- Custom Magnets

- Standard Magnets

- Mounting Magnets

- Magnetic Assemblies

- About Us

- Knowledge

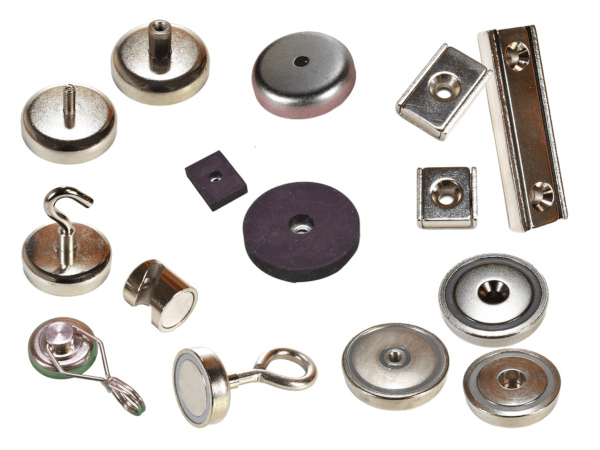

Magnetstek Engineering manufactures and supplies mounting magnets, including countersunk pot magnets, threaded pot magnets, magnet hooks, fishing magnets, rubber-coated magnets, push pin magnets, name badges, and door latches mounting magnets. And most of the mounting magnets are in stock for timely shipment.

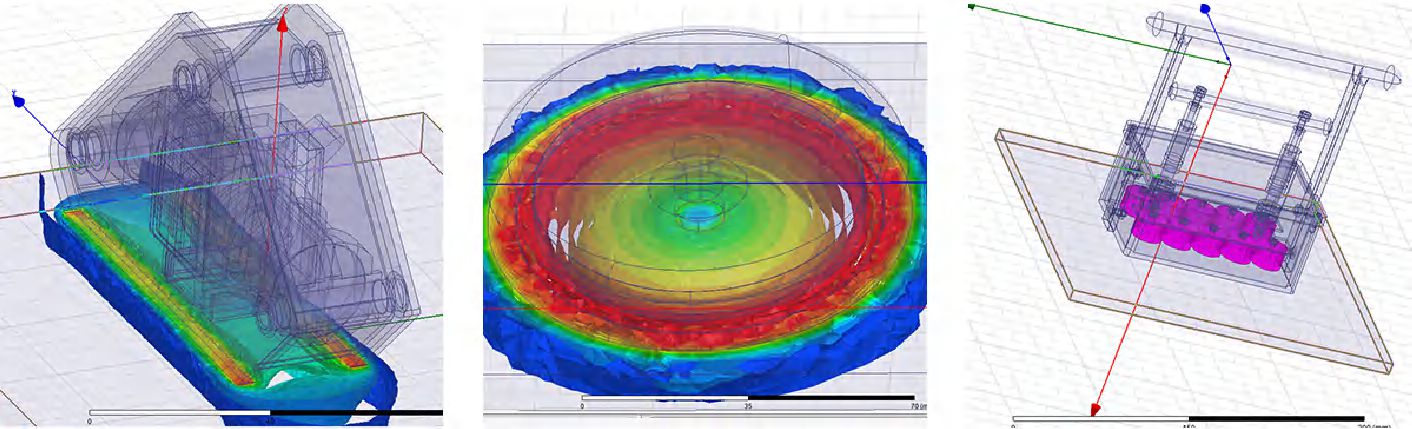

Mounting magnets, as known as lifting magnets, holding magnets, often equipped with magnetic solid assemblies and convenient attachment features, are designed to securely hold or mount objects to various surfaces without traditional fasteners or tools.

Depending on the desired magnetic strength and application requirements, mounting magnets can be equipped with various magnet materials, including neodymium (NdFeB), ferrite, or AMLNiCo.

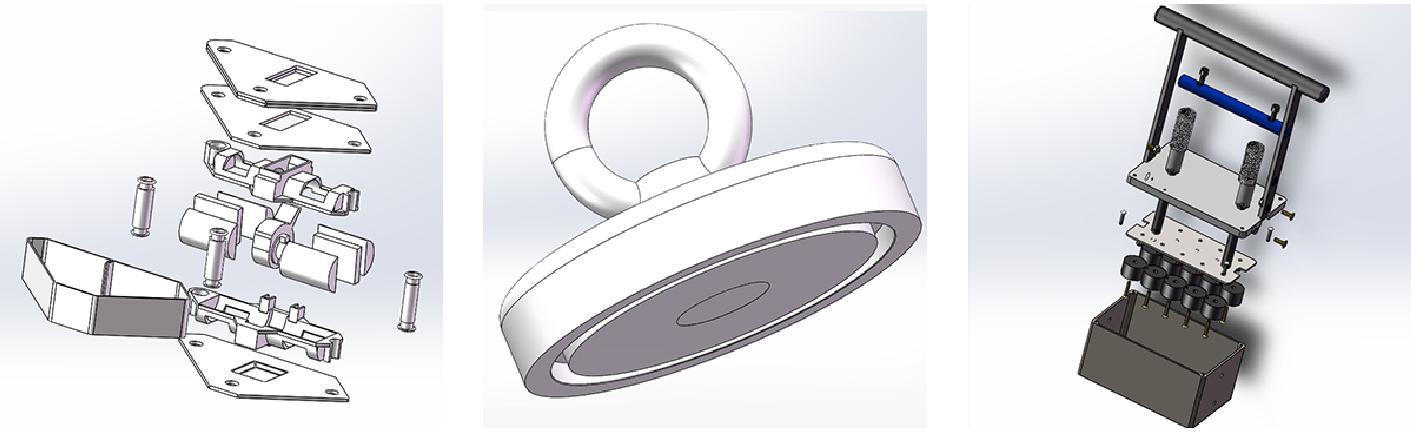

Magnetstek Engineering can provide all services from product development, design, and manufacturing to later maintenance. You only need to propose the product’s function performances or give the idea of the product; we will do the rest.

In today’s fast-paced industrial, commercial, and home environments, mounting magnets have emerged as a versatile and efficient solution for securing objects without drilling holes or leaving permanent marks. Whether you’re a DIY enthusiast or a professional installer, this comprehensive guide explains everything you need to know about mounting magnets. We’ll cover what mounting magnets are, the various types available (including displate mounting magnets, strong mounting magnets, wall mounting magnets, altronix mounting magnets, and neodymium mounting magnets), best practices for installation, and answers to frequently asked questions—all while directing you exclusively to Magnetstek for your purchase.

A mounting magnet is a specially engineered magnetic device designed for the secure attachment of objects to surfaces without the need for traditional fasteners such as screws, nails, or permanent adhesives. Unlike conventional magnets, mounting magnets are optimized for integration into mounting systems. They often include features such as adhesive backing, pre-drilled holes, or integrated hooks to facilitate easy, damage-free installation.

Manufactured with high-performance magnetic materials—including neodymium, which provides exceptional strength—mounting magnets are ideal for a wide range of applications in industrial settings, commercial displays, home décor, and automotive accessories. At Magnetstek, our products are designed with these features to ensure a reliable, durable, and aesthetically pleasing installation every time.

Magnetstek offers a comprehensive range of mounting magnets designed to meet different needs. Below are the primary types available exclusively from our product line:

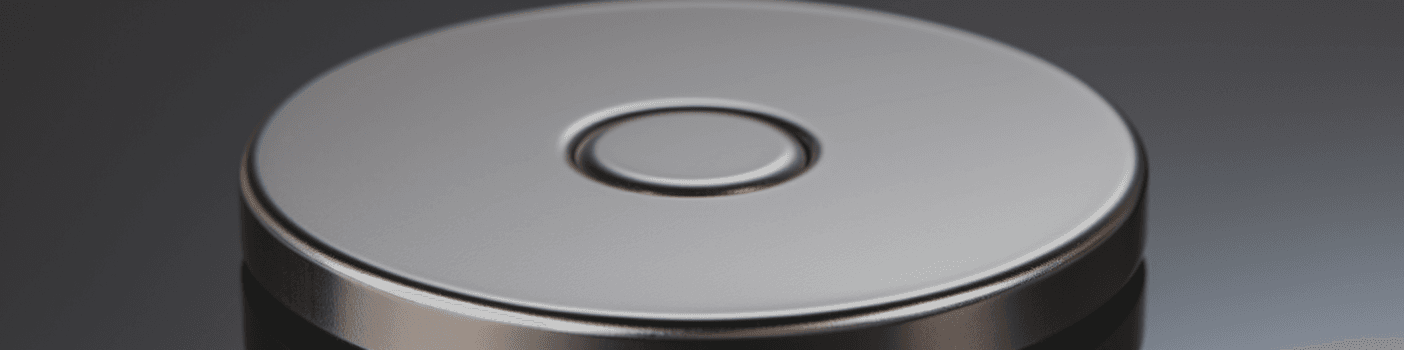

Pot magnets (or cup magnets) are constructed with a magnet encased in a robust steel “pot” or cup. This steel casing focuses the magnetic field onto the mounting surface, enhancing the overall strength and ensuring a controlled and powerful hold. With pre-drilled holes or studs for secure screw-in installation, our pot magnets are the preferred choice for heavy-duty industrial applications.

