Introduction

The relentless pursuit of higher efficiency, smaller footprints, and improved precision in robotics has led to a surge in demand for advanced motor technologies. At the heart of many of these innovations is the high-performance permanent magnet, particularly the thin disc magnet. These compact, robust magnets are essential in high-speed robot joint motors, enabling agile movements, precise positioning, and energy-efficient operation. As the robotics industry—encompassing sectors from industrial automation to medical devices—continues to grow, optimizing thin disc magnets becomes a pivotal engineering challenge.

This article provides a comprehensive exploration of the optimization of thin disc magnets for robot joint motors. We’ll delve into the unique properties of these magnets, material selection, manufacturing methods, integration within motor assemblies, recent technological advancements, and practical considerations for maximizing both performance and lifespan. Drawing on expertise from MagnetsTek Engineering, a leading provider of high-performance magnet solutions, we aim to illuminate the current state and future potential of thin disc magnets in robotics.

1. The Role of Permanent Magnets in Robot Joint Motors

1.1 Motor Fundamentals and the Importance of Permanent Magnets

Electric motors are ubiquitous in robotics, converting electrical energy into mechanical motion. In robot joints, brushless DC (BLDC) and permanent magnet synchronous motors (PMSM) are the most common, prized for their high torque-to-weight ratios, efficiency, and controllability. The performance of these motors hinges significantly on the quality and characteristics of the permanent magnets used in the rotor.

Permanent magnets generate the magnetic field necessary for torque production without continuous energy input, making them more energy-efficient compared to electromagnets. This efficiency is particularly important in robotics, where power constraints, thermal management, and weight reduction are paramount.

1.2 Why Thin Disc Magnets?

Thin disc magnets are especially suitable for robot joint motors for several reasons:

– **Compactness:** Their slim profile allows integration into confined spaces, enabling sleek, lightweight joint designs.

– **Precision:** Uniform magnetic properties and tight manufacturing tolerances enable precise control over motor performance, essential for robotics applications where accurate movement is critical.

– **High-Speed Capability:** Thin discs can be used in rotors spinning at up to 60,000 RPM, as produced by MagnetsTek, reducing inertia and improving dynamic response.

– **Customizability:** They can be engineered in diameters as small as 0.05mm and thicknesses as thin as 0.1mm, matching the exact requirements of micro and macro robotic joints alike.

2. Material Science: Selecting the Right Magnetic Material

2.1 Overview of Magnet Materials

Material selection is a foundational step in optimizing thin disc magnets. The main categories include:

– **Neodymium Iron Boron (NdFeB):** The strongest commercially available magnets, offering superior magnetic energy density. Available in grades up to N56, they are ideal for applications demanding high torque in small packages.

– **Samarium Cobalt (SmCo):** While not quite as strong as NdFeB, SmCo magnets excel in high-temperature stability (up to 600°C) and corrosion resistance, making them suitable for harsh or thermally demanding environments.

– **Alnico:** Known for excellent temperature stability but lower magnetic strength, used in niche applications.

– **Ferrite (Ceramic):** Economical and corrosion-resistant, but with lower energy density, ferrites are less common in high-performance robot joints.

2.2 Key Material Properties Affecting Performance

The effectiveness of a thin disc magnet in a robot joint motor depends on:

– **Maximum Energy Product (BHmax):** Indicates the magnet’s strength. Higher BHmax allows for greater torque and efficiency.

– **Coercivity (Hc):** Measures resistance to demagnetization—a critical factor in applications subject to vibration, shock, or high temperature.

– **Operating Temperature Range:** Determines thermal stability. NdFeB magnets with high-grade (e.g., N52M, N55H) or special coatings can withstand higher operational temperatures.

– **Corrosion Resistance:** Essential for durability, especially in humid or aggressive environments.

MagnetsTek Engineering’s portfolio includes neodymium magnets up to N56 grade and SmCo magnets rated for up to 600°C, giving engineers flexibility to select the optimal material for their robot joint application.

3. Manufacturing Precision: Machinability and Customization

3.1 The Art and Science of Machining Thin Disc Magnets

The machinability of modern magnetic materials has opened new frontiers in motor design. Advanced techniques enable the production of thin disc magnets with:

– **Diameters as small as 0.05mm**

– **Thicknesses down to 0.1mm**

– **Tolerances as tight as 0.005mm**

Techniques include:

– **Drilling:** For adding mounting holes or features.

– **Milling:** For non-standard shapes or cutouts.

– **Grinding:** To achieve ultra-thin profiles and smooth finishes.

– **Punching:** For high-volume production of small discs.

Such precise machining allows integration into micro-motors, compact actuators, and specialized robotic joints, where every micron counts.

3.2 Customization and Integration

Every robot design presents unique constraints—space, weight, torque, and environmental factors. Custom-shaped magnets and assemblies are increasingly in demand. MagnetsTek leverages advanced inspection (using projectors and microscopes) and high-precision production lines to deliver custom solutions, including:

– **Disc, ring, arc, and segment shapes**

– **Rubber-coated or adhesive-backed variants for easy mounting**

– **Special coatings (perylene, NiCuNi, epoxy) for enhanced durability**

This customization is crucial for achieving optimal magnetic field orientation, