Unveiling the Power of Micro Magnets: Exploring the World of Precision Magnets

Unleashing the unseen potential of micro magnets, we delve into the fascinating world of precision magnets. These small yet mighty devices have the power to revolutionize various industries, from electronics to healthcare and everything in between. Whether it’s improving the performance of your favorite gadgets or advancing medical treatments, the applications of these micromagnets are boundless.

With their exceptional strength and precision, these magnets offer a level of control and accuracy that was previously unimaginable. From magnetic sensors that enhance our everyday devices to powerful magnetic resonance imaging (MRI) systems that aid in diagnostics, the impact of micromagnets is genuinely remarkable.

In this article, we will unveil the secrets behind micro magnets’ power, exploring their intricate design and manufacturing processes and the unparalleled benefits they bring. We will also uncover the cutting-edge research and innovative developments pushing the boundaries of what these tiny wonders can achieve.

Join us on this captivating journey as we delve into the world of precision magnets and discover how they shape our present and future in extraordinary ways.

Table of Contents

I. The science behind micro magnets

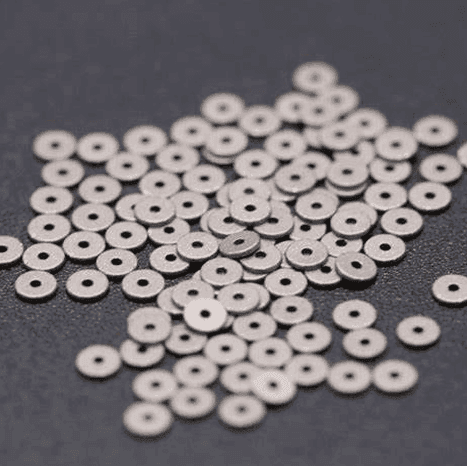

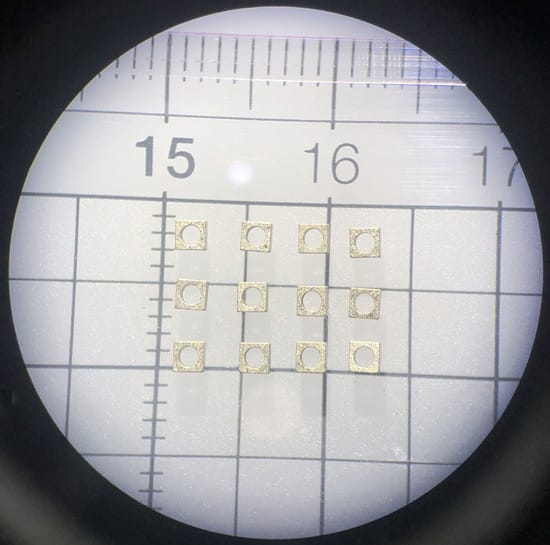

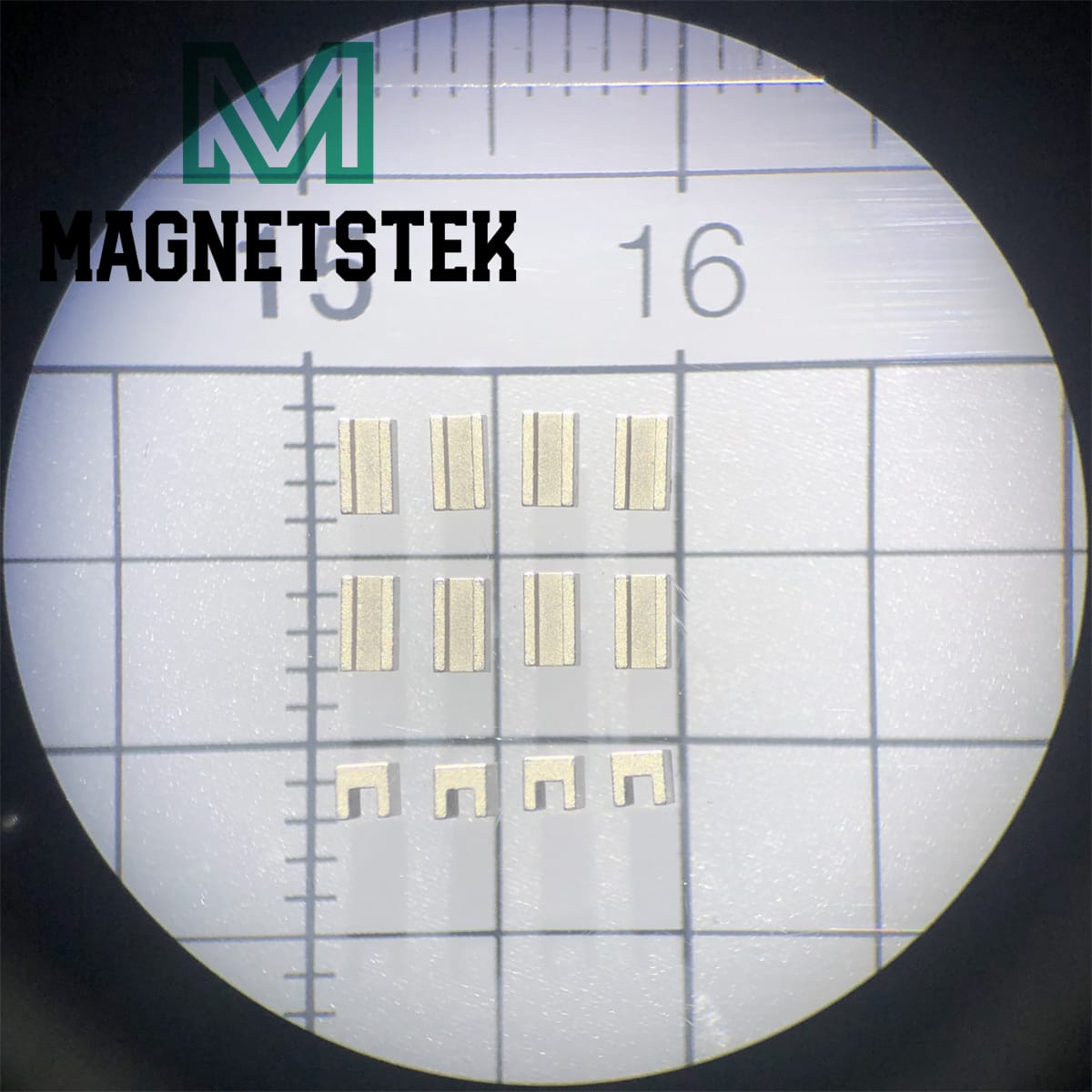

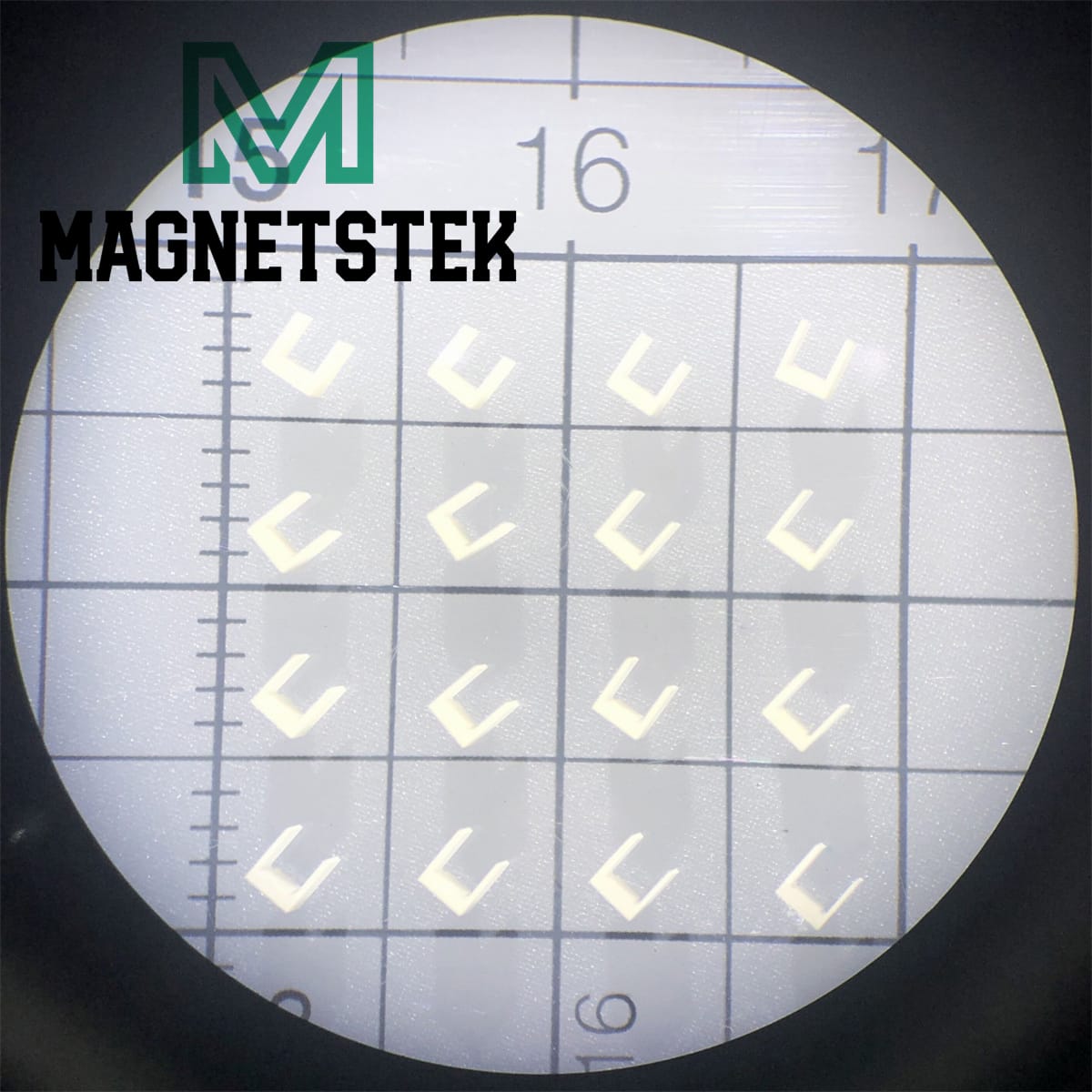

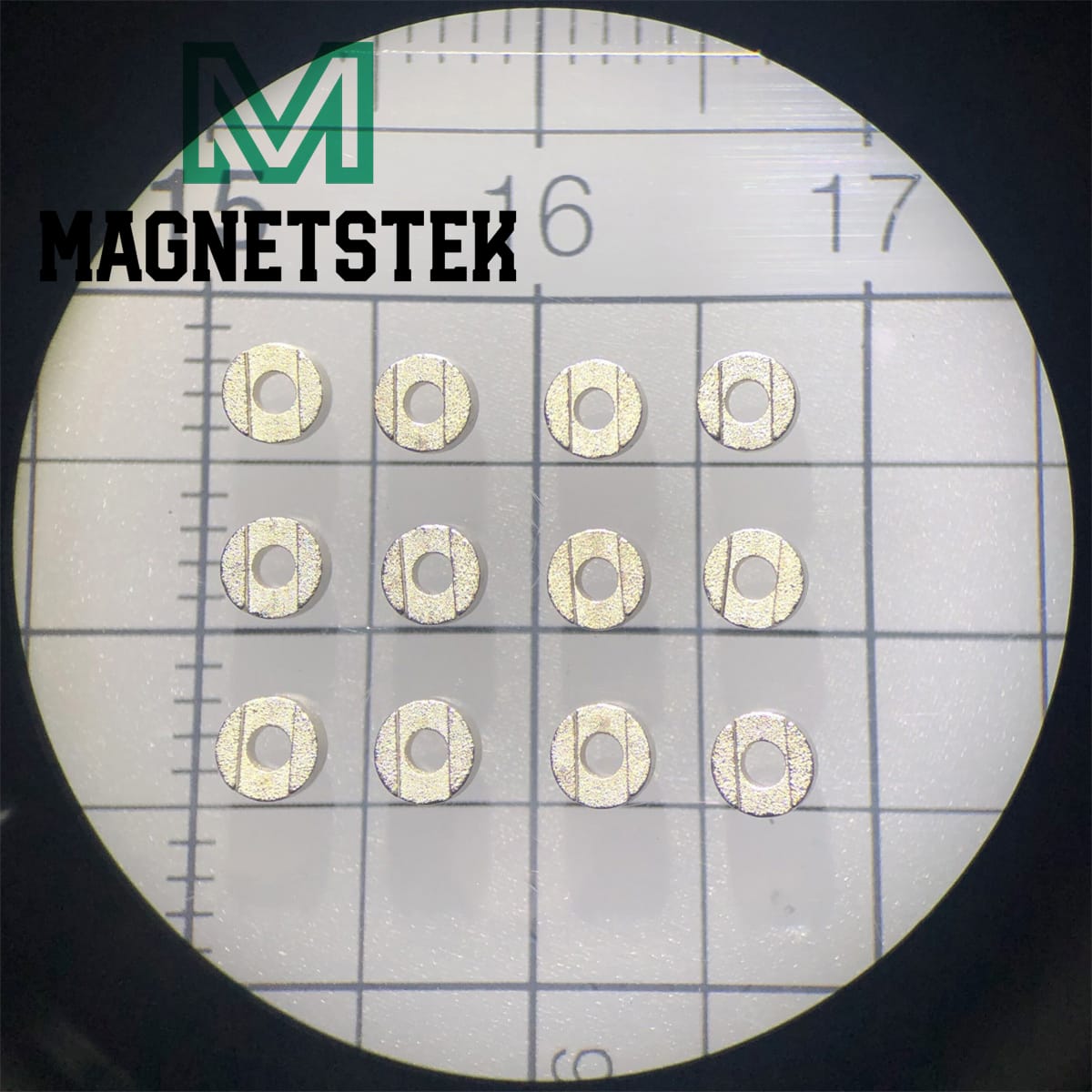

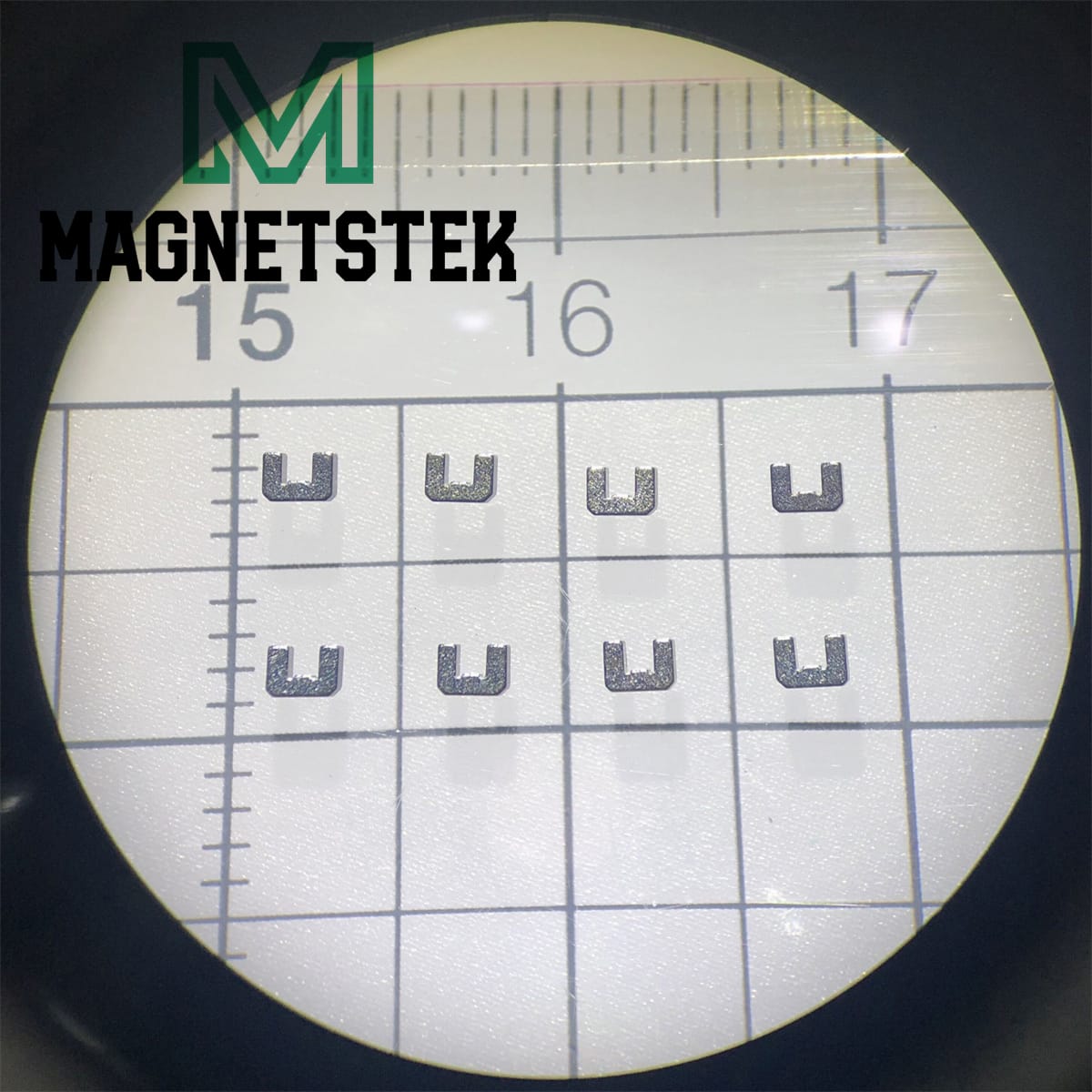

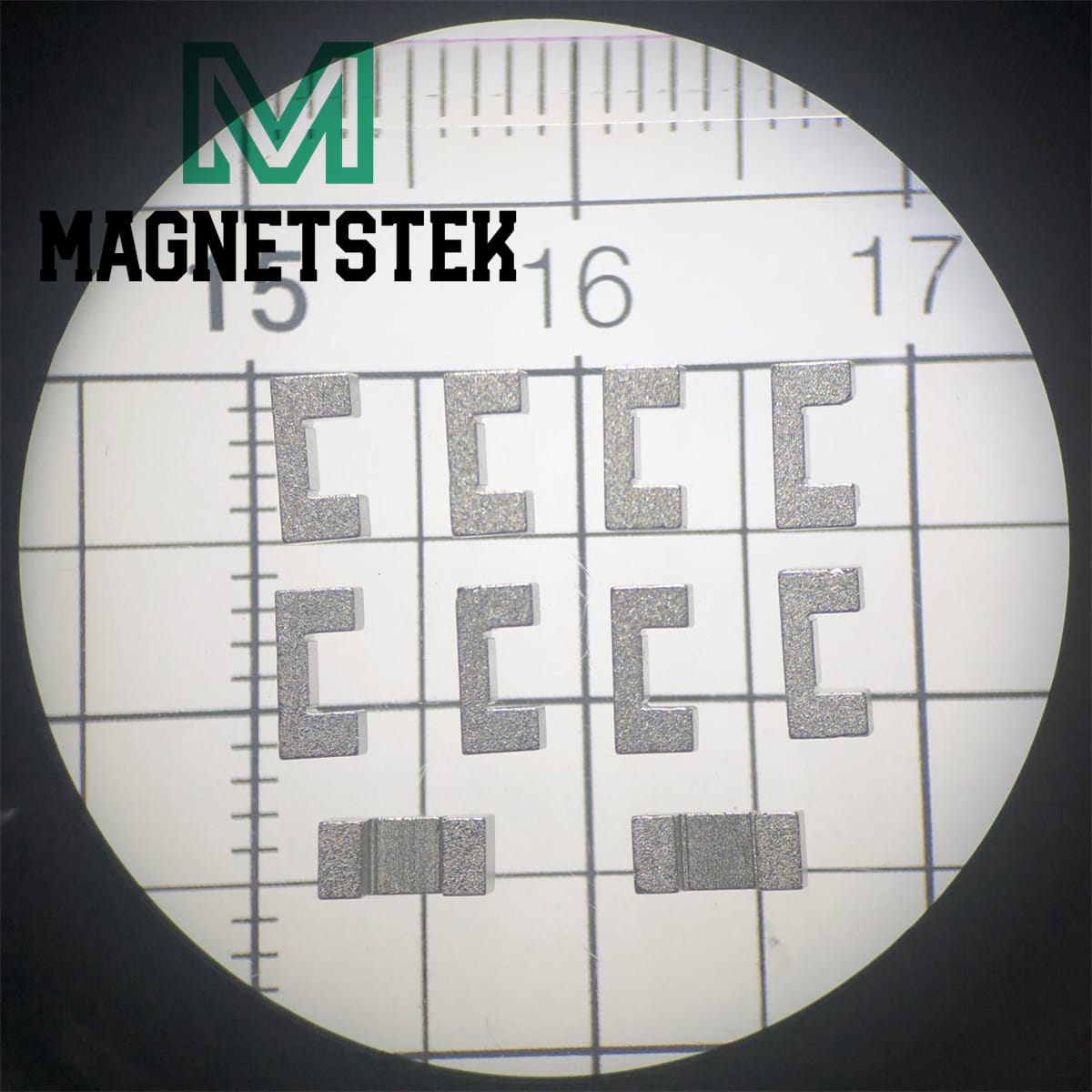

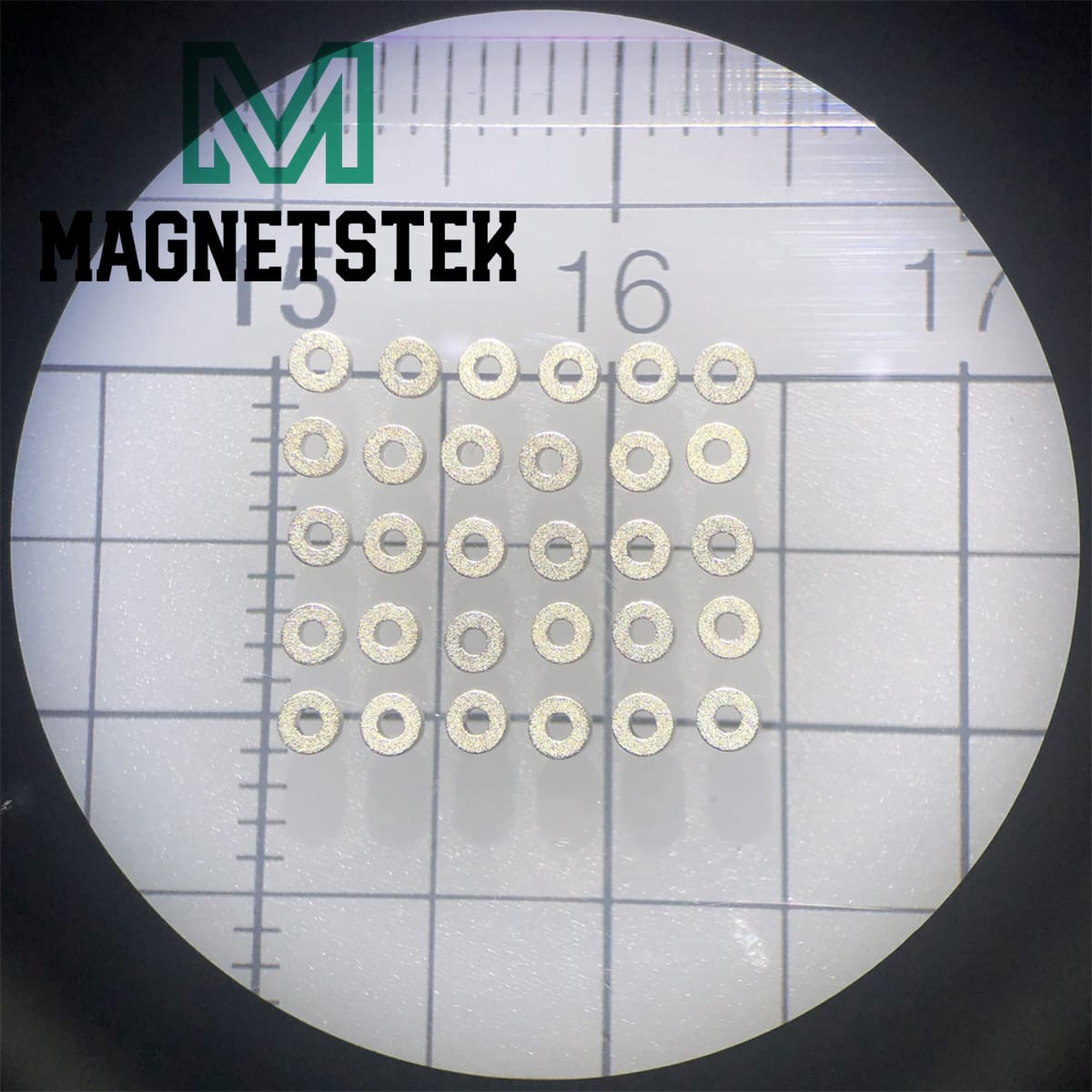

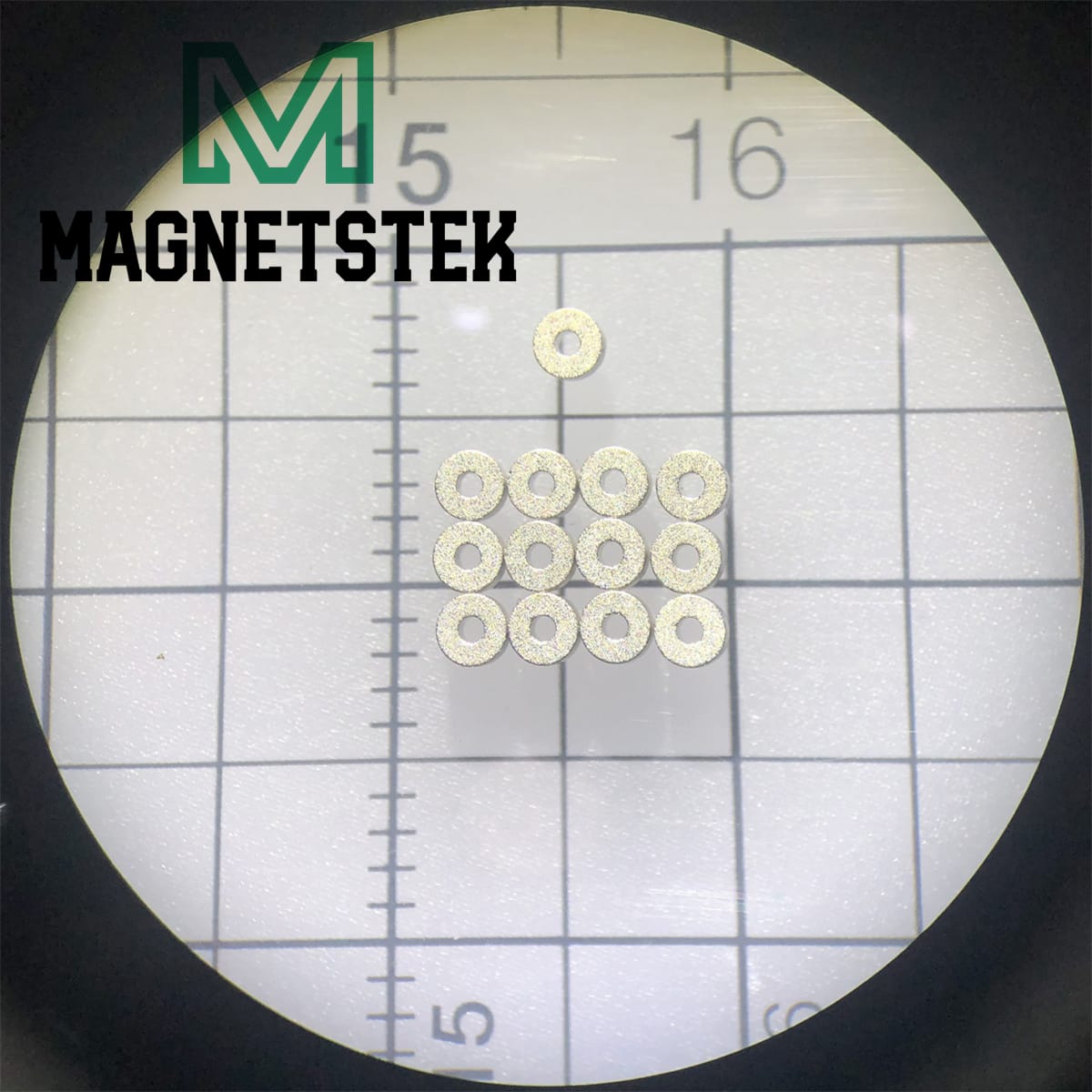

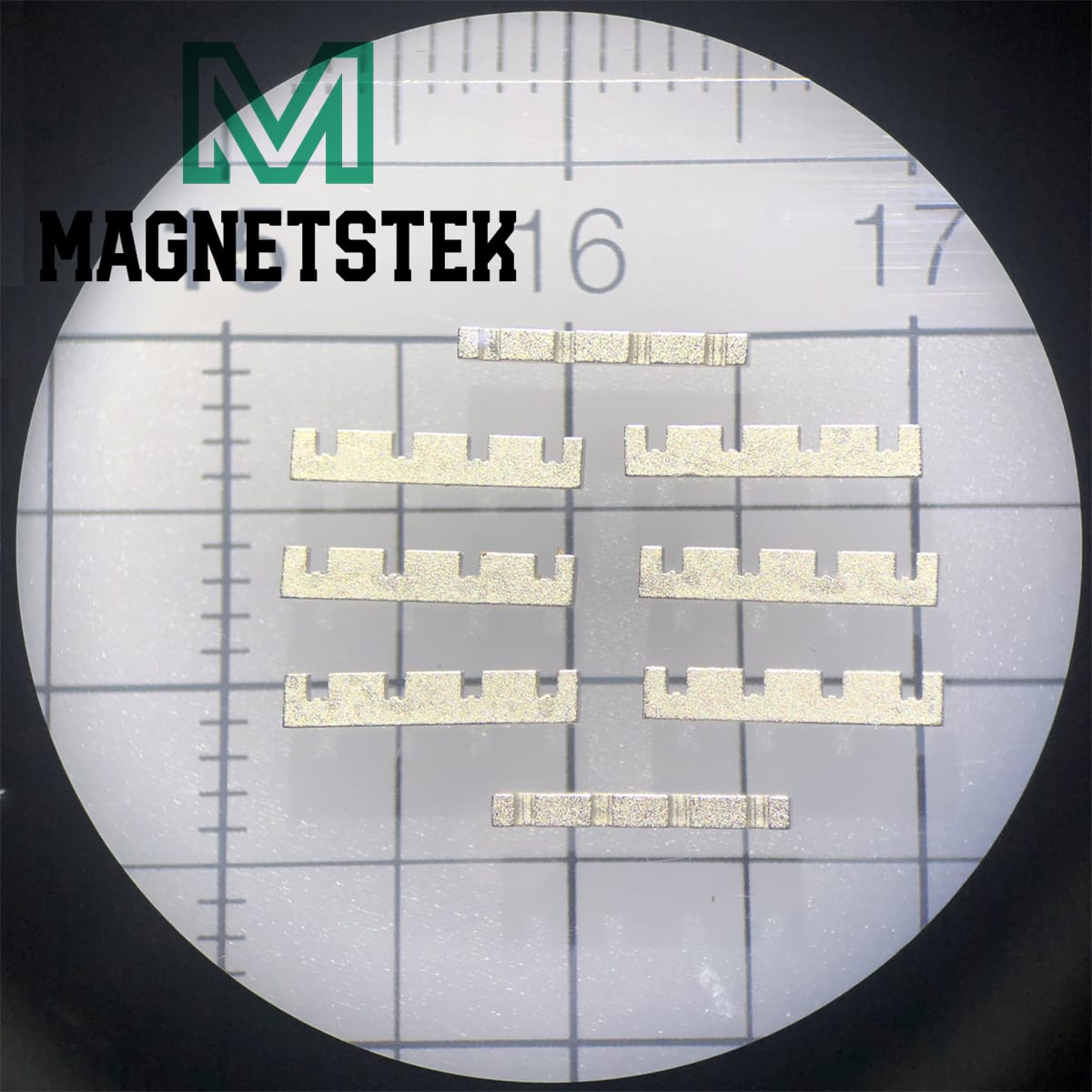

