- Custom Magnets

- Standard Magnets

- Mounting Magnets

- Magnetic Assemblies

- About Us

- Knowledge

Alnico permanent magnets are made up of alloys whose significant constituents are iron, aluminum, nickel, and cobalt, though other elements (e.g., copper and titanium) may be included in minor amounts.

Grades of Alnico vary in cobalt content, which ranges from zero (Alnico 3) to 40% (Alnico 8). Lower grades (1, 2, 3, and 4) are unoriented, whose magnetic properties are isotropic and equal in all directions. Anisotropic grades (Alnico 5, 6, 8, and 9) are designed to produce high magnetic production in a specified direction.

AlNiCo grades vary in different areas of the world. There are mainly USA, MMPA, IEC, DIN, and UK standards.

| Grade | Residual Induction (Br.) kGs mT | Coercive Force(Hcb.) Oe kA/m | Intrinsic Coercive Force(Hcj.) Oe kA/m | Max. Energy Product(BH.) KJ/m3 MGOe | Density g/cm3 ℃ | Tw Max | Remark | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| AlNiCo1 | 7.2 | 720 | 470 | 37 | 480 | 38 | 11.1 | 1.4 | 6.9 | 450 | Isotropic |

| AlNiCo2 | 7.5 | 750 | 560 | 45 | 580 | 46 | 13.5 | 1.7 | 7.1 | 450 | |

| AlNiCo3 | 7 | 700 | 480 | 38 | 500 | 40 | 10.7 | 1.35 | 6.9 | 450 | |

| AlNiCo5 | 12.8 | 1280 | 640 | 51 | 640 | 51 | 43.8 | 5.5 | 7.3 | 525 | Anisotropic |

| AlNiCo5DG | 13.3 | 1330 | 670 | 53 | 670 | 53 | 57.7 | 6.5 | 7.3 | 525 | |

| AlNiCo5-7 | 13.5 | 1350 | 740 | 59 | 740 | 59 | 59.7 | 7.5 | 7.3 | 525 | |

| AlNiCo6 | 10.5 | 1050 | 780 | 62 | 800 | 64 | 31 | 3.9 | 7.3 | 525 | |

| AlNiCo8 | 8.2 | 820 | 1650 | 131 | 1860 | 148 | 42.2 | 5.3 | 7.3 | 550 | |

| AlNiCo8HC | 7.2 | 720 | 1900 | 151 | 2170 | 173 | 39.8 | 5 | 7.3 | 550 | |

| AlNiCo9 | 10.6 | 1060 | 1500 | 119 | 1500 | 119 | 71.6 | 9 | 7.3 | 550 | |

| Grade | Residual Induction(Br.) kGs mT | Coercive Force(Hcb.) Oe kA/m | Intrinsic Coercive Force(Hcj.) Oe kA/m | Max. Energy Product BH. KJ/m3 MGOe | Density g/cm3 | Tw Max ℃ | Remark | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| AlNiCo2 | 7.1 | 710 | 550 | 44 | 570 | 45 | 11.9 | 1.5 | 6.9 | 450 | Isotropic |

| AlNiCo5 | 10.9 | 1090 | 620 | 49 | 630 | 50 | 31 | 3.9 | 7.3 | 525 | Anisotropic |

| AlNiCo6 | 9.4 | 940 | 790 | 63 | 820 | 65 | 23.1 | 2.9 | 7.3 | 525 | |

| AlNiCo8 | 7.4 | 740 | 1500 | 119 | 1690 | 134 | 31.8 | 4 | 7.3 | 550 | |

| AlNiCo8HC | 6.7 | 670 | 1800 | 143 | 2020 | 161 | 35.8 | 4.5 | 7.3 | 550 | |

| Grade | Residual Induction(Br.) kGs mT | Coercive Force(Hcb.) Oe kA/m | Max. Energy Product BH. KJ/m3 MGOe | USA stand MMPA | IEC stand IEC | DIN stand DE | UK stand UK | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LN10 | 6.5 | 650 | 530 | 42 | 10 | 1.2 | AlNiCo3 | AlNiCo9/3 | / | / | ||

| LNG11 | 7.2 | 720 | 480 | 37 | 11.2 | 1.4 | AlNiCo1 | AlNiCo8/4 | AlNiCo120 | AlNi | ||

| LNG13 | 7 | 700 | 620 | 50 | 13 | 1.6 | AlNiCo2 | AlNiCo12/6 | AlNiCo160 | AlNiCo | ||

