional tolerances (full or sampling), and magnetic performance (full or sampling) as per requirements

Custom or standard packaging, quantity verification, boxing, magnetizing shields, and testing reports

We use different methods, like laser cutting or stamping, to make what our customers need. Sometimes we also make the surface nice by polishing or plating it. We pay attention to make sure everything is the right size, looks good, and has a mark so we know what it is.

Rigorous inspections are conducted during the manufacturing process, encompassing visual inspection, dimensional measurements, positional tolerance checks, trial assembly, and quantity counting.

Thorough cleaning is performed using ultrasonic technology, ensuring the pristine condition of the components. Visual inspection and quantity counting are also carried out.

The annealing process is precisely controlled, considering hydrogen gas flow rate, temperature, and time.

The final products undergo comprehensive inspections, including visual examination, dimensional measurements, positional tolerance checks, assembly (if required), magnetic performance testing, and quantity counting.

Custom or standard packaging, quantity verification, boxing, testing reports, and delivery manifests

At Magnetstek Engineering, we prioritize quality in every aspect of our production process. With our state-of-the-art testing equipment and stringent quality management systems, we ensure the delivery of superior products that exceed customer expectations.

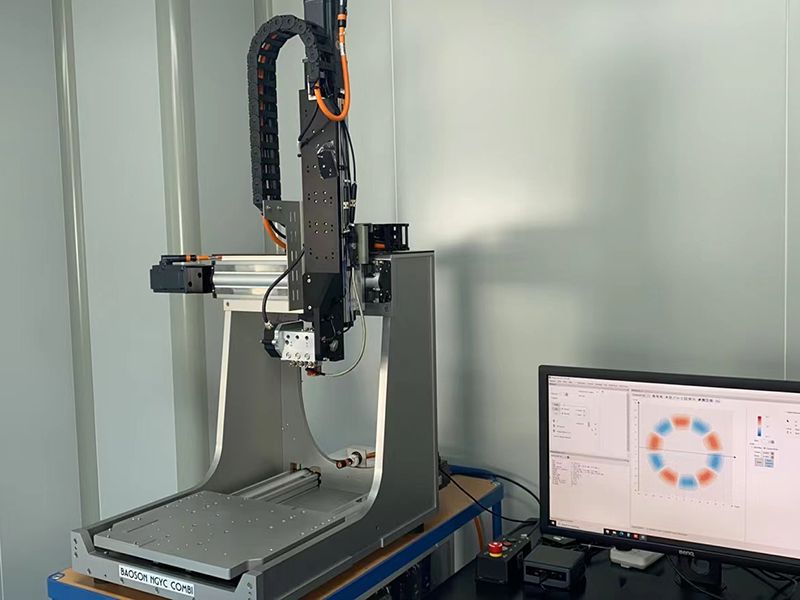

Our manufacturing facility is equipped with state-of-the-art testing equipment to ensure that only the highest quality products are produced. We use high-precision magnetic field cameras, magnet performance analyzers, particle analyzers, 2D imaging measurement devices, coordinate measuring machines (CMM), roughness testers, coating thickness gauges, cylindricity gauges, laser micrometers, laser height gauges, Keyence’s one-click imaging systems, and magnetic inclination angle detectors to conduct comprehensive inspections. Our investment in automated inspection devices further minimizes the chances of human error and enhances the overall quality of our products.

We operate under the ISO 9001:2015 and IATF 16949:2016 quality management systems, adhering to VDA6.3 standards for comprehensive monitoring, detection, prevention, and timely correction of potential failure modes throughout the production process. We conduct inspections for every step of the manufacturing process to prevent the flow of non-conforming products to subsequent stages. Before shipment, we conduct either complete or random sampling inspections of dimensions and magnetic performance according to customer requirements. Our quality control measures have demonstrated long-term reliability and repeatability.

Thanks to our scientific management practices and strict adherence to product quality, Magnetstek Engineering has been recognized as an Enterprise for Export Product Quality Assurance and a Prestigious Brand.

MagnetsTek invests heavily in product development annually, distinguishing us from other suppliers in the industry.