- Custom Magnets

- Standard Magnets

- Mounting Magnets

- Magnetic Assemblies

- About Us

- Knowledge

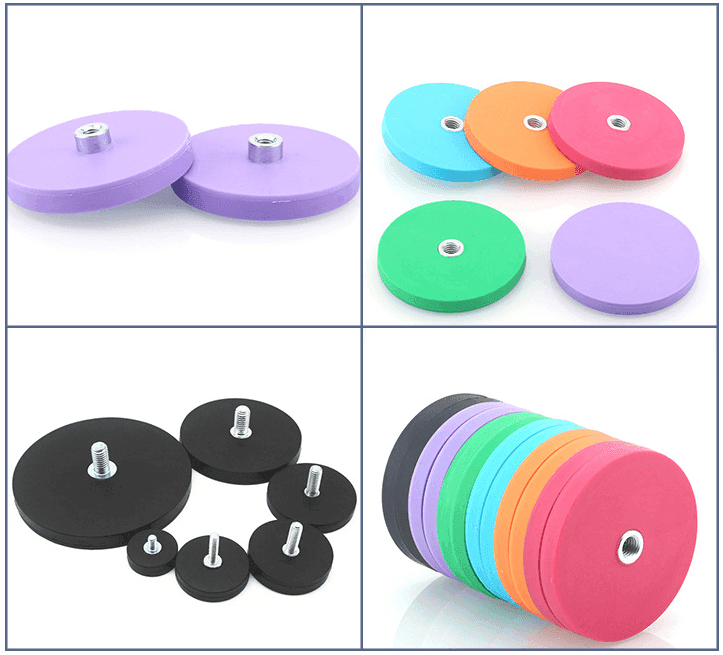

Rubber-coated magnets are magnets encased in a layer of rubber or plastic material (TPR). This coating serves several purposes, such as holding LED lights, protecting surfaces, and adding functionality and protection to the magnet. The cover can also help reducing sliding and water-proof. To ensure strong attraction, MagnetsTek only uses the powerful Neodymium Magnets inside.

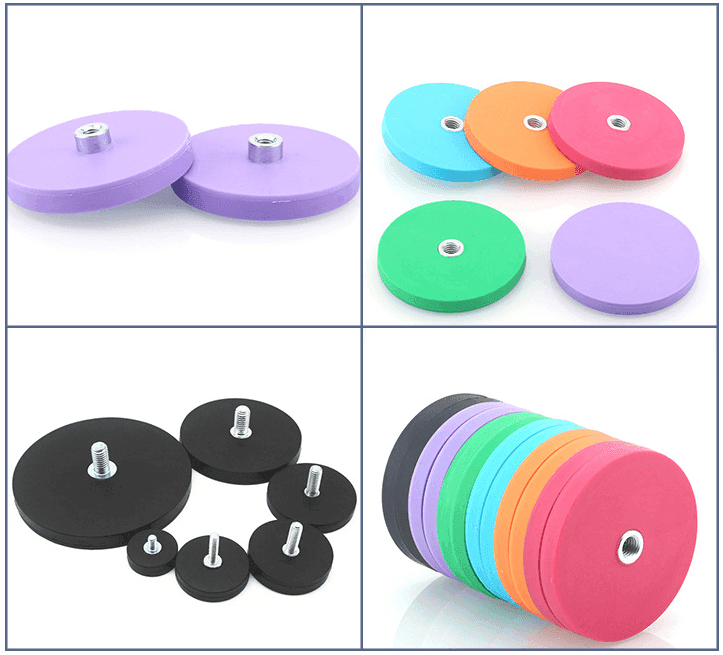

Rubber-coated magnets are used in many holding applications. MagnetsTek provides various custom services, including options for materials, sizes, colors, threading, and more.