| LNGT18 | 5.8 | 580 | 1250 | 100 | 18 | 2.2 | I. AlNiCo 8 | AlNiCo17/9 | / | / | ||

| LNG16 | 8 | 800 | 660 | 53 | 16 | 2 | AlNiCo4 | / | / | / | ||

| LNG34 | 11.8 | 1180 | 550 | 44 | 34 | 4.25 | AlNiCo5C | / | / | / | ||

| LNG37 | 12 | 1200 | 600 | 48 | 37 | 4.65 | AlNiCo37/5 | AlNiCo500 | Alcomax2 | |||

| LNG40 | 12.2 | 1220 | 630 | 50 | 40 | 5 | AlNiCo5 | / | / | |||

| LNG44 | 12.5 | 1250 | 650 | 52 | 44 | 5.5 | AlNiCo44/5 | Alcomax3 | ||||

| LNG52 | 13 | 1300 | 690 | 55 | 52 | 6.5 | AlNiCo5DG | AlNiCo52/6 | AlNiCo600 | Alcomax3 S.C. | ||

| LNG60 | 13.3 | 1330 | 750 | 60 | 60 | 7.5 | AlNiCo5-7 | / | AlNiCo700 | Columax | ||

| LNGT28 | 10.5 | 1050 | 700 | 56 | 28 | 3.5 | AlNiCo6 | AlNiCo26/6 | AlNiCo400 | Alcomax4 | ||

| LNGT30 | 10.5 | 1050 | 750 | 60 | 30 | 3.75 | ||||||

| LNGT32 | 8 | 800 | 1280 | 102 | 32 | 4 | AlNiCo8 | AlNiCo38/11 | AlNiCo350 | Hycomax2 | ||

| LNGT40 | 8.2 | 820 | 1400 | 112 | 40 | 5 | ||||||

| LNGT44 | 8.8 | 880 | 1540 | 123 | 44 | 5.5 | AlNiCo8B | / | AlNiCo450 | Hycomax3 | ||

| LNGT48A | 9.3 | 930 | 1540 | 123 | 48 | 6 | AlNiCo8HE | |||||

| LNGT48B | 8.5 | 850 | 1650 | 132 | 48 | 6 | ||||||

| LNGT60 | 9 | 900 | 1380 | 110 | 60 | 7.5 | AlNiCo60/11 | / | / | |||

| LNGT72 | 10.5 | 1050 | 1410 | 112 | 72 | 9 | AlNiCo9 | / | / | / | ||

| LNGT80 | 10.8 | 1080 | 1540 | 123 | 80 | 10 | ||||||

| LNGT88 | 11 | 1100 | 1575 | 126 | 88 | 11 | ||||||

| LNGT92 | 11.5 | 1150 | 1575 | 126 | 92 | 11.5 | ||||||

| LNGT36J | 7 | 700 | 1750 | 140 | 36 | 4.5 | AlNiCo8HC | AlNiCo36/15 | / | / | ||

| LNGT40J | 7.2 | 720 | 1900 | 152 | 40 | 5 | ||||||

| LNGT44J | 8.2 | 820 | 1800 | 144 | 44 | 5.5 | AlNiCo44/15 | / | / | |||

| Grade | Residual Induction(Br.) kGs mT | Coercive Force(Hcb.) kA/m Oe | Intrinsic Coercive Force(Hcj.) kA/m Oe | Max. Energy Product BH. KJ/m3 MGOe | Density g/cm3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| FLN8 | 5.2 | 520 | 40 | 500 | 43 | 540 | 45148 | 1-1.25 | 6.8 | ||

