Enhancing Your Projects with 3M Adhesive-Backed Magnets: Versatile, Reliable, and Innovative Solutions

In today’s competitive market, finding reliable, versatile, and high-performance components for your projects is essential. One such innovation that has revolutionized the way we approach magnetic solutions is the 3M adhesive-backed magnet. At Magnetstek, we understand the value of quality and performance, and our comprehensive guide on 3M adhesive-backed magnets will help you explore their features, applications, and benefits while boosting your SEO rankings with a focus on key search terms such as 3M adhesive magnets, 3M self-adhesive magnets, 3M peel-and-stick magnets, and many more.

This article delves into the technology behind 3M adhesive-backed magnets, their varied applications across industries, detailed product specifications, and answers to frequently asked questions. Whether you are a DIY enthusiast, a business owner, or an engineer seeking reliable mounting solutions, this guide is designed to provide in-depth information while elegantly weaving in keywords that are vital for optimizing your online presence.

Table of Contents

What Are 3M Adhesive-Backed Magnets?

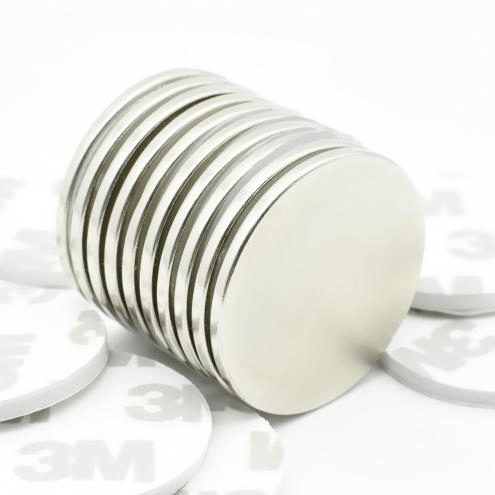

3M adhesive-backed magnets are advanced magnetic products that combine the superior magnetic performance of high-quality materials with the convenience of 3M’s industry-leading adhesive technology. These magnets come with a built-in adhesive layer that allows them to be applied to a wide range of surfaces without the need for additional mounting hardware. Whether you refer to them as 3M adhesive magnets, 3M adhesive-backed magnets, or even 3M self-adhesive magnets, their underlying concept remains consistent: an easy-to-use, reliable solution that offers both strong magnetic attraction and durable adhesion.

The innovation behind these magnets is twofold:

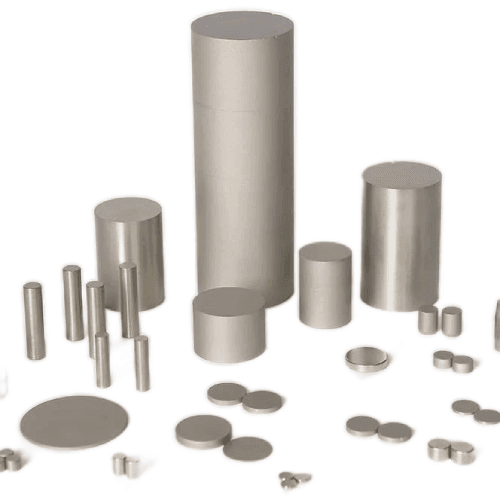

- Magnetic Strength: Leveraging materials like neodymium, these magnets provide impressive magnetic force, making them ideal for industrial, commercial, and personal applications.

- Adhesive Technology: The incorporated 3M adhesive is renowned for its reliability and longevity, ensuring that the magnet remains firmly attached to the desired surface. This is why terms like 3M peel-and-stick magnets and 3M magnetic strips with adhesive are often used interchangeably by professionals who demand performance and convenience.

Product Specifications and Varieties

3M adhesive-backed magnets are available in various forms and sizes, tailored to meet the demands of different applications. They come in shapes such as discs, strips, and custom dimensions to accommodate specific project requirements. Whether you’re looking for 3M adhesive magnet tape for creative displays or 3M adhesive neodymium magnets for heavy-duty applications, there is a product in this category to suit your needs.

Below is a table summarizing some common product specifications for 3M adhesive-backed magnets:

| Feature | Specification/Range | Notes |

|---|---|---|

| Magnet Shape | Disc, Strip, Custom Shapes | Options available to match design requirements. |

| Size Options | 10mm, 15mm, 20mm (diameter); Variable Width for strips | Custom sizes available upon request. |

| Magnetic Material | Neodymium, Ferrite | Neodymium offers higher magnetic force. |

| Adhesive Type | 3M high-performance adhesive | Provides long-lasting, durable adhesion. |

| Adhesive Application | Peel-and-stick, double-sided | Convenient for quick installations. |

| Temperature Range | Up to 80°C (approx.) | Suitable for most indoor applications. |

| Environmental Resistance | Some models offer water resistance | Check specifications for outdoor use. |

Table 1: Product Specifications for 3M Adhesive-Backed Magnets

This table highlights the diversity in product design that ensures these magnets can be integrated into a multitude of applications. For example, if you need 3M mounting magnets that are capable of withstanding varying temperature ranges or require 3M double-sided adhesive magnets for a specific installation scenario, the variety in this product line makes it easy to find the perfect match.

