- Custom Magnets

- Standard Magnets

- Mounting Magnets

- Magnetic Assemblies

- About Us

- Knowledge

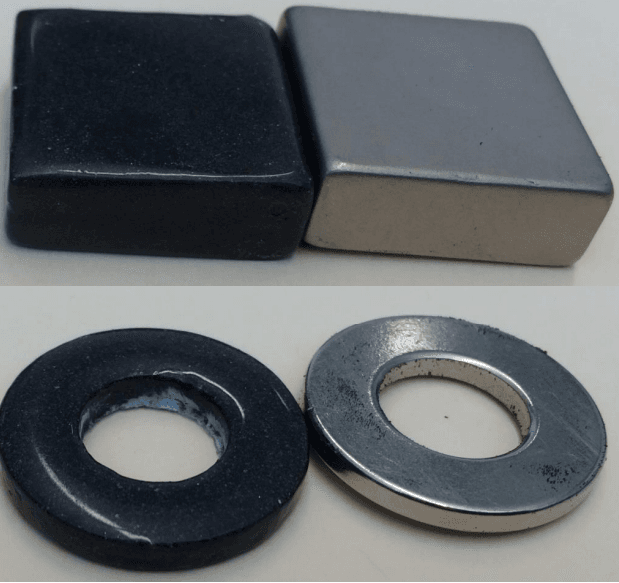

Bonded magnets are permanent magnets made by mixing magnetic powders with a polymer binder (usually a resin). This process allows for the creation of complex shapes and designs, making bonded magnets versatile and suitable for various applications. Bonded NdFeB magnets and SmCo magnets are usually present when we talk about bonded magnets.

MagnetsTek Engineering is a trusted manufacturer and supplier of bonded magnets. We can custom bonded magnets according to your designs, with short lead times and good prices. We also have large inventory of various bonded magnets, to save your research & development time and costs.

Electric Motors and Sensors: Bonded magnets are used in small motors and sensors where complex shapes and sizes are required.

Automotive Components: They find applications in various automotive components, such as sensors and actuators.

Consumer Electronics: Bonded magnets are used in speakers, headphones, and other electronic devices.

Medical Devices: The ability to create custom shapes makes bonded magnets suitable for various medical applications.

Complex Shapes: Bonded magnets can be manufactured in complex shapes that are challenging to achieve with traditional magnet materials. The accuracy can be up to 0.01mm.