| FLNG12 | 7 | 700 | 40 | 500 | 43 | 540 | 45274 | 1.5-1.75 | 6.9 | ||

| FLNG14 | 5.7 | 570 | 76 | 950 | 78 | 980 | 14-16 | 1.75-2.0 | 6.9 | ||

| FLNG18 | 5.6 | 560 | 88 | 1100 | 90 | 1130 | 18-22 | 2.25-2.75 | 7 | ||

| FLNG28 | 10.5 | 1050 | 46 | 580 | 47 | 590 | 28-33 | 3.5-4.15 | 7.3 | ||

| FLNG34 | 11 | 1100 | 48 | 600 | 50 | 630 | 33-38 | 4.1-4.7 | 7.3 | ||

| FLNG35 | 12.2 | 1220 | 50 | 630 | 51 | 640 | 35-39 | 4.4-4.9 | 7.3 | ||

| FLNGT28 | 10 | 1000 | 56 | 700 | 57 | 710 | 28-30 | 3.5-3.8 | 7.3 | ||

| FLNGT31 | 7.8 | 780 | 104 | 1300 | 106 | 1130 | 33-36 | 3.9-4.5 | 7.3 | ||

| FLNGT38 | 8 | 800 | 123 | 1550 | 126 | 1580 | 38-42 | 4.75-5.3 | 7.3 | ||

| FLNGT42 | 8.8 | 880 | 120 | 1500 | 122 | 1530 | 42-44 | 5.3-5.5 | 7.3 | ||

| FLNGT44 | 9 | 900 | 120 | 1500 | 125 | 1560 | 44-48 | 5.5-6.0 | 7.3 | ||

| FLNG33J | 6.5 | 650 | 136 | 1700 | 150 | 1880 | 31-36 | 4.1-4.5 | 7.3 | ||

| FLNGT40J | 8 | 800 | 1440 | 1800 | 155 | 1950 | 40-44 | 5.0-5.5 | 7.3 | ||

| FLNGT44J | 8.2 | 820 | 1520 | 1900 | 160 | 2000 | 44-48 | 5.5-6.0 | 7.3 | ||

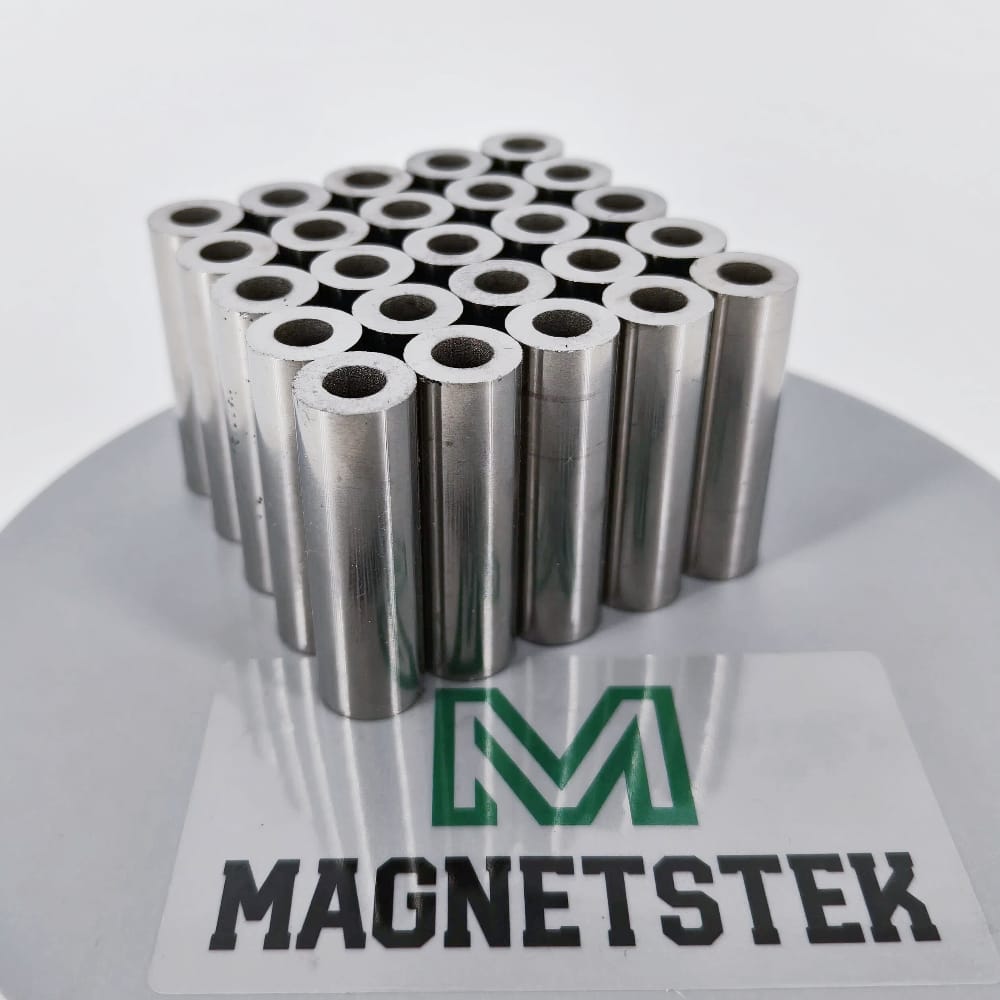

Magnetstek Engineering can provide any grade of above AlNiCo magnets. Feel free to talk to our expert team for assistance.