Introduction

Neodymium magnets, also known as NdFeB or rare-earth magnets, have fundamentally transformed the landscape of modern engineering. Owing to their [1], compactness, and versatility, [2] are now embedded in a multitude of advanced technologies spanning automotive, aerospace, medical, mechanical, railway, renewable energy, electronics, and everyday office uses. This article provides a comprehensive exploration into the applications, customization, technical considerations, and future trends of [2], drawing on industry-leading practices and real-world engineering demands.

1. Understanding Neodymium Magnets

1.1 Composition and Core Properties

Neodymium magnets are composed primarily of neodymium, iron, and boron, forming the crystalline structure Nd2Fe14B. This structure is responsible for their remarkable magnetic energy product, which far surpasses that of conventional magnets such as ferrite or AlNiCo. Key properties include:

- Exceptional magnetic strength (up to 1.4 Tesla)

- Compact size-to-force ratio

- High coercivity and remanence

- Customizable shapes, sizes, and magnetization directions

- Sensitivity to corrosion (often addressed via coatings)

- Operational temperature limits, with variants available for higher temperature stability

1.2 Types of Neodymium Magnets

NdFeB magnets are available in two primary forms:

- Sintered Neodymium Magnets: Highest energy density and strength; used in motors, MRI, and demanding industrial applications.

- Bonded Neodymium Magnets: Created via powder and resin bonding; offer design flexibility for complex shapes, multi-pole configurations, and miniaturized components (e.g., sensors, micro-motors).

1.3 Customization Options

Custom neodymium magnets can be tailored according to:

- Shape: Discs, blocks, rings, arcs, spheres, cylinders, custom geometries

- Size: From microns (micro magnets) to centimeters (large assemblies)

- Grade: N35 to N56, with higher grades offering greater strength

- Coating: Nickel-copper-nickel (NiCuNi), zinc, gold, black epoxy, PTFE, and more for corrosion resistance

- Magnetization Direction: Axial, radial, diametric, or custom orientations

- Operating temperature: Standard up to 80°C, high-temperature grades up to 230°C or more