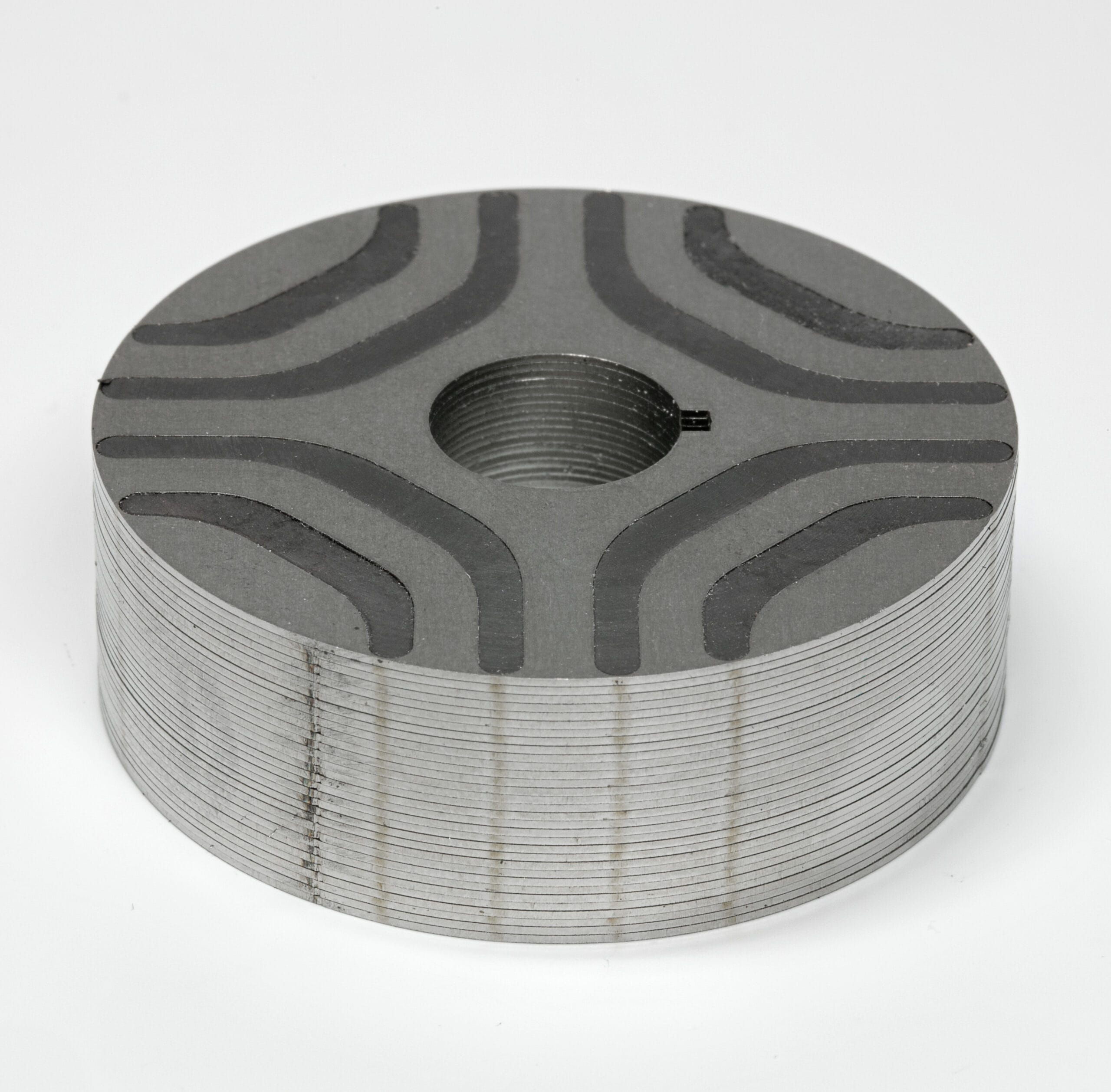

Particular Magnetization Directions: Bonded magnets can be magnetized with multi-poles and radial poles. Even a 32-pole magnet ring is widespread on a bonded magnet.

Isotropic or Anisotropic: Bonded magnets can be produced in isotropic (uniform magnetic properties in all directions) or anisotropic (preferential magnetic orientation) forms.

Cost-Effective: The production process of bonded magnets is often more cost-effective than sintered magnets.

Mixing: Magnetic powders, typically made of neodymium (NdFeB) SmCo or ferrite, are combined with a polymer binder.

Molding: The mixture is then molded into the desired shape, ranging from simple blocks to intricate, detailed forms.

| Item | Grade | Remanence/Br | Coercivity/HcB | Intrinsic Coercivity/HcJ. | Max Energy Product/(BH)max | Max Working Temperature/TwMax | Density/ρ | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | ° C | g/cm³ | ||

| Compression Molding NdFeB Magnet | KBM-2 | 0.30~0.40 | 3.0-4.0 | 160~240 | 2.0~3.0 | 480~640 | 6.0~8.0 | 16~24 | 2.0~3.0 | ≤120 | 4.5~6.0 |

