- Custom Magnets

- Standard Magnets

- Mounting Magnets

- Magnetic Assemblies

- About Us

- Knowledge

Magnetic separators are used in various industrial applications to remove ferrous contaminants from liquids or dry products. As a manufacturer and supplier of magnets and magnetic assemblies, Magnestek Engineering can leverage our expertise to design and produce effective magnetic separators.

| Magnet | Neodymium Magnets, SmCo magnets available | |||

| Strength | 6,000Gauss/8,000Gs/10,000Gs/12,000Gs/13,500Gs/Customized | |||

| Diameter | 16mm/19mm/22mm/25mm/32mm/38mm/Customized | |||

| Length | 200mm/250mm/300mm/400mm/500mm/1,000mm/Customized | |||

| Adapters | Closed/Sealed/Sealed Threaded | |||

Neodymium (NdFeB) magnets are commonly used for their strong magnetic properties. These magnets are arranged along the length of the filter bar to create a magnetic field.

The magnets are typically housed in a cylindrical tube or bar made of stainless steel or other non-magnetic materials. This housing provides structural support and protects the magnets from damage.

The ends of the magnetic filter bar are often sealed with plugs or caps, ensuring that the magnetic field is concentrated through the open sides of the bar.

When a liquid or dry product containing ferrous particles passes through or close to the magnetic filter bar, the strong magnetic field attracts and captures the ferrous contaminants.

The magnetic filter bar must be cleaned periodically to remove the accumulated ferrous particles. This is typically done by removing the filter bar from its housing, wiping off the contaminants, and reinserting it.

Used to remove metal contaminants from food products, such as grains, powders, and liquids.

Applied in the chemical processing industry to purify liquids and protect processing equipment from ferrous contamination.

Used in the processing of plastic resins to ensure the final product is free from metal impurities.

Employed in mining and aggregate processing to remove ferrous contaminants from raw materials.

Utilized in water treatment processes to remove iron and other magnetic particles from water.

Select the appropriate grade of rare earth magnets to achieve the desired magnetic strength for effective separation.

Choose a durable and corrosion-resistant material for the housing, such as stainless steel, to ensure longevity and suitability for different environments.

Design the filter bar with consideration for the size and configuration that best suits the application and installation requirements.

By manufacturing high-quality magnetic filter bars, you can provide solutions for industries that require efficient removal of ferrous contaminants from their processes, contributing to improved product quality and equipment protection.

Magnetic separators are indispensable pieces of equipment used across a wide range of industries. Their primary role is to remove magnetic contaminants from raw materials or to separate valuable minerals from waste. They play a vital role not only in mining and metallurgy but also in food processing, recycling, and chemical production. In this article, we will discuss the fundamentals of magnetic separation, explore different types of magnetic separators—including low and high intensity variants—and look at specific applications, brands, and equipment lists. By the end, you will have a clearer understanding of what magnetic separators are used for, their benefits and disadvantages, and how they are integrated into modern production processes.

Magnetic separators work by using magnetic fields to attract ferromagnetic particles (or weakly magnetic particles, if the separator is designed for that purpose) away from nonmagnetic material. Originally developed for mining, these machines have evolved to find uses in many industries:

Magnetic separation offers a physical method to segregate materials without the need for chemical additives, making it an eco-friendly and efficient technique.