2. Automotive Industry Applications

2.1 Revolutionizing Electric Mobility

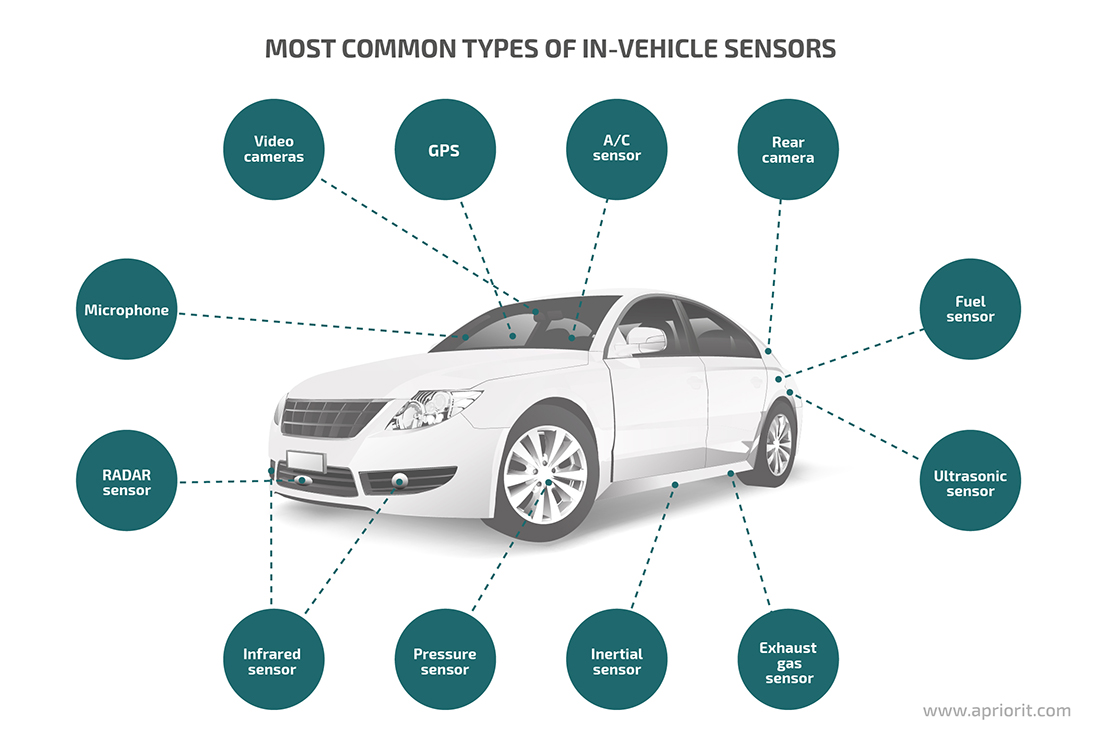

The automotive sector stands as one of the most dynamic adopters of custom [1]. With the global shift towards electric vehicles (EVs) and hybrid electric vehicles (HEVs), the demand for high-performance magnets is soaring. : Neodymium magnets are critical in permanent magnet synchronous motors (PMSMs), which provide high torque density, efficiency, and compactness. These motors drive EV propulsion, power steering, window mechanisms, and seat adjusters. Regenerative Braking Systems: Custom magnets enable the conversion of kinetic to electrical energy, improving vehicle energy efficiency and range. Sensors and Actuators: Hall effect sensors, wheel speed sensors (for ABS), throttle and position sensors, and actuators for automatic doors and windows all utilize custom-shaped [1]. Audio Systems: High-fidelity in-car speakers and microphones rely on small yet powerful [1] for superior sound clarity. Magnetic Couplings: Used for contactless torque transmission in pumps and fans, enhancing reliability and reducing maintenance.

2.2 Advantages in Automotive Engineering

- Enables downsizing of components without compromising power

- Improves energy efficiency and vehicle range

- Enhances sensor accuracy and responsiveness

- Reduces noise and vibration in electromechanical systems

- Supports innovative features such as wireless charging and magnetic mounting

3. Mechanical Engineering Applications

3.1 Powering Industrial Machinery

Custom neodymium magnets are foundational in mechanical engineering due to their ability to provide robust, reliable, and precise magnetic fields in compact packages.

- Electric Motors and Generators: From factory automation to robotics, servo motors, and CNC equipment, neodymium magnets are integral for high power density and fast response.

- Magnetic Couplings and Drives: Employed in pumps, mixers, and agitators where leak-proof operation and corrosion resistance are critical (e.g., chemical processing, food industry).

- Permanent Magnetic Chucks: Used for secure, vibration-free workholding in machining, grinding, and welding processes.

- Magnetic Bearings: Enable frictionless, maintenance-free rotation in high-speed turbines and precision machinery.

- Linear Actuators: Neodymium magnets allow for compact, high-force linear motion solutions in automation and robotics.

- Magnetic Separators: Custom-designed neodymium magnet assemblies efficiently remove ferrous contaminants in recycling, mining, and food processing.

3.2 Advantages for Mechanical Systems

- High holding force and stability

- Reduces mechanical wear and extends machine life

- Precision and repeatability in automated processes

- Enables compact, lightweight equipment design

- Facilitates innovative non-contact solutions

4. Medical Equipment and Healthcare Applications

4.1 Magnetic Resonance Imaging (MRI) and Diagnostics

Medical imaging and diagnostics have reached new heights of accuracy and reliability with the integration of custom neodymium magnets.

- MRI Machines: High-grade, custom-shaped neodymium magnets generate strong, stable magnetic fields required for high-resolution imaging of soft tissue structures. Advanced designs enable open MRI systems and portable imaging devices.

- Nuclear Magnetic Resonance (NMR): Used in spectroscopy and molecular analysis, benefiting from custom magnet arrays for improved sensitivity.

- Magnetic Sensors and Encoders: Enable precise position, motion, and speed feedback in robotic surgery, infusion pumps, and diagnostic tools.

- Magnetic Therapy Devices: Neodymium magnets are incorporated in pain relief and physiotherapy equipment for their targeted, consistent magnetic fields.

- Hearing Aids and Cochlear Implants: Micro-sized neodymium magnets facilitate secure, discreet mounting and signal transmission.

4.2 Medical Industry Requirements and Benefits

- Biocompatible coatings (e.g., gold, PTFE) for safe patient interaction

- Stringent manufacturing and testing standards (ISO, RoHS)

- Enables miniaturization of life-saving medical devices

- Improves diagnostic accuracy and patient comfort

5. Aerospace and Defense Industry Applications

5.1 Pushing the Boundaries of Flight and Security

Aerospace and defense applications demand reliability, high performance, and resistance to extreme environments—areas where custom neodymium magnets excel.

- Actuators and Servo Systems: High-torque, lightweight motors for control surfaces, landing gear, and robotic systems.

- Sensors and Navigation Systems: Precision position and speed sensors in avionics, inertial navigation, and satellite systems.

- Radar and Communication Systems: Custom magnets for high-frequency antennas, magnetic switches, and signal processing equipment.

- Missile Guidance and Defense Electronics: Miniaturized actuators and sensors for accurate targeting and stabilization.

- Ion Propulsion and Submarine Motors: High-efficiency, corrosion-resistant magnets for advanced propulsion and stealth technologies.

- Magnetic Levitation and Suspension: Used in vibration isolation, instrument calibration, and experimental aerospace projects.

5.2 Aerospace-Specific Magnet Challenges

- High-temperature stability and specialized coatings for harsh environments

- Compliance with aerospace quality and safety standards

- Ultra-lightweight, high-strength custom magnet assemblies

6. Railway Industry Applications

6.1 Magnetic Levitation (Maglev) and Beyond

Railway engineering is being redefined by the use of custom neodymium magnets, especially in high-speed and advanced transportation systems.

- Maglev Trains: Neodymium magnets generate strong repulsive forces for frictionless levitation and propulsion, enabling speeds exceeding 500 km/h.

- Linear Motors: Employed in high-efficiency, low-maintenance drive systems for urban transit and automated people movers.

- Railway Sensors: Custom magnet assemblies are integral in track monitoring, speed regulation, and safety systems.

- Door Actuators and Braking Systems: Compact, reliable actuation and energy recovery in train operations.

6.2 Impact on Transportation Engineering

- Reduces wear and tear, lowering maintenance costs

- Enables higher speeds and smoother rides

- Improves safety through precise sensor and actuator feedback

- Supports sustainable, energy-efficient transportation solutions

7. Electronics and Consumer Product Applications

7.1 Enhancing Everyday Life and Technology

The electronics sector is a primary beneficiary of miniaturized, powerful neodymium magnets, driving innovation in consumer and industrial devices.

- Speakers and Headphones: Compact neodymium magnets deliver clear, powerful audio with minimal distortion, enabling lightweight, high-fidelity sound systems.

- Hard Disk Drives (HDDs): Custom magnets precisely actuate the read/write heads, achieving rapid, accurate data access.

- Microphones and Sensors: Miniaturized magnetic components for portable electronics and IoT devices.

- Mobile Devices: Magnetic mounting, wireless charging, and haptic feedback mechanisms rely on innovative magnet integration.

- Smart Wearables: Ultra-small magnets enable secure closures and sensor operation in fitness trackers and medical devices.

- Magnetic Data Storage: Tape drives and other archival technologies benefit from stable, high-strength magnets.

7.2 Advantages for Electronics Manufacturers

- Supports device miniaturization without sacrificing performance

- Customizable shapes for unique form factors and tight tolerances

- Reliable, repeatable performance for mass production

8. Renewable Energy Applications

8.1 Powering a Sustainable Future

Renewable energy systems depend on high-efficiency, long-life magnetic components for power generation and conversion.

- Wind Turbines: Direct-drive and gearless wind turbine generators use large, custom neodymium magnets for high power output and reduced maintenance.

- Hydroelectric Generators: Improved efficiency and reliability in both small-scale and large-scale installations.

- Solar Panel Actuators: Magnetic mechanisms for panel tracking and orientation systems.

- Energy Storage Systems: Advanced battery and flywheel systems employ neodymium magnets for contactless energy transfer and regulation.

8.2 Impact on Renewable Technology

- Enables higher power density and efficiency

- Reduces mechanical losses and increases equipment lifespan

- Facilitates the transition to greener, low-maintenance infrastructure

9. Office, Home, and Daily Life Applications

9.1 From Whiteboards to DIY Projects

Custom neodymium magnets are not limited to heavy industry; they have become fixtures in office, household, and creative settings owing to their strong yet unobtrusive nature.

- Whiteboard Magnets and Pushpins: Securely hold notes, schedules, and documents in offices, classrooms, and conference rooms.

- Magnetic Closures: Used in bags, jewelry, and cases for ease of use and durability.

- Magnetic Hooks and Mounts: For organizing keys, tools, and kitchenware; available in a range of strengths and shapes for different weights and surfaces.

- Crafts and DIY: Magnets facilitate creative projects, model-making, and temporary fixings.

- Retail Displays and Signage: Magnetic mounting systems allow for quick and clean changes in commercial environments.

9.2 Benefits in Everyday Applications

- Easy to install, remove, and reposition

- Safe and reliable for organizing and displaying items

- Supports modern, minimalist design aesthetics

10. Customization Considerations for Engineering Projects

10.1 Selecting the Right Magnet for Your Application

To harness the full potential of neodymium magnets, customization is essential. Key factors to consider include:

- Size and Shape: Determine based on required holding force, available space, and integration with other components.

- Grade and Strength: Select the magnetic grade (e.g., N35-N56) according to the desired field strength, operating temperature, and cost constraints.

- Coating and Finish: Choose coatings that offer the necessary protection against corrosion, wear, or chemical exposure (e.g., NiCuNi, black epoxy, PTFE).

- Operating Environment: Account for temperature extremes, humidity, vibration, and regulatory requirements (medical, aerospace, etc.).

- Magnetization Direction: Align with application needs—axial, radial, or custom orientations.

- Integration Method: Consider assembly (e.g., press-fit, adhesive, mechanical fastening), proximity to sensitive electronics, and demagnetization risks.

- Certifications: For critical industries, ensure compliance with ISO, RoHS, and relevant medical or aerospace standards.

10.2 Tips for Maximizing Performance and Lifespan

- Handle with care—neodymium magnets are brittle and can snap if mishandled.

- Store with spacers to prevent accidental attraction and surface chipping.

- Ensure proper alignment during integration to avoid demagnetization or performance loss.

- Apply suitable coatings to extend lifespan in corrosive or humid environments.

- Regular inspection and maintenance in high-wear applications.

11. Safety Considerations in Handling Neodymium Magnets

- Keep away from pacemakers and sensitive medical devices due to strong magnetic fields.

- Avoid placing magnets near magnetic storage media (credit cards, hard drives) to prevent data loss.

- Use gloves and eye protection when handling large or strong magnets to prevent pinching or injury.

- Store magnets in a secure, separated manner to avoid accidental collision.

- Educate personnel on proper handling, especially in industrial environments.

12. Trends and Future Directions in Magnet Engineering

12.1 Innovations in Magnet Design and Manufacturing

The future of custom neodymium magnets is defined by ongoing advances in material science, precision manufacturing, and application-driven design:

- Development of higher-temperature and corrosion-resistant grades

- 3D printing of bonded magnets for complex geometries and rapid prototyping

- Multi-pole and hybrid magnet assemblies for advanced motors and sensors

- Integration into smart systems, IoT devices, and autonomous vehicles

- Eco-friendly magnet recycling and rare-earth recovery programs

- Increased use in renewable energy storage and transmission technologies

12.2 Sustainability and Resource Efficiency

With the rising demand for rare-earth elements, sustainability initiatives are gaining momentum:

- Efforts to reduce neodymium content via optimized magnet design

- Closed-loop recycling processes for end-of-life magnets

- Research into alternative materials and composites

13. Why MagnetsTek Engineering Sets the Industry Standard

MagnetsTek Engineering exemplifies cutting-edge expertise in custom neodymium magnet solutions:

- Over 20 years of experience in rare-earth magnet R&D and manufacturing

- Grades up to N56 and full magnetization up to 120mm thickness

- Advanced coatings and high-temperature options

- ISO9001, ISO/TS16949 certified, RoHS compliant

- Professional team of engineers and PhDs for expert consultation

- Rapid prototyping and scalable production capacity

- Global supply chain and industry-leading quality assurance

14. Conclusion: Harnessing the Power of Custom Neodymium Magnets

Custom neodymium magnets represent a pivotal advancement in modern engineering, enabling powerful, compact, and efficient solutions across a spectrum of industries. Their versatility—from automotive propulsion and medical imaging to aerospace navigation and consumer electronics—continues to drive technological progress and innovation. By leveraging tailored magnet design, advanced materials, and best practices in integration, engineers and manufacturers can realize next-generation products that are smarter, safer, and more sustainable.

To fully unlock the potential of neodymium magnets, collaboration with experienced magnet manufacturers and experts is essential. This ensures that every application benefits from optimized performance, reliability, and longevity, positioning custom neodymium magnets as foundational to the future of engineering.

“`