| KBM-4 | 0.40~0.50 | 4.0~5.0 | 240~320 | 3.0~4.0 | 560~720 | 7.0~9.0 | 32~44 | 4.0~5.5 | ≤120 | 5.2~6.0 | |

| KBM-6 | 0.50~0.60 | 5.0~6.0 | 320~400 | 4.0~5.0 | 480~640 | 6.0~8.0 | 48~60 | 6.0~7.5 | ≤120 | 5.5~6.0 | |

| KBM-8 | 0.60~0.68 | 6.0~6.8 | 360~440 | 4.5~5.5 | 640~800 | 8.0~10.0 | 64~72 | 8.0~9.0 | ≤150 | 5.8~6.1 | |

| KBM-8H | 0.60~0.65 | 6.0~6.5 | 400~480 | 5.0~6.0 | 1120~1280 | 14.0~16.0 | 60~68 | 7.5~8.5 | ≤160 | 5.8~6.2 | |

| KBM-8L | 0.65~0.68 | 6.5~6.8 | 400~480 | 5.0~6.0 | 900~1120 | 11.0~14.0 | 64~72 | 8.0~9.0 | ≤160 | 5.8~6.2 | |

| KBM-9 | 0.60~0.68 | 6.0~6.8 | 400~480 | 5.0~6.0 | 640~800 | 8.0~10.0 | 68~72 | 8.5~9.0 | ≤150 | 5.8~6.2 | |

| KBM-10 | 0.68~0.73 | 6.8~7.3 | 400~480 | 5.0~6.0 | 640~800 | 8.0~10.0 | 76~84 | 9.5~10.5 | ≤150 | 5.8~6.2 | |

| KBM-12 | 0.71~0.75 | 7.1~7.5 | 440~520 | 5.5~6.5 | 720~800 | 9.0~10.0 | 84~96 | 10.5~12.0 | ≤150 | 6.0~6.2 | |

| KBM-12L | 0.72~0.76 | 7.2~7.6 | 400~480 | 5.0~6.0 | 480~640 | 6.0~8.0 | 84~96 | 10.5~12.0 | ≤140 | 6.0~6.2 | |

| Injection Molding NdFeB Magnet | KBI-3 | 0.20~0.30 | 2.0~3.0 | 160~240 | 2.0~3.0 | 480~640 | 6.0~8.0 | 12~24 | 1.5~3.0 | ≤100 | 3.9~4.4 |

| KBI-4 | 0.35~0.45 | 3.5~4.5 | 240~320 | 3.0~4.0 | 560~720 | 7.0~9.0 | 24~36 | 3.0~4.5 | ≤120 | 4.2~4.9 | |

| KBI-5 | 0.45~0.52 | 4.5~5.2 | 320~360 | 4.0~4.5 | 560~720 | 7.0~9.0 | 36~44 | 4.5~5.5 | ≤120 | 4.5~5.0 | |

| KBI-5H(PPS) | 0.48~0.52 | 4.8~5.2 | 400~480 | 5.0~6.0 | 880~1040 | 11.0~13.0 | 36~44 | 4.5~5.5 | ≤150 | 4.9~5.4 | |

| KBI-6 | 0.50~0.55 | 5.0~5.5 | 320~440 | 4.0~5.5 | 640~800 | 8.0~10.0 | 44~52 | 5.5~6.5 | ≤120 | 4.7~5.1 | |

| KBI-7 | 0.54~0.64 | 5.4~6.4 | 320~400 | 4.0~5.0 | 640~800 | 8.0~10.0 | 52~60 | 6.5~7.5 | ≤120 | 5.0~5.5 | |

| KBI-8 | 0.64~0.74 | 6.4~7.4 | 400~480 | 5.0~6.0 | 640~800 | 8.0~10.0 | 68~76 | 8.5~9.5 | ≤120 | 5.5~5.9 | |

| Injection Molding Ferrite Magnet | KBI-F1.5 | 0.22~0.24 | 2.2~2.4 | 160~167 | 2.00~2.10 | 231~240 | 2.90~3.00 | 11.6~12.4 | 1.45~1.55 | ≤120 | 3.25 |

