Menu

NdFeB magnets are graded based on their magnetic properties and performance characteristics. The “NdFeB Magnet Grades” is a standardized way to communicate the material’s maximum energy product, a crucial indicator of its strength. Magnetstek Engineering has been supplying Neodymium Magnets for over 20 years. We manufacture strong Neodymium magnets according to our customers’ requirements and offer competitive prices. Our NdFeB Magnet Grades ranged from N35 to N56 and N to NTH.

The standard notation for NdFeB Magnet Grades consists of the following format: Nxx, where “N” stands for Neodymium and “xx” represents a two-digit number. The higher the number, the higher the maximum energy product and, consequently, the stronger the magnet. Additionally, some grades may include additional specifications ending with one or two letters, such as “H”, “M”, and “UH”. This gives information on the maximum working temperature resistance.

Magnetstek Engineering achieved exceptional NdFeB Magnet Grades of N54 and N56, which are even stronger than N52. We have also pushed the industry’s maximum operation temperature to 250°C/482°F (Grade NxxTH).

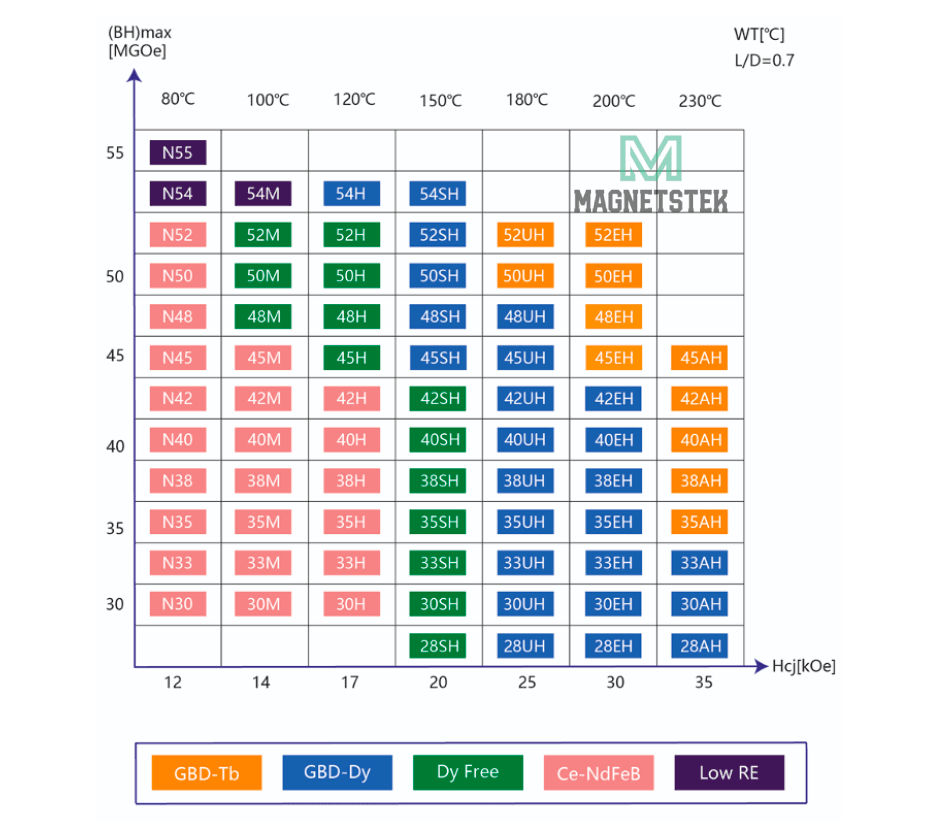

Here are the NdFeB Magnet Grades we provide now:

These are among the lower grades, with N35 being less powerful and N52 being stronger within this range. The maximum operating temperature is 80°C/176°F while 70°C/158°F for N50 and N52.

The “M” in these grades indicates a medium temperature rating. These magnets are suitable for applications where elevated temperatures are a consideration. The maximum operating temperature is 100°C/212°F.

The “H” denotes a high-temperature rating, making these magnets more suitable for applications where heat resistance is essential. The maximum operating temperature is 120°C/248°F.

