- Custom Magnets

- Standard Magnets

- Mounting Magnets

- Magnetic Assemblies

- About Us

- Knowledge

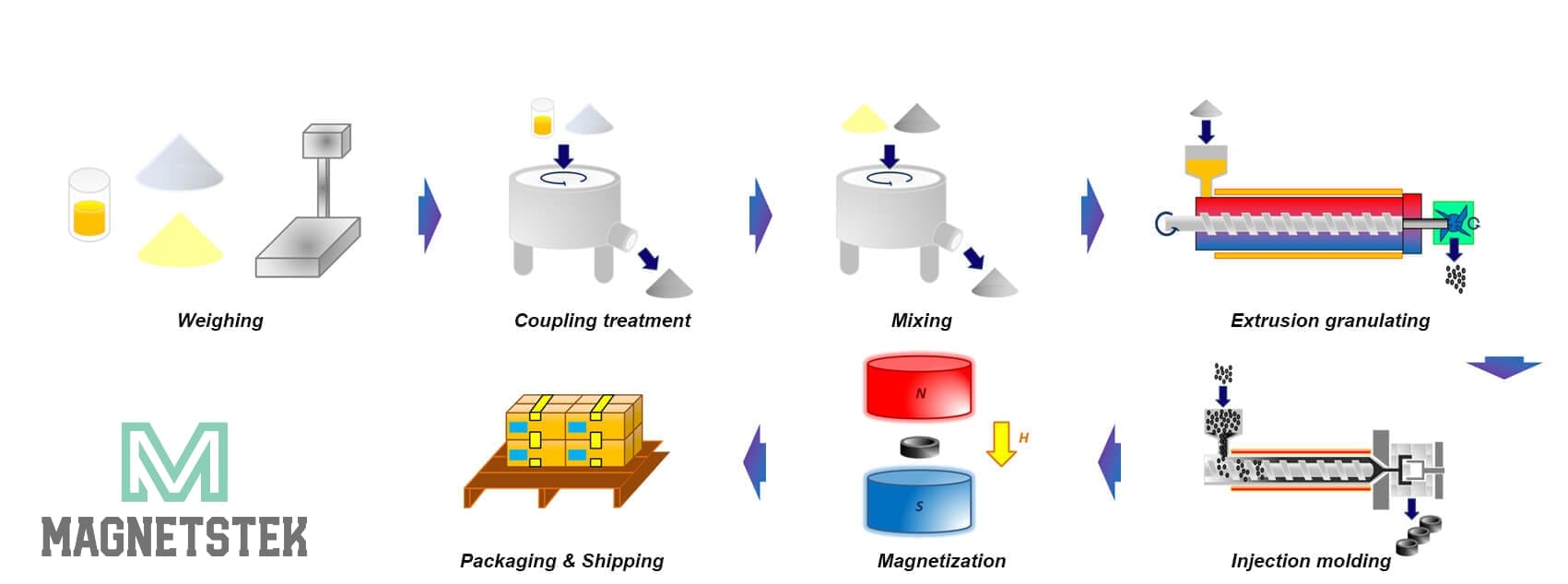

Injection Molded Magnets are a versatile solution in the realm of magnetic materials, combining the benefits of plastic molding with the powerful properties of magnetic materials. These magnets are created by injecting a mixture of magnetic powder and a polymer binder into a mold, producing highly complex and precise shapes. This process allows for the creation of intricate designs that are not feasible with traditional magnetic production methods, making them ideal for a wide range of applications.

MagnetsTek works with a wide-ranging combination of magnetic materials and polymers including:

Ferrite: These are more cost-effective and provide good magnetic properties, suitable for less demanding applications.

Samarium Cobalt (SmCo): Offering excellent thermal stability and resistance to demagnetization, SmCo magnets are perfect for high-temperature environments, withstanding temperatures up to 350°C.

Choosing the right combination of materials will affect the product’s resistance to moisture absorption, physical strength, magnetic properties, and maximum operating temperature.