| KBI-F1.9 | 0.27~0.29 | 2.7~2.9 | 180~186 | 2.25~2.33 | 216~228 | 2.70~2.85 | 14.8~15.6 | 1.85~1.95 | ≤120 | 3.63 | |

| KBI-F2.0 | 0.28~0.29 | 2.8~2.9 | 184~200 | 2.30~2.50 | 216~246 | 2.70~3.10 | 15.6~16.4 | 1.95~2.05 | ≤120 | 3.7 | |

| KBI-F2.1 | 0.28~0.29 | 2.8~2.9 | 190~204 | 2.38~2.55 | 224~249 | 2.80~3.12 | 16.4~17.2 | 2.05~2.15 | ≤120 | 3.75 | |

| KBI--F1.7(PPS) | 0.25~0.26 | 2.5~2.6 | 167~175 | 2.10~2.20 | 208~216 | 2.60~2.70 | 13.6~14.0 | 1.70~1.75 | ≤160 | 3.65 | |

| Grade | Remanence/Br | Coercivity/HcB | Intrinsic Coercivity/HcJ. | Max Energy Product/(BH)max | ||||

|---|---|---|---|---|---|---|---|---|

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | |

| SCZ-4T | 3.8-4.2 | 380-420 | 200-280 | 2.5-3.5 | 640-1030 | 8.0-13.0 | 28-36 | 3.5-4.5 |

| SCZ-5T | 4.1-5.4 | 410-540 | 265-360 | 3.3-4.5 | 640-1200 | 8.0-15.0 | 36-44 | 4.5-5.5 |

| SCZ-9 | 6.1-6.6 | 610-660 | 320~400 | 4.0~5.0 | 480~640 | 6.0~8.0 | 48~60 | 6.0~7.5 |

| SCZ-11 | 6.4-7.2 | 610-660 | 430-510 | 5.4-6.4.4 | 640-1200 | 8.0-15.0 | 76-88 | 9.5-11.0 |

| Grade SCZ-4T and SCZ-5T are isotropic material. | ||||||||

Magnets play a critical role in many modern technologies—from electric motors and sensors to consumer electronics and medical devices. Among the variety of magnetic materials available, bonded magnets have emerged as a versatile and cost-effective solution that meets many application requirements. This article explores the world of bonded magnets, with a particular focus on bonded neodymium (NdFeB) magnets. We discuss how bonded magnets are manufactured, compare them with traditional sintered magnets, and address several common questions about magnet types and performance.

Bonded magnets are manufactured by combining magnetic powders with a polymer binder. Unlike conventional sintered magnets—which require high-temperature processing and result in a dense, fully crystalline product—bonded magnets are produced by mixing magnetic particles with a plastic binder and forming the mixture into the desired shape at low temperatures. This process allows for greater complexity in design, the use of near-net shape manufacturing, and lower production costs for certain applications.

Over the past few decades, advancements in polymer chemistry and magnetic materials have contributed to the popularity of bonded magnets. They are now widely used in areas where complex geometries, weight savings, or cost reduction are critical factors. Moreover, the flexibility of the manufacturing process allows engineers to tailor magnetic properties to meet specific requirements.

Bonded magnets consist of magnetic powders such as NdFeB, ferrite, or samarium cobalt combined with a polymer binder like nylon, epoxy, or polyphenylene sulfide. The resulting composite is then molded or pressed into a desired shape. Because the process operates at relatively low temperatures, it avoids some of the limitations associated with high-temperature sintering.

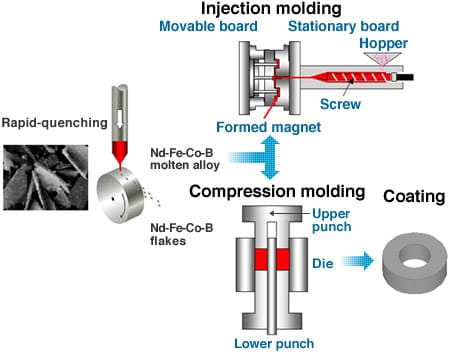

The manufacturing process for bonded magnets is quite distinct from that of sintered magnets. It typically involves several key steps:

