Ferrite Magnets: A Comprehensive Guide to Composition, Applications, and Comparisons

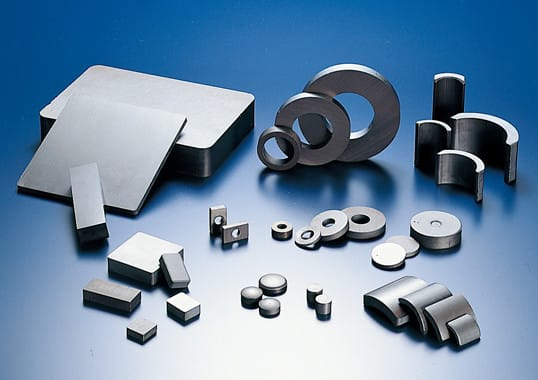

Ferrite magnets, often referred to as ceramic magnets or hard ferrite magnets, have been a staple in various industries for decades. Known for their electrical insulation, cost-effectiveness, and excellent corrosion resistance, these magnets have found their way into countless applications—from household appliances to industrial machinery. This article provides an in‐depth exploration of ferrite magnets, covering everything from their composition and manufacturing process to their uses, characteristics, and how they compare to neodymium magnets. We’ll also answer frequently asked questions such as “Are ferrite magnets the same as ceramic magnets?” and “Do ceramic magnets break easily?”

Table of Contents

Introduction

Ferrite magnets have played a vital role in the evolution of permanent magnet technology since their introduction in the 1950s. Their development offered a more affordable alternative to rare-earth magnets while providing adequate performance for many everyday applications. Ferrite magnets are made from iron oxide combined with either strontium or barium compounds, giving them unique magnetic properties that set them apart from other types of permanent magnets.

Despite being one of the older magnet technologies, ferrite magnets remain highly relevant today due to their durability, cost-effectiveness, and versatility. Whether you are designing a new appliance, developing a magnetic sensor, or simply curious about the differences between various magnet types, understanding ferrite magnets is essential.

What Is a Ferrite Magnet?

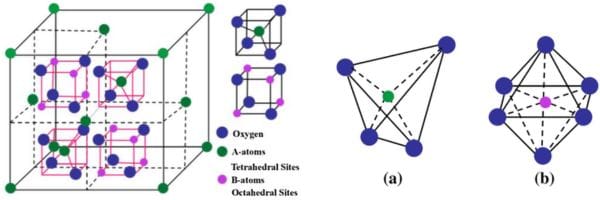

A ferrite magnet is a type of ceramic permanent magnet made primarily from iron oxide (Fe₂O₃) mixed with either barium carbonate (BaCO₃) or strontium carbonate (SrCO₃). The two most common variants are:

- Strontium Ferrite Magnets:More common and typically used in a variety of applications.

- Barium Ferrite Magnets:Known for slightly different magnetic and mechanical properties.

Because they are electrically insulating and non-metallic, ferrite magnets are often called ceramic magnets. This insulation makes them particularly useful in applications where electrical conductivity could lead to issues like eddy current losses.

Ferrite Magnet Composition

The unique properties of ferrite magnets are a direct result of their composition. The main ingredients include:

- Iron Oxide (Fe₂O₃):Provides the magnetic properties.

- Barium Carbonate (BaCO₃) or Strontium Carbonate (SrCO₃):Acts as the binding compound and influences the overall magnetic strength and temperature stability.

- Additional Additives:In some cases, small amounts of other compounds may be added to enhance performance characteristics such as coercivity (resistance to demagnetization) and stability.

The sintering process, which involves heating the pressed powder mixture at high temperatures, helps fuse these components together into a solid ceramic structure. The result is a robust magnet that, while brittle compared to some metallic magnets, offers high resistance to corrosion and excellent stability over time.

