Introduction

The field of robotics has witnessed remarkable transformations in recent years, driven by the integration of advanced materials, innovative actuation techniques, and intelligent control systems. Among the most promising innovations is the development of **magnetically controlled soft robots**—a class of devices that leverage the power of magnetic induction to achieve versatile, non-contact, and highly precise manipulation. Unlike traditional rigid robots, soft robots are built from compliant materials that mimic the flexibility and adaptability of biological tissues, allowing them to safely interact with delicate environments and complex anatomical structures.

Magnetic induction control, in particular, has emerged as a transformative technology, enabling wireless actuation, programmable shape-morphing, and remote navigation of soft robots. This article explores the principles, materials, fabrication techniques, control strategies, applications, and future directions of magnetically controlled soft robots, drawing on advances in micromagnetics, magnetic assemblies, and flexible magnetic materials.

—

1. Fundamentals of Magnetically Controlled Soft Robotics

1.1. What are Soft Robots?

Soft robots are machines constructed from highly deformable materials such as silicones, elastomers, hydrogels, or flexible polymers. Unlike their rigid counterparts, soft robots can bend, twist, elongate, and compress in response to external stimuli. This flexibility makes them ideal for tasks that require gentle handling, adaptability, and safe operation in environments where traditional robots may cause damage or are unable to maneuver.

1.2. Magnetic Actuation: A Non-Contact Control Paradigm

Magnetic actuation involves the use of externally applied magnetic fields to manipulate embedded or attached magnetic materials inside the robot. The key advantages of magnetic control include:

– **Remote actuation**: No physical connection (wires, tubes) is needed for movement.

– **Programmable response**: Magnetic field strength, orientation, and gradient can be precisely tuned.

– **Biocompatibility**: Magnetic fields can penetrate biological tissues with negligible energy absorption, making them suitable for medical applications.

– **Miniaturization**: Magnetic fields can actuate micro- and nanoscale devices that other methods cannot address.

This non-contact paradigm enables both gross and fine control of soft robots, even in confined or sensitive environments.

1.3. Types of Magnetic Fields Used

– **Static fields**: Generated by permanent magnets. Provide constant force or torque.

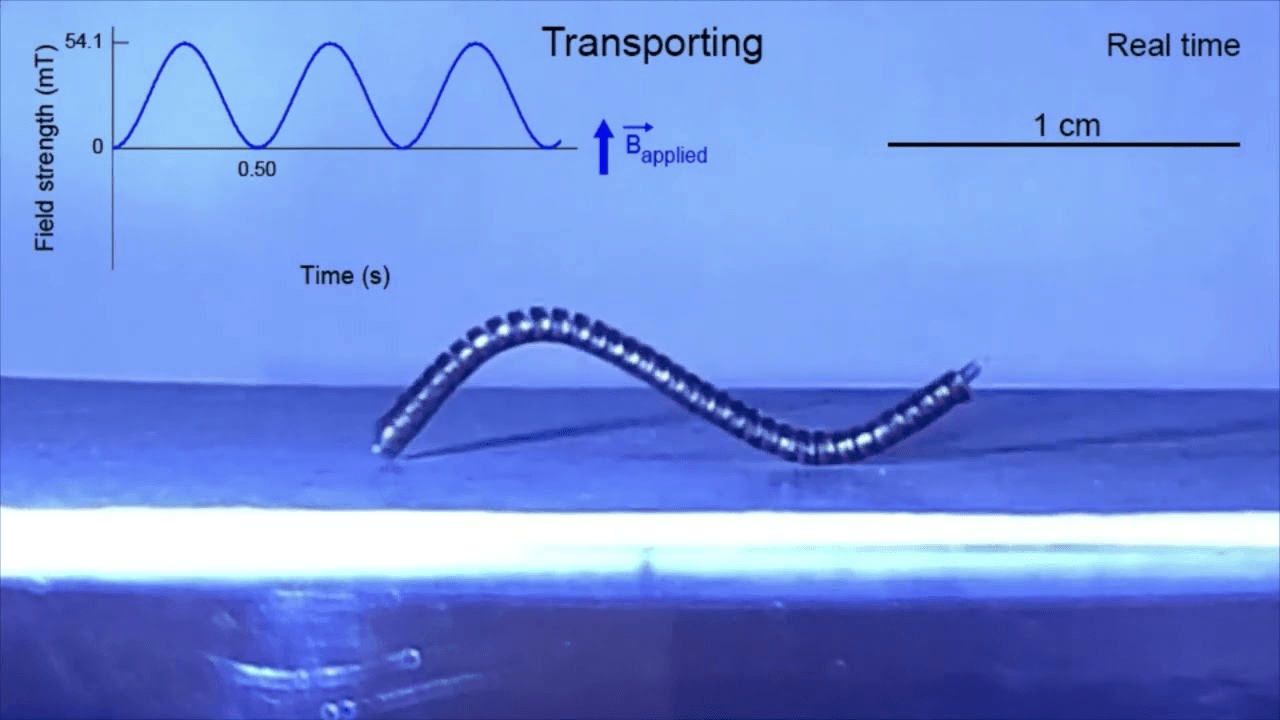

– **Oscillating fields**: Generated by electromagnets. Enable dynamic actuation (vibration, rotation).

– **Gradient fields**: Used to pull or push the robot in a specific direction.

– **Rotating fields**: Induce spinning or rolling motions.

—

2. Materials and Fabrication of Magnetically Responsive Soft Robots

2.1. Magnetic Materials for Actuation

The choice of magnetic material determines the robot’s responsiveness, range of motion, and biocompatibility. Common materials include:

– **Permanent magnets**: Neodymium Iron Boron (NdFeB), Samarium Cobalt (SmCo), Ferrite magnets. These offer high remanence and coercivity.

– **Soft magnetic materials**: Ferrite, iron oxide, or metallic alloys, useful for temporary magnetization.

– **Magnetic composites**: Magnetic particles (NdFeB, ferrite) embedded in a soft matrix (silicone, rubber, hydrogel). Rubber magnets and flexible magnet sheets are widely used due to ease of shaping and biocompatibility.

2.2. Flexible Magnetic Composites

– **Rubber magnets**: Produced by mixing ferrite or rare-earth powder with rubber or polymer binder, yielding a bendable, durable, and cuttable material.

– **Magneto-elastomers**: Elastomeric matrices loaded with micro- or nano-magnets, tailored for tunable mechanical and magnetic properties.

– **Hydrogel-magnet composites**: Used for soft bio-inspired robots, these allow actuation in moist or biological environments.

2.3. Fabrication Techniques

– **Molding and casting**: The most common method, where the magnet-loaded polymer is shaped using molds.

– **3D printing**: Allows for complex geometries and spatial programming of magnetic domains (voxel-level control).

– **Lamination and laser cutting**: For thin, flexible sheets (rubber magnets), enabling rapid prototyping.

– **Magnetization direction control**: After fabrication, the composite is exposed to a strong external field to set the desired magnetization profile, a critical step for programmable actuation.

—

3. Magnetic Induction Control: Principles and Implementation

3.1. Magnetic Induction Basics

Magnetic induction refers to the process by which a changing magnetic field induces a force or motion in a magnetic object. In soft robotics, this principle is harnessed to exert forces or torques on embedded magnetic domains within the robot body.

3.2. Control Strategies

– **Global field control**: The entire robot (or multiple robots) is actuated using a uniform or rotating magnetic field, often generated by arrays of external electromagnets.

– **Gradient control**: By creating spatial gradients in the magnetic field, robots can be pulled, pushed, or steered along complex paths.

