- Custom Magnets

- Standard Magnets

- Mounting Magnets

- Magnetic Assemblies

- About Us

- Knowledge

AlNiCo magnets, short for Aluminum-Nickel-Cobalt magnets, are a type of permanent magnet known for their excellent temperature stability and corrosion resistance. AlNiCo delivers impressive flux density at an economical price. Alnico magnets are also inherently corrosion-resistant.

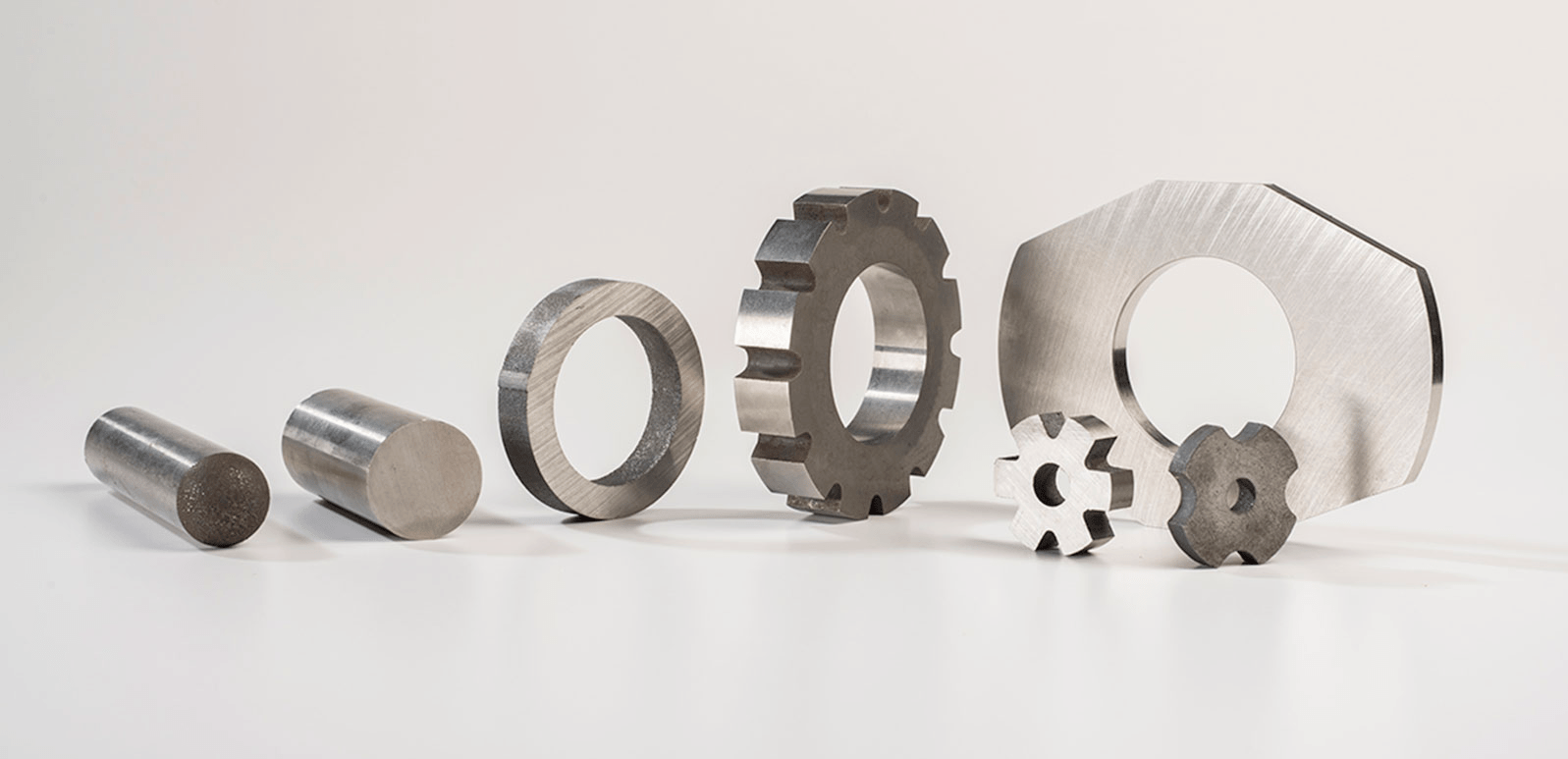

Magnetstek Engineering offers a complete line of cast and sintered AlNiCo products, including:

We at Magnetstek Engineering can manufacture your assembly –house, making both the magnetic and non-magnetic components, and assemble these parts, allowing you to receive a completed sub-assembly. We can also work with your component suppliers and our own to develop the most cost-effective solution to your needs.

Feel free to talk to our expert team for further assistance.

Alnico permanent magnets are made up of alloys whose significant constituents are iron, aluminum, nickel, and cobalt, though other elements (e.g., copper and titanium) may be included in minor amounts. Grades of Alnico vary in cobalt content, which ranges from zero (Alnico 3) to 40% (Alnico 8). Lower grades (1, 2, 3, and 4) are unoriented, whose magnetic properties are isotropic and equal in all directions. Their magnetic output is relatively low. Anisotropic grades (Alnico 5, 6, 8, and 9) are designed to produce high magnetic production in a specified direction. Orientation is achieved during heat treatment by cooling the product from about 1093° C (2000° F) at a controlled rate within a magnetic field that conforms to the preferred magnetization direction.

Alnico 5, the most widely used grade, delivers energy to a magnetic circuit more economically than any other Alnico grade. Alnico 8 possesses the highest coercive force of all Alnico grades, excellent energy per unit volume, and a low reversible temperature coefficient. It is recommended for applications exposed to demagnetizing solid fields or where space considerations dictate a short magnetic length.

The most efficient use of Alnico requires that it be magnetized after the magnet has been assembled with its Pole pieces in the final magnetic circuit. Shipping the product non-magnetized also eliminates the need for special packaging and prevents contamination by stray iron chips, etc. Magnetic saturation at the end-use location requires the application of a magnetizing force 4 to 5 times greater than the coercive force of the material. For Alnico 5, a magnetizing force of 3000 oersteds (240 KA/m) is recommended. For Alnico 8, the magnetizing force should be at least 7000 oersteds (560 KA/m). The magnetizing force needs to be applied only momentarily. Thus, impulse magnetizers employing a capacitor discharge are commonly used. Direct current magnetizers are also effective.

Alnico magnets offer excellent stability concerning temperature changes: reversible change is 0.02% per degree Centigrade. Heating may produce an irreversible loss of magnet strength. The magnitude of loss depends upon the dimensions of the magnet and its composition but is usually less than 5% and may be recovered by remagnetization. At temperatures exceeding 1000° F (538° C), a metallurgical change takes place, which causes magnetic strength to reduce rapidly. This change will not be recovered by remagnetization.

External magnetic fields can also induce partial demagnetization. In some critical applications, it is desirable to stabilize the magnet by intentionally reducing magnetic output by 5% to 10%. Such stabilization may reduce or even eliminate the effect of stray external fields.