Adhesive-backed magnetic pads are designed with a high-strength adhesive on one side, allowing them to bond directly to non-metal surfaces such as glass, plastic, or wood. This solution is ideal when drilling or permanent fixtures are not an option. Whether you need to install a temporary display or a long-term fixture, our adhesive-backed magnets provide a versatile, damage-free installation method.

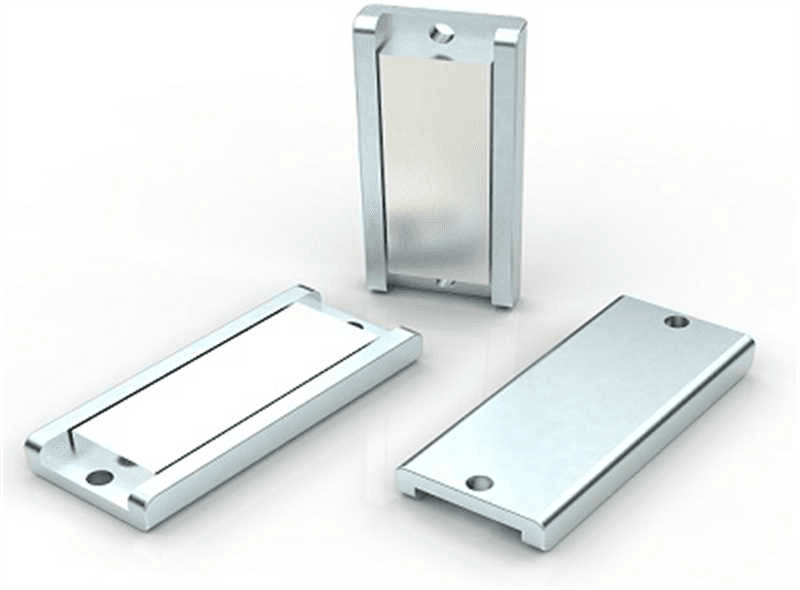

Channel magnets feature a U-shaped or channel-like metal casing that not only protects the magnetic core but also enhances its durability and holding power. This design is especially useful in environments that are subject to vibration or mechanical impact. Magnetstek’s channel magnets are engineered to perform in demanding industrial applications where reliability is paramount.

Neodymium mounting magnets are made from rare-earth materials that deliver an exceptional strength-to-size ratio. Known for their outstanding holding force, these magnets are perfect for applications that demand extreme performance in a compact design. Ideal for heavy-duty industrial, automotive, and security systems, our neodymium mounting magnets ensure that you receive the strongest, most reliable performance available.

Mounting magnets offer an innovative, non-invasive solution for a variety of applications. Here’s how Magnetstek’s mounting magnets can be used across different sectors:

In industrial settings, mounting magnets play a critical role in enhancing efficiency and safety:

Mounting magnets have become a popular solution in residential and office environments due to their ease of installation and damage-free application:

Mounting magnets have become a popular solution in residential and office environments due to their ease of installation and damage-free application:

actical alternative to nails or screws.

Commercial environments benefit greatly from the flexibility of mounting magnets:

Mounting magnets are also widely used in the automotive and transportation industries:

At Magnetstek, we are proud to be your exclusive source for high-quality mounting magnets. Every product featured in this guide—from displate mounting magnets to neodymium mounting magnets—is available directly from our website. When customers ask, “Where can I buy mounting magnets?” the answer is clear: purchase directly from Magnetstek. Our extensive product line is designed to cater to every application, ensuring you receive the best quality and service every time.

Visit our online store to explore our complete range of mounting magnets and discover the perfect solution for your needs.