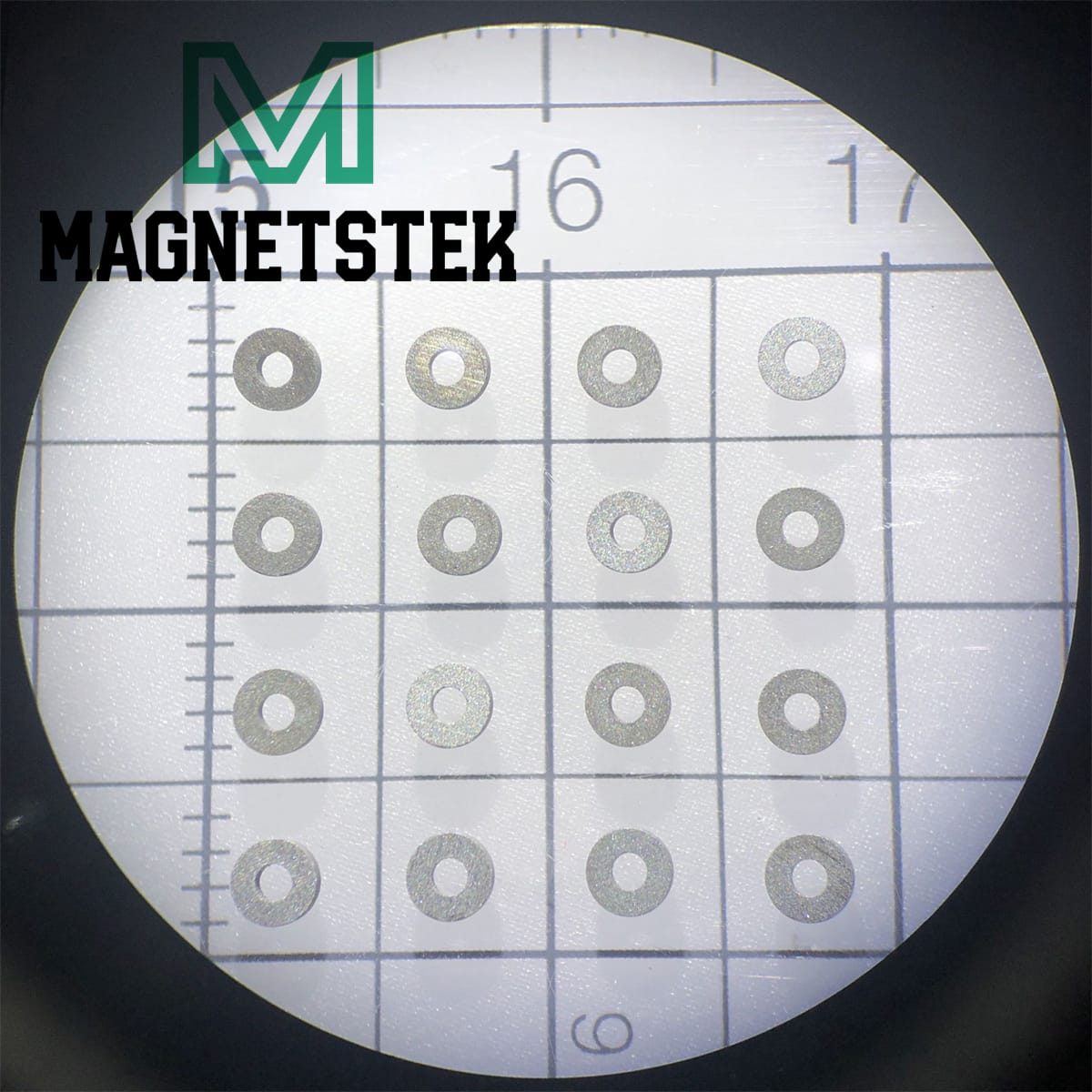

Micro magnets, also known as precision magnets, are tiny yet compelling devices that have captured the attention of scientists, engineers, and innovators across various industries. These miniature marvels possess unique properties that set them apart from their larger counterparts, making them indispensable in multiple applications.

At the heart of micromagnets lies the science of magnetism, a fundamental force of nature that has fascinated humanity for centuries. Magnetism results from the intricate dance of subatomic particles, specifically the electrons, within the material. In the case of micromagnets, the material is typically a rare-earth alloy, such as neodymium or samarium-cobalt, which exhibits powerful magnetic fields.