Versatile Applications Across Industries

3M adhesive-backed magnets have found applications in a multitude of industries thanks to their flexibility and ease of use. Let’s explore some of the key sectors that benefit from these innovative products.

1. Industrial Applications

In industrial settings, efficiency and durability are crucial. 3M adhesive magnets are commonly used in:

In industrial settings, efficiency and durability are crucial. 3M adhesive magnets are commonly used in:

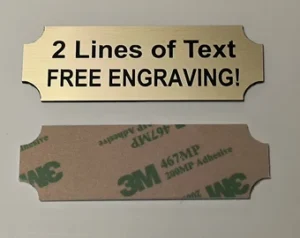

- Labeling and Nameplates: Adhesive-backed magnets are ideal for attaching nameplates, warning signs, and labels to machinery. Their robust adhesion ensures that information remains visible even in high-vibration environments.

- Equipment Organization: Many manufacturing facilities use these magnets to organize tools and parts, creating a safer and more efficient work environment.

2. Retail and Commercial Displays

Retail environments thrive on visual appeal and flexibility. 3M adhesive-backed magnets play a significant role in creating dynamic displays:

- Promotional Signage: Retailers use magnetic strips and discs with adhesive to create changeable product displays. This flexibility allows for quick updates and seasonal promotions.

- Visual Merchandising: The sleek design of 3M adhesive magnet tape and 3M sticky magnets ensures that displays look clean and professional without unsightly hardware.

3. Office and Educational Settings

The office and education sectors benefit from the ease of installation and reusability of these magnets:

- Whiteboards and Bulletin Boards: Office spaces and classrooms often rely on these magnets to secure documents and visual aids. The ability to apply and remove them without damage makes them an excellent choice.

- Modular Workspaces: In modern office environments, flexibility is key. Adhesive-backed magnets help create customizable workspaces and collaborative areas.

4. Creative and DIY Projects

For artists and hobbyists, 3M adhesive-backed magnets open up a world of creative possibilities:

- Interactive Installations: Art installations and exhibits often incorporate magnets to allow for modular designs that can be rearranged as needed.

- Home Organization: DIY enthusiasts use magnetic strips and discs to organize household items such as tools, recipes, and photos, blending functionality with style.

5. Automotive and Aerospace Uses

The automotive and aerospace industries demand components that can withstand rigorous conditions. 3M adhesive-backed magnets are used in:

- Component Labeling: In vehicles and aircraft, magnets are used to label and organize parts, helping streamline maintenance and repair processes.

- Temporary Fixtures: These magnets can temporarily hold components during assembly or testing, offering flexibility and reliability.

6. Custom Solutions and Branding

Businesses looking for bespoke solutions often turn to 3M adhesive-backed magnets for their customizability:

- Promotional Items: Custom-shaped magnets can be used as unique branding tools on products, packaging, or at events.

- Corporate Signage: Companies incorporate these magnets into office decor and signage, reinforcing brand identity in a modern, understated manner.

Installation and Best Practices

Achieving optimal performance from 3M adhesive-backed magnets is largely dependent on proper installation. Here are some best practices to ensure a strong and lasting bond:

Surface Preparation

- Clean and Dry: Always clean the surface thoroughly to remove dust, oil, and moisture. A clean surface allows the adhesive to bond more effectively.

- Smooth Surface: For maximum adhesion, choose smooth, non-porous surfaces. In cases where the surface is rough, a primer or additional cleaning agent may be necessary.

Application Process

- Peel-and-Stick: The typical application involves peeling off the protective backing and firmly pressing the magnet onto the surface. This method is characteristic of 3M peel-and-stick magnets and is both quick and effective.

- Pressure Application: After placement, apply even pressure for at least 30 seconds. This step helps to ensure that the adhesive sets properly.

Environmental Considerations

- Temperature: Most products are rated for use in temperatures up to approximately 80°C. However, be sure to consult product specifications if you intend to use them in high-temperature environments.

- Moisture Resistance: While some magnets are designed to be water resistant, prolonged exposure to moisture can affect adhesion. Always check if the particular model is suitable for outdoor or damp environments.

Maintenance and Care

- Regular Cleaning: Dust and debris can accumulate around the magnet. Periodically cleaning the area with a soft, damp cloth will maintain the adhesive’s performance.

- Inspect Adhesion: For magnets used in high-traffic or industrial settings, regular checks can help ensure that the bond remains secure over time.

Following these installation and care tips will not only extend the life of your 3M adhesive-backed magnets but also ensure that they perform reliably in your chosen applications.