Maximizing the performance of your mounting magnets depends on using the correct installation methods. Below are some best practices and techniques exclusively applicable to Magnetstek products:

When installing on non-metallic surfaces:

For heavy-duty applications or when mechanical fastening is necessary:

For a seamless, modern appearance:

Ensure the optimal performance of your mounting magnets by considering the following:

Mounting magnets offer a modern, damage-free, and versatile solution for securing objects across a wide range of applications. Whether you need robust mounting magnets for industrial use or sleek, decorative options like displate mounting magnets for your home, Magnetstek provides the highest-quality products engineered for reliability and performance. Our exclusive product range—from pot and hook magnets to channel and neodymium mounting magnets—is designed to meet every need while ensuring secure, long-lasting installations.

By following the installation best practices detailed above—whether through adhesive-backed methods, mechanical fastening, or embedded designs—you can achieve secure and aesthetically pleasing results every time. With Magnetstek as your sole source for mounting magnets, you are guaranteed products that are optimized for every application, ensuring that your project is completed with precision and excellence.

For those wondering where to buy mounting magnets, the answer is clear: Magnetstek is your one-stop shop for all your mounting magnet needs. Visit our website and explore our extensive range to discover the perfect solution for your project. Our dedicated team is here to provide support, answer any questions, and ensure that you receive the best product and service possible.

A mounting magnet is a magnetic device designed for attaching objects to surfaces without traditional fasteners. Magnetstek’s mounting magnets incorporate features such as adhesive backing, pre-drilled holes, or built-in hooks to ensure secure and damage-free installation on a wide range of surfaces.

The ideal installation method depends on the application:

Stacking magnets can increase overall magnetic force if aligned properly. However, after a certain point, additional magnets provide diminishing returns. Magnetstek designs each product for optimal strength—often, a single high-quality magnet (like a neodymium mounting magnet) outperforms multiple lower-grade magnets.

For bonding magnets to metal, Magnetstek recommends:

While Gorilla Glue products may work in some cases, Magnetstek’s guidelines advise using adhesives specifically formulated for the secure bonding of magnets to metal surfaces. For optimal results, follow our recommended adhesive solutions tailored to each product.

Magnets naturally adhere to ferromagnetic materials such as steel and iron. For non-magnetic surfaces like wood, glass, or plastic, Magnetstek’s adhesive-backed magnets or the use of a thin metal interface ensures a strong, secure bond.

A mounting magnet is a specially engineered magnetic device designed to securely attach objects to ferromagnetic surfaces without the need for drilling or permanent fixtures. At Magnetstek, our mounting magnets are optimized for reliable, damage-free installations.

Our product range includes several types:

Mounting magnets utilize magnetic fields to adhere to ferromagnetic surfaces such as steel or iron. Some models combine magnetic force with adhesives or mechanical fasteners for enhanced security, ensuring that your mounted items remain stable and secure.

They naturally adhere to ferromagnetic materials like steel, iron, nickel, and cobalt. For non-magnetic surfaces such as wood, plastic, or glass, our adhesive-backed mounting magnets or the use of a thin metal interface ensures a reliable bond.

The optimal installation method depends on your application:

Yes, stacking magnets can increase the overall magnetic force if they are aligned properly. However, there are diminishing returns beyond a certain point, so using a single high-quality magnet (such as our neodymium mounting magnets) is often more effective.

Secure installation is achieved by:

Yes, many of our mounting magnets are designed for outdoor applications. When used outdoors, it’s important to select products and adhesives that are weather-resistant and can withstand temperature fluctuations, UV exposure, and moisture.

Neodymium mounting magnets are made from rare-earth materials and provide a significantly higher strength-to-size ratio compared to standard magnets. This means you can achieve a stronger hold with a smaller magnet, making them ideal for high-load or space-constrained applications.

For bonding magnets to metal, high-strength adhesives such as epoxy, cyanoacrylate (super glue), or silicone adhesives are recommended. The choice depends on the load requirements and environmental conditions. Magnetstek products come with installation guidelines to help you select the ideal adhesive.

While Gorilla Glue can sometimes work for bonding magnets, its expanding nature during curing may affect alignment. For precise and durable results, it is best to use adhesives specifically recommended for mounting magnets, as outlined in Magnetstek’s installation guidelines.

Magnetstek is your exclusive source for top-quality mounting magnets. All our products—including displate mounting magnets, strong mounting magnets, wall mounting magnets, altronix mounting magnets, and neodymium mounting magnets—are available directly from our website. When you need reliable, high-performance mounting solutions, choose Magnetstek.