| Material | Neodymium Magnet + A3 Steel Bracket + Rubber / TPR Cover |

| Color | Black, White, Grey, Red, Yellow, Blue, Green, … |

| Shape | Round, Rectangular, or Customized |

| Size (mm) | Diameter 12/18/22/28/31/34/36/43/57/66/88/135mm, or Customized |

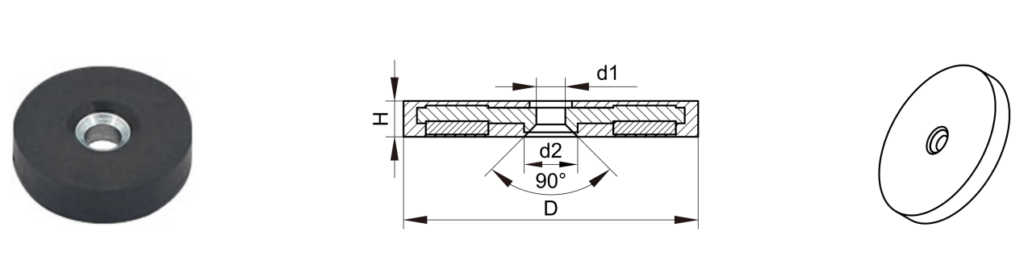

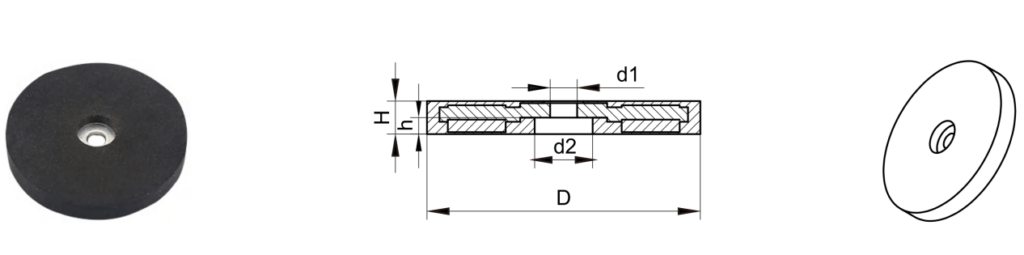

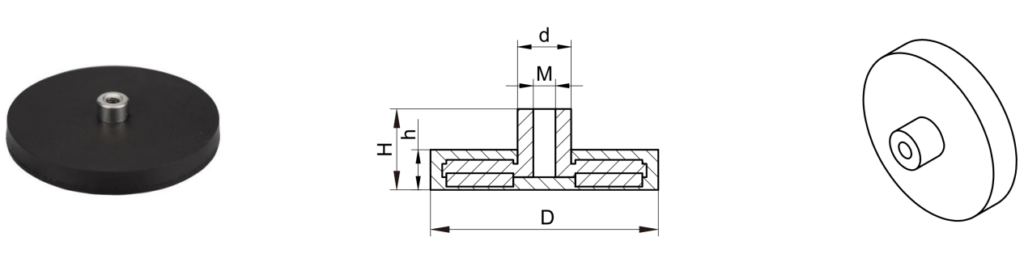

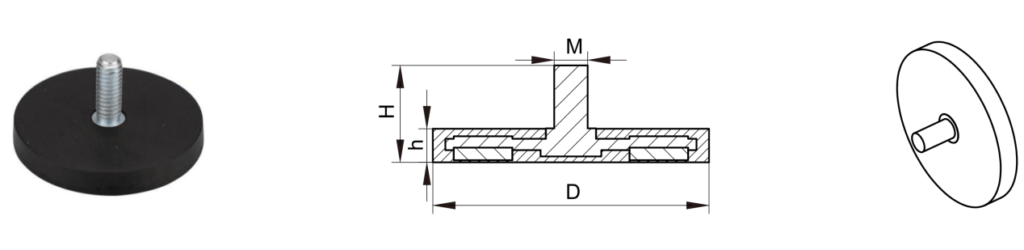

| Connection | Straight Hole, Screwfix Hole, Outer Thread, Inner Thread, Flat Inner Thread |

| Thread | M3~M12, 1/4-20, 6-32, 8-32, 10-24, 12-24, 3/8-16 (Metric & Imperial) |

| Advantages | Surface Protection, Anti-Slip, Water-Proof, Corrosion Resistance, Noise Reduction, Vibration Dampening |

| Model | D | d1 | d2 | H | Weight | Pull-off Force |

|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (g) | (kg) | |

| STA22 | 22 | 4.5 | 8.6 | 6 | 8 | 2 |

| STA34 | 34 | 4.5 | 8.6 | 8 | 20 | 6 |

| STA43 | 43 | 4.5 | 8.6 | 6 | 27 | 9 |

| Model | D | d1 | d2 | h | H | Weight | Pull-off Force |

|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (g) | (kg) | |

| STB22 | 22 | 4.5 | 8.6 | 3 | 6 | 8 | 2 |

| STB34 | 34 | 4.5 | 8.6 | 4 | 8 | 20 | 6 |

| STB43 | 43 | 4.5 | 8.6 | 3 | 6 | 27 | 9 |

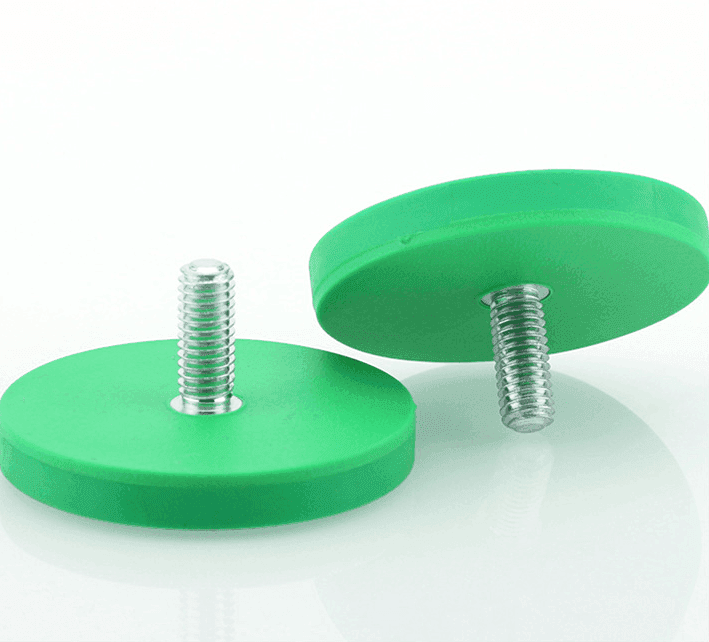

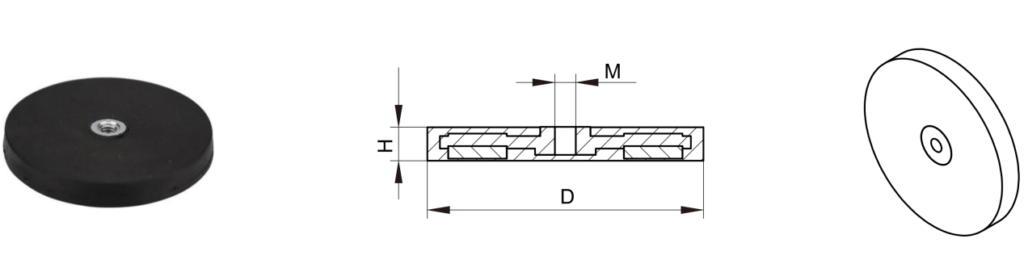

| Model | D | d | h | H | Thread | Weight | Pull-off Force |

|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | M | (g) | (kg) | |

| STD22 | 22 | 8 | 6 | 11.5 | M4 | 12 | 4.5 |

| STD34 | 34 | 8 | 6 | 12 | M4 | 22 | 6 |

| STD43 | 43 | 8 | 6 | 12 | M4 | 33 | 8 |

| STD66 | 66 | 12 | 8 | 14.2 | M5 | 104 | 20 |

| STD88 | 88 | 12 | 8.5 | 15.8 | M8 | 200 | 42 |

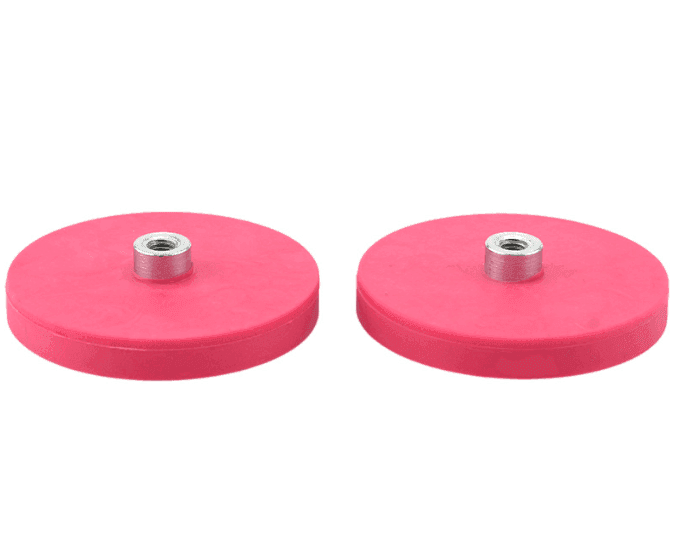

| Model | D | h | H | Thread | Weight | Pull-off Force |

|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | M | (g) | (kg) | |

| STC22 | 22 | 6 | 12.5 | M4 | 14 | 4.5 |

| STC34 | 34 | 6 | 14.5 | M4 | 25 | 6 |

| STC43 | 43 | 6 | 21 | M6 | 32 | 8 |

| STC66 | 66 | 8 | 23 | M8 | 107 | 20 |

| STC88 | 88 | 8.5 | 24.5 | M8 | 193 | 42 |

| Model | D | H | Thread | Weight | Pull-off Force |

|---|---|---|---|---|---|

| (mm) | (mm) | M | (g) | (kg) | |

| STP22 | 22 | 6 | M4 | 11 | 3 |

| STP34 | 34 | 6 | M4 | 20 | 6 |

| STP43 | 43 | 6 | M4 | 29 | 8 |

| STP66 | 66 | 8 | M6 | 100 | 20 |

| STP88 | 88 | 8.5 | M8 | 186 | 42 |

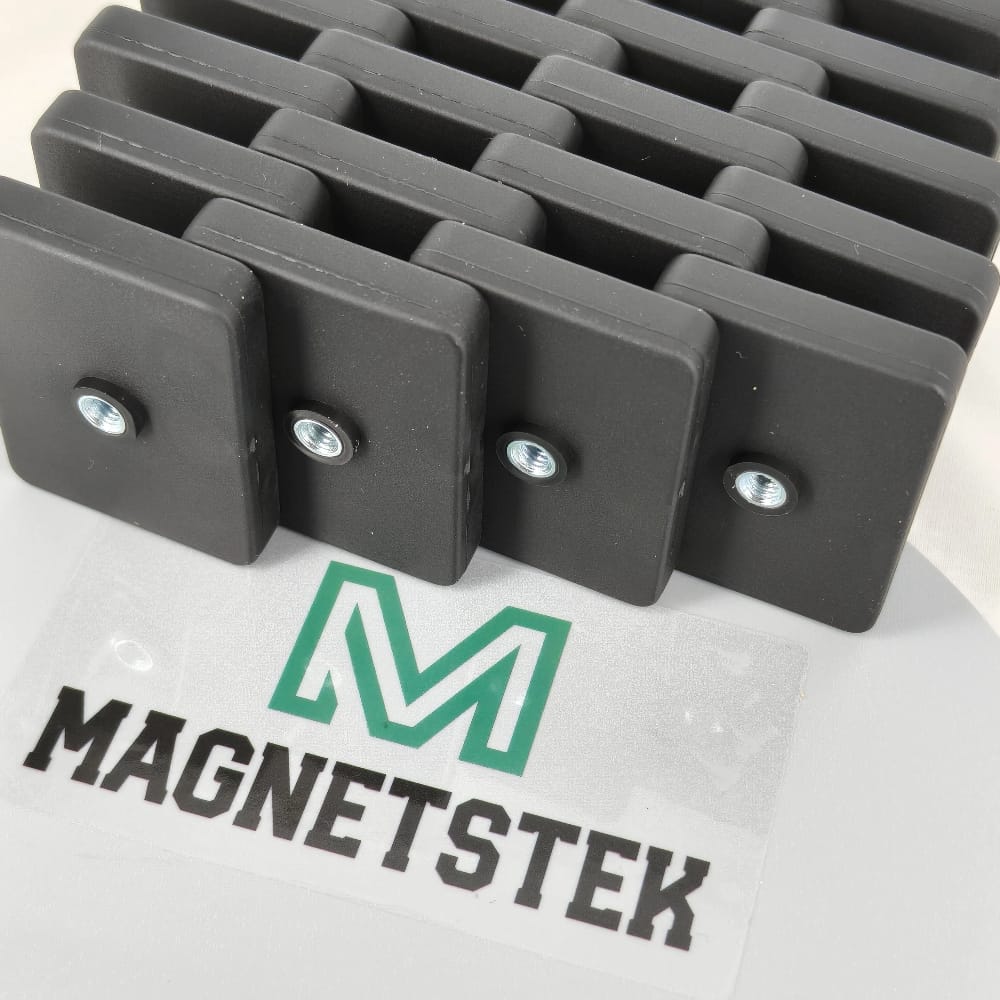

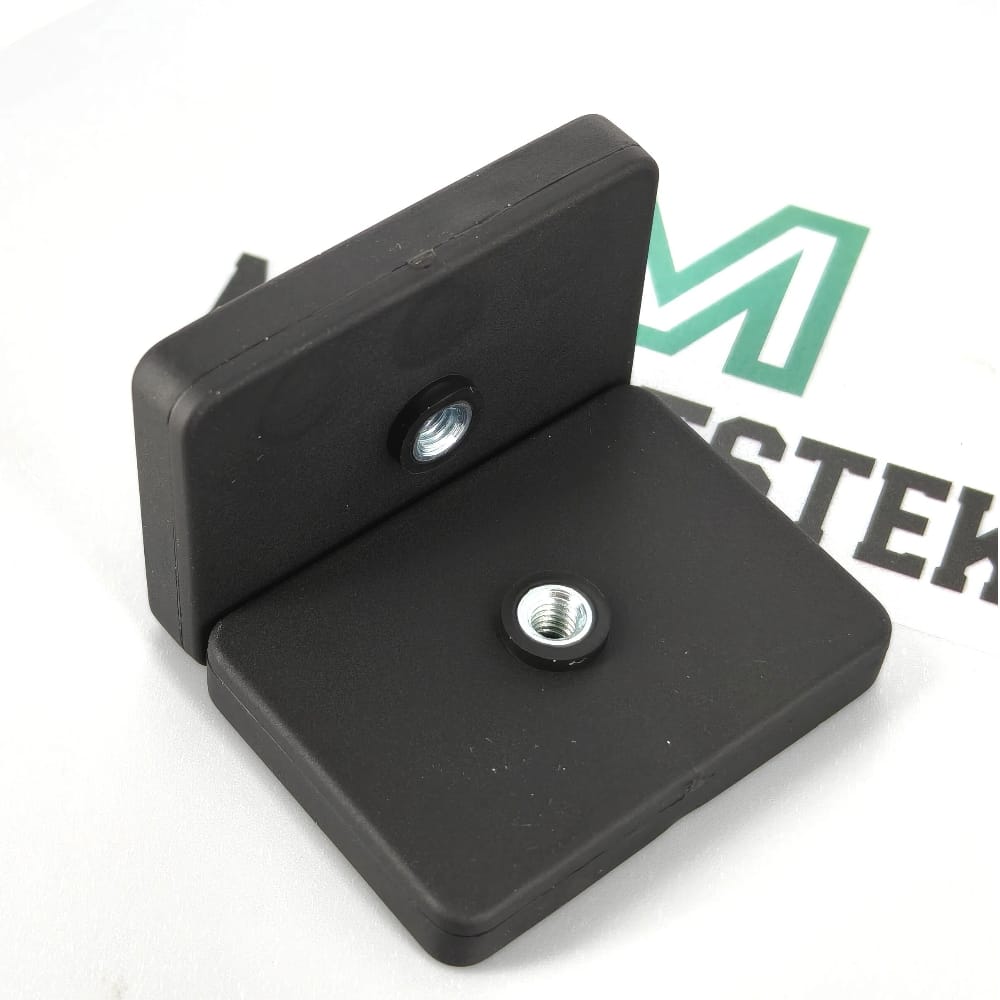

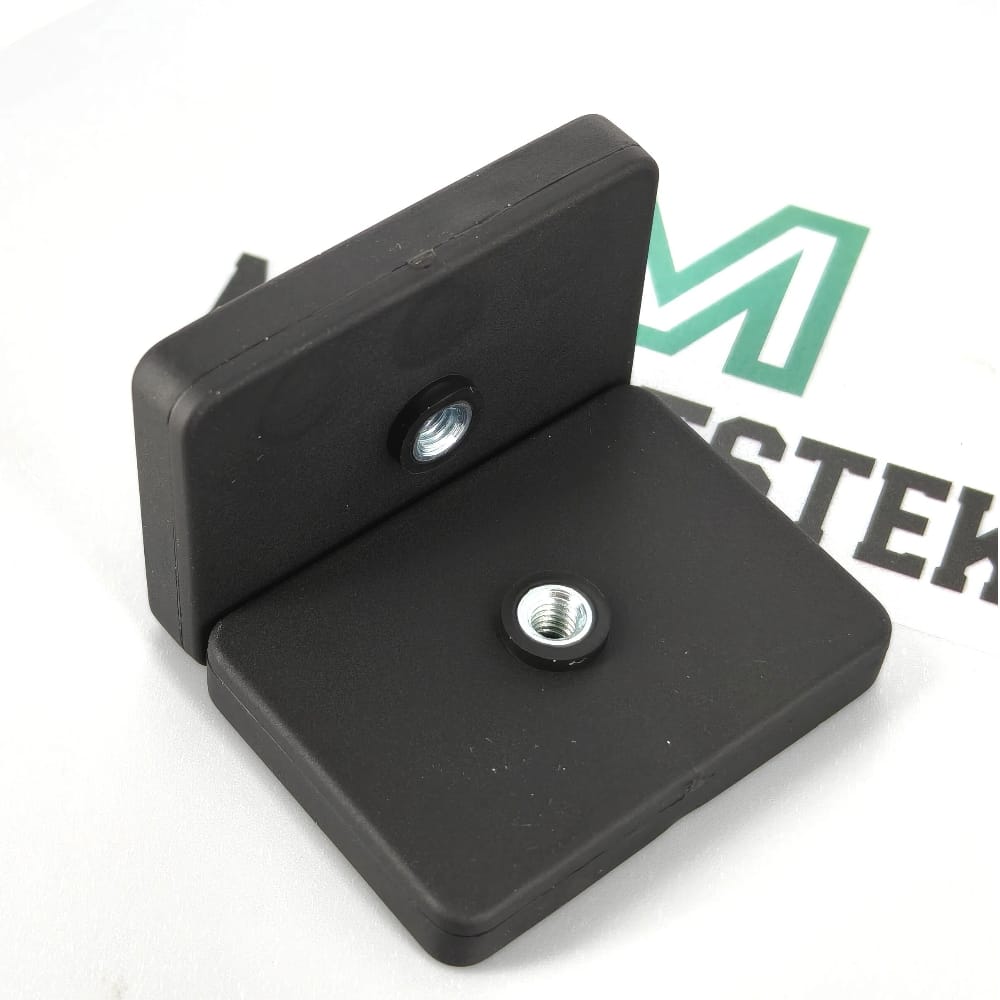

| Material | NdFeB Magnet + Rubber / TPR |

| Color | Black, White, Grey, Red, Yellow, Blue, Green, … |

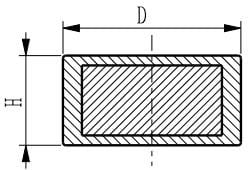

| Shape | Rectangular |

| Size | Tailored Size |

| Connection | Straight Hole, Screwfix Hole, Outer Thread, Inner Thread, Flat Inner Thread |

| Thread | M3~M12, 1/4-20, 6-32, 8-32, 10-24, 12-24, 3/8-16 |

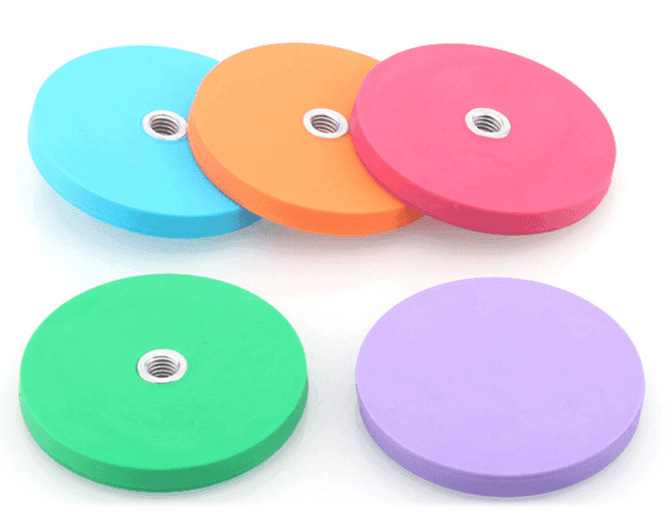

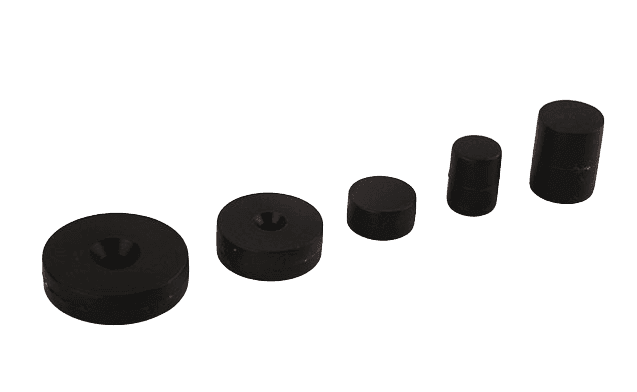

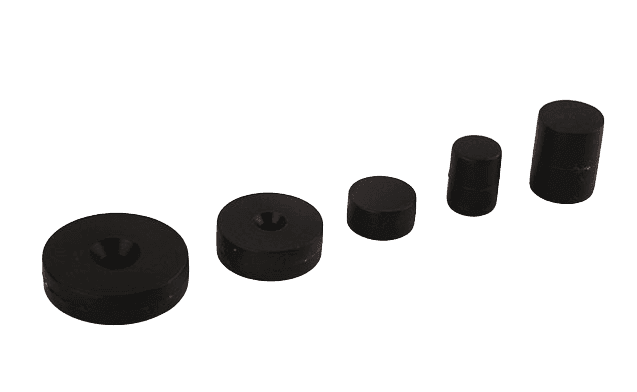

| Material | NdFeB Magnet + Rubber / TPR |

| Color | Black, White, Grey, Red, Yellow, Blue, Green, … |

| Shape | Round, Disc, Button, With/Without Hole |

| Size | Tailored Sizes |

| Connection | Straight Hole, Screwfix Hole, Outer Thread, Inner Thread, Flat Inner Thread |

| Thread | M3~M12, 1/4-20, 6-32, 8-32, 10-24, 12-24, 3/8-16 |

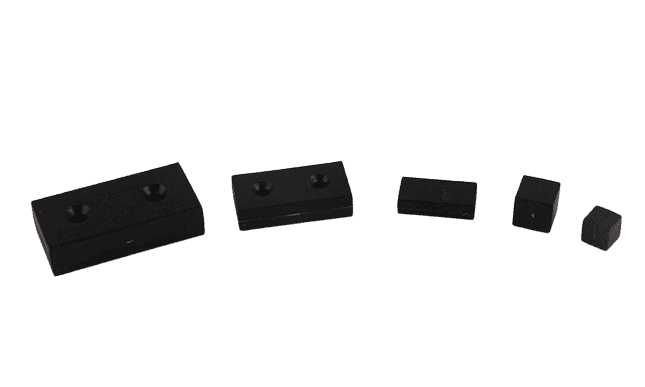

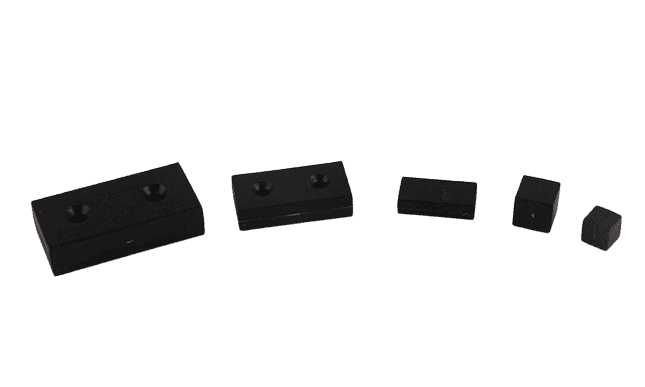

| Material | NdFeB Magnet + Rubber / TPR |

| Color | Black, White, Grey, Red, Yellow, Blue, Green, … |

| Shape | Rectangular, Block, Bar, Cube, With or Without Hole(s) |

| Size | Tailored Sizes |

| Connection | Straight Hole, Screwfix Hole, Outer Thread, Inner Thread, Flat Inner Thread |

| Thread | M3~M12, 1/4-20, 6-32, 8-32, 10-24, 12-24, 3/8-16 |

One size of Diameter 12.7mm * Height 6.35mm (Dia.1/2”*1/4”), 8-color options, with the weight of 4 grams, the button can fix up to 12 sheets A4 paper

Protection and Durability

The rubber coating provides a protective layer that helps prevent the magnet from chipping, scratching, or damaging delicate surfaces. It adds durability and extends the lifespan of the magnet.

Anti-Slip

The rubber coating can provide a non-slip surface, making the magnet easier to handle and reducing the risk of slippage when used on smooth or vertical surfaces.

Corrosion Resistance, Water-Proof

Rubber-coated magnets are often more resistant to corrosion than exposed metal magnets. This is particularly beneficial for outdoor or humid environments. Fully coated magnets are also 100% water-proof.

Noise Reduction

The rubber layer can dampen the noise produced when magnets come into contact with metal surfaces, making them suitable for applications where noise reduction is essential.

Vibration Dampening

The rubber coating helps dampen vibrations, making rubber-coated magnets suitable for applications where stability and reduced movement are crucial.

Rubber-coated magnets are used in industrial settings for applications like holding and securing metal parts or tools without scratching surfaces.

Rubber-coated magnets are used in displays to hold signs securely without damaging the surface or leaving marks.

Rubber-coated magnets are commonly used in magnetic mounts for holding various items, such as lights, cameras, or tools, without causing damage to the mounting surface.

Rubber-coated magnets are used for fridge magnets, providing a protective layer that prevents scratching or marring the surface of the appliance.

In workshops or garages, rubber-coated magnets are used in magnetic tool holders to secure tools without damaging their surfaces.

Rubber-coated magnets are used in educational settings for activities that involve arranging magnets on whiteboards or other surfaces without causing damage.

Rubber-coated magnets can be used for various organizational purposes, such as holding notes, keys, or small items on magnetic surfaces without leaving marks.

Rubber-coated magnets are used in magnetic vehicle signs, providing a protective layer and preventing damage to the vehicle’s finish.

MagnetsTek invests heavily in product development annually, distinguishing us from other suppliers in the industry.