- Custom Magnets

- Standard Magnets

- Mounting Magnets

- Magnetic Assemblies

- About Us

- Knowledge

Magnet Rotors and Motors are components used in various devices, particularly electric motors and generators. These magnet rotors incorporate magnets to generate a magnetic field that interacts with the stator to produce motion or electrical energy.

MagnetsTek Engineering designs and manufactures arc magnets, magnet rotors and magnetic motors. The typical product line includes Coreless Metal Brushed DC Motor, Graphite Brushed DC Motor, Brushless DC Motor (High-speed Motor, 40,000~60,000 RPM), and Gearbox. We can save you much research and development time and costs with thousands of existing models.

Feel free to talk to an expert to choose or customize your model.

Neodymium (NdFeB) magnets are often chosen for their strong magnetic properties and are frequently used to construct magnet rotors. Other magnets, like samarium cobalt magnets, ferrites magnets can also be used for different applications.

You can always find magnets in daily life, such as scooters, electric bicycles, hair dryers, and wind turbines, cars, boats, fans, and more.

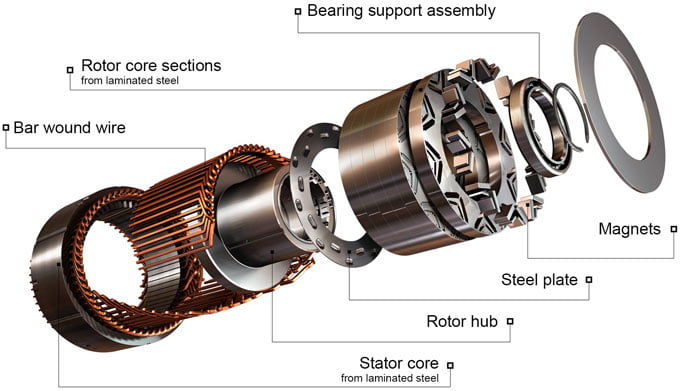

The rotor typically consists of a central shaft or core and a structure that holds the magnets in place. This structure can be made from various materials, including metals or composites.

MagnetsTek Engineering specializes in producing high-performance magnets, magnetic assemblies, precision thin metals, and electric motor components and assemblies designed for optimal efficiency in electric machines. Our brushless motor can reach 40,000~60,000 RPM.

Notable specifications for magnet rotors include advanced materials like samarium cobalt or neodymium iron boron, constituting permanent magnets. The magnetic motor typically comprised magnetic steel, a metal shaft, or metal shell. Depending on the specific application requirements, the rotor magnet may undergo sintering, molding, or injection molding, utilizing NdFeB magnet or Ferrite magnet material to create multi-pole magnetic rings. These magnet rotors find applications in high-s, liners, stepper motors, and more. Additionally, customization of permanent magnet motor rotors is available, accommodating various magnetic materials, and tailored drawings are welcomed.

Depending on the application, additional balancing elements may be integrated into the rotor to minimize vibrations and ensure smooth rotation.

Permanent magnet rotors have magnets that maintain their magnetic strength without needing an external power source. These are commonly used in permanent magnet motors.

In some applications, magnet rotors are designed to have variable magnetic flux. This flexibility allows for control over the motor’s speed and efficiency.

In advanced applications, magnet rotors are used in magnetic levitation systems where the rotor is suspended without physical contact, reducing friction and wear.

Magnet rotors are a crucial component in various electric motor types, including brushless DC motors and permanent magnet synchronous motors.

In generators, magnet rotors are used to convert mechanical energy into electrical energy by inducing a current in the stator coils.

High-speed transportation systems, such as maglev trains, utilize magnet rotors for magnetic levitation, allowing for efficient and frictionless movement.

Permanent magnet rotors are employed in the generators of wind turbines to convert the kinetic energy of the wind into electrical energy.

The magnetic rotor, also known as the permanent magnet rotor, constitutes the dynamic component of an electric motor. Serving as the moving element within devices such as electric motors and generators, the magnetic rotor is strategically designed with multiple poles, each alternating in polarity between north and south. These opposing poles rotate around a central axis, typically a shaft positioned at the midpoint. This fundamental rotor design finds application in various fields, including the In-wheel Motor of Electric Sports Cars with a wheel size of 16 inches.

MagnetsTek Engineering specializes in delivering high-performance permanent magnet motor components and sub-assemblies tailored for aerospace, defense, industrial, automotive, and motorsport applications.

In the realm of energy conversion, there is a technological breakthrough that is revolutionizing efficiency and sustainability: motor permanent magnets. These powerful magnets hold the key to transforming energy in a more efficient and environmentally friendly way. In this article, we will delve into the untapped potential of motor permanent magnets and how they are reshaping the landscape of energy.

With their ability to generate a strong magnetic field, motor permanent magnets offer a game-changing solution for various applications, from electric vehicles to wind turbines and beyond. By harnessing the power of these magnets, we can achieve higher energy efficiency, reduced energy consumption, and decreased carbon emissions.