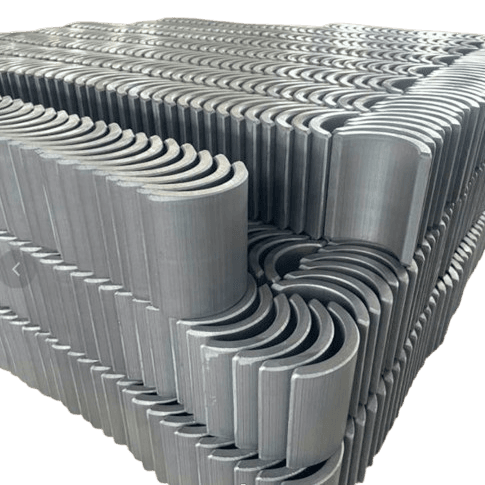

How Ferrite Magnets Are Made

The manufacturing process of ferrite magnets involves several key steps:

- Mixing and Milling:Raw materials such as iron oxide and carbonate compounds are carefully weighed, mixed, and milled to achieve a uniform particle size.

- Calcining:The mixture is heated in a controlled environment to facilitate chemical reactions between the components.

- Pressing:The calcined powder is then pressed into the desired shape using high-pressure dies.

- Sintering:The pressed magnets are heated at high temperatures in a furnace. This step is critical as it fuses the particles together and sets the magnet’s crystalline structure.

- Machining and Coating:Post-sintering, the magnets may be machined to precise dimensions. If necessary, a coating is applied to improve mechanical strength and corrosion resistance.

This process, while energy-intensive, results in magnets that are both cost-effective and durable, which is why they are widely used across industries.

Grades and Types of Ferrite Magnets

| Ferrite Grade | Remanence (Br) | Coercive Force (Hc) | Intrinsic Coercive Force (Hd) | Maximum Energy Product (BH) max | ||||

|---|---|---|---|---|---|---|---|---|

| kG | T | kOe | kA/m | kOe | kA/m | MGOe | kJ/m^3 | |

| Y8T | 2.0 - 2.35 | 0.20 - 0.235 | 1.57 - 2.01 | 125 - 160 | 2.64 - 3.52 | 210 - 280 | 0.8 - 1.2 | 6.5 - 9.5 |

| Y10T | 2.0 - 2.35 | 0.20 - 0.235 | 1.61 - 2.01 | 128 - 160 | 2.64 - 3.52 | 210 - 280 | 0.8 - 1.2 | 6.4 - 9.6 |

| Y20 | 3.2 - 3.8 | 0.32 - 0.38 | 1.70 - 2.39 | 135 - 190 | 1.76 - 2.45 | 140 - 195 | 2.3 - 2.8 | 18 - 22 |

| Y22H | 3.1 - 3.6 | 0.31 - 0.36 | 2.76 - 3.14 | 220 - 250 | 3.52 - 4.02 | 280 - 320 | 2.5 - 3.0 | 20 - 24 |

| Y23 | 3.2 - 3.7 | 0.32 - 0.37 | 2.14 - 2.39 | 170 - 190 | 2.39 - 2.89 | 190 - 230 | 2.5 - 3.2 | 20 - 25 |

| Y25 | 3.6 - 4.0 | 0.36 - 0.40 | 1.70 - 2.14 | 135 - 170 | 1.76 - 2.51 | 140 - 200 | 2.8 - 3.5 | 22.5 - 28 |

| Y26H | 3.6 - 3.9 | 0.36 - 0.39 | 2.76 - 3.14 | 220 - 250 | 2.83 - 3.20 | 225 - 255 | 2.9 - 3.5 | 23 - 28 |

| Y26H-1 | 3.6 - 3.9 | 0.36 - 0.39 | 2.51 - 3.14 | 200 - 250 | 2.83 - 3.20 | 255 - 255 | 2.9 - 3.5 | 23 - 28 |

| Y26H-2 | 3.6 - 3.8 | 0.36 - 0.38 | 3.30 - 3.62 | 263 - 288 | 4.0 - 4.40 | 318 - 350 | 3.0 - 3.5 | 24 - 28 |

| Y27H | 3.7 - 4.0 | 0.37 - 0.40 | 2.58 - 3.14 | 205 - 250 | 2.64 - 3.20 | 210 - 255 | 3.1 - 3.6 | 25 - 29 |

| Y28 | 3.7 - 4.0 | 0.37 - 0.40 | 2.20 - 2.64 | 175 - 210 | 2.26 - 2.76 | 180 - 220 | 3.3 - 3.8 | 26 - 30 |

| Y28H-1 | 3.8 - 4.0 | 0.38 - 0.40 | 3.02 - 3.27 | 240 - 260 | 3.14 - 3.52 | 250 - 280 | 3.4 - 3.8 | 27 - 30 |

| Y28H-2 | 3.3 - 3.8 | 0.33 - 0.38 | 3.41 - 3.71 | 271 - 295 | 4.80 - 5.09 | 382 - 405 | 3.3 - 3.8 | 26 - 30 |

| Y30 | 3.7 - 4.0 | 0.37 - 0.40 | 2.20 - 2.64 | 175 - 210 | 2.26 - 2.76 | 180 - 220 | 3.3 - 3.8 | 26 - 30 |

| Y30BH | 3.8 - 3.9 | 0.38 - 0.39 | 2.80 - 2.95 | 223 - 235 | 2.90 - 3.08 | 231 - 245 | 3.4 - 3.8 | 27 - 30 |

| Y30H-1 | 3.8 - 4.0 | 0.38 - 0.40 | 2.89 - 3.46 | 230 - 275 | 2.95 - 3.64 | 235 - 290 | 3.4 - 4.0 | 27 - 32 |

| H30H-2 | 3.95 - 4.15 | 0.395 - 0.415 | 3.46 - 3.77 | 275 - 300 | 3.90 - 4.21 | 310 - 335 | 3.4 - 4.1 | 31 - 34 |

| Y32 | 4.0 - 4.2 | 0.40 - 0.42 | 2.01 - 2.39 | 160 - 190 | 2.07 - 2.45 | 165 - 195 | 3.8 - 4.2 | 30 - 33.5 |

| Y32H-1 | 4.0 - 4.2 | 0.40 - 0.42 | 2.39 - 2.89 | 190 - 230 | 2.89 - 3.14 | 230 - 250 | 4.0 - 4.4 | 31.5 - 35 |

| Y32H-2 | 4.0 - 4.4 | 0.40 - 0.44 | 2.81 - 3.02 | 224 - 240 | 2.89 - 3.14 | 230 - 250 | 3.9 - 4.3 | 31 - 34 |

| Y33 | 4.1 - 4.3 | 0.41 - 0.43 | 2.76 - 3.14 | 220 - 250 | 2.83 - 3.20 | 225 - 255 | 4.0 - 4.4 | 31.5 - 35 |

| Y33H | 4.1 - 4.3 | 0.41 - 0.43 | 3.14 - 3.39 | 250 - 270 | 3.14 - 3.46 | 250 - 275 | 4.0 - 4.4 | 31.5 - 35 |

| Y34 | 4.2 - 4.4 | 0.42 - 0.44 | 2.51 - 2.89 | 200 - 230 | 2.58 - 2.95 | 205 - 235 | 4.1 - 4.5 | 32.5 - 36 |

| Y35 | 4.3 - 4.5 | 0.43 - 0.45 | 2.70 - 3.00 | 215 - 239 | 2.74 - 3.03 | 217 - 241 | 4.2 - 4.8 | 33.1 - 38.2 |

| Y36 | 4.3 - 4.5 | 0.43 - 0.45 | 3.10 - 3.41 | 247 - 271 | 3.14 - 3.44 | 250 - 274 | 4.4 - 4.8 | 35.1 - 38.3 |

| Y38 | 4.4 - 4.6 | 0.44 - 0.46 | 3.58 - 3.83 | 285 - 305 | 3.69 - 3.90 | 294 - 310 | 4.6 - 5.1 | 36.6 - 40.6 |

| Y40 | 4.4 - 4.6 | 0.44 - 0.46 | 4.15 - 4.45 | 330 - 354 | 4.27 - 4.52 | 350 - 360 | 3.7 - 5.3 | 37.5 - 41.8 |

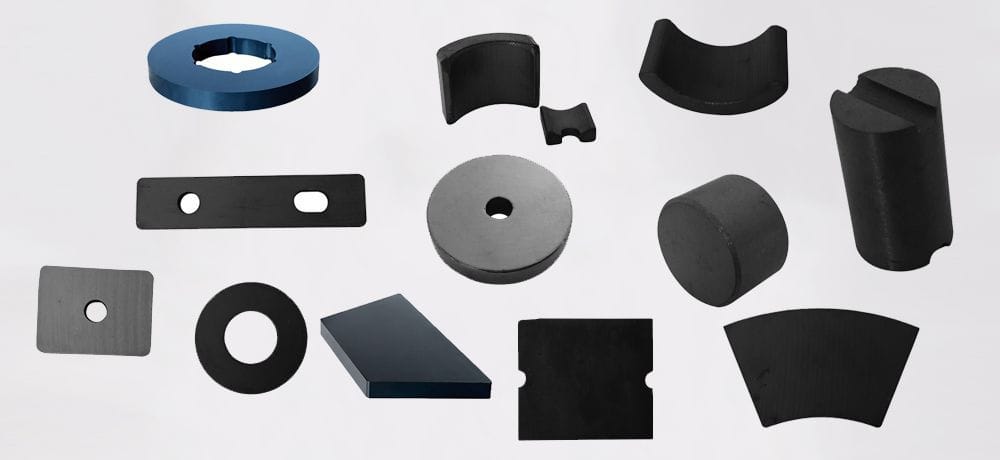

Ferrite magnets come in different grades and types, primarily defined by their composition and resultant properties. The two main types are:

1. Strontium Ferrite Magnets

Composition:Iron oxide combined with strontium carbonate.

- Characteristics:Higher coercivity and a slightly lower magnetic strength compared to barium ferrites.

- Applications:Commonly used in motors, sensors, loudspeakers, and various household devices.

2. Barium Ferrite Magnets

- Composition:Iron oxide mixed with barium carbonate.

- Characteristics:Typically exhibits a stronger magnetic field but may have slightly different temperature coefficients.

- Applications:Often found in applications that require higher magnetic performance at room temperature, such as certain electronic devices and specialized motors.

| Property | Strontium Ferrite | Barium Ferrite |

| Composition | Fe₂O₃ + SrCO₃ | Fe₂O₃ + BaCO₃ |

| Magnetic Strength | Moderate (widely used) | Generally stronger |

| Coercivity | High | Moderately high |

| Temperature Stability | Good, with stable performance | Excellent at room temperature |

| Common Applications | Motors, sensors, loudspeakers | Electronic devices, specialized motors |

Ferrite Coatings

Ferrite magnets, being ceramic in nature, are inherently brittle. To improve their durability and prevent chipping or cracking during handling and operation, coatings may be applied. These coatings also serve to protect the magnet’s surface from moisture and other environmental factors that could lead to corrosion over time. Common coating materials include:

- Nickel Plating:Provides a protective metallic layer.

- Epoxy Coatings:Offer a robust, flexible cover that can absorb impacts.

- Polyurethane:Used for its excellent adhesion and resistance to abrasion.

The choice of coating depends largely on the application requirements and the environmental conditions the magnet will face.

Applications of Ferrite Magnets

Ferrite magnets have a diverse range of applications due to their cost-effectiveness, corrosion resistance, and stable magnetic properties. Some of the most common uses include:

Industrial and Commercial Applications

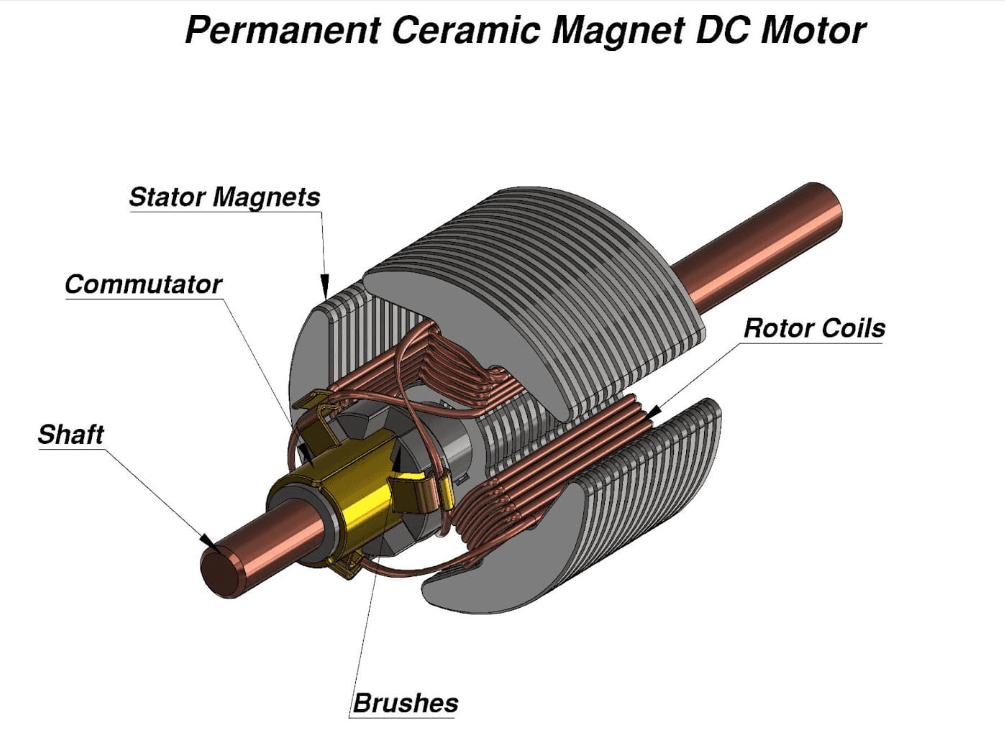

- Electric Motors and Generators:Ferrite magnets are often used in various types of motors and generators, providing the necessary magnetic field to drive electrical systems.

- Sensors and Actuators:Their consistent magnetic properties make them ideal for precision sensors and actuators in industrial automation.

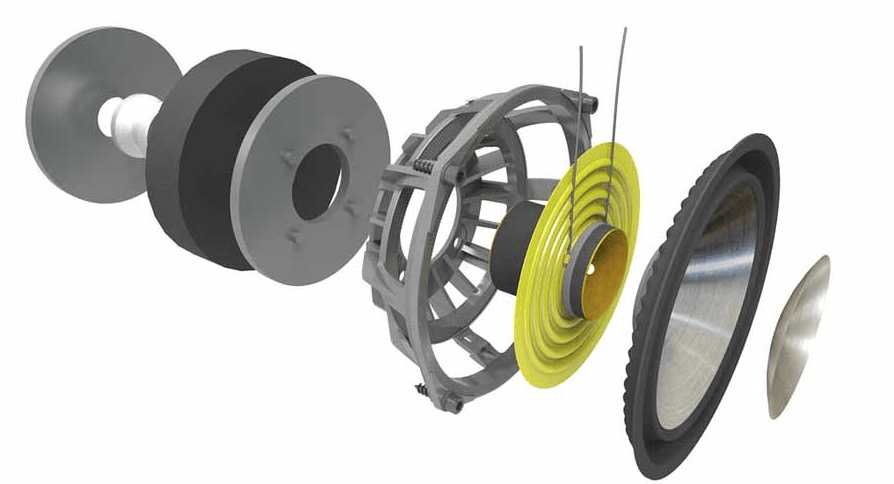

- Loudspeakers and Audio Equipment:Ferrite magnets are widely used in audio devices, where they help drive sound production in speakers.

- Magnetic Assemblies:Used in magnetic couplings, brakes, and other assemblies where reliable magnetic performance is essential.

Consumer Applications

- Refrigerator Magnets:Perhaps the most familiar application, these magnets are safe, inexpensive, and effective for holding notes and photos on refrigerators.

- Magnetic Toys:Their low cost and safety (non-toxic and electrically insulating) make them popular in a variety of toys.

- Home Appliances:Ferrite magnets are found in door locks, magnetic closures, and various other components that require a reliable magnetic force.

Specialized Applications

- Medical Devices:In certain low-field MRI devices and diagnostic equipment, ferrite magnets provide the necessary magnetic properties without the high cost of rare-earth alternatives.

- Renewable Energy:Ferrite magnets are used in wind turbines and other renewable energy systems where durability and cost are critical factors.

- Automotive Industry:From sensors to motors and actuators, ferrite magnets are a key component in many automotive applications.

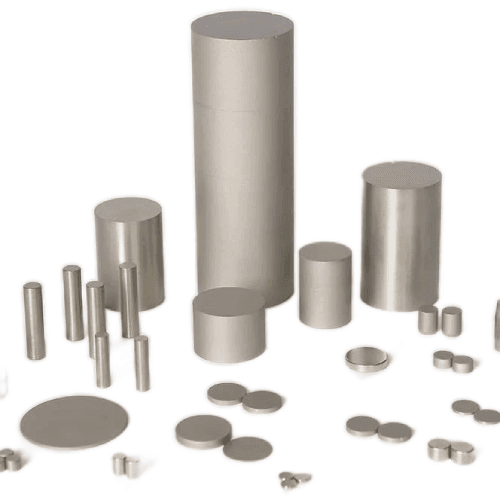

Ferrite Magnet vs. Neodymium Magnet

While ferrite magnets have many attractive properties, they are often compared with neodymium magnets, a type of rare-earth magnet known for its superior magnetic strength. Here’s a detailed comparison:

Property | Ferrite (Ceramic) Magnets | Neodymium Magnets |

Magnetic Strength | Moderate; sufficient for many uses | Extremely high; among the strongest permanent magnets available |

Cost | Low-cost, very economical | Higher cost due to rare-earth elements and complex processing |

Temperature Stability | Good; can operate over a wide temperature range, though high temperatures can reduce magnetism | Sensitive to high temperatures; generally require careful thermal management |

Corrosion Resistance | Excellent; inherently resistant to rust and corrosion | Poor without protective coatings; prone to oxidation |

Mechanical Properties | Brittle; can chip or crack under impact | Also brittle, but often require additional handling precautions |

Applications | Motors, sensors, household items, industrial components | High-performance motors, magnetic resonance imaging (MRI), advanced electronics, high-end audio |

Key Considerations

- Cost vs. Performance:Ferrite magnets are favored for applications where cost is a primary concern, while neodymium magnets are chosen for high-performance applications requiring strong magnetic fields.

- Durability:Ferrite magnets excel in corrosion resistance, whereas neodymium magnets often need additional protective coatings.

- Thermal Management:Applications involving high temperatures may lean towards ferrite magnets, as neodymium magnets can lose their magnetic properties if overheated.

Ferrite Magnet Price

One of the most attractive features of ferrite magnets is their affordability. The raw materials for ferrite magnets are abundant and inexpensive compared to the rare-earth elements used in neodymium magnets. As a result, ferrite magnets are generally:

- Cost-Effective:Making them the preferred choice for mass-produced consumer products.

- Economical for Bulk Applications:In industrial settings, where large quantities of magnets are needed, the lower cost can lead to significant savings.

However, the lower price does come with trade-offs in terms of magnetic strength and some mechanical properties. For many applications, especially those where extreme magnetic performance is not essential, ferrite magnets offer the best balance between cost and functionality.

Advantages and Disadvantages of Ferrite Magnets

One of the most attractive features of ferrite magnets is their affordability. The raw materials for ferrite magnets are abundant and inexpensive compared to the rare-earth elements used in neodymium magnets. As a result, ferrite magnets are generally:

- Cost-Effective:Making them the preferred choice for mass-produced consumer products.

- Economical for Bulk Applications:In industrial settings, where large quantities of magnets are needed, the lower cost can lead to significant savings.

However, the lower price does come with trade-offs in terms of magnetic strength and some mechanical properties. For many applications, especially those where extreme magnetic performance is not essential, ferrite magnets offer the best balance between cost and functionality.

Advantages

- Cost-Effectiveness:Their low production cost makes them ideal for a wide range of applications.

- Corrosion Resistance:The ceramic nature of ferrite magnets means they are highly resistant to rust and other forms of corrosion.

- Electrical Insulation:Being electrically non-conductive, they prevent eddy current losses in AC applications.

- Thermal Stability:Ferrite magnets can maintain their magnetic properties over a broad temperature range.

- Availability:Their raw materials are abundant, ensuring steady production and supply.

Disadvantages

- Cost-Effectiveness:Their low production cost makes them ideal for a wide range of applications.

- Corrosion Resistance:The ceramic nature of ferrite magnets means they are highly resistant to rust and other forms of corrosion.

- Electrical Insulation:Being electrically non-conductive, they prevent eddy current losses in AC applications.