The table below provides an overview of the major manufacturing steps involved in creating bonded magnets:

| Manufacturing Step | Description | Key Considerations |

| Powder Preparation | Production of high-quality magnetic powder with controlled particle size. | Particle shape, size distribution, and purity affect final magnetic properties. |

| Binder Mixing | Blending the magnetic powder with a polymer binder in precise proportions. | Uniform mixing is essential to ensure consistent magnetic performance across the magnet. |

| Molding/Forming | Shaping the powder-binder mixture using injection molding, compression molding, or extrusion techniques. | Near-net shape formation minimizes the need for additional machining and reduces waste. |

| Curing | Solidifying the binder (especially in thermosetting polymers) to permanently bond the particles together. | Temperature and curing time must be controlled to optimize mechanical strength without damaging the magnetic powder. |

| Finishing | Trimming, surface treatment, or additional machining to achieve final dimensions and surface quality. | Ensures that the magnet meets precise application requirements in terms of size, shape, and finish. |

Table 1: Overview of Bonded Magnet Manufacturing Process

This process contrasts sharply with the sintering process used to create traditional magnets, where powdered material is compacted and then heated to near-melting temperatures to fuse the particles together.

One of the most frequently discussed topics in the field of magnetic materials is the difference between bonded and sintered NdFeB magnets. Neodymium magnets are prized for their extremely high magnetic strength, but the production method plays a significant role in the final properties.

The following table provides a side-by-side comparison of these two types of NdFeB magnets:

Property | Bonded NdFeB Magnets | Sintered NdFeB Magnets |

Manufacturing Process | Polymer mixing, molding, and curing at low temperatures. | Powder pressing and high-temperature sintering (~1000°C). |

Magnetic Density | Lower density due to the presence of non-magnetic binder. | High density with optimized crystalline structure. |

Magnetic Performance | Generally lower remanence and energy product. | Superior magnetic properties with higher Br and BH_max values. |

Shape Flexibility | Can be molded into complex, near-net shapes. | Limited to simpler shapes; post-processing machining often required. |

Cost | Typically lower cost for complex shapes and lower production temperatures. | Higher production cost due to energy consumption and machining requirements. |

Thermal Performance | Lower maximum operating temperature due to binder limitations. | Can generally operate at higher temperatures due to robust material structure. |

Table 2: Comparison of Bonded vs. Sintered NdFeB Magnets

This comparison clearly illustrates that while sintered magnets often outperform bonded magnets in pure magnetic performance, bonded magnets offer unmatched versatility in design and cost-effectiveness for many applications.

| Advantages | Disadvantages |

|---|---|

| Ability to form complex, intricate shapes | Lower magnetic density due to the binder |

| Energy-efficient, low-temperature production | Reduced magnetic performance (lower BH_max and Br) |

| Cost-effective for custom and small-batch production | Limited maximum operating temperature |

| High geometric precision with near-net shape formation | Potential mechanical strength issues compared to sintered magnets |

| Customizable to meet specific design requirements | Possible aging and chemical degradation of the binder |

The field of magnetics often gives rise to several common questions that reflect both the technical complexity and practical considerations involved in magnet use. Below we address some of these frequently asked questions.

Bonded magnets are made by blending fine magnetic powders (such as NdFeB) with a polymer binder. This mixture is then processed into the desired shape using methods like injection molding or compression molding. The process avoids the high-temperature sintering step, making it ideal for complex geometries and cost-sensitive applications. The curing step (for thermosetting binders) solidifies the material into a permanent magnet.

The primary differences lie in the manufacturing process and resultant material properties:

In broad terms, magnets can be categorized into three main types:

Ceramic (Ferrite) Magnets:

Made from a mixture of iron oxide and barium or strontium carbonate.

They are inexpensive and widely used in consumer electronics and motors but have lower magnetic strength compared to neodymium magnets.

Neodymium Magnets (NdFeB):

Known for their high magnetic strength and are used in demanding applications such as electric motors, hard disk drives, and medical devices.

They come in both sintered and bonded forms, with sintered magnets offering higher performance and bonded magnets offering greater design flexibility.