Detailed FAQ Section

Below is a comprehensive FAQ section that addresses common questions about 3M adhesive-backed magnets. These FAQs have been developed to offer clear, practical insights and answer common concerns.

| FAQ | Answer |

|---|---|

| 1. What are 3M adhesive-backed magnets? | They are magnets with a built-in 3M adhesive layer, designed for easy, secure mounting on various surfaces without needing extra hardware. |

| 2. Which surfaces are ideal for these magnets? | They adhere well to metal, plastic, glass, and wood. The key is a clean, smooth, and dry surface to maximize adhesion. |

| 3. How strong is the magnetic force? | The force varies by product. For instance, 3M adhesive neodymium magnets offer a higher pull force compared to standard ferrite magnets, making them suitable for demanding applications. |

| 4. Can these magnets be reused? | Generally, they are designed for one-time application. Removing and reapplying may weaken the adhesive, so proper initial placement is important. |

| 5. What size and shape options are available? | There is a broad range: from small discs to long strips. Custom sizes and shapes can be provided, allowing tailored solutions for specific applications. |

| 6. How do I install these magnets? | Installation is simple—clean the surface, peel off the backing, and press the magnet firmly in place. Allow at least 30 seconds of pressure, and full curing typically occurs in 24 hours. |

| 7. Are these magnets suitable for outdoor use? | Some models are designed for outdoor conditions, but always check the product specifications regarding temperature and moisture exposure. |

| 8. Do they leave any residue upon removal? | In most cases, if removed after prolonged use, a slight adhesive residue may remain, which can usually be cleaned with a mild solvent or cleaning agent. |

| 9. How long does the adhesive take to cure? | Full adhesion strength is typically achieved after about 24 hours, ensuring a robust and lasting bond. |

| 10. Can the magnetic strips be cut to a custom length? | Yes, many of the adhesive magnetic strips can be easily trimmed with scissors or a utility knife to fit your specific requirements. |

| 11. What are the temperature limitations for these magnets? | Most products are rated for use up to around 80°C. It is best to review individual product details if used in extreme conditions. |

| 12. Where can I purchase 3M adhesive-backed magnets? | These magnets are available through various retailers, specialized suppliers, and industrial hardware stores, ensuring you have multiple options to choose from. |

Table 2: Frequently Asked Questions (FAQs) Summary

The FAQ section addresses practical concerns and provides clear, actionable answers, ensuring that whether you are a new user or an experienced professional, you have the essential information at your fingertips.

Real-World Examples and Use Cases

Case Study 1: Industrial Equipment Labeling

A manufacturing facility integrated 3M adhesive magnets into their labeling system for heavy machinery. The magnets were used to attach durable nameplates and safety labels, ensuring that crucial information remained visible and secure even in high-vibration environments. The high-performance 3M adhesive allowed for quick application and reliable long-term performance.

Case Study 2: Dynamic Retail Displays

A retail chain redesigned its promotional displays using 3M magnetic strips with adhesive. These strips allowed for frequent changes in product placement and signage without the need for permanent fixtures. The flexibility and clean aesthetic of the magnets enhanced the overall customer experience and allowed for efficient updates during seasonal promotions.

Case Study 3: Creative DIY Projects

A local art collective utilized 3M peel-and-stick magnets in a series of interactive installations. Artists appreciated the ease of repositioning and the non-damaging nature of the adhesive when experimenting with various display configurations. The magnets not only served a functional purpose but also added a modern, minimalist touch to the overall design.

Advantages of 3M Adhesive-Backed Magnets

The adoption of 3M adhesive-backed magnets brings numerous advantages to any application:

- Ease of Installation: The peel-and-stick design eliminates the need for additional mounting hardware, streamlining the installation process.

- Versatility: With a range of sizes, shapes, and magnetic strengths, these products cater to diverse applications—from industrial to creative projects.

- Reliability: The high-quality 3M adhesive ensures a secure and lasting bond, even in demanding conditions.

- Aesthetic Integration: Their sleek design and unobtrusive appearance allow them to be integrated seamlessly into any environment.

- Customizability: Whether you need a specific size or shape, many products can be tailored to your unique requirements, ensuring a perfect fit for your application.

- Durability: Designed for long-term use, these magnets perform consistently over time, reducing maintenance needs and enhancing overall efficiency.

Conclusion

3M adhesive-backed magnets stand out as an exemplary product that marries strength, durability, and versatility. Their innovative design—combining powerful magnetic materials with reliable 3M adhesive technology—ensures that they meet the demands of a wide range of applications. From industrial labeling and equipment organization to dynamic retail displays and creative art installations, these magnets provide a flexible solution that enhances both functionality and aesthetic appeal.

At the heart of these products is a commitment to quality. Whether you are installing 3M adhesive magnets in an industrial setting or using 3M self-adhesive magnets in your next DIY project, you can be confident in their performance. The ease of installation, combined with robust adhesive technology, makes these magnets an ideal choice for projects that require secure, lasting adhesion with minimal fuss.

This comprehensive guide has explored the various aspects of 3M adhesive-backed magnets—from product specifications and diverse applications to practical installation tips and frequently asked questions. With detailed insights into how these magnets work and the benefits they bring, users are well-equipped to select the right product for their needs and achieve optimal performance in their projects.

For anyone seeking a reliable magnetic solution that does more than just hold items in place, 3M adhesive-backed magnets offer the perfect blend of convenience, strength, and versatility. Embrace a smarter approach to mounting and labeling with a product that has been designed to meet the high standards demanded by modern applications. Whether for industrial, commercial, or creative purposes, these magnets are a testament to the innovation and quality that 3M brings to every solution.