The strength of a micromagnet is measured in terms of its magnetic flux density or the number of magnetic field lines per unit area. These tiny magnets can generate magnetic fields that are hundreds of times more potent than the Earth’s magnetic field, making them incredibly powerful for their size. This remarkable property is achieved through the precise control and alignment of the magnetic domains within the material, which are the microscopic regions where the magnetic moments of the electrons are aligned in a specific direction.

II. Applications of precision magnets

The versatility of micromagnets is truly astounding. They find applications in a wide array of industries, from consumer electronics to medical diagnostics and beyond. One of the most prevalent uses of these precision magnets is in electronics, where they play a crucial role in the functioning of various devices.

In smartphones, micro magnets are employed in the camera module to provide stabilization, ensuring crisp and clear images even during the most dynamic movements. They also play a vital role in the haptic feedback systems, creating subtle vibrations that provide a tactile response to user interactions. Beyond smartphones, micromagnets are found in countless other electronic devices, from computer hard drives and speakers to magnetic sensors and even magnetic levitation systems.

In the medical field, micromagnets have become indispensable tools for diagnostic and therapeutic applications. Magnetic resonance imaging (MRI) machines, which are instrumental in the early detection and monitoring of various medical conditions, rely on the precise control of magnetic fields generated by powerful superconducting magnets. These magnets, in turn, are often composed of smaller micromagnets strategically arranged to create the necessary magnetic field gradients.

III. Advantages of using micro magnets

The advantages of utilizing micro magnets in various applications are numerous and profound. One of the primary benefits is their exceptional strength-to-size ratio, which allows for the development of compact and lightweight devices without compromising performance. This makes micro magnets ideal for integration into small-scale products, from wearable electronics to implantable medical devices.

Another key advantage of micro magnets is their unparalleled precision and control. The ability to precisely manipulate and direct magnetic fields at the microscopic level enables engineers and scientists to create highly accurate and responsive systems. This precision is crucial in applications such as magnetic sensors, where the slightest changes in the magnetic field can be detected and translated into valuable data.