Injection molded magnets can range from very simple to highly complex shapes. Depending on the magnetic material used, parts may require magnetic orientation during the injection molding process to optimize their magnetic properties.

The maximum use temperature depends on both the magnetic alloy powder and the binder. For instance, ferrite powders in nylon 6 or PPS have been tested successfully at 150°C and 180°C, respectively. Conversely, nylon 12 melts above 170°C and is not recommended for use above 150°C. High-energy NdFeB grades, with an intrinsic coercivity of 9,500 Oersteds (760 kA/m), experience significant irreversible magnetic loss above 120°C, regardless of the binder used. Maximum use temperatures are detailed on each product’s specification sheet.

Injection molded magnets can be manufactured in complex shapes that are challenging to achieve with traditional magnet materials. The accuracy/tolerance can be up to 0.01mm.

The magnetic properties of these magnets can be tailored by adjusting the type and amount of magnetic powder in the mixture, providing flexibility in magnetic strength and orientation.

| Grade | IM-06 | IM-07 | IM-20 | IM-40 | IM-50 | IM-60 | IM-70 | IM-80 | |

| Residual Induction (Br) | (mT) | 155-170 | 245-265 | 275-290 | 400-500 | 450-550 | 480-580 | 530-620 | 580-650 |

| (Gs) | 1550-1700 | 2450-2650 | 2750-2900 | 4000-5000 | 4500-5500 | 4800-5800 | 5300-6200 | 5800-6500 | |

| Coercive Force (Hcb) | (kA/m) | 111-119 | 175-191 | 191-207 | 255-310 | 302-358 | 334-382 | 358-413 | 382-430 |

| (0e) | 1400-1500 | 2200-2400 | 2400-2600 | 3200-3900 | 3800-4500 | 4200-4800 | 4500-5200 | 4800-5400 | |

| Intrinsic Coercive Force (Hcj) | (kA/m) | 218-238 | 243-259 | 226-250 | 640-800 | 640-800 | 640-800 | 640-800 | 640-800 |

| (Oe) | 2800-3000 | 3050-3250 | 2800-3150 | 8000-10000 | 8000-10000 | 8000-10000 | 8000-10000 | 8000-10000 | |

| Max Energy Product (BH)max | (kJ/m3) | 4.4-5.5 | 12.4-14.0 | 15.6-16.4 | 28-36 | 36-44 | 44-52 | 52-56 | 56-64 |

| (MGOe) | 0.6 | 1.55-1.75 | 1.95-2.05 | 3.5-4.5 | 4.5-5.5 | 5.5-6.5 | 6.5-7.0 | 7.0-8.0 | |

| Temp Coefficient | (%/°C) (Br/Br) | -0.19 | -0.19 | -0.19 | -0.1 | -0.1 | -0.1 | -0.1 | -0.1 |

| Temp Coefficient | (%/°C) (Hc/Hc) | 0.2~0.3 | 0.2~0.3 | 0.2~0.3 | -0.4 | -0.4 | -0.4 | -0.4 | -0.4 |

| Density | (g/cm3) | 3.6 | 3.7 | 3.8 | 4.5 | 4.8 | 5 | 5.2 | 5.2 |

| Tensile Strength | (MPa) | 60 | 60 | 75 | 35 | 35 | 36 | 37 | 37 |

| Flexural Strength | (MPa) | 100 | 95 | 180 | 72 | 72 | 70 | 75 | 75 |

| Flexural Modulus | (MPa) | 13000 | 17000 | 25000 | 15000 | 15000 | 15000 | 15000 | 15000 |

| Water Absorption | (%) | 0.04 | 0.01 | 0.05 | 0.05 | 0.05 | 0.05 | 0.04 | 0.05 |

| Heat Deflection Temp. | (°C) | 130 | 220 | 176 | 130 | 150 | 150 | 150 | 150 |

Injection molded magnets are used in a wide range of industries and applications, including: