Neodymium magnets, commonly referred to as NdFeB magnets, are renowned for their exceptional magnetic strength and versatility across a broad spectrum of industries—from electronics and automotive to renewable energy and medical devices. However, a fundamental challenge persists: these magnets are highly susceptible to corrosion, particularly when exposed to moisture, chemicals, or harsh environmental conditions. To address this vulnerability and extend their operational lifespan, various protective coatings are applied. The choice of coating not only determines the magnet’s durability and corrosion resistance but also impacts its appearance, cost, and suitability for specific applications.

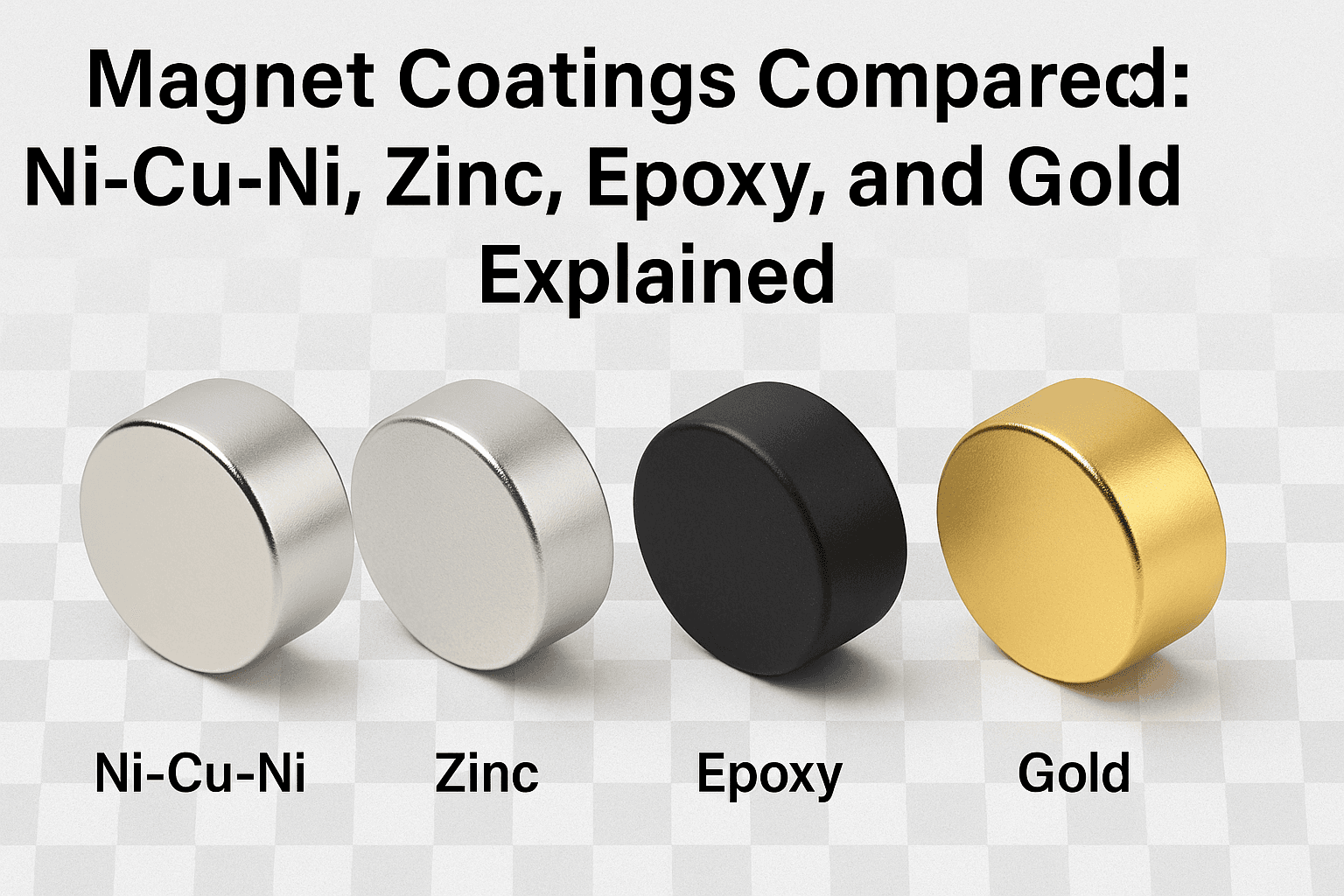

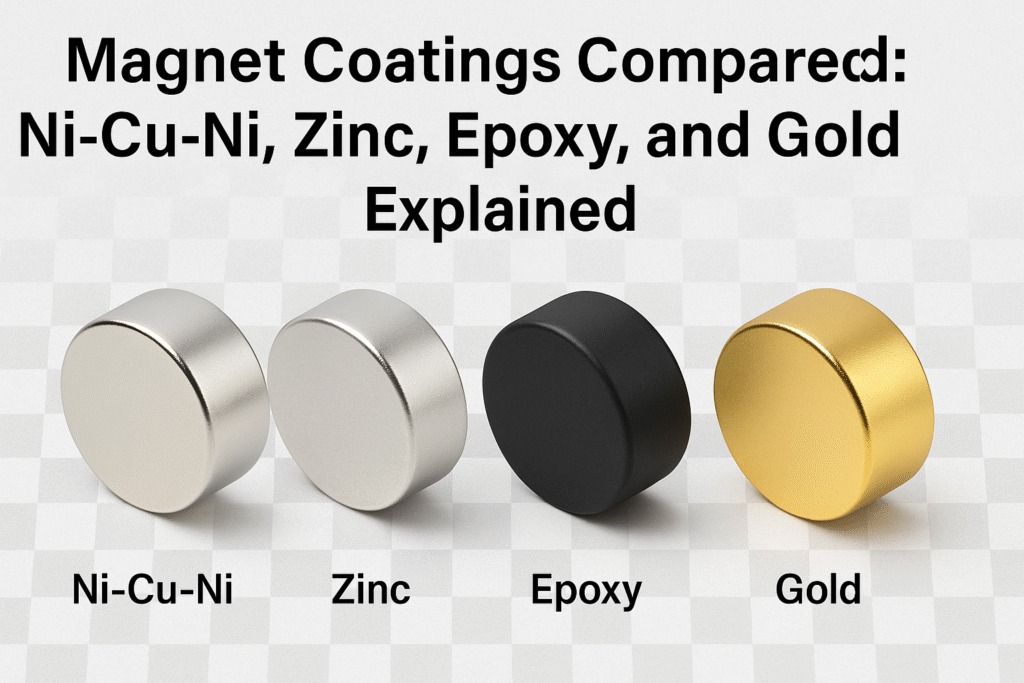

This comprehensive guide examines and compares the most prevalent magnet coating types—Ni-Cu-Ni (Nickel-Copper-Nickel), Zinc, Epoxy, and Gold. We will explore their structures, properties, advantages, disadvantages, and real-world use cases, equipping engineers, designers, and buyers with the knowledge to make informed decisions for any application.

—

1. Why Magnet Coatings Are Essential

1.1 The Corrosion Problem in Neodymium Magnets

Neodymium magnets are composed primarily of neodymium, iron, and boron (NdFeB). While this composition grants them outstanding magnetic properties, it also makes them prone to rapid oxidation—especially the iron component—when exposed to oxygen and moisture. Unprotected, neodymium magnets can rust, degrade, or even disintegrate, leading to loss of magnetic performance and potential system failure.

1.2 Functions of Magnet Coatings

Protective coatings serve several critical functions:

- Corrosion resistance: Preventing oxidation and chemical attack.

- Mechanical protection: Minimizing chipping, cracking, and abrasion.

- Enhanced aesthetics: Improving surface appearance and color for commercial or decorative uses.

- Special functionality: Providing biocompatibility, electrical insulation, or increased friction.

The choice of coating depends on the application’s environment, durability requirements, and cost considerations. Let’s explore the leading options in detail.

—

2. Ni-Cu-Ni (Nickel-Copper-Nickel) Coating

2.1 Structure and Application

Ni-Cu-Ni, the industry’s standard neodymium magnet coating, consists of three distinct metallic layers:

- First nickel layer: Directly adheres to the magnet, providing a smooth base and initial barrier against corrosion.

- Copper interlayer: Offers superior adhesion and additional corrosion resistance, enhancing the overall robustness of the coating.

- Second nickel layer: Acts as the outer shield, delivering mechanical durability and a bright, silvery finish.

This tri-layer coating is typically applied via electrolytic plating (electroplating), resulting in a uniform, tightly bonded protective shell around the magnet.

2.2 Properties and Specifications

- Appearance: Shiny, metallic, silver-like.

- Thickness: 15–21 μm (micrometers).

- Corrosion resistance: Excellent for most indoor and moderate outdoor environments.

- Mechanical strength: Good resistance to chipping and abrasion compared to softer coatings.

- Salt Spray Test: Typically withstands 24 hours (ASTM B117 standard).

- Pressure Cooker Test: Up to 48 hours.

- Cost: Moderate; offers a strong balance between price and protection.

2.3 Advantages

- Excellent general-purpose corrosion protection.

- Visually appealing for visible or consumer-facing applications.

- Good mechanical durability for handling and assembly.

- Widely accepted in the industry; compatible with most adhesives and potting compounds.

2.4 Limitations

- Not suitable for prolonged exposure to aggressive chemicals, marine environments, or direct immersion in water.

- Nickel allergies may be a concern in some biomedical or skin-contact applications.

- Surface can be scratched if subjected to severe mechanical stress.

2.5 Typical Applications

- Motors and generators

- Electronics and sensors

- Magnetic tools and assemblies

- Consumer magnet products (hobby, office, crafts)

- Magnetic separators in dry environments

—

3. Zinc (Zn) Coating

3.1 Structure and Application

Zinc coatings are commonly applied through electroplating as a single metallic layer. This process is less complex than Ni-Cu-Ni plating and is often chosen for cost-sensitive or short-term applications.

Zinc-coated magnets are available in:

- White zinc: Dull gray/blue finish

- Colorful zinc: Iridescent or rainbow-like tint, achieved by chromate passivation

3.2 Properties and Specifications

- Appearance: Matte gray, bluish, or iridescent depending on passivation

- Thickness: 7–15 μm

- Corrosion resistance: Moderate; inferior to Ni-Cu-Ni, especially in humid or salt-laden environments

- Mechanical strength: Lower hardness; more susceptible to abrasion than nickel plating

- Salt Spray Test: Typically passes 12 hours

- Pressure Cooker Test: Up to 24 hours

- Cost: Lower than Ni-Cu-Ni; ideal for budget-conscious projects

3.3 Advantages

- Cost-effective for large-scale, non-critical applications

- Provides basic corrosion protection for indoor use

- Unique visual appearance for specific design aesthetics

- Faster coating process than multi-layer plating

3.4 Limitations

- Shorter corrosion resistance; not recommended for marine, outdoor, or high-humidity environments

- Prone to white rust (zinc oxide) after extended exposure to moisture

- Less durable under mechanical stress than nickel coatings

- Not suitable for long-term, mission-critical applications

3.5 Typical Applications

- Temporary fixtures and prototypes

- Low-cost consumer products

- Non-visible magnetic assemblies

- Short-lifecycle industrial uses

—

4. Epoxy Coating

4.1 Structure and Application

Epoxy coatings are polymer-based. The process involves dipping, spraying, or electrostatic powder coating the magnet with an epoxy resin, which is then cured (hardened) to form a solid, continuous barrier. Epoxy coatings are available in various colors, including clear and black, providing both functional and aesthetic options.

4.2 Properties and Specifications

- Appearance: Glossy or matte, black or clear

- Thickness: 20–28 μm (thicker than metallic coatings)

- Corrosion resistance: Superior; ideal for marine, chemical, and outdoor environments

- Mechanical strength: Good impact absorption, but may chip under severe mechanical shock

- Salt Spray Test: Typically passes 48 hours

- Pressure Cooker Test: Up to 72 hours

- Electrical insulation: Epoxy is a non-conductor, useful in electronic assemblies

- Cost: Slightly higher than Ni-Cu-Ni, but justified for harsh environments

4.3 Advantages

- Excellent protection against moisture, saltwater, and chemicals

- Absorbs minor impacts, reducing the risk of chipping

- Black epoxy provides a discreet, non-reflective surface (ideal for medical, audio, or security products)

- Can be combined with Ni-Cu-Ni (Ni-Cu-Ni + Epoxy) for dual protection

- Electrical insulation for sensitive assemblies

4.4 Limitations

- Less scratch-resistant than metal coatings; surface can be marred by sharp objects

- Can chip if subjected to hard mechanical impact

- Epoxy may degrade under prolonged UV exposure (outdoor sunlight)

- Not suitable for applications requiring very high working temperatures (typically up to 120°C–150°C)

4.5 Typical Applications

- Marine and underwater equipment

- Automotive sensors exposed to road salt and chemicals

- Medical devices (where black, non-reflective surfaces are preferred)

- Outdoor magnetic assemblies (signage, security devices)

- Electronic applications requiring electrical insulation

—

5. Gold (Au) Coating

5.1 Structure and Application

Gold coatings are typically applied as a very thin layer over a Ni-Cu-Ni base. The process uses electroplating, ensuring a uniform and adherent finish. Gold is prized for its aesthetic value and functional properties.

5.2 Properties and Specifications

- Appearance: Bright, lustrous gold

- Thickness: 16–23 μm (total, including Ni-Cu-Ni base)

- Corrosion resistance: Excellent; gold is chemically inert and non-reactive

- Biocompatibility: Suitable for medical and skin-contact applications

- Salt Spray Test: Up to 36 hours

- Pressure Cooker Test: Up to 72 hours

- Cost: Highest among standard coatings; gold is a precious metal

5.3 Advantages

- Maximum corrosion resistance; gold does not tarnish or oxidize

- Unique, luxury aesthetic for visible or decorative applications

- Biocompatible; safe for use in medical devices, jewelry, and body-contact magnets

- Non-magnetic and non-reactive surface

5.4 Limitations

- High cost; not feasible for large-scale or industrial assemblies

- Surface is relatively soft; susceptible to scratching and wear if not handled carefully

- Usually applied as a very thin layer; relies on underlying Ni-Cu-Ni for mechanical strength

5.5 Typical Applications

- Medical implants and devices

- Magnetic jewelry and fashion accessories

- High-end consumer electronics

- Luxury packaging or decorative assemblies

- Specialized laboratory or scientific equipment

—

6. Other Notable Coatings

While Ni-Cu-Ni, Zinc, Epoxy, and Gold are the most common, other coatings are used for niche applications:

- Parylene: Ultra-thin, conformal polymer coating; excellent for biocompatibility and chemical resistance in medical and electronics.

- Silver: Applied over Ni-Cu-Ni; provides antimicrobial properties and a premium finish, but is softer than gold.

- Phosphating: Inexpensive, basic corrosion protection; black or gray appearance, often used as a primer for further coatings.

- Rubber/Plastic: Adds grip and impact resistance; ideal for mounting magnets or applications where surface scratching must be avoided.

- Chrome: Provides a hard, reflective finish; used where appearance and wear resistance are critical.

—

7. Comparative Analysis: Key Properties and Performance

7.1 Summary Table

| Coating Type | Typical Thickness (μm) | Corrosion Resistance | Salt Spray (hours) | Mechanical Strength | Appearance | Cost | Best Use Cases |

|---|---|---|---|---|---|---|---|

| Ni-Cu-Ni | 15–21 | High | 24 | Good | Shiny, silver | $$ | General purpose, visible parts |

| Zinc | 7–15 | Moderate | 12 | Moderate | Dull gray, blue, or colorful | $ | Low-cost, indoor, non-visible |

| Epoxy | 20–28 | Very High | 48 | Good (impact resistant) | Black, clear, or colored | $$$ | Marine, automotive, electronics |

| Gold (over Ni-Cu-Ni) | 16–23 | Excellent | 36 | Soft (surface) | Bright gold | $$$$ | Medical, jewelry, luxury |

7.2 Environmental and Application Suitability

- Indoor, dry environments: Ni-Cu-Ni or Zinc suffice

- Humid, wet, or marine settings: Epoxy or Ni-Cu-Ni + Epoxy highly recommended

- Medical or body-contact: Gold (over Ni-Cu-Ni) or Parylene; avoid nickel for allergy-sensitive applications

- High aesthetic demand: Gold, Silver, or Chrome

- Harsh chemicals or saltwater: Epoxy, Parylene, or even a customized multi-layer system

—

8. Specialized Coating Combinations and Advanced Options

In demanding environments, hybrid or multi-layer coatings are sometimes specified. Examples include:

- Ni-Cu-Ni + Epoxy: Combines the mechanical strength of metal plating with the chemical resistance of epoxy; commonly used for underwater or salt-spray-exposed magnets.

- Ni-Cu + Black Nickel: Adds a dark, decorative finish atop the nickel system, with similar corrosion resistance for visible, consumer-facing products.

- Ni-Cu-Ni + Gold/Silver: Used in medical, scientific, or luxury applications requiring both functionality and aesthetics.

Salt spray and pressure cooker test results further validate the performance of these combinations, with Ni-Cu-Ni + Epoxy and Ni-Cu-Ni + Gold demonstrating the highest endurance.

—

9. Key Factors When Choosing a Magnet Coating

Selecting the optimal coating requires a careful evaluation of several factors:

9.1 Environmental Exposure

- Is the magnet exposed to moisture, humidity, or salt?

- Are corrosive chemicals or extreme temperatures involved?

9.2 Physical and Mechanical Demands

- Will the magnet be subject to high impact, abrasion, or wear?

- Is electrical insulation required?

9.3 Aesthetics and Visibility

- Is the magnet visible in the final product?

- Are specific colors or finishes desired?

9.4 Biocompatibility and Regulatory Requirements

- Will the magnet come into contact with the human body or food?

- Are there allergy or regulatory constraints?

9.5 Budget and Lifecycle

- Is cost minimization the primary concern, or is long-term durability more important?

- How long is the expected service life?

—

10. Case Studies: Magnet Coating Selection in Real-World Applications

10.1 Industrial Automation: Ni-Cu-Ni for Motors and Actuators

In electric motors and robotic grippers, Ni-Cu-Ni plating offers the necessary mechanical and corrosion resistance for thousands of operational cycles. Its moderate cost and bright finish make it ideal for both functional and visible components on assembly lines.

10.2 Automotive Sensors: Epoxy for Harsh Road Environments

Automotive magnets, especially those exposed to under-hood conditions or road spray, benefit from epoxy coatings. These provide superior resistance to salt, chemicals, and temperature fluctuations—critical for ABS sensors and electric power steering.

10.3 Wearable Technology: Gold for Biocompatibility

In medical devices or magnetic jewelry, gold coatings are preferred for skin-contact safety and their non-reactive, hypoallergenic nature. The underlying Ni-Cu-Ni ensures structural integrity, while the gold delivers a premium aesthetic and corrosion barrier.

10.4 Consumer Electronics: Zinc for Cost-Effective Solutions

For internal magnetic assemblies in budget electronics, where the risk of environmental exposure is low, zinc coating provides economical protection and rapid manufacturing turnaround.

—

11. Frequently Asked Questions (FAQs)

11.1 Can neodymium magnets be used without coatings?

Rarely. Uncoated neodymium magnets oxidize rapidly, losing strength and often disintegrating. Only in controlled, inert atmospheres or for very short-term use is this ever considered.

11.2 Is Ni-Cu-Ni coating safe for biomedical use?

Nickel can cause allergic reactions in sensitive individuals. For biomedical or skin-contact applications, use gold, Parylene, or medical-grade epoxy coatings.

11.3 How can I test the quality of a magnet coating?

Standardized tests such as salt spray (ASTM B117) and pressure cooker testing assess corrosion resistance. Visual inspection, thickness measurement, and adhesion testing are also recommended.

11.4 Can coatings be reapplied after damage?

While metal platings are difficult to repair, epoxy coatings can sometimes be reapplied. For best results, consult your magnet supplier for recoating or replacement.

—

12. Advances in Magnet Coating Technologies

Research continues to improve magnet coatings, focusing on:

- Nanostructured coatings for enhanced corrosion resistance

- Conformal coatings (e.g., Parylene) for complex geometries

- Hybrid polymer/metal multilayers for extreme environments

- Environmentally friendly, RoHS-compliant surface treatments

These innovations promise even better performance and durability for next-generation magnetic materials and assemblies.

—

13. Conclusion: Matching Coating to Application

Choosing the right coating for your neodymium or rare earth magnet is essential for maximizing performance, longevity, and overall value. Here’s a quick recap:

- Ni-Cu-Ni: The all-rounder; excellent for most industrial, commercial, and general-purpose uses.

- Zinc: Cost-effective; best for protected, low-risk environments or disposable products.

- Epoxy: The go-to for harsh, wet, or chemically aggressive settings; also provides impact resistance and color options.

- Gold: For luxury, biocompatibility, or visible applications where aesthetics and safety are paramount.

For specialized requirements, hybrid or advanced coatings like Parylene or Ni-Cu-Ni + Epoxy may be the optimal solution. Always consult with a reputable magnet manufacturer, such as Magnetstek Engineering, to tailor the coating system to your unique application needs.

—

Related Products

Custom Neodymium Magnets with Coatings

—

By understanding the strengths and limitations of each coating type, you can ensure your magnet solutions deliver optimal performance and durability—no matter the environment or application. For further assistance or to request a quote, contact Magnetstek Engineering’s expert team.