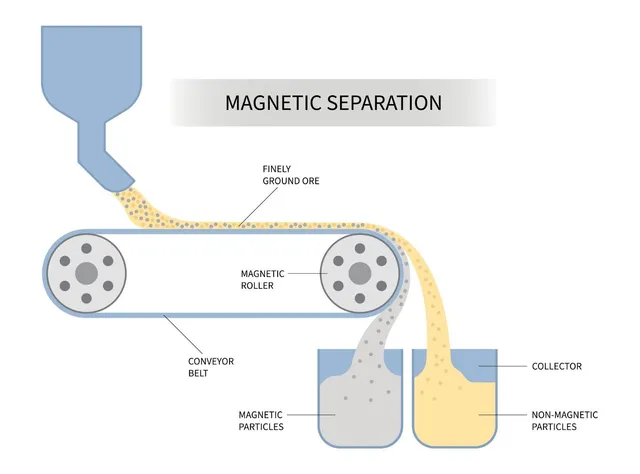

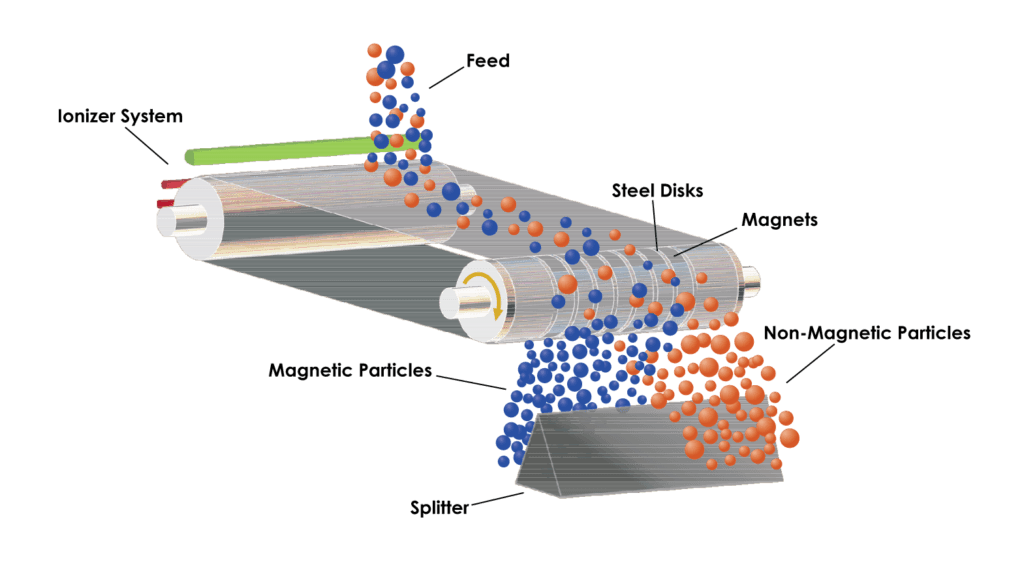

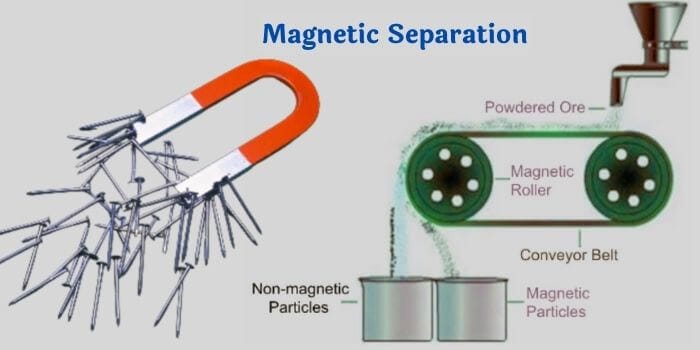

The operation of a magnetic separator is based on the principle that magnetic materials will be attracted to a magnetic field, whereas nonmagnetic materials remain largely unaffected. The process can be summarized as follows:

The operation of a magnetic separator is based on the principle that magnetic materials will be attracted to a magnetic field, whereas nonmagnetic materials remain largely unaffected. The process can be summarized as follows:

This simple yet effective process allows for the efficient removal of unwanted metal contaminants or the extraction of valuable magnetic minerals.

Magnetic separators can be broadly classified based on the intensity of the magnetic field they generate and their design features. The two primary categories are low intensity magnetic separators and high intensity magnetic separators. Additionally, there are specialized designs tailored to specific industries.

Low intensity separators are typically used for separating ferromagnetic materials from nonmagnetic materials. They generate a magnetic field with a strength generally less than 1000 gauss. These separators are common in:

Low intensity separators are typically used for separating ferromagnetic materials from nonmagnetic materials. They generate a magnetic field with a strength generally less than 1000 gauss. These separators are common in:

High intensity separators are designed to handle weakly magnetic minerals that do not respond well to low intensity fields. They produce much stronger magnetic fields (ranging from 6000 to 20000 gauss) and are typically used in:

High intensity separators are designed to handle weakly magnetic minerals that do not respond well to low intensity fields. They produce much stronger magnetic fields (ranging from 6000 to 20000 gauss) and are typically used in:

Several companies have specialized in designing and manufacturing magnetic separators. Two notable names include:

The table below summarizes key characteristics of various types of magnetic separators:

| Type/Brand | Magnetic Field Intensity | Primary Applications | Notable Features |

|---|---|---|---|

| Low Intensity Magnetic Separators | Up to 1000 gauss | Food processing, recycling, pharmaceuticals, and chemical production | Energy-efficient; ideal for strong ferromagnetic separation |

| High Intensity Magnetic Separators | 6000 – 20000 gauss | Mining, mineral processing, specialized industrial processes | Capable of extracting weakly magnetic minerals |

| Malvern Engineering Magnetic Separators | Variable (customizable design) | Mining, heavy industry, high-volume processing | Robust design; automated controls; adjustable magnetic fields |

| Steiner Magnetic Separators | Both low and high intensity | Various industrial applications requiring high reliability | Emphasis on energy efficiency; low maintenance |

Table 1. Comparison of Different Types and Brands of Magnetic Separators

Magnetic separators are used in many different fields due to their ability to efficiently and safely remove metal contaminants or recover valuable minerals. Below are some key application areas:

Purpose: In the food industry, magnetic separators are primarily used to ensure product safety by removing ferrous contaminants that might have been introduced during processing. Metal fragments can occur due to wear and tear on machinery, and even small amounts can pose serious safety hazards.

How They Work in Food Processing:

Benefits:

Purpose: In mining, magnetic separators are essential for extracting iron ore and other magnetic minerals from crushed rock or mineral slurry. They enhance the concentration of the valuable mineral, reducing impurities and improving overall ore quality.