Not only are motor permanent magnets more energy-efficient, but they also open up new possibilities for renewable energy sources. The integration of these magnets into electric motors and generators allows for the conversion of mechanical energy into electrical energy with minimal losses.

Join us as we unveil the immense power of motor permanent magnets and explore their vital role in driving the transition towards a more sustainable future. Together, we can harness the potential of this innovative technology and pave the way for a greener tomorrow.

Motor permanent magnets utilize the unique properties of certain materials, such as neodymium-iron-boron (NdFeB) or samarium-cobalt (SmCo), to generate a powerful and stable magnetic field. These magnets are typically made by aligning the magnetic domains within the material, resulting in a magnet with a consistent and strong magnetic field.

When placed in close proximity to a coil of wire, the magnetic field of the motor permanent magnet induces an electric current in the wire through electromagnetic induction. This current can then be harnessed to perform useful work, such as driving an electric motor or generating electricity in a generator.

This inherent magnetism also allows for higher energy efficiency. Since motor permanent magnets do not require an external power source to generate a magnetic field, they can convert a larger percentage of the input energy into useful work. This results in reduced energy consumption and lower operating costs.

Additionally, motor permanent magnets are highly reliable and durable. Unlike electromagnets that can degrade over time due to overheating or electrical failures, motor permanent magnets are not prone to such issues. This makes them ideal for applications that require long-term operation and minimal maintenance.

NdFeB magnets are known for their exceptional magnetic properties, including high magnetic strength and resistance to demagnetization. These magnets are widely used in various applications, ranging from electric vehicles and wind turbines to computer hard drives and audio speakers.

On the other hand, SmCo magnets offer superior thermal stability and resistance to corrosion compared to NdFeB magnets. This makes them suitable for high-temperature applications, such as aerospace and military equipment.

Another significant application is in wind turbines. Motor permanent magnets are used in the generators of wind turbines to convert the rotational energy of the blades into electrical energy. By using motor permanent magnets, wind turbines can operate at higher efficiencies, making wind energy a more viable and sustainable power source.

In addition to EVs and wind turbines, motor permanent magnets are also utilized in various other applications, such as industrial machinery, robotics, medical devices, and renewable energy systems like solar power inverters. The versatility and efficiency of motor permanent magnets make them a vital component in driving the advancement of these industries.

While motor permanent magnets offer numerous advantages, there are also challenges associated with their use. One of the primary challenges is the availability of rare-earth elements, such as neodymium and samarium, which are essential components in motor permanent magnets. The limited supply of these elements can lead to price volatility and potential supply chain disruptions.

Furthermore, the manufacturing process of motor permanent magnets involves complex techniques and specialized equipment. This can result in higher production costs and limited scalability, especially for large-scale applications. However, ongoing research and development efforts are focused on addressing these challenges and finding alternative materials or manufacturing methods.

To overcome the challenges associated with motor permanent magnets, researchers and engineers are constantly exploring innovative solutions. One such innovation is the development of magnet recycling and reclamation techniques. By recovering and reusing motor permanent magnets from end-of-life products, the reliance on new magnet production can be reduced, mitigating the environmental impact and ensuring a more sustainable supply chain.

Another area of innovation is the development of magnet-free or magnet-less motor technologies. These technologies aim to replace the use of motor permanent magnets with alternative solutions, such as electromagnetic coils or superconducting materials. While still in the early stages of development, these magnet-free motor technologies have the potential to offer similar efficiency and performance benefits without the reliance on rare-earth elements.

In the context of electric vehicles, the use of motor permanent magnets allows for more efficient energy conversion from the battery to the wheels, resulting in longer driving ranges and reduced reliance on fossil fuels. This contributes to a greener transportation sector and helps combat climate change.

In the field of renewable energy, motor permanent magnets play a crucial role in improving the efficiency of wind turbines, solar power inverters, and other renewable energy systems. By maximizing the conversion of renewable energy into usable electricity, motor permanent magnets enable a more sustainable and reliable power generation.

Furthermore, advancements in magnet recycling and reclamation technologies will play a key role in ensuring a sustainable supply chain for motor permanent magnets. By closing the loop and recovering magnets from discarded products, the environmental impact of magnet production can be minimized.

Lastly, the ongoing research into magnet-free motor technologies has the potential to reshape the landscape of energy conversion. These technologies, if successfully developed, could offer alternative solutions to motor permanent magnets, reducing the reliance on rare-earth elements and further improving the efficiency and sustainability of energy conversion processes.

Motor permanent magnets have emerged as a game-changing solution in the realm of energy conversion. Their ability to generate a strong magnetic field without the need for an external power source makes them highly efficient and reliable. From electric vehicles to wind turbines and beyond, motor permanent magnets are revolutionizing various industries and driving the transition towards a more sustainable future.

While challenges remain, ongoing research and innovation in motor permanent magnet technology are paving the way for a greener and more efficient energy landscape. By harnessing the immense power of motor permanent magnets and exploring alternative solutions, we can unlock the full potential of this technology and pave the way for a more sustainable and energy-efficient tomorrow. Together, let us embrace the power of motor permanent magnets and create a brighter future for generations to come.