The Comprehensive Guide to Rubber Magnets: Design, Manufacturing, and Applications

Rubber magnets have become an essential part of modern life, serving both functional and decorative purposes. Their unique blend of flexibility, durability, and versatility makes them a popular choice in industries ranging from education to advertising. In this in-depth article, we will explore what rubber magnets are, how they work, and how they’re made. We’ll also delve into various specialized types—from rubber magnets for kids to custom designs and novelty items like rubber duck magnets—providing insight into the diverse applications and market trends associated with these innovative products.

Table of Contents

What Is a Rubber Magnet?

Definition and Composition

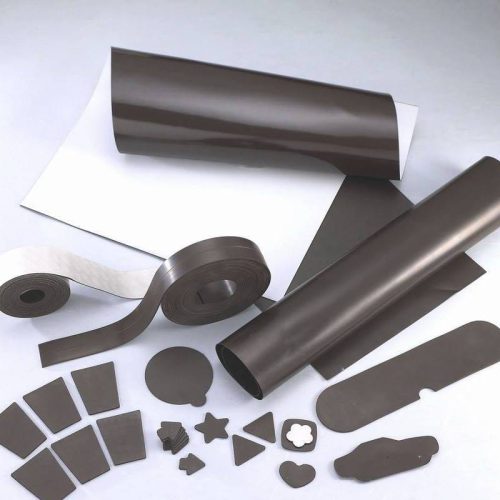

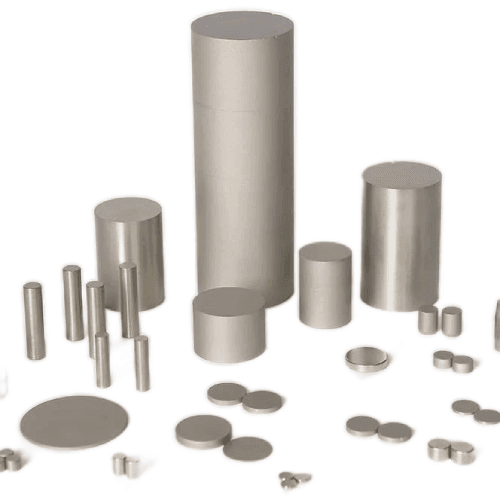

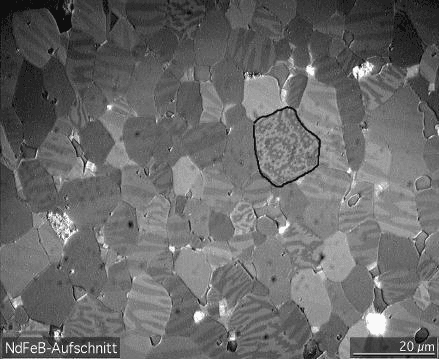

A rubber magnet is a flexible magnet made by combining magnetic powder—often ferrite or rare-earth materials—with a flexible binder, usually a form of rubber or a synthetic polymer. The resulting composite material retains the magnetic properties of the powder while being soft, bendable, and easy to cut into various shapes and sizes. This flexibility makes rubber magnets ideal for applications that require conformability to curved surfaces or that involve frequent handling.

Properties and Characteristics

Rubber magnets are renowned for several key characteristics:

- Flexibility:Unlike rigid magnets, rubber magnets can be bent, twisted, or even rolled up without losing their magnetic properties.

- Customization:They can be easily printed or cut into custom shapes, making them popular for promotional items and decorative accessories.

- Safety:Their soft, rubbery exterior minimizes the risk of injury or damage if handled improperly.

- Lightweight:Their low weight enhances their utility in applications where a heavy magnet might be impractical.