How They Work in Mining:

Benefits:

Beyond food and mining, magnetic separators are used in various industrial settings:

Real-Life Example:

A typical recycling facility might use a series of magnetic separators to extract iron and steel from a mixed waste stream, ensuring that subsequent processing steps yield high-purity recycled materials.

Magnetic separators are also pivotal in manufacturing processes where product quality is paramount. For example, in the production of high-grade steel, any unwanted metallic impurities can compromise the final product. Similarly, in the manufacturing of certain electronic components, even trace amounts of magnetic contaminants can cause defects.

Magnetic separators are used to separate magnetic materials from nonmagnetic ones. They are critical in removing ferrous contaminants from raw materials and ensuring the purity of the final product in industries such as mining, food processing, recycling, and chemical manufacturing.

While magnetic separation is highly effective, there are some limitations:

The benefits of magnetic separation include:

Magnetic separation is a key process in many roles:

Real-life examples include:

The primary task of magnetic separators is to:

Many products have benefited from magnetic separation technology:

Below is a list of key equipment commonly used in magnetic separation, along with their functions:

| Equipment | Function | Typical Application |

|---|---|---|

| Magnetic Separator Unit | Generates the magnetic field necessary for separation | Mining, food processing, recycling, chemicals |

| Feeder System | Ensures a consistent flow of material into the separator | Continuous processing lines |

| Conveyor Belts | Transports the material through various processing stages | Integrated production lines |

| Scrapers/Detachers | Remove the collected magnetic material from the separator surface | Automated cleaning and collection processes |

| Control and Monitoring System | Manages the magnetic field strength and overall operation | Modern, automated manufacturing systems |

| Magnetic Filter Bars | Serve as additional filtering components to capture fine magnetic particles | Food processing, water treatment, chemical manufacturing |

Table 2. Essential Equipment for Magnetic Separation Processes

Magnetic Filter Bars are specialized components designed to complement traditional magnetic separators. They are typically elongated bars with a magnetic coating or embedded magnets that capture and trap fine magnetic particles from liquids, slurries, or powders. These bars are particularly useful when:

Magnetic Filter Bars are specialized components designed to complement traditional magnetic separators. They are typically elongated bars with a magnetic coating or embedded magnets that capture and trap fine magnetic particles from liquids, slurries, or powders. These bars are particularly useful when:

By adding Magnetic Filter Bars to a separation system, manufacturers can significantly enhance the overall efficiency and reliability of the magnetic separation process.

To successfully integrate magnetic separation into an industrial process, it is crucial to have not only the separators themselves but also auxiliary equipment. A robust installation will often include the following:

This integration helps maintain product quality while maximizing operational efficiency. The design and implementation of these systems require careful planning and ongoing maintenance to address issues such as wear and buildup of separated material.

The price of magnetic separators varies widely based on several factors:

In general, while initial capital expenditure may be significant, the long-term benefits—including reduced waste, improved product quality, and lower operating costs—often justify the investment.

As industries continue to evolve, so does the technology behind magnetic separators. Several trends are emerging:

Magnetic separators have become a cornerstone in the efficient processing of raw materials across many industries. Their ability to separate magnetic from nonmagnetic materials makes them essential in ensuring product quality, safety, and environmental compliance. Whether in the realm of mining—where high intensity separators extract valuable minerals—or in food processing—where low intensity separators safeguard consumer health—this technology continues to evolve.

Investing in the right magnetic separation equipment, such as those from reputable manufacturers like Malvern Engineering and Steiner, can offer significant long-term returns. They not only improve process efficiency but also contribute to safer, cleaner, and more sustainable production practices.

Whether you are considering upgrading an existing processing line or integrating magnetic separation into a new design, understanding the types of separators, their applications, and the supporting equipment is critical. The detailed comparison and equipment list provided above should serve as a useful guide in making informed decisions.

The strength of the magnetic field determines how effectively magnetic separators can attract and capture magnetic particles. Higher magnetic field strength improves separation efficiency, especially for weakly magnetic materials. However, excessive strength can lead to material buildup and require more frequent cleaning.

Magnetic separators are widely used in industries such as mining, food processing, pharmaceuticals, ceramics, recycling, and chemical manufacturing. They help remove metal contaminants from raw materials, ensuring product purity and protecting processing equipment from damage.

Yes, but the performance depends on the type of magnet used. Standard magnetic separators may lose effectiveness in extreme heat, while high-temperature-resistant magnets like neodymium or samarium-cobalt can maintain strong magnetic fields. For humid environments, corrosion-resistant coatings or stainless-steel housings are recommended.

Most magnetic separators are highly energy-efficient since they rely on permanent magnets rather than electricity. Some advanced models use electromagnetic systems that require power but offer adjustable separation strength. Eco-friendly options include self-cleaning separators and those designed with recyclable materials.

Regular maintenance ensures optimal performance. Best practices include:

Key considerations include:

These Q&As help clarify important aspects of magnetic separators and their applications.