- Custom Magnets

- Standard Magnets

- Mounting Magnets

- Magnetic Assemblies

- About Us

- Knowledge

Pot magnets have a steel cup or pot surrounding the magnet, creating a closed magnetic circuit. This design focuses on and enhances the magnetic strength on one face of the magnet. Magnetstek Engineering supplies pot magnets with countersunk holes, male and female threads, and other pot magnets like magnet button.

Pot magnets can be customized on magnet materials (NdFeB magnet/Ferrite Magnets), steel cover materials (Nickel-plated Iron/stainless steel), and sizes (magnet size, thread size, etc.).

Feel free to work with Magnestek Engineering for your unique models.

Pot magnets—sometimes called cup magnets or mounting magnets—are a unique class of permanent magnets designed for focused clamping and mounting applications. They derive their name from their pot‐ or cup-shaped ferromagnetic casing that encases the magnet itself. This protective housing not only shields the brittle magnet from mechanical impacts but also enhances its pull force by concentrating the magnetic field on the open face. In this article, we explore the inner workings of pot magnets, their construction, applications, and future trends, with extra sections to help you navigate the topic.

Pot magnets are a remarkable blend of material science and engineering innovation. Their design has evolved from simple magnetic components to advanced assemblies used in many modern applications. In this section, we provide an overview of the fundamental concepts behind pot magnets.

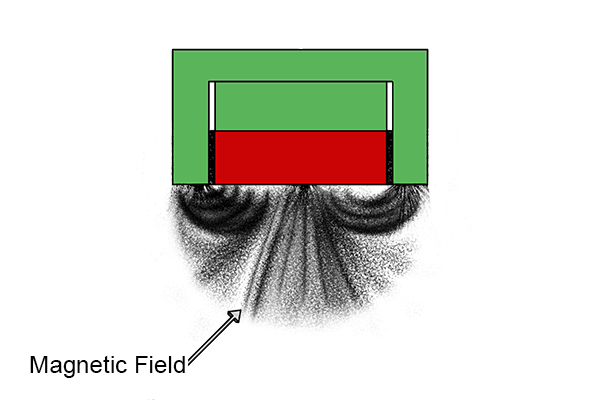

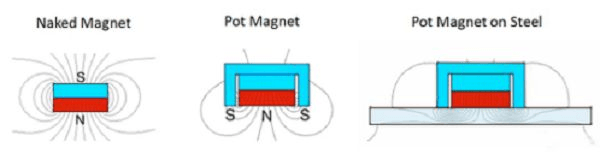

At their core, pot magnets are permanent magnets partially enclosed by a ferromagnetic cup or “pot.” The magnetic material—often a neodymium (NdFeB), ceramic (ferrite), AlNiCo, or samarium cobalt (SmCo) magnet—is positioned inside the steel casing. One face of the magnet is exposed, which is the active magnetic surface that interacts with ferromagnetic objects. The encasing metal not only protects the magnet but also channels the magnetic flux, increasing the pull force at the clamping surface.

Permanent magnets have been used for centuries, but the mid 20th century introduction of rare earth magnets revolutionized the industry. Neodymium magnets, in particular, brought about a need for a design that could harness their extraordinary strength while protecting their fragile nature. This led to the creation of the pot magnet—a design that is now critical in many high-performance applications.

Magnetic Core:

The heart of a pot magnet is its magnetic core. Neodymium magnets are popular due to their high energy product, but ceramic, AlNiCo, and SmCo magnets are also used. Each material provides different benefits in terms of strength, cost, temperature resistance, and corrosion resistance.

Protective Casing:

Typically made of mild steel or ferritic stainless steel, the casing serves to protect the magnet from physical damage and to focus the magnetic field by reducing the effective air gap.

Pot magnets are manufactured using a combination of powder metallurgy and precision machining. The magnetic material is sintered, cut to exact dimensions, and magnetized along a chosen axis—axial magnetization is common. The steel pot is then bonded or pressed onto the magnet, often followed by protective coatings that enhance durability and corrosion resistance.

Table 1: Common Materials for Pot Magnets

| Material | Magnetic Strength | Advantages | Typical Applications |

| Neodymium (NdFeB) | Very High | Exceptionally strong; compact size | Industrial clamping, mounting, tool holding |

| Ceramic (Ferrite) | Moderate | Cost-effective; corrosion-resistant | Home organization, light-duty applications |

| AlNiCo | Moderate to High | High temperature resistance | High-temperature industrial applications |

| Samarium Cobalt (SmCo) | High | Excellent temperature stability; corrosion resistant | Aerospace, medical equipment |

Pot magnets come in several variants to suit various applications:

Pot magnets are generally stronger in specific applications compared to equivalent bare magnets. Their unique design provides several advantages:

In summary, while the magnetic material itself may have the same inherent strength as that in a bare magnet, the construction of a pot magnet enhances its functional pull force and makes it more efficient for clamping and mounting applications.

Pot magnets are essential in industrial settings for:

In home environments, pot magnets are used to:

Custom pot magnets are tailored for:

The design of pot magnets—with their focused magnetic field and reduced air gap—results in a pull force that is significantly higher than that of a bare magnet of comparable size.

The robust steel casing protects the magnet from physical damage and environmental factors, while additional coatings further enhance resistance to corrosion and oxidation.

With features such as threaded posts, countersunk holes, or integrated hooks, pot magnets offer flexible mounting options that simplify installation and provide secure fastening without the need for adhesives.

Pot magnets perform best within specified temperature ranges. Standard neodymium magnets, for example, are usually rated for use up to about 80°C. For high-temperature applications, alternative materials or specialized grades should be considered.

Optimal performance requires direct contact with a ferromagnetic surface. Air gaps, surface roughness, or coatings (such as paint or rust) can diminish the effective pull force, so surface preparation is essential.

Due to their strong magnetic fields, pot magnets must be handled with care:

Disc and block magnets typically radiate magnetic force in all directions. In contrast, pot magnets focus their magnetic strength on one side, resulting in higher pull forces for clamping applications.

Adhesive magnets rely on glue for attachment and are less robust, while electromagnets require power and generate heat. Pot magnets offer a permanent, energy-efficient solution with simple mounting options and high reliability.

Ongoing research into new magnetic materials and improved manufacturing techniques is driving innovations that enhance the performance and durability of pot magnets. These advancements promise even more compact designs with greater pull forces.

Future designs may see pot magnets integrated with sensors to monitor performance, temperature, and wear. This smart integration can facilitate predictive maintenance and enhance safety in critical applications.

With a growing emphasis on eco-friendly manufacturing, future developments are likely to include more sustainable production methods. Enhanced customization options through advanced CAD and rapid prototyping will further tailor pot magnets for specific applications.

Always follow safety protocols when handling high-strength magnets:

In specialized applications—such as medical or aerospace—adhere to strict safety and handling guidelines to prevent accidental damage or interference. Always consult industry-specific standards when incorporating pot magnets into sensitive systems.

Pot magnets represent a fusion of smart design and advanced material science, offering a robust, reliable solution for a wide range of applications. Their construction—featuring a high-performance magnetic core encased in a protective steel pot—enables a concentrated pull force that surpasses that of conventional magnets.

With diverse material options and design variations, pot magnets serve both industrial and home applications—from heavy-duty assembly and tool organization to innovative DIY projects. As technology continues to advance, future trends such as smart integration, sustainable production, and enhanced customization will further elevate their role in various industries.

By understanding the principles, advantages, and practical considerations of pot magnets, engineers, designers, and hobbyists can make informed decisions that optimize performance, safety, and longevity. Whether securing industrial components or creating modern home solutions, pot magnets continue to be an indispensable tool in the modern age.

A pot magnet is a permanent magnet enclosed in a pot- or cup-shaped ferromagnetic casing that protects the magnet and focuses its magnetic field on one face.

They work by channeling the magnetic flux through the steel casing, which minimizes the air gap and concentrates the magnetic pull on the exposed face for enhanced clamping force.

Pot magnets are typically made with magnetic cores such as neodymium (NdFeB), ceramic (ferrite), AlNiCo, or samarium cobalt (SmCo) and are encased in steel or ferritic stainless steel.

They are widely used for industrial clamping, tool holding, mounting signs and panels, organizing kitchen tools, and even specialized applications in medical or aerospace equipment.

Yes, the design of pot magnets enhances the effective pull force by focusing the magnetic field on a single surface, making them stronger for clamping applications compared to a bare magnet of the same size.

Consider factors such as the required pull force, the material of the magnet, environmental conditions (like temperature and corrosion), and mounting options (e.g., threaded or countersunk designs).

Standard neodymium pot magnets typically operate up to about 80°C, but high-temperature variants or other materials like AlNiCo and SmCo can be used in hotter environments.

They should be mounted on clean, smooth ferromagnetic surfaces to minimize air gaps, and secure fastening methods such as screws or bolts should be used if available.

Regularly inspect them for signs of wear, corrosion, or physical damage. Keep the mounting surface clean and ensure proper storage when not in use.

Yes, many manufacturers offer custom pot magnets with specific dimensions, thread configurations, or coatings to meet unique application requirements.

Pot magnets produce strong magnetic fields that can interfere with electronic devices, so they should be kept at a safe distance from sensitive equipment.

Always handle them carefully with protective gear, keep them away from children and electronic devices, and store them with keeper plates or non-magnetic separators to avoid accidental snapping or damage.