Samarium Cobalt Magnets:

These magnets provide excellent thermal stability and corrosion resistance, making them suitable for high-temperature applications, though they are generally more expensive than neodymium magnets.

Yes, you can glue a magnet to another magnet using the appropriate adhesive. High-strength adhesives such as epoxy or cyanoacrylate are typically used. It is important, however, to consider the polarity and orientation of the magnets during bonding to ensure that the desired magnetic coupling is achieved.

Steel in its conventional form is not generally used as a permanent magnet because it lacks sufficient magnetic properties. However, certain steel alloys—such as alnico (an alloy composed primarily of aluminum, nickel, and cobalt)—are used to create permanent magnets. These magnets have been historically important in various applications, though they have largely been replaced in high-performance contexts by neodymium magnets.

The strongest magnets—particularly those used in high-performance applications—are typically made by carefully controlling the manufacturing process:

In many applications, magnets need to be securely attached to metal substrates. The process of bonding magnets to metal is critical in industries such as automotive, aerospace, and consumer electronics. There are two primary methods to achieve this:

Adhesive Bonding:

Mechanical Fastening:

Polymer bonded magnets refer to magnets produced using a polymer matrix, which offers benefits such as flexibility in shape and lower production costs. These magnets can be molded into intricate geometries and are especially useful for applications where weight savings and reduced machining are important. Advances in polymer science have led to the development of binders that offer improved thermal and mechanical properties, expanding the range of applications for polymer bonded magnets.

The market for bonded magnets continues to expand, driven by the increasing demand for miniaturized and high-performance components. Bonded magnets are used in:

Market trends indicate that ongoing research into magnetic powders and binder chemistries is likely to further improve the performance and thermal stability of bonded magnets. Additionally, the development of environmentally friendly production methods is becoming increasingly important, with manufacturers exploring recyclable binders and energy-efficient processing techniques.

The future of bonded magnets is promising, especially as industries demand ever more precise and miniaturized components. With advances in nanotechnology and materials science, researchers are continuously exploring ways to increase the energy product of bonded magnets while maintaining the benefits of near-net shape manufacturing. Innovations in binder technology could also lead to magnets that are more resistant to high temperatures and environmental degradation.

Moreover, the ongoing drive for sustainability is influencing production methods. Manufacturers are increasingly focusing on reducing energy consumption and exploring renewable materials for binders, which could lead to a greener production process without compromising performance.

Bonded magnets represent a crucial segment of the magnetic materials industry, offering unique advantages in terms of design flexibility, cost-effectiveness, and manufacturing efficiency. While they may not match the absolute magnetic performance of sintered magnets, their ability to be molded into complex shapes and produced with lower energy inputs makes them highly attractive for a wide range of applications.

In summary, this article has covered:

Bonded NdFeB magnets, in particular, serve as an excellent example of how modern manufacturing techniques can balance performance with production efficiency. As industries continue to push for innovation, the role of bonded magnets is set to grow, supporting the next generation of high-performance, miniaturized devices across a myriad of sectors.

The evolution of bonded magnet technology is a testament to the ongoing collaboration between materials science and manufacturing engineering. It illustrates how traditional materials can be reinvented through innovative processes to meet the demands of a rapidly changing technological landscape.

Whether you are an engineer designing the next breakthrough electric motor or a researcher exploring new magnetic materials, understanding the nuances between bonded and sintered magnets is essential. With the flexibility to create intricate shapes and the potential to lower production costs, bonded magnets have firmly established their place in modern industry.

In a world where every gram and every micron of material can make a significant difference, the ability to tailor magnetic properties to specific needs is invaluable. From the automotive industry’s push for more efficient electric motors to the burgeoning field of portable electronics and high-precision sensors, bonded magnets offer a pathway to innovation that is both practical and cost-effective.

As research continues and manufacturing techniques evolve, we can expect to see even greater improvements in the performance of bonded magnets. With enhanced thermal stability, improved energy products, and environmentally friendly processing methods on the horizon, the future of magnetic materials looks brighter than ever.