Comparison with Other Magnets

| Type | Description | Target Market/Application |

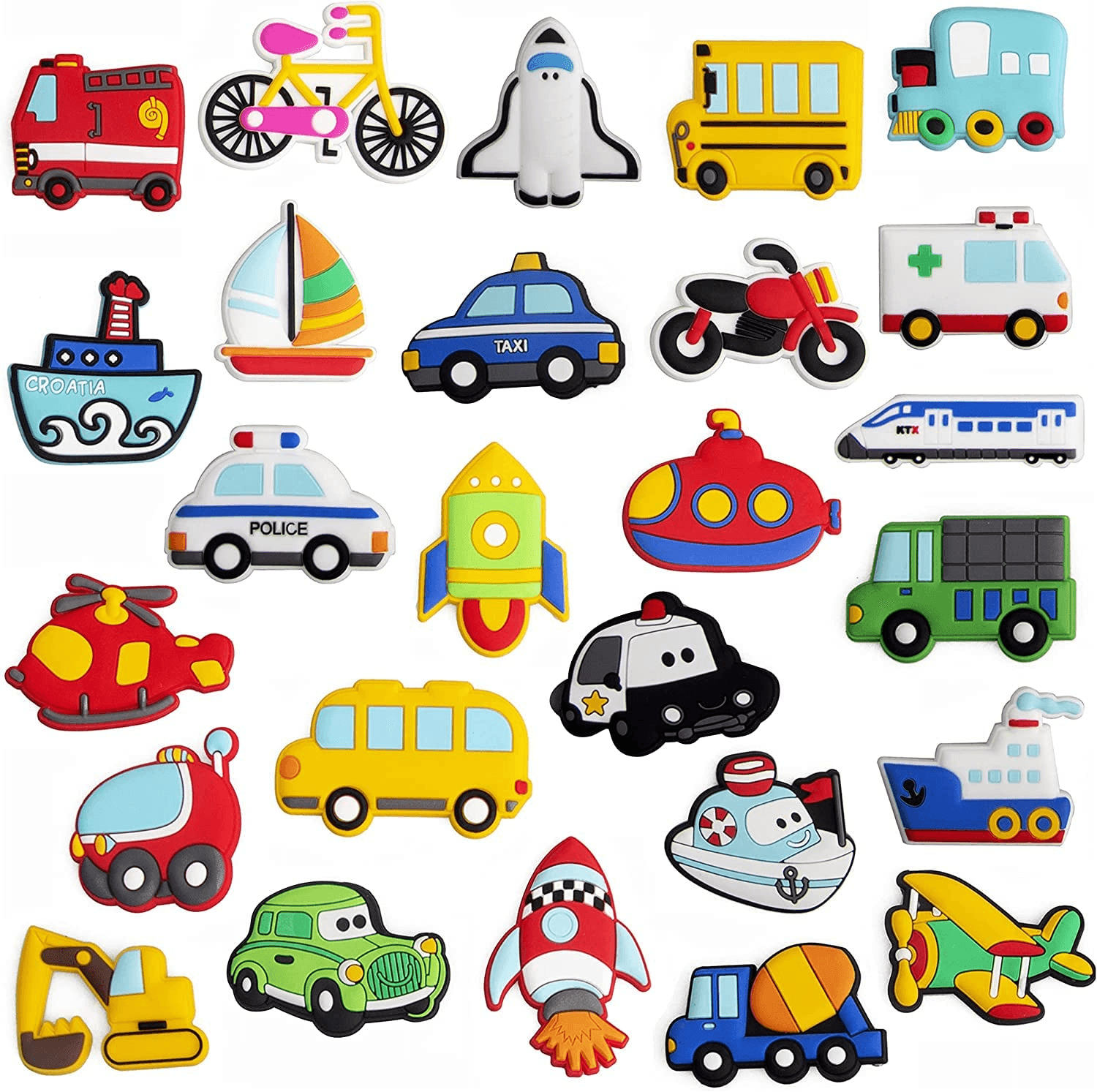

| Rubber Magnets for Kids | Fun, colorful magnets designed with kid-friendly shapes and themes. | Educational tools, crafts, and play areas |

| Rubber Magnets Custom | Customizable magnets that can feature logos, images, or personalized designs. | Marketing, branding, and corporate giveaways |

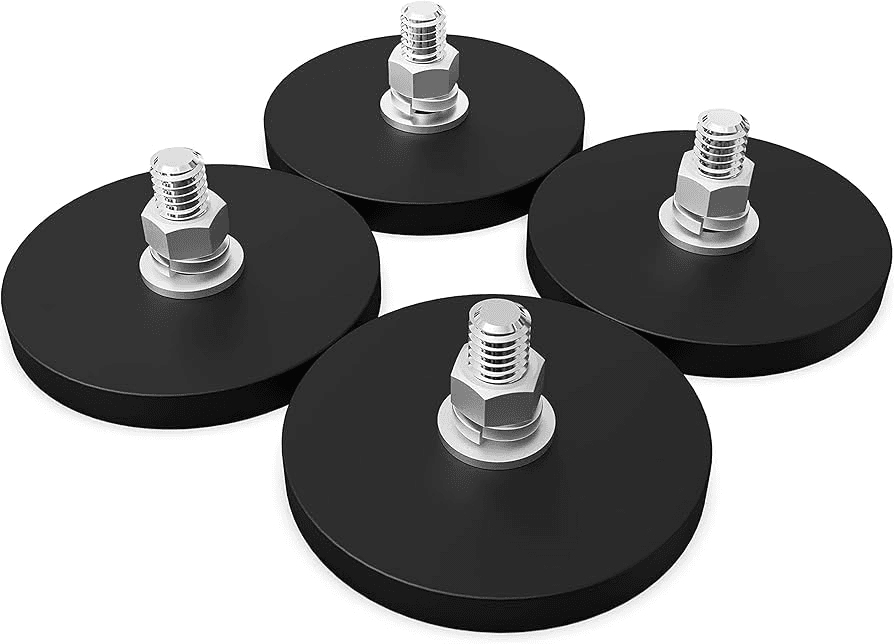

| Magnets Rubber Coated | Traditional magnets covered with a rubber layer to provide durability and a non-abrasive surface. | Industrial use, tool accessories, and safety magnets |

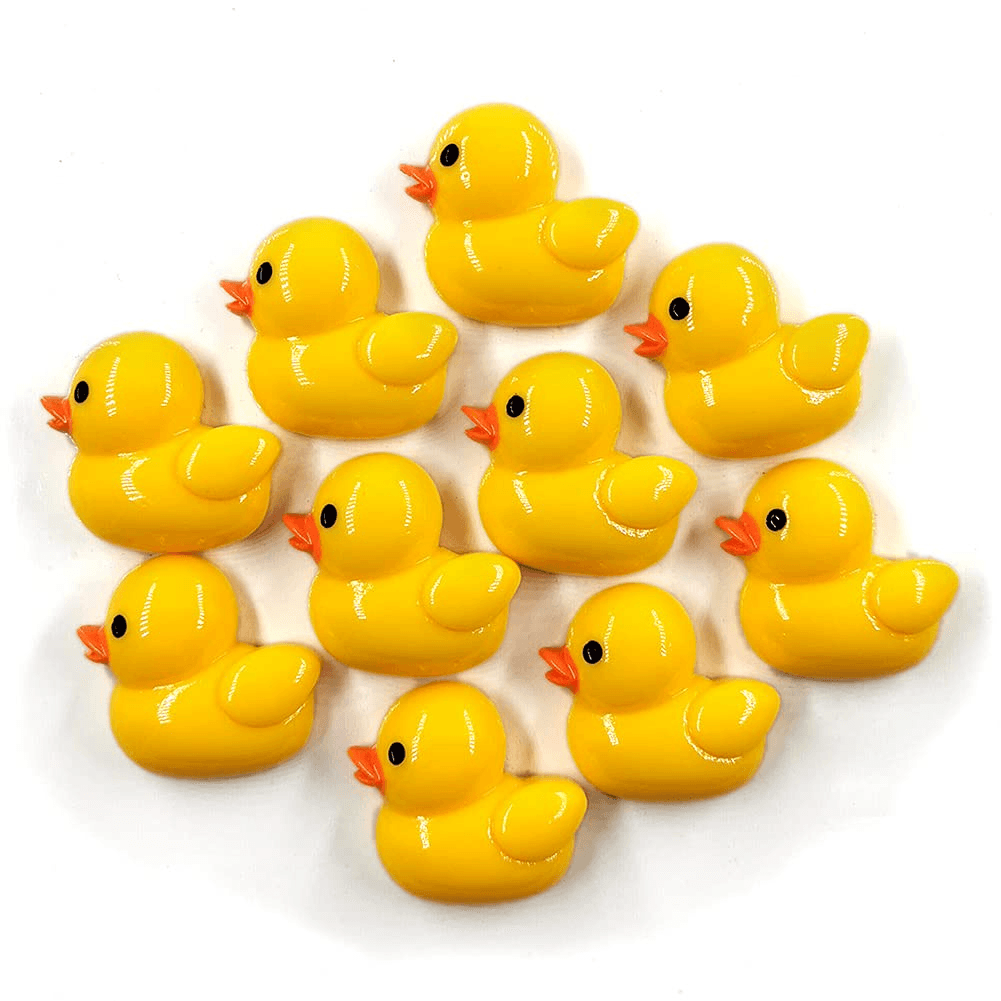

| Rubber Duck Magnets | Novelty magnets designed in the shape of rubber ducks, often used as collectibles or playful decor items. | Souvenirs, novelty gifts, and home decor |

| Rubber Covered Magnets | Magnets with a rubber outer layer to enhance grip and reduce surface scratching. | Home and office use, refrigerator magnets |

| Rubber Fridge Magnets | Flexible, decorative magnets primarily used to display photos or reminders on refrigerators. | Home decoration and messaging |

| Rubber Coated Magnets on Amazon | A variety of rubber-coated magnets available online, often reviewed for quality and versatility. | Online shoppers, hobbyists, and DIY enthusiasts |

| Flexible Rubber Magnets | General-purpose flexible magnets that can be easily manipulated into various forms. | Art projects, advertising, and versatile installations |

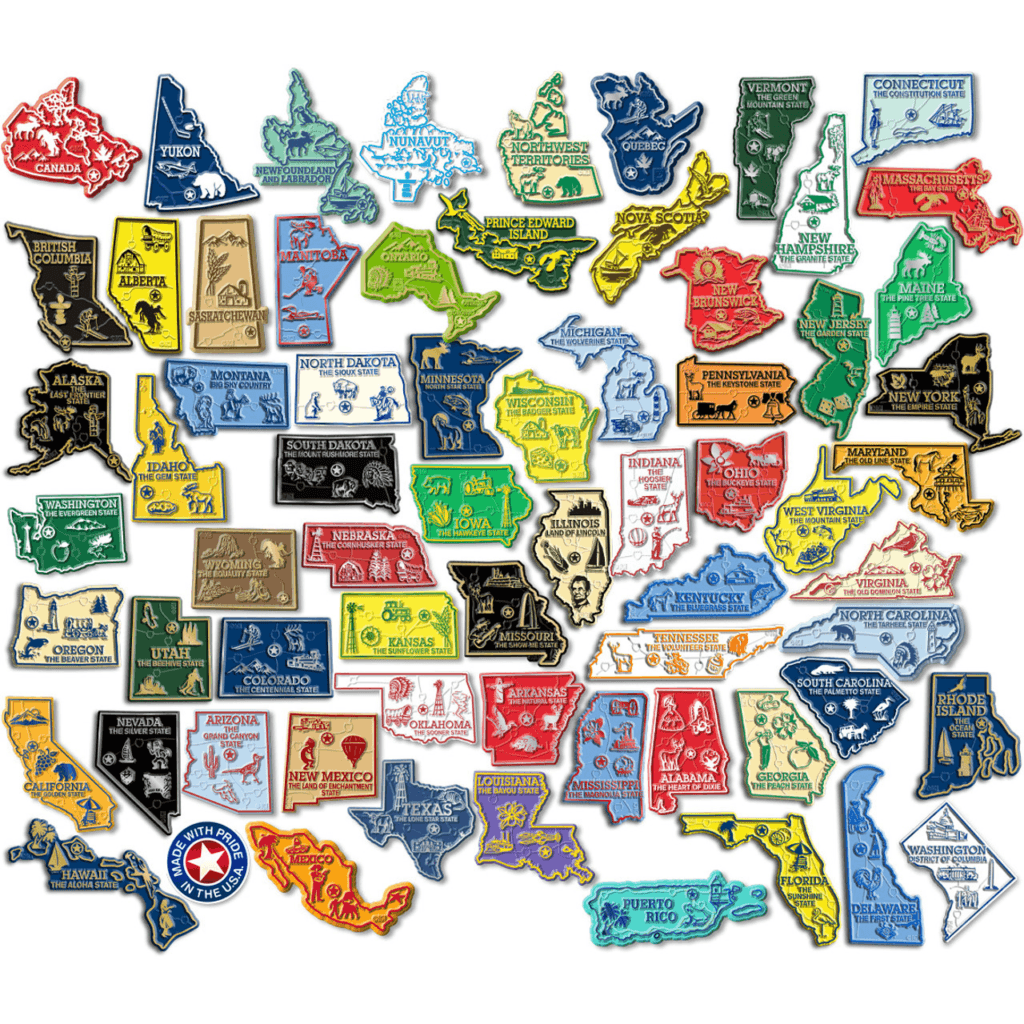

| Rubber State Magnets | Magnets shaped like the outlines of U.S. states, commonly used in educational settings and as souvenirs. | Education, souvenirs, and collectible items |

How Do Rubber Magnets Work?

At the heart of every magnet is the phenomenon of magnetism, which arises from the alignment of tiny magnetic domains within a material. In permanent magnets, such as those used in rubber magnets, these domains are aligned in the same direction, creating a net magnetic field. The strength of this field depends on the material used and the degree of alignment.

Rubber Magnets: Combining Flexibility and Magnetism

In a rubber magnet, the magnetic powder (commonly ferrite) is mixed with a flexible binder. During the manufacturing process, the mixture is spread into thin sheets and allowed to cure. The binder holds the magnetic particles in place while still allowing for a degree of movement within the matrix. This combination enables the magnet to bend without breaking the alignment of the magnetic domains significantly, ensuring that the magnet retains its useful properties even when flexed.

Magnetic Circuit and Interaction

When a rubber magnet is applied to a ferromagnetic surface (like a refrigerator door), the magnet’s field interacts with the surface’s atoms. The magnetic domains in the magnet create an attractive force, pulling the magnet toward the metal. The flexibility of the magnet allows it to maximize the contact area, which helps to secure the magnet firmly to the surface, even if it’s curved or uneven.

How Do You Make a Rubber Magnet?

Materials and Ingredients

The manufacturing of rubber magnets involves a blend of materials:

- Magnetic Powder:Ferrite powder is the most common, though other magnetic materials can be used.

- Binder:A flexible, rubbery polymer that holds the magnetic particles together. This can be a natural rubber or a synthetic variant, chosen for its durability and compatibility with the magnetic powder.

- Curing Agents and Additives:Chemicals that help the binder set and enhance the magnet’s performance and longevity.

Step-by-Step Manufacturing Process

- The process of making rubber magnets is both an art and a science, requiring precision and attention to detail. Below is a simplified outline of the steps involved:

Table 2. Manufacturing Process of Rubber MagnetsStep Description 1. Material Selection Choose the appropriate magnetic powder and binder based on the desired properties of the magnet. 2. Mixing Combine the magnetic powder with the binder and any additives in a controlled environment to ensure uniform distribution. 3. Forming the Sheet Spread the mixture into a thin, even layer using rollers or molds. 4. Curing Heat or chemically treat the sheet to set the binder, locking the magnetic particles in place. 5. Cutting and Shaping Once cured, the magnet sheet is cut into desired shapes and sizes, tailored to specific applications. 6. Finishing Apply any additional coatings (e.g., a protective rubber layer) and perform quality control checks. Each step in this process is critical. For example, uniform mixing ensures that the magnetic particles are evenly distributed throughout the binder, which is essential for consistent magnetic performance. The curing process solidifies the composite material while maintaining the flexibility needed for the magnet to perform its intended function.

Quality Control and Customization

After the manufacturing process, quality control tests are conducted to ensure that the magnets meet industry standards. These tests evaluate factors like magnetic strength, flexibility, adhesion, and durability. Custom orders—such as rubber magnets with printed logos or specific shapes—are often produced using the same basic process, with adjustments made to the cutting and finishing stages to accommodate the unique design requirements.

Diverse Applications of Rubber Magnets

Rubber magnets are incredibly versatile, and their uses span a wide range of industries and consumer products. Below, we explore several popular types and their applications.

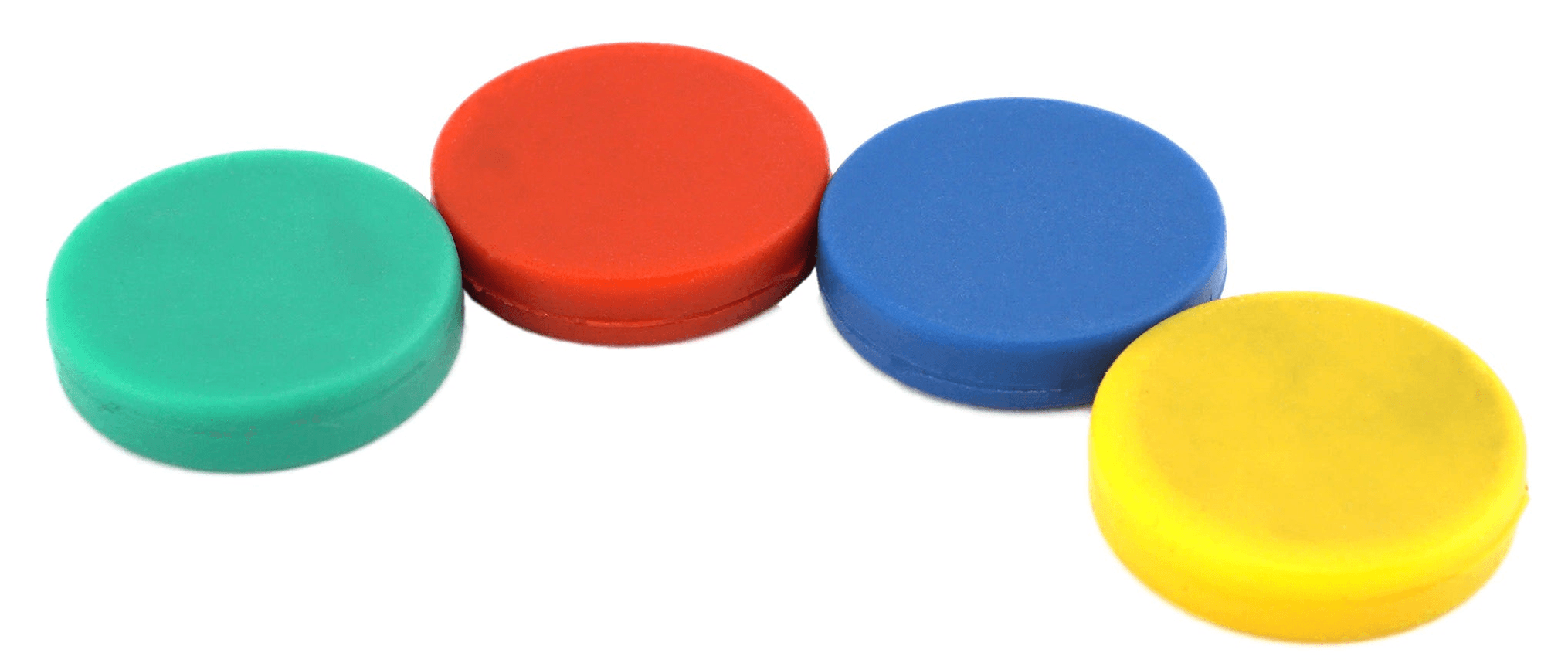

1.Rubber Magnets for Kids

Educational Tools and Crafts

Rubber magnets designed for children are typically bright, engaging, and safe. They are used in educational settings to help teach basic concepts of magnetism, colors, shapes, and numbers. Their flexibility and durability make them ideal for crafts, puzzles, and interactive play.

Safety and Durability

Parents and educators prefer these magnets because they are less likely to cause injury. Their soft, rubbery surfaces are safer for young children, and they are less prone to breaking compared to traditional, rigid magnets.

2. Custom Rubber Magnets

Branding and Promotional Items

Versatile Design Options

With advances in printing technology, businesses can now order custom rubber magnets in virtually any design, color, or shape. This makes them an ideal medium for creative advertising that stands out from traditional print and digital media.

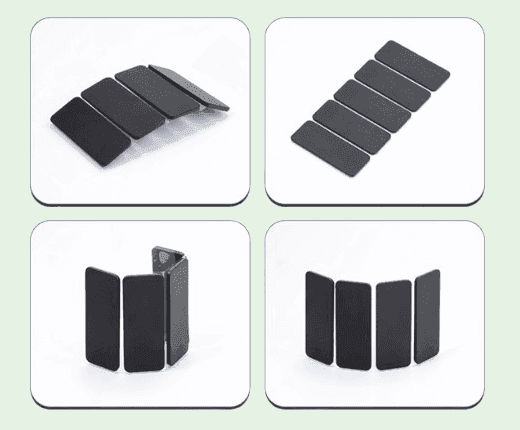

3. Magnets with Rubber Coating

Enhanced Protection and Usability

Magnets that are rubber coated combine the strength of traditional magnets with the protective benefits of a rubber exterior. This coating helps prevent surface scratches and corrosion while also providing a non-slip grip. They are widely used in industrial applications and as tool attachments, where durability is critical.

Industrial and Commercial Applications

4. Rubber Duck Magnets

Novelty and Collectible Items

Rubber duck magnets are a delightful twist on the traditional refrigerator magnet. Shaped like the iconic rubber duck, these magnets serve as novelty items and collectibles. They often feature vibrant colors and playful designs that appeal to both children and adults.

Souvenirs and Gifts

Due to their fun and recognizable design, rubber duck magnets are popular souvenirs and gift items, often purchased during vacations or as quirky additions to a home’s décor.

5. Rubber Covered and Fridge Magnets

Home Decor and Messaging

Rubber covered magnets, including the ever-popular rubber fridge magnets, are widely used in homes and offices. They serve a dual purpose: functional tools for holding notes and photos, and decorative items that enhance the look of a refrigerator or office board.

Easy Customization

These magnets can be produced in a variety of shapes, sizes, and colors. Custom designs are particularly popular for personalized gifts and small business promotions.

6. Flexible Rubber Magnets

Versatility in Form and Function

Flexible rubber magnets are celebrated for their ease of manipulation. They can be easily cut, stretched, or molded into almost any shape, making them an excellent choice for creative applications in art, design, and advertising.

Wide Range of Applications

From large-scale commercial installations to small craft projects, the adaptability of flexible rubber magnets makes them a preferred option for innovative designers and hobbyists alike.

7.Rubber State Magnets

Educational and Souvenir Items

Rubber state magnets, which are shaped like the outlines of U.S. states, serve a dual purpose. They are used in educational settings to teach geography and state-related facts, while also being popular as souvenirs or collectible items.

Design and Practicality

These magnets often feature vibrant colors and can be customized with additional details, such as state capitals or historical facts, adding an extra layer of engagement for users.

Advantages and Limitations of Rubber Magnets

Advantages

- Flexibility and Safety:Their soft, pliable nature minimizes damage to surfaces and reduces the risk of injury.

- Customization:Rubber magnets can be easily printed or cut into custom shapes, which is ideal for branding and personalized gifts.

- Cost-Effective:They are relatively inexpensive to produce, making them accessible for a wide range of applications.

- Versatility:From educational tools for kids to industrial applications, rubber magnets serve many purposes.

- Durability:Despite their flexible nature, many rubber magnets are designed to withstand frequent handling and environmental stresses.

Limitations

- Lower Magnetic Strength:Compared to rigid ceramic or neodymium magnets, rubber magnets typically have a weaker magnetic pull.

- Environmental Sensitivity:The binder materials may degrade under extreme temperatures or prolonged exposure to ultraviolet light.

- Limited Load Capacity:Their flexible design means they are not ideal for heavy-duty lifting or industrial applications that require high-strength magnets.

Market Trends and Future Outlook

Growing Demand for Customization

As businesses and consumers increasingly seek personalized products, the market for custom rubber magnets continues to grow. Advances in digital printing and cutting technologies have enabled manufacturers to produce magnets with intricate designs and vibrant colors quickly and cost-effectively.

Sustainability and Eco-Friendly Materials

Environmental concerns are prompting manufacturers to explore more sustainable materials for both the magnetic powder and the binder. Innovations in biodegradable polymers and recycled magnetic materials could pave the way for greener rubber magnets in the near future.

Technological Advancements

Research into new composite materials and improved manufacturing techniques is driving enhancements in both the magnetic strength and durability of rubber magnets. These advancements are expected to expand their range of applications, particularly in fields where flexible yet reliable magnetism is essential.

Global Market Expansion

With the rise of online marketplaces, such as Amazon, consumers around the world have easier access to a wide variety of rubber magnets. This increased accessibility is fostering competition among manufacturers and driving innovation in product design and quality.

The Future of Rubber Magnets

With ongoing innovations in material science and manufacturing, the future of rubber magnets is bright. As manufacturers continue to improve magnetic strength, durability, and eco-friendly attributes, rubber magnets are poised to expand into new markets and applications. Whether used for educational purposes, artistic expression, or industrial utility, these magnets embody a perfect blend of science and creativity.

In summary, rubber magnets are more than just a tool for sticking notes to a fridge—they are a dynamic product with a rich history, a fascinating manufacturing process, and an ever-growing array of applications. Their ability to combine functionality with creative design continues to drive innovation, making them a compelling subject for further exploration and application.

This article has provided a detailed exploration of rubber magnets—from their basic definition and operation to the intricacies of their manufacturing process and diverse applications. With insights into various types such as rubber magnets for kids, custom designs, rubber duck and state magnets, and more, it is clear that rubber magnets hold a significant place in both everyday life and specialized industries. Whether you are a hobbyist, educator, marketer, or manufacturer, understanding the science and art behind rubber magnets can open up new avenues for creativity and innovation.

As the market evolves, manufacturers and designers alike will continue to leverage the unique properties of rubber magnets, ensuring that these flexible, versatile products remain at the forefront of both functional and decorative magnet solutions. With the integration of new technologies and sustainable materials, the potential for rubber magnets is virtually limitless, offering exciting opportunities for customization, improved performance, and broader applications in the years to come.

Conclusion

Rubber magnets represent a unique convergence of science, art, and practicality. Their flexible, lightweight, and customizable nature makes them an indispensable tool in various settings—from the playful creativity of rubber magnets for kids and novelty rubber duck magnets to the precision of custom rubber magnets used in branding and industrial applications.