Introduction

Cryogenic magnetization and low temperature magnet assemblies represent the cutting edge of modern magnetic technology. These advanced assemblies are fundamental to high-precision applications in scientific research, medical imaging, industrial automation, transportation, and energy systems. This article explores the science, engineering, materials, manufacturing, and applications of cryogenic magnetization and low temperature magnet assemblies, providing a comprehensive guide for engineers, researchers, and decision-makers.

Understanding Magnetism and Magnet Assemblies

To appreciate the challenges and opportunities in cryogenic magnetization, it’s essential to understand the basics of magnetism and magnet assemblies.

Principles of Magnetism

Magnets generate a magnetic field due to the alignment of magnetic moments in their atomic structure. The strength, direction, and stability of this field depend on the material’s composition and treatment. Magnetic assemblies combine magnets—permanent or electromagnets—with other materials (such as steel housings or plastic holders) to optimize performance, durability, and integration into larger systems.

Types of Magnet Assemblies

- Permanent Magnet Assemblies: Combine rare earth or ferrite magnets with housings for enhanced field strength and mechanical protection.

- Electromagnet Assemblies: Use coils and soft-magnetic cores to generate controlled magnetic fields when powered.

- Superconducting Magnet Assemblies: Employ coils made from superconducting wire cooled to cryogenic temperatures to achieve exceptionally strong and stable fields with zero resistance.

- Custom-Shaped Assemblies: Engineered for unique geometric or functional requirements, including Halbach arrays and sensor-specific designs.

The Science of Cryogenic Magnetization

What is Cryogenic Magnetization?

Cryogenic magnetization involves the process of magnetizing materials or operating magnet assemblies at extremely low temperatures, typically below 77 K (liquid nitrogen) and often as low as 4.2 K (liquid helium). At these temperatures, certain materials enter a superconducting state, completely losing electrical resistance and enabling the creation of ultra-strong magnetic fields.

Why Low Temperatures Matter

Operating magnets at cryogenic temperatures unlocks several advantages:

Superconductivity: Materials like niobium-titanium (NbTi) and niobium-tin (Nb3Sn) become superconducting, supporting persistent currents without energy loss.

Higher Magnetic Fields: Resistance-less coils can carry much higher currents, producing stronger, more stable fields.

Thermal Stability: Low temperatures reduce thermal noise and drift, essential for precision applications.

Unique Magnetic Effects: Superconductors exhibit the Meissner effect, expelling magnetic fields and enabling frictionless levitation and bearings.

Materials for Cryogenic Magnetization

- Superconducting Wire: NbTi, Nb3Sn, and MgB2 are standard for superconducting coils.

- Permanent Magnets: NdFeB (Neodymium-Iron-Boron), SmCo (Samarium-Cobalt), AlNiCo, and ferrite magnets each offer specific benefits and limitations at low temperatures.

- Structural Materials: Stainless steel, copper, and specialized composites are used for housings, supports, and thermal management.

Magnetization Techniques at Low Temperatures

- Pulsed Field Magnetization: High-current pulses are used to magnetize superconducting bulks or permanent magnets in situ at cryogenic temperatures.

- Persistent Current Mode: Superconducting coils can be energized and “locked” into a persistent, lossless current loop, maintaining a field indefinitely.

- Field Cooling: Some applications, such as superconducting levitation, involve cooling materials in the presence of an external magnetic field to trap flux lines.

Design Considerations for Low Temperature Magnet Assemblies

Material Selection

The choice of material is crucial for ensuring performance and longevity at cryogenic temperatures.

- NdFeB Magnets: Offer the highest energy product but can suffer from brittleness and irreversible loss if not properly designed for low temperatures.

- SmCo Magnets: Excellent thermal stability, operational up to 600°C and down to cryogenic levels, making them ideal for scientific and aerospace applications.

- Ferrite Magnets: Stable at low temperature but with lower magnetic strength than rare earth magnets.

- Superconductors: Only function in the superconducting state at cryogenic temperatures. Sensitive to mechanical stress and require precise cooling infrastructure.

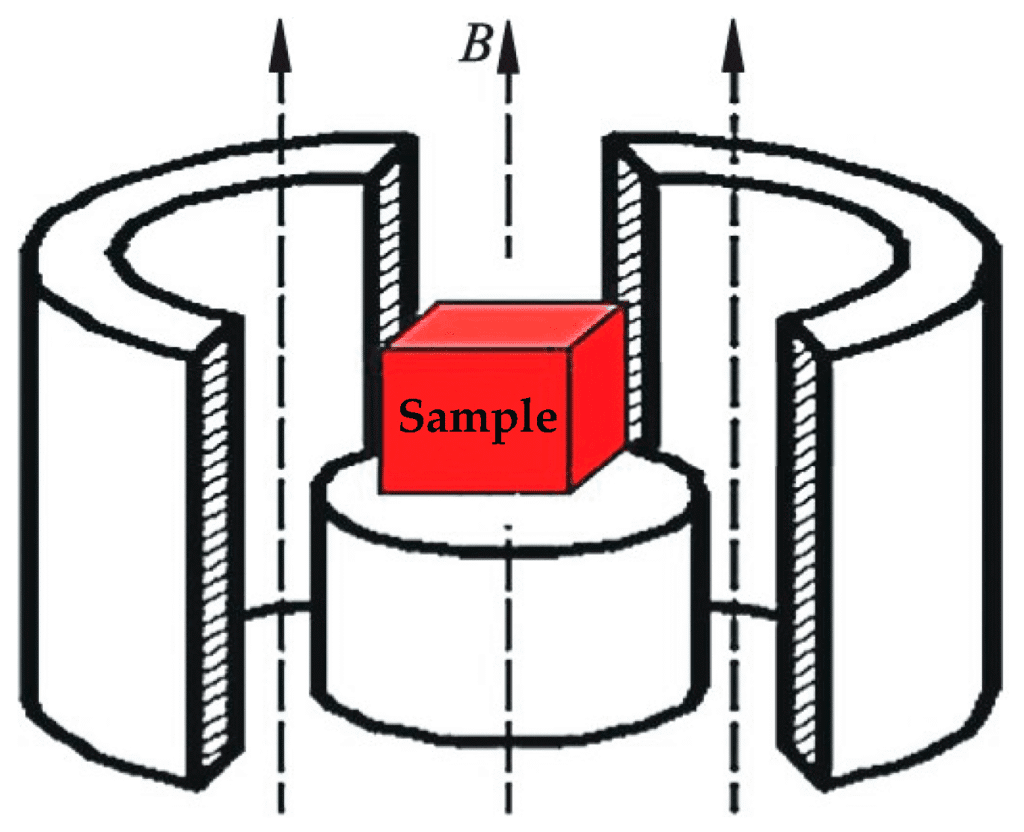

Magnetization Direction

The direction of magnetization (axial, radial, diametric, or multipolar) affects field shape, assembly integration, and performance in the final application. For example, Halbach arrays use specific magnetization orientations to enhance or cancel magnetic fields on particular faces.

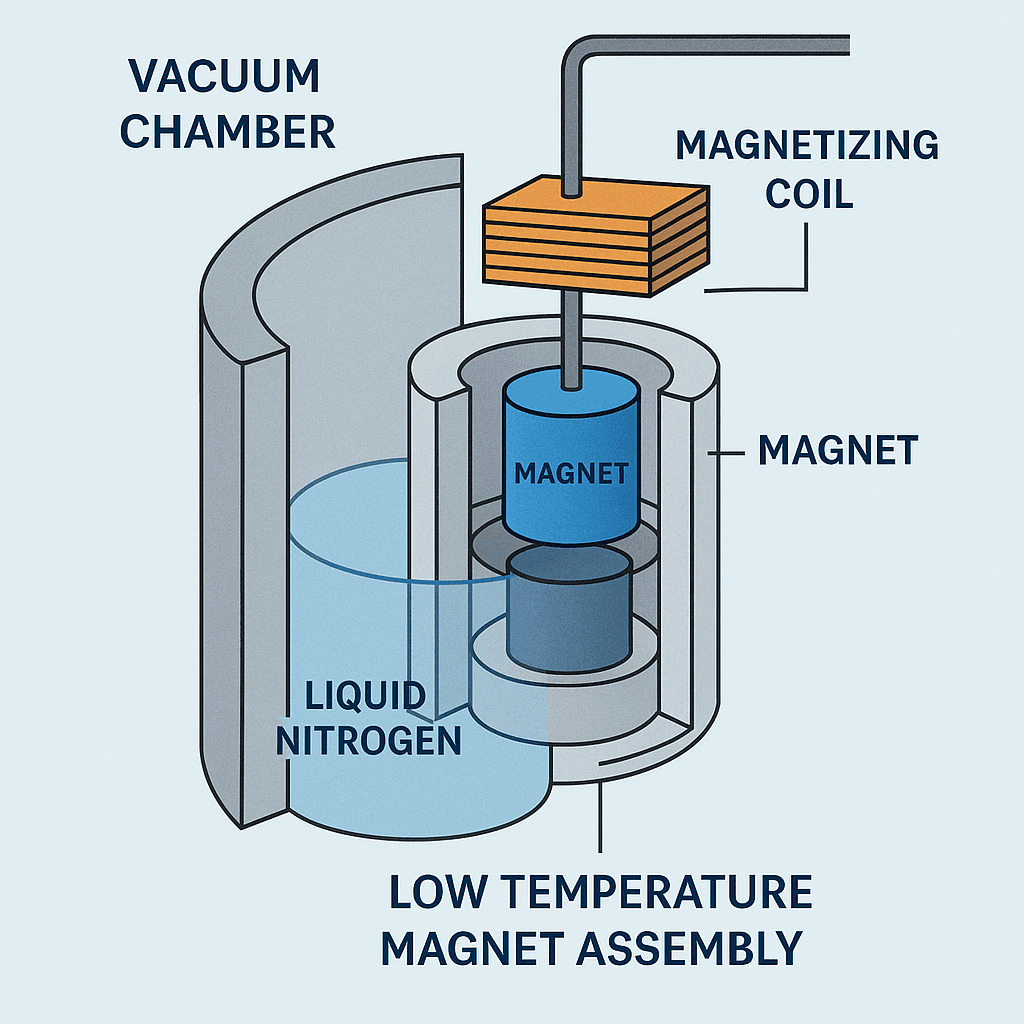

Thermal Management and Cooling

Maintaining uniform cryogenic temperatures is vital. Magnet assemblies often include:

- Vacuum Insulation: Prevents heat transfer from the environment.

- Multi-layer Insulation (MLI): Reduces radiation heat leak.

- Thermal Anchoring: Connects warm and cold parts with minimal thermal conduction.

- Active Cooling Systems: Employ cryocoolers, liquid helium, or nitrogen baths.

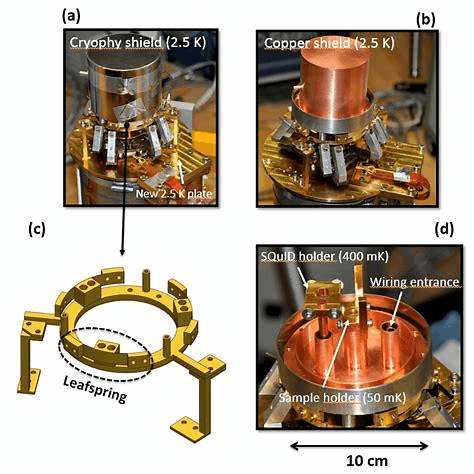

Mechanical and Structural Design

At low temperatures, materials contract and may become brittle. Assemblies must be designed to accommodate thermal contraction, prevent mechanical stress on brittle components (especially superconducting wires and ceramic magnets), and ensure reliable operation over repeated thermal cycles.

Magnetic Shielding

Sensitive environments (such as MRI rooms or quantum computing labs) require careful magnetic shielding to prevent stray fields from affecting nearby equipment or personnel.

Manufacturing Processes for Cryogenic Magnet Assemblies

Machining and Precision Engineering

Manufacturing high-performance magnet assemblies for cryogenic applications demands extraordinary precision:

- Machining Tolerances: Down to 0.005mm, especially for micro-magnets and sensor assemblies.

- Surface Treatments: Protective coatings (e.g., perylene, nickel) are used to prevent corrosion and outgassing in vacuum environments.

- Integration with Non-Magnetic Components: Plastic, ceramics, and composite materials are often used for spacers, supports, and encapsulation.

Assembly and Integration

Magnetstek Engineering offers integrated assembly services:

- Custom Shaping: Magnets can be drilled, milled, or molded into complex geometries for specialized applications.

- Encapsulation: Magnets are housed in non-magnetic or ferromagnetic casings to enhance strength, durability, and field shaping.

- Sensor Integration: Magnets are paired with Hall sensors, reed switches, or other electronic elements for real-time monitoring and feedback.

Quality Control and Testing

Rigorous testing is performed throughout production:

- Magnetic Field Mapping: Ensures field uniformity and strength.

- Cryogenic Cycling: Assemblies are tested under repeated cooling and warming cycles to verify structural integrity and magnetic stability.

- Automated Inspection: Advanced cameras, laser micrometers, magnetic inclination detectors, and particle analyzers ensure compliance with stringent quality standards (ISO9001, ISO/TS16949, RoHS).

Magnetization

Permanent magnets are magnetized using extremely strong pulsed magnetic fields, sometimes after assembly. For superconducting coils, persistent current switches are used to establish and maintain the desired field.

Key Types of Low Temperature Magnet Assemblies

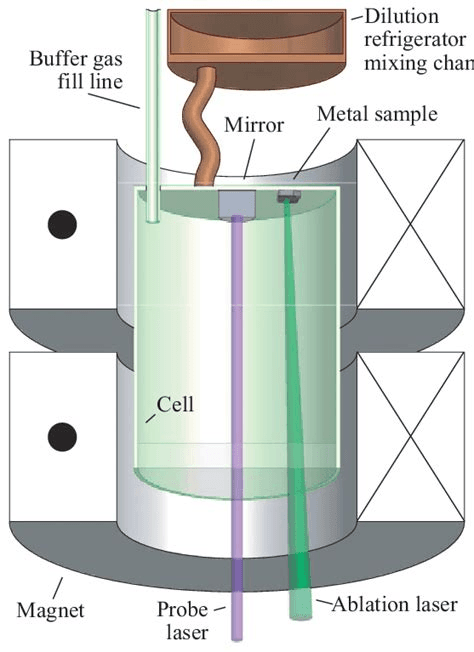

Superconducting Magnet Assemblies

These are at the heart of MRI machines, NMR spectrometers, particle accelerators, and maglev trains. They consist of superconducting wire wound into coils, cooled to cryogenic temperatures, and housed in robust, vacuum-insulated dewars.

- Features: Up to 7T+ fields, persistence without energy input, extreme field uniformity.

- Applications: Medical imaging, scientific research, magnetic separation, maglev transportation.

Halbach Array Magnet Assemblies

Halbach arrays use a specific arrangement of permanent magnets to produce a strong, unidirectional field on one side while cancelling it on the opposite. This is especially beneficial in sensor arrays, motor rotors, and maglev systems.

- Features: Customizable geometry, field direction, and strength; can be implemented with cryogenic-compatible materials.

- Applications: Compact motors, advanced research prototypes, frictionless bearings.

Magnetic Filter Bars and Separators

Used in industrial and scientific environments to separate ferromagnetic materials at low or variable temperatures.

- Features: Customizable length, diameter, magnetic strength (up to 13,500Gs), and housing material (mild steel, ferritic stainless steel).

- Applications: Food processing, pharmaceutical production, cryogenic material handling.

Custom-Shaped and Micro Magnet Assemblies

For extreme miniaturization or specialized applications, magnets can be produced as small as 0.05mm in diameter and 0.1mm thick, with tight tolerances and custom field orientation.

- Features: Micro-magnets for sensors, actuators, or MEMS devices; molded magnets for complex integration.

- Applications: Position sensors, medical devices, aerospace instrumentation.

Applications of Cryogenic Magnetization and Low Temperature Magnet Assemblies

Medical Imaging: MRI and NMR Technologies

MRI (Magnetic Resonance Imaging) relies almost exclusively on superconducting magnet assemblies, which must be cooled to 4.2K with liquid helium. The extremely stable and uniform fields (1.5T–7T+) generated enable high-resolution, non-invasive imaging of soft tissues. Advanced MRI systems may also integrate magnetic levitation for frictionless patient transport or vibration isolation, further improving image clarity.

NMR (Nuclear Magnetic Resonance) spectrometers, essential for chemical analysis and biomolecular research, similarly depend on cryogenically cooled superconducting magnets.

Magnetic Levitation and Frictionless Bearings

Magnetic levitation, enabled by the Meissner effect in superconductors, allows for frictionless bearings, high-speed maglev trains, and vibration-isolated platforms. Cryogenic cooling ensures stable superconducting states, zero energy loss, and long operational life.

- Industrial Automation: Precision transport of fragile components without contact.

- Energy Storage: Flywheel systems with magnetic bearings for lossless energy retention.

Scientific Research and Prototyping

Particle accelerators, fusion reactors, and quantum computing all require high-field, ultra-stable magnetic environments—only possible with cryogenic magnet assemblies.

Industrial and Sensor Applications

- Magnetic Separators: Removing ferrous contaminants in cryogenic environments (e.g., pharmaceutical, chemical industries).

- Sensor Assemblies: Integrating micro-magnets with precision sensors in automotive, aerospace, and process control systems.

- Motor and Generator Rotors: High-efficiency, low-loss operation in high-precision electric motors.

Energy and Sustainability

Low temperature magnet assemblies are increasingly used in wind turbines, energy storage systems, and power generation, where maximizing efficiency and minimizing energy loss are paramount.

Challenges and Engineering Solutions

Thermal Management and Cryogenics

Handling extreme cold requires robust vacuum insulation, multi-layer shielding, and reliable cryocoolers. All materials and joints must withstand thermal cycling without cracking or loss of magnetic properties.

Demagnetization and Stability

At cryogenic temperatures, some magnets (especially certain grades of NdFeB) may become brittle or exhibit altered magnetic properties. Material selection and protective coatings, along with careful design for mechanical stress relief, are essential.

Handling and Safety

Large, powerful magnet assemblies can present serious handling hazards. Automated assembly, robotic manipulation, and stringent safety protocols are implemented to protect workers and equipment.

Miniaturization and Customization

As devices shrink, integrating micro-magnets and sensor assemblies at cryogenic temperatures requires advanced manufacturing techniques, such as laser cutting, micro-molding, and high-precision assembly.

Cost and Sustainability

Cryogenic systems involve significant upfront and operational costs. Research into new superconductors, recycled rare earth materials, and rare-earth-free magnet alternatives is ongoing to improve sustainability and affordability.

Technological Innovations and Future Directions

Advanced Superconductors

The development of higher temperature superconductors (HTS) promises to reduce cooling requirements, making cryogenic magnet assemblies more accessible and cost-effective.

Halbach Arrays and Magnetic Field Engineering

Innovative field shaping (e.g., Halbach arrays) continues to improve efficiency and reduce stray field effects, enabling more compact and powerful systems.

Recycling and Rare Earth Alternatives

New recycling technologies and research into rare-earth-free magnets help address supply chain and environmental concerns.

Integration with Smart Systems

Combining magnet assemblies with real-time sensors, feedback loops, and digital controls enables unprecedented precision in industrial, medical, and research applications.

Best Practices for Design, Manufacturing, and Integration

1. Define Application Requirements

Carefully delineate field strength, homogeneity, direction, temperature range, mechanical loads, and integration needs.

2. Material Selection

Choose the magnet type and grade based on operational temperature, required field, size constraints, and compatibility with other system components.

3. Thermal and Mechanical Design

Design for differential contraction, insulate against heat leaks, and provide robust mechanical support.

4. Magnetization and Field Testing

Ensure correct magnetization direction and field characteristics through advanced testing and mapping.

5. Assembly and Packaging

Use specialized jigs, automated handling, and protective housings for safety and durability.

6. Certification and Quality Assurance

Adhere to industry standards (ISO9001, ISO/TS16949, RoHS) and perform thorough inspection and documentation.

7. Ongoing Support and Maintenance

Provide post-sales service, including monitoring, re-magnetization, and repair as required.

Case Studies: Real-World Implementations

Case Study 1: MRI Superconducting Magnet Assembly

A leading hospital upgrades its MRI suite with a next-generation 7T scanner. Magnetstek Engineering designs and produces a superconducting magnet assembly using NbTi wire, with a field stability of 0.1 ppm over a 60 cm bore. The assembly incorporates multi-layer insulation, persistent current switches, and robust vibration damping. Result: improved image resolution, faster scan times, and reduced operational costs due to zero-resistance coil operation.

Case Study 2: Halbach Array for Industrial Automation

An advanced robotics manufacturer requires a compact, high-strength magnetic array for a frictionless conveyor system operating at -40°C. A custom Halbach array using SmCo magnets and stainless steel housing is developed, providing a unidirectional field of 1.2T and ensuring stable performance across the required temperature range.

Case Study 3: Magnetic Filter Bar for Cryogenic Pharmaceutical Processing

A pharmaceutical plant needs to remove ferrous contaminants from cryogenically cooled product streams. Magnetstek Engineering supplies custom filter bars using NdFeB magnets (Grade N56, 12,000Gs), sealed in ferritic stainless steel housings, ensuring compliance with hygiene and cryogenic stability requirements.

Conclusion: Harnessing the Power of Cryogenic Magnetization

Cryogenic magnetization and low temperature magnet assemblies are transforming industries by enabling unprecedented performance, precision, and efficiency. From MRI machines and maglev trains to quantum computing and advanced manufacturing, this technology is at the forefront of innovation.

Advances in materials science, cryogenics, field engineering, and manufacturing are continually pushing the boundaries—making these assemblies more powerful, accessible, and sustainable. As applications expand and technologies mature, cryogenic magnetization will remain a cornerstone of progress in science, medicine, energy, and industry.

For organizations seeking to leverage these advantages, partnering with experienced manufacturers like Magnetstek Engineering ensures access to expert design, high-quality production, and ongoing support—paving the way for success in the most demanding applications.

Related Products

Halbach Array Magnetic Assemblies