The “SH” signifies a super high-temperature rating, suitable for applications with even higher operating temperatures. The maximum operating temperature is 150°C/302°F.

The “UH” indicates an ultra-high-temperature rating, making these magnets suitable for extremely high-temperature environments. The maximum operating temperature is 180°C/356°F.

The “EH” represents an extra high-temperature rating, suitable for applications requiring a balance of high strength and temperature resistance. The maximum operating temperature is 200°C/392°F.

The maximum operating temperature is 230°C/446°F.

8. N30TH, N33TH, N35TH

The maximum operating temperature is 250°C/482°F.

| Grade | Remanence Induction/Br. | Coercive Force/HcB | Intrinsic Coercive Force/HcJ | Maximum Energy Product/(BH)max | Max Working Temp. | Curie Temp. | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| T | KGs | KA/m | KOe | KA/m | KOe | KJ/m³ | MGOe | °C/°F | °C/°F | |

N35 | 1.17-1.21 | 11.7-12.1 | ≥876 | ≥11 | ≥955 | ≥12 | 263-279 | 33-35 | 80/176 | 310/590 |

N38 | 1.23-1.30 | 12.3-13.0 | ≥876 | ≥11 | ≥955 | ≥12 | 287-318 | 36-40 | 80/176 | 310/590 |

N40 | 1.26-1.32 | 12.6-13.2 | ≥876 | ≥11 | ≥955 | ≥12 | 302-334 | 38-42 | 80/176 | 310/590 |

N42 | 1.29-1.35 | 12.9-13.5 | ≥876 | ≥11 | ≥955 | ≥12 | 318-350 | 40-44 | 80/176 | 310/590 |

N45 | 1.32-1.38 | 13.2-13.8 | ≥876 | ≥11 | ≥955 | ≥12 | 334-366 | 42-46 | 80/176 | 310/590 |

N48 | 1.37-1.43 | 13.7-14.3 | ≥876 | ≥11 | ≥955 | ≥12 | 358-390 | 45-49 | 80/176 | 310/590 |

N50 | 1.40-1.45 | 14.0-14.5 | ≥876 | ≥11 | ≥955 | ≥12 | 374-406 | 47-51 | 70/158 | 310/590 |

N52 | 1.42-1.48 | 14.2-14.8 | ≥836 | ≥10.5 | ≥876 | ≥11 | 390-422 | 49-53 | 70/158 | 310/590 |

N54 | 1.45-1.49 | 14.5-14.9 | ≥836 | ≥10.5 | ≥955 | ≥11 | 406-437 | 51-55 | 80/176 | 310/590 |

N56 | 1.47-1.51 | 14.7-15.1 | ≥836 | ≥10.5 | ≥876 | ≥12 | 414-454 | 52-57 | 80/176 | 310/590 |

N35M | 1.17-1.21 | 11.7-12.1 | ≥892 | ≥11.2 | ≥1114 | ≥14 | 263-279 | 33-35 | 100/212 | 340/644 |

N38M | 1.23-1.30 | 12.3-13.0 | ≥915 | ≥11.5 | ≥1114 | ≥14 | 287-318 | 36-40 | 100/212 | 340/644 |

N40M | 1.26-1.32 | 12.6-13.2 | ≥939 | ≥11.8 | ≥1114 | ≥14 | 302-334 | 38-42 | 100/212 | 340/644 |

N42M | 1.29-1.35 | 12.9-13.5 | ≥963 | ≥12.1 | ≥1114 | ≥14 | 318-350 | 40-44 | 100/212 | 340/644 |

N45M | 1.32-1.38 | 13.2-13.8 | ≥987 | ≥12.4 | ≥1114 | ≥14 | 334-366 | 42-46 | 100/212 | 340/644 |

N48M | 1.37-1.43 | 13.7-14.3 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 358-390 | 45-49 | 100/212 | 340/644 |