– **Programmable domain actuation**: By encoding different magnetization directions within the robot (e.g., using Halbach arrays or spatially varying composite fabrication), complex deformations such as folding, twisting, or crawling can be achieved in response to a single field.

3.3. Magnetic Assemblies for Advanced Control

– **Electromagnetic systems**: Enable dynamic field shaping for precision navigation (e.g., MRI-based actuation, custom electromagnet arrays).

– **Permanent magnet arrays**: Used in portable or wearable systems where dynamic actuation is less critical.

– **Hybrid assemblies**: Combine permanent and electromagnets for both static holding and dynamic movement.

3.4. Sensor Integration and Feedback

Modern soft robots are increasingly integrated with sensors—such as Hall effect sensors, strain gauges, or flexible electronics—to provide closed-loop feedback. This allows for adaptive control in real time and enhances safety, especially in biomedical or delicate industrial operations.

—

4. Design and Programming of Magnetically Controlled Soft Robots

4.1. Geometric Design Considerations

– **Actuator placement**: The distribution and orientation of magnetic particles or magnets determine the achievable degrees of freedom.

– **Shape morphing**: By designing non-uniform magnetization, robots can be programmed to bend, roll, or snap into desired configurations.

– **Mechanical properties**: The stiffness, elasticity, and damping of the matrix material influence the robot’s speed, strength, and precision.

4.2. Programming Magnetization Profiles

– **Voxel-level programming**: Using 3D printing or selective magnetization, designers can encode spatially varying magnetic domains for complex, multi-modal actuation.

– **Halbach arrays**: Special arrangements that focus magnetic fields on one side, increasing efficiency and control.

– **Custom assemblies**: For unique applications, custom-shaped magnet assemblies (rings, arcs, spheres, or blocks) can be fabricated and integrated.

4.3. Simulation and Modeling Tools

– **Finite element analysis (FEA)**: Used to simulate both the mechanical deformation and magnetic field interactions.

– **Magnetic field mapping**: Precise modeling of field strength and gradients is crucial for predicting robot behavior.

—

5. Applications of Magnetically Controlled Soft Robots

5.1. Biomedical Engineering and Healthcare

– **Minimally invasive surgery (MIS)**: Soft robots can navigate tortuous paths inside the body, deliver drugs, or perform tissue manipulation without large incisions.

– **Targeted drug delivery**: Magnetically actuated microrobots can transport therapeutic agents directly to disease sites, minimizing side effects.

– **Tissue engineering**: Magnetic fields can guide cell-laden hydrogels into complex scaffolds, aiding regenerative medicine.

– **Medical imaging synergy**: Integration with MRI systems allows precise actuation and visualization, leveraging the strong, uniform fields of clinical and research MRI magnets.

5.2. Industrial Automation

– **Non-contact manipulation**: Soft robots can handle fragile, high-precision components in clean rooms or hazardous environments.

– **Assembly and sorting**: Magnetic induction control enables rapid, reconfigurable assembly lines with minimal downtime.

– **Magnetic levitation transport**: Soft robots can be levitated and steered to transport goods without mechanical wear.

5.3. Environmental and Exploration Robotics

– **Search and rescue**: Flexible robots can squeeze through rubble or collapsed structures, guided by magnetic fields from a safe distance.

– **Marine and space applications**: Magnetically actuated robots can operate in extreme or remote environments where tethered control is impractical.

5.4. Consumer Electronics and Wearables

– **Haptic feedback**: Micro-magnet-based soft actuators deliver precise vibration or tactile sensation in smart devices.

– **Adaptive wearables**: Flexible magnetic composites can be shaped to fit the user, providing dynamic support or sensing.

—

6. Advances in Magnetic Materials and Magnet Assemblies

6.1. Micro Magnets: Precision at the Smallest Scale

The miniaturization of magnetic materials—enabled by advances in manufacturing and material science—has been pivotal for soft robotic applications. Micro magnets offer high precision, rapid response, and energy efficiency, allowing actuation in millimeter or even micrometer scales.

– **Materials**: Neodymium, samarium cobalt, ferrite, and custom bonded magnets.

– **Form factors**: Discs, rings, blocks, spheres, and custom shapes.

– **Surface coatings**: Rubber, plastic (TPR), or biocompatible polymers for corrosion resistance and safety.

6.2. Flexible Rubber Magnets

Rubber magnets, composed of ferrite or rare-earth powders in a flexible binder, are central to soft robot design. Their ability to bend, twist, and cut to size without losing magnetic properties makes them ideal for conformal applications and repeated handling.

– **Manufacturing**: Mixing, extrusion, calendaring, and magnetization.

– **Customization**: Thickness, strength, and magnetizing direction can be tailored to specific robotic tasks.

6.3. Advanced Magnet Assemblies

– **Halbach arrays**: Create highly directional fields, increasing actuation efficiency.

– **Rotor motors**: Used for rotary actuation in soft robots; permanent magnets or custom assemblies enhance torque and precision.

– **Magnetic separators**: For sorting, filtering, or cleaning tasks in robotic systems.

—

7. Control Systems, Sensing, and Automation

7.1. Closed-Loop Control

Integrating magnetic sensors (e.g., Hall effect, giant magnetoresistance) and strain gauges allows soft robots to sense their own deformation and position, enabling adaptive, closed-loop control for greater precision and safety.

7.2. IoT Integration and Smart Systems

– **Real-time monitoring**: Wireless sensors track robot performance and environmental conditions.

– **Predictive maintenance**: Embedded sensors can detect wear or failure, enabling timely interventions.

– **Remote operation**: Cloud-connected control systems allow operators to steer robots from anywhere.

7.3. Energy Efficiency and Sustainability

Magnetically actuated robots often consume less power than pneumatic or hydraulic systems, especially at small scales. Advances in energy-efficient magnet materials (such as high-grade neodymium or samarium cobalt) and optimization of actuation protocols further reduce energy demands.

—

8. Challenges and Limitations

8.1. Magnetic Interference and Safety

– **Interference**: Strong magnetic fields can disrupt nearby electronics or medical implants (e.g., pacemakers).

– **Shielding**: Advanced designs employ local shielding or field shaping to minimize unintended interactions.

– **Regulatory standards**: Especially for medical and consumer applications, compliance with electromagnetic safety standards is mandatory.

8.2. Miniaturization and Handling

– **Assembly challenges**: Micro magnets are difficult to manipulate and integrate without specialized tools.

– **Fatigue and durability**: Repeated deformation may degrade magnetic or mechanical properties over time.

8.3. Field Control Complexity

– **Precision field generation**: Requires advanced algorithms and hardware, especially for multi-degree-of-freedom robots.

– **Scaling up**: Larger robots need stronger fields, which may require significant infrastructure.

—

9. Innovations and Research Synergy

9.1. Cross-Disciplinary Advances

Progress in one area—such as MRI magnet design, magnetic levitation, or micro-magnet development—has direct benefits for soft robotics. High-field, uniform, and precisely controlled magnets (as used in MRI) have enabled new paradigms in medical microrobotics and remote actuation.

9.2. New Materials and Magnet-Free Approaches

While most soft robots rely on embedded magnets, research is exploring **magnet-free actuation** using electromagnetic coils or even superconducting materials. These approaches could reduce dependence on rare-earth elements and open new possibilities for energy-efficient, sustainable robotics.

9.3. Miniaturization and Customization

Shrinking magnet assemblies and improving machinability (down to 0.05mm diameter, 0.1mm thickness) enable integration into ever-smaller robots. Custom shapes, coatings, and magnetization directions allow for unprecedented design freedom.

9.4. Integration with Emerging Technologies

– **MEMS and nanoelectronics**: Embedding micro-magnets with electronic circuits for intelligent, responsive robots.

– **Artificial intelligence**: Machine learning algorithms optimize control strategies for complex actuation tasks.

– **Additive manufacturing**: Multi-material 3D printing enables the integration of magnetic domains, sensors, and electronics in a single build process.

—

10. Future Trends in Magnetically Controlled Soft Robotics

10.1. Medical and Healthcare Robotics

– **Microsurgical robots**: Capable of navigating through blood vessels or tissues for ultra-minimally invasive procedures.

– **Implantable devices**: Soft robots powered by external magnetic fields, eliminating the need for onboard batteries.

– **Cell therapy and tissue engineering**: Magnetic guidance for cell placement and scaffold assembly.

10.2. Swarm Robotics and Distributed Systems

– **Collective actuation**: Coordinating multiple soft robots using global fields for advanced tasks (e.g., assembly, environmental monitoring).

– **Programmable matter**: Reconfigurable materials and robots that can change shape or function on demand.

10.3. Industrial and Environmental Automation

– **Smart manufacturing**: Adaptable, reconfigurable assembly lines using magnetically controlled soft robots.

– **Robotics in hazardous environments**: Non-contact control allows operation in high-radiation, chemically aggressive, or otherwise dangerous settings.

10.4. Education and Consumer Applications

– **Educational kits**: Demonstrate the principles of magnetism, soft robotics, and programmable actuation.

– **Wearable and interactive devices**: Smart garments or accessories that adapt to user needs via magnetic actuation.

—

11. Case Studies and Real-World Examples

11.1. MRI-Guided Soft Microrobots

– **Principle**: Use the strong, controlled magnetic fields of MRI scanners to steer and actuate micro-scale soft robots inside the body.

– **Applications**: Targeted drug delivery, biopsy, minimally invasive interventions.

– **Advantages**: Non-invasive, high-precision, real-time imaging.

11.2. Magnetically Actuated Surgical Tools

– **Flexible endoscopes**: Soft, steerable tips actuated by external magnets.

– **Tissue retractors and grippers**: Soft actuators that minimize trauma and adapt to tissue contours.

11.3. Industrial Levitation and Transport

– **Maglev conveyors**: Soft robots or carriers levitated and actuated by programmable magnetic fields for contamination-free transport.

– **Fragile goods handling**: Non-contact manipulation reduces breakage and wear.

11.4. Educational Demonstrators

– **Science kits**: Rubber magnets, flexible composites, and programmable magnet assemblies used to teach physics, engineering, and robotics.

—

12. Safety, Standards, and Best Practices

12.1. Handling and Assembly Safety

– Wear gloves and use non-magnetic tweezers when handling micro magnets.

– Store magnets away from electronic devices, pacemakers, and credit cards.

12.2. Standards Compliance

– ISO9001, ISO/TS16949, and RoHS standards are crucial for safe and sustainable manufacturing.

– Medical devices must comply with ISO 13485 and electromagnetic compatibility (EMC) regulations.

12.3. Environmental Considerations

– Recyclable and sustainable magnet materials (e.g., ferrite vs. rare-earth).

– Minimizing rare-earth usage by developing efficient magnet-free actuator alternatives.

—

13. Conclusion

Magnetically controlled soft robots represent a leap forward in the evolution of robotics, combining the adaptability of soft materials with the precision, versatility, and programmability of magnetic actuation. Advances in micro magnet fabrication, smart magnetic assemblies, and wireless control systems are opening up new frontiers in medicine, industry, environmental science, and everyday life.

As research continues, the boundaries between disciplines—magnetics, materials science, engineering, and medicine—are blurring, leading to innovations that were once thought impossible. From implantable surgical tools to frictionless industrial conveyors and programmable matter, the future of magnetically controlled soft robotics is bright, sustainable, and profoundly transformative.

Related Products

Magnetic Rotor Motor Assemblies

Halbach Array Magnetic Assemblies