- Thermal Stability:Ferrite magnets can maintain their magnetic properties over a broad temperature range.

- Availability:Their raw materials are abundant, ensuring steady production and supply.

Conclusion

Ferrite magnets remain a cornerstone of magnetic technology due to their affordability, durability, and versatility. From household refrigerator magnets to industrial motors and sensors, their unique composition and manufacturing process have allowed them to maintain a significant role even as newer magnet technologies have emerged.

Their primary advantages—cost-effectiveness, excellent corrosion resistance, and good thermal stability—make them ideal for many everyday and industrial applications. However, users must also consider their limitations, such as lower magnetic strength and brittleness, especially when compared with neodymium magnets.

By understanding the composition, types, manufacturing processes, and applications of ferrite magnets, engineers and designers can make informed decisions about when and how to use them effectively. Whether you are evaluating the best magnet for a high-performance motor or simply exploring the differences between ferrite and neodymium, the information provided in this guide should serve as a comprehensive resource.

In summary, while ferrite magnets may not offer the extreme magnetic strength of neodymium magnets, their overall performance, cost benefits, and reliability make them indispensable in a vast array of applications. For anyone involved in designing electronic devices, industrial machinery, or even everyday household items, ferrite magnets provide a practical and efficient solution that has stood the test of time.

By exploring topics such as ferrite magnet composition, manufacturing, types, coatings, applications, and a detailed comparison with neodymium magnets, we hope this guide has answered your key questions. Whether you are a student, engineer, or simply a curious reader, the versatility and continued relevance of ferrite magnets remain a testament to their enduring value in modern technology.

Feel free to refer back to the tables provided in this article for a quick comparison between the different types of magnets and a summary of the main differences between ferrite and neodymium magnets. With ongoing advancements in materials science, ferrite magnets continue to evolve, ensuring they remain a competitive choice in many magnetic applications worldwide.

This comprehensive overview of ferrite magnets covers nearly every aspect of their properties, uses, and comparisons with other magnet types. Whether you’re designing a new product or studying magnet technology, understanding the full spectrum of ferrite magnet characteristics is essential for achieving optimal performance and cost efficiency in your projects.

Frequently Asked Questions (FAQs)

Are Ferrite Magnets the Same as Ceramic Magnets?

Yes. The terms “ferrite magnet,” “ceramic magnet,” and “hard ferrite magnet” are interchangeable. They all refer to magnets made from iron oxide combined with either barium or strontium compounds. The term “ceramic” comes from the manufacturing process and the electrically insulating properties of the material.

Do Ceramic Magnets Break Easily?

Ceramic magnets are inherently brittle because of their ceramic composition. While they are durable in terms of resisting corrosion and chemical degradation, they can chip or crack if subjected to significant mechanical shock or impact. For applications where mechanical stress is a concern, proper handling and, if necessary, protective coatings or encapsulation should be considered.

Which Magnet Is Better, Ferrite or Neodymium?

It depends on the application. Ferrite magnets are less expensive and offer excellent corrosion resistance and thermal stability, making them ideal for many consumer and industrial applications. Neodymium magnets, on the other hand, provide a much stronger magnetic field, which is critical for high-performance applications, but they are more expensive and require careful handling and protection against corrosion.

What Is Ferrite Used For?

Ferrite magnets are used in a wide array of applications, including:

- Motors and Generators:Providing the necessary magnetic field in electric motors.

- Sensors and Actuators:Offering reliable magnetic properties in automation and control systems.

- Loudspeakers:Enhancing sound quality in audio devices.

- Refrigerator Magnets:Common in household items.

- Magnetic Assemblies:Used in couplings, brakes, and various other mechanical systems.

- Medical and Renewable Energy Devices:In applications where cost and durability are essential.

What Are the Disadvantages of Ferrite Magnets?

Some of the key disadvantages include:

- Lower Magnetic Strength:They are not as powerful as rare-earth magnets.

- Brittleness:Their ceramic structure makes them susceptible to mechanical damage.

- Limited Performance at Extreme Temperatures:Though generally stable, extreme high temperatures can negatively impact their magnetic properties.

- Not Ideal for Miniaturized High-Power Applications:In devices where space is limited but high magnetic strength is needed, other magnet types may be more suitable.