Micro magnets also excel in terms of energy efficiency, as they can generate powerful magnetic fields with minimal energy input. This property is particularly important in applications where power consumption is a critical factor, such as in portable electronics or energy-constrained systems. By leveraging the efficiency of micro magnets, designers can develop devices that operate for longer durations on a single charge or battery.

IV. Types of precision magnets

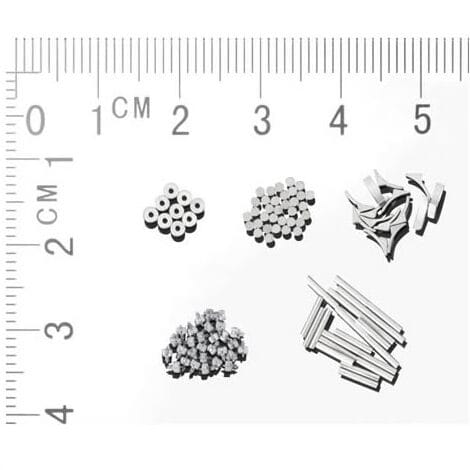

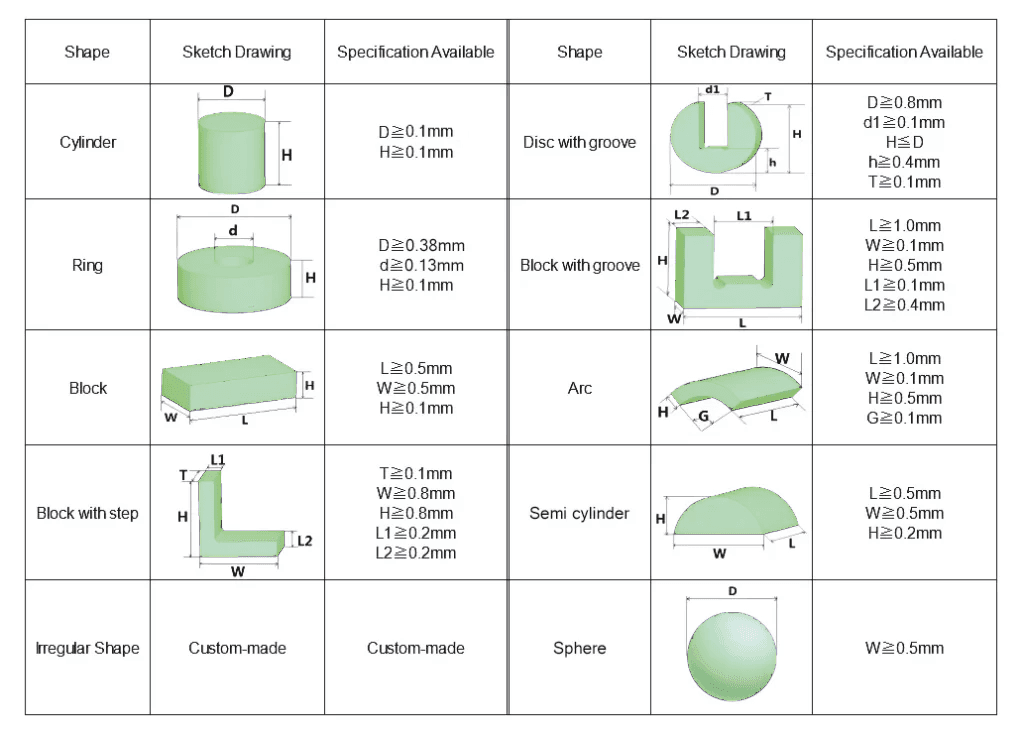

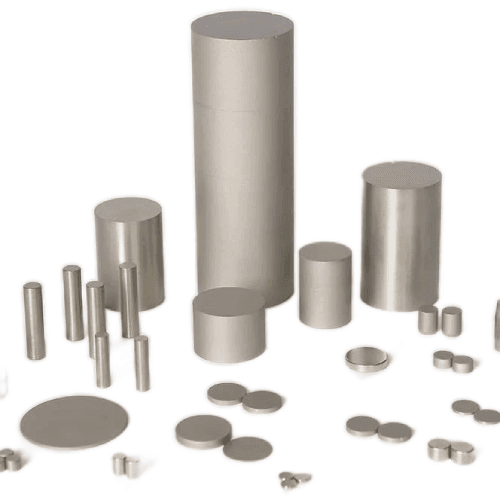

The world of precision magnets is diverse, with a wide range of specialized types catering to the unique needs of different applications.

One of the most common and widely used varieties is the neodymium magnet, which is renowned for its exceptional strength and versatility.

Neodymium magnets, also known as NdFeB magnets, are composed of a rare-earth alloy that includes neodymium, iron, and boron. These magnets are known for their high energy density, meaning they can generate powerful magnetic fields in a compact form factor. They are extensively used in a variety of products, from computer hard drives and speakers to magnetic tools and medical equipment.

Another type of precision magnet is the samarium-cobalt (SmCo) magnet, which offers superior thermal stability and corrosion resistance compared to neodymium magnets. These magnets are particularly well-suited for applications that require operation in high-temperature or harsh environments, such as in the aerospace and defense industries.

V. Factors to consider when choosing micro magnets

When selecting micro magnets for a specific application, there are several crucial factors to consider to ensure optimal performance and compatibility. One of the primary factors is the magnetic strength, which is typically measured in terms of the magnet’s maximum energy product (BHmax).

The magnetic strength of a micro magnet is directly related to its size and composition, with higher-strength magnets generally being smaller in size. However, it’s important to strike a balance between magnetic strength and other physical characteristics, such as size, weight, and shape, to meet the specific requirements of the application.

Another important factor to consider is the operating temperature range of the micro magnet. Different magnet materials have varying temperature tolerances, and it’s essential to choose a magnet that can withstand the expected operating conditions without losing its magnetic properties or experiencing demagnetization.

VI. Common challenges in working with precision magnets

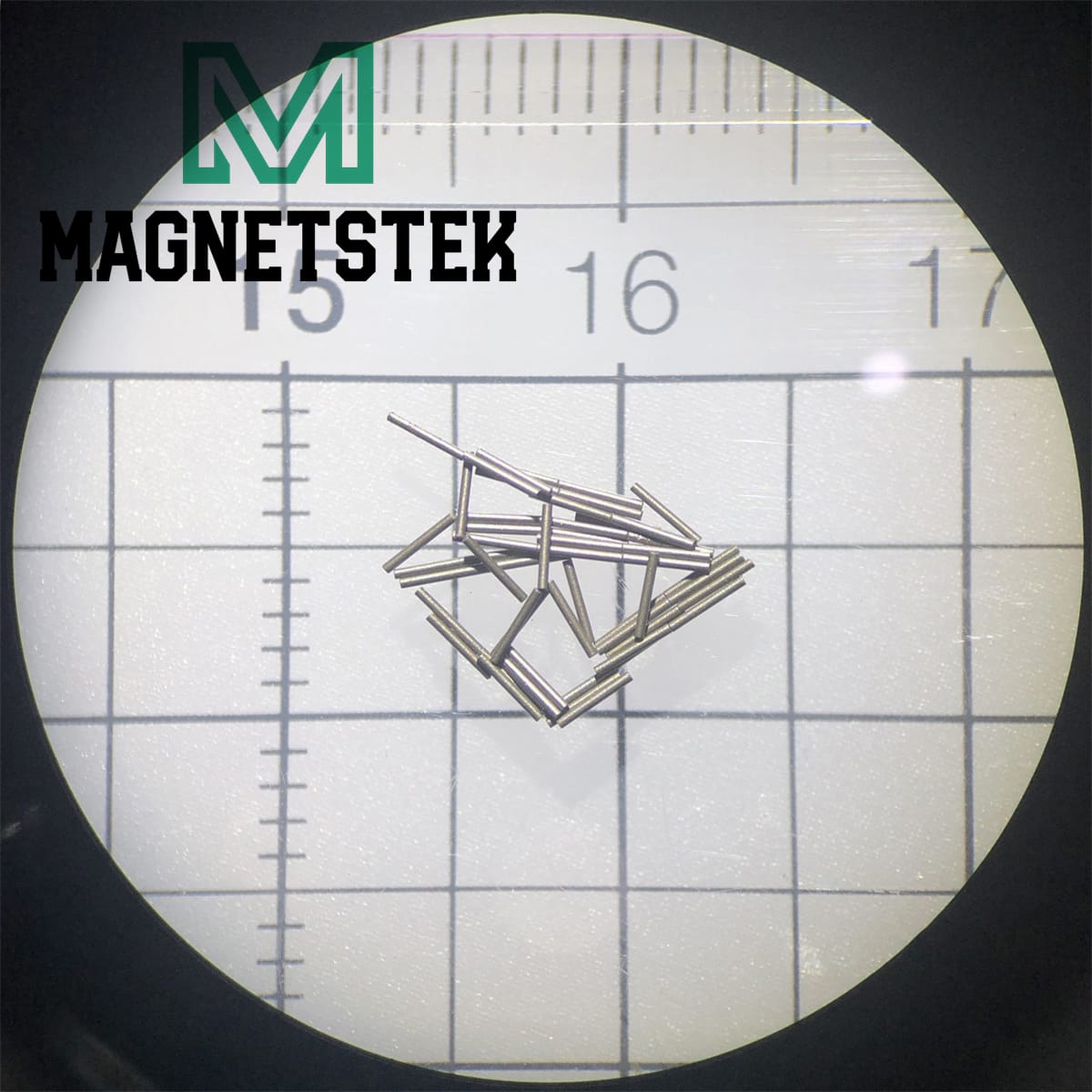

While micro magnets offer numerous benefits, they also present unique challenges that must be addressed to ensure successful integration and performance. One of the primary challenges is the handling and assembly of these tiny, yet powerful, devices.

Due to their small size and strong magnetic fields, micro magnets can be difficult to manipulate and position accurately, especially during the manufacturing or assembly process. Improper handling can lead to the magnets attracting to each other or to nearby metallic objects, causing misalignment or even damage to the components.

Another challenge is the potential for demagnetization, which can occur when the micro magnets are exposed to strong external magnetic fields or high temperatures. This can significantly impact the performance of the device or system, and it requires careful consideration of the operating environment and the use of appropriate shielding or cooling mechanisms.

VII. Tips for handling and storing micro magnets

Handling and storing micro magnets require special care and attention to ensure their long-term performance and integrity. One of the most important tips is to use non-magnetic tools and equipment when working with these precision magnets. This includes using plastic or non-metallic tweezers, containers, and workbenches to avoid unwanted magnetic interactions.

When storing micro magnets, it’s crucial to keep them in a dry, temperature-controlled environment, away from strong magnetic fields or sources of heat. Proper storage in individual containers or on magnetic-resistant surfaces can help prevent the magnets from attracting to each other or nearby metallic objects, which could lead to damage or demagnetization.

It’s also essential to exercise caution when handling micro magnets, as their strong magnetic fields can pose a safety hazard. Proper personal protective equipment, such as gloves, should be worn to avoid pinching or trapping fingers between the magnets. Additionally, keeping micro magnets away from electronic devices, pacemakers, and other sensitive equipment is crucial to prevent interference or potential damage.

VIII. Future trends in precision magnet technology

As the demand for smaller, more powerful, and more efficient devices continues to grow, the development of micro magnets is poised to undergo significant advancements in the coming years. One of the most promising areas of research is the exploration of new magnetic materials and alloys that can further enhance the performance and capabilities of precision magnets.

Researchers are actively investigating materials such as ferrites, which offer improved thermal stability and corrosion resistance, as well as alternative rare-earth alloys that can provide even stronger magnetic fields. These advancements in material science will enable the creation of micro magnets with higher energy densities, allowing for even more compact and powerful devices.

Additionally, the integration of micro magnets with emerging technologies, such as microelectromechanical systems (MEMS) and nanoelectronics, is expected to open up new frontiers in various industries. This convergence of micro-scale magnetic components with advanced electronic and mechanical systems will pave the way for innovative applications, from miniaturized medical implants to highly sensitive magnetic sensors and beyond.

IX. Conclusion: Harnessing the power of micro magnets for innovation

The power of micro magnets is truly remarkable, and their impact on our everyday lives is far-reaching and profound. From the smartphones we rely on to the medical devices that save lives, these tiny yet mighty components are the unsung heroes behind many of the technologies we take for granted.

As we continue to push the boundaries of what’s possible, the role of micro magnets will only become more crucial. Whether it’s advancing the frontiers of electronics, healthcare, or any other industry, these precision magnets will play a vital role in shaping the future through their unparalleled strength, precision, and efficiency.

By harnessing the power of micro magnets, innovators and researchers are unlocking new possibilities and transforming the way we interact with the world around us. As we delve deeper into the fascinating world of these small wonders, the potential for groundbreaking discoveries and life-changing innovations is truly limitless. The future is bright, and micro magnets are leading the charge towards a more connected, efficient, and technologically advanced world.