Ultimately, the choice between bonded and sintered magnets will depend on the specific requirements of the application at hand. While sintered magnets remain the gold standard for applications demanding the highest magnetic performance, bonded magnets offer a compelling alternative when design complexity, cost, and production efficiency are paramount.

Bonded magnets are widely used in applications requiring complex geometries and miniaturization. They are commonly found in consumer electronics (e.g., speakers, headphones, and cell phones), automotive sensors, small motors and actuators, medical devices (e.g., MRI components and diagnostic equipment), and in various industrial applications where precise magnetic components are needed.

The most common polymers include thermoplastics such as nylon, polyphenylene sulfide (PPS), and polyoxymethylene (POM), as well as thermosetting resins like epoxy. The choice depends on the desired properties—such as temperature resistance, mechanical strength, and chemical stability—of the final magnet.

The binder content directly influences the magnetic particle density. Higher binder content typically leads to lower magnetic density and reduced energy product (BH_max) because the binder is non-magnetic. However, a controlled binder amount is necessary for mechanical integrity and processability, creating a balance between magnetic performance and physical robustness.

The powder-to-binder ratio commonly ranges from about 85:15 to 95:5 by weight. The ideal ratio depends on the specific magnetic powder, desired magnetic properties, and processing technique. Lower binder content yields higher magnetic performance, while slightly higher binder ratios can improve mechanical properties and processing ease.

While sintered magnets often have higher magnetic performance, bonded magnets can be quite durable when designed properly. Their lifespan depends on environmental factors, mechanical stresses, and the quality of the binder. In applications where temperature and chemical exposure are controlled, bonded magnets can offer reliable long-term performance, though they may be more susceptible to degradation in harsh conditions compared to sintered magnets.

Yes, bonded magnets can be engineered to perform well in high-frequency or high-vibration environments. Their ability to be formed into precise shapes with uniform particle distribution often translates into predictable dynamic performance. However, the choice of binder and proper design considerations are crucial to ensure that the magnet withstands mechanical stresses without premature failure.

Environmental factors significantly impact bonded magnets. High humidity can affect the binder, potentially leading to swelling or degradation, while elevated temperatures may exceed the thermal limits of the polymer matrix, causing a reduction in magnetic performance or mechanical integrity. Manufacturers often select specialized binders and coatings to mitigate these effects in demanding environments.

Recycling bonded magnets is more challenging than recycling sintered magnets due to the composite nature of the material. The process generally involves mechanical separation or thermal treatment to degrade the binder and recover the magnetic powder. However, ongoing research aims to improve recycling methods by developing more environmentally friendly binders and separation technologies.

Industries that benefit from the design flexibility and cost-effectiveness of bonded magnets include automotive (sensors, actuators, and motors), consumer electronics (smartphones, audio devices, and appliances), medical equipment (diagnostic and therapeutic devices), robotics, and industrial automation. Their ability to be molded into complex shapes makes them particularly valuable in high-precision applications.

Bonded magnets generally have a lower production cost for complex or custom shapes because they require less machining and lower energy processing. While sintered magnets offer superior magnetic performance, their manufacturing process is more energy-intensive and often involves additional machining, driving up costs. For many applications where extreme magnetic strength is not critical, bonded magnets can be a more economical choice.

Recent advancements include the development of high-performance polymer binders that can withstand higher temperatures and harsher chemical environments, improvements in powder processing techniques (such as improved particle size control and coating), and enhanced molding methods that provide better alignment of magnetic particles. These innovations are helping to narrow the performance gap between bonded and sintered magnets while expanding the range of practical applications.

Common degradation mechanisms include thermal degradation of the binder, moisture absorption leading to swelling or chemical breakdown, mechanical wear or impact damage, and chemical corrosion in aggressive environments. Additionally, prolonged exposure to high temperatures may lead to demagnetization or loss of magnetic properties. Protective coatings and proper material selection are key strategies to mitigate these issues.