N50M | 1.40-1.45 | 14.0-14.5 | ≥1043 | ≥13.1 | ≥1114 | ≥14 | 374-406 | 47-51 | 100/212 | 340/644 |

N52M | 1.42-1.48 | 14.2-14.8 | ≥1059 | ≥13.3 | ≥1114 | ≥14 | 390-422 | 49-53 | 100/212 | 340/644 |

N33H | 1.14-1.17 | 11.4-11.7 | ≥820 | ≥10.3 | ≥1353 | ≥17 | 247-263 | 31-33 | 120/248 | 340/644 |

N35H | 1.17-1.24 | 11.7-12.4 | ≥876 | ≥11.0 | ≥1353 | ≥17 | 263-295 | 33-37 | 120/248 | 340/644 |

N38H | 1.23-1.30 | 12.3-13.0 | ≥915 | ≥11.5 | ≥1353 | ≥17 | 286-318 | 36-40 | 120/248 | 340/644 |

N40H | 1.26-1.32 | 12.6-13.2 | ≥939 | ≥11.8 | ≥1353 | ≥17 | 302-334 | 38-42 | 120/248 | 340/644 |

N42H | 1.29-1.35 | 12.9-13.5 | ≥963 | ≥12.1 | ≥1353 | ≥17 | 318-350 | 40-44 | 120/248 | 340/644 |

N45H | 1.32-1.38 | 13.2-13.8 | ≥987 | ≥12.4 | ≥1353 | ≥17 | 334-366 | 42-46 | 120/248 | 340/644 |

N48H | 1.37-1.43 | 13.7-14.3 | ≥1011 | ≥12.7 | ≥1353 | ≥17 | 358-390 | 45-49 | 120/248 | 340/644 |

N50H | 1.40-1.45 | 14.0-14.5 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 374-406 | 47-51 | 120/248 | 340/644 |

N30SH | 1.08-1.12 | 10.8-11.2 | ≥804 | ≥10.1 | ≥1592 | ≥20 | 223-239 | 28-30 | 150/302 | 340/644 |

N33SH | 1.14-1.21 | 11.4-12.1 | ≥852 | ≥10.7 | ≥1592 | ≥20 | 247-279 | 31-35 | 150/302 | 340/644 |

N35SH | 1.17-1.24 | 11.7-12.4 | ≥876 | ≥11.0 | ≥1592 | ≥20 | 263-295 | 33-37 | 150/302 | 340/644 |

N38SH | 1.23-1.29 | 12.3-12.9 | ≥915 | ≥11.5 | ≥1592 | ≥20 | 287-318 | 36-40 | 150/302 | 340/644 |

N40SH | 1.26-1.32 | 12.6-13.2 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-334 | 38-42 | 150/302 | 340/644 |

N42SH | 1.29-1.35 | 12.9-13.5 | ≥963 | ≥12.1 | ≥1592 | ≥20 | 318-350 | 40-44 | 150/302 | 340/644 |

N45SH | 1.32-1.38 | 13.2-13.8 | ≥987 | ≥12.4 | ≥1592 | ≥20 | 334-366 | 42-46 | 150/302 | 340/644 |

N48SH | 1.37-1.43 | 13.7-14.3 | ≥1011 | ≥12.7 | ≥1592 | ≥20 | 358-390 | 45-49 | 150/302 | 340/644 |

N50SH | 1.40-1.45 | 14.0-14.5 | ≥1027 | ≥12.9 | ≥1592 | ≥20 | 374-406 | 47-51 | 150/302 | 340/644 |

N28UH | 1.04-1.08 | 10.4-10.8 | ≥780 | ≥9.8 | ≥1990 | ≥25 | 207-223 | 26-28 | 180/356 | 350/662 |

N30UH | 1.08-1.13 | 10.8-11.3 | ≥796 | ≥10.0 | ≥1990 | ≥25 | 223-255 | 28-31 | 180/356 | 350/662 |

N33UH | 1.14-1.18 | 11.4-11.8 | ≥852 | ≥10.5 | ≥1990 | ≥25 | 247-279 | 31-35 | 180/356 | 350/662 |

N35UH | 1.17-1.24 | 11.7-12.4 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 263-295 | 33-37 | 180/356 | 350/662 |

N38UH | 1.23-1.29 | 12.3-12.9 | ≥915 | ≥11.5 | ≥1990 | ≥25 | 287-318 | 36-40 | 180/356 | 350/662 |

N40UH | 1.26-1.32 | 12.6-13.2 | ≥939 | ≥11.8 | ≥1990 | ≥25 | 302-334 | 38-42 | 180/356 | 350/662 |

N42UH | 1.28-1.35 | 12.8-13.5 | ≥963 | ≥12.1 | ≥1990 | ≥25 | 310-350 | 39-44 | 180/356 | 350/662 |

N45UH | 1.32-1.38 | 13.2-13.8 | ≥987 | ≥12.4 | ≥1990 | ≥25 | 334-366 | 42-46 | 180/356 | 350/662 |

N48UH | 1.37-1.42 | 13.7-14.2 | ≥1019 | ≥12.8 | ≥1910 | ≥24 | 358-390 | 45-49 | 180/356 | 350/662 |

N30EH | 1.08-1.15 | 10.8-11.5 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-255 | 28-32 | 200/392 | 350/662 |

N33EH | 1.14-1.21 | 11.4-12.1 | ≥851 | ≥10.7 | ≥2388 | ≥30 | 247-279 | 31-35 | 200/392 | 350/662 |

N35EH | 1.17-1.24 | 11.7-12.4 | ≥876 | ≥11.0 | ≥2388 | ≥30 | 263-295 | 33-37 | 200/392 | 350/662 |

N38EH | 1.23-1.29 | 12.3-12.9 | ≥915 | ≥11.5 | ≥2388 | ≥30 | 287-318 | 36-40 | 200/392 | 350/662 |

N40EH | 1.26-1.32 | 12.6-13.2 | ≥939 | ≥11.8 | ≥2388 | ≥30 | 302-334 | 38-42 | 200/392 | 350/662 |

N42EH | 1.28-1.35 | 12.8-13.5 | ≥963 | ≥12.1 | ≥2388 | ≥30 | 310-350 | 39-44 | 200/392 | 350/662 |

N45EH | 1.33-1.38 | 13.3-13.8 | ≥995 | ≥12.5 | ≥2308 | ≥29 | 334-366 | 42-46 | 200/392 | 350/662 |

N28AH | 1.04-1.12 | 10.4-11.2 | ≥772 | ≥9.7 | ≥2786 | ≥35 | 207-239 | 26-30 | 230/446 | 350/662 |

N30AH | 1.08-1.15 | 10.8-11.5 | ≥812 | ≥10.2 | ≥2786 | ≥35 | 223-255 | 28-32 | 230/446 | 350/662 |

N33AH | 1.14-1.21 | 11.4-12.1 | ≥852 | ≥10.7 | ≥2786 | ≥35 | 247-279 | 31-35 | 230/446 | 350/662 |

N35AH | 1.17-1.24 | 11.7-12.4 | ≥876 | ≥11.0 | ≥2786 | ≥35 | 263-295 | 33-37 | 230/446 | 350/662 |

N38AH | 1.23-1.27 | 12.3-12.7 | ≥923 | ≥11.6 | ≥2786 | ≥35 | 287-318 | 36-40 | 230/446 | 350/662 |

N40AH | 1.26-1.31 | 12.6-13.1 | ≥939 | ≥11.8 | ≥2628 | ≥33 | 302-334 | 38-42 | 230/446 | 350/662 |

N30TH | 1.08-1.13 | 10.8-11.3 | 820 | 10.3 | ≥3182 | ≥40 | 223-247 | 28-31 | 250/482 | 350/662 |

N33TH | 1.11-1.17 | 11.1-11.7 | 851 | 10.7 | ≥3182 | ≥40 | 239-271 | 31-34 | 250/482 | 350/662 |

N35TH | 1.17-1.22 | 11.7-12.2 | 867 | 10.9 | ≥3182 | ≥40 | 263-287 | 33-36 | 250/482 | 350/662 |

MagnetsTek invests heavily in product development annually, distinguishing us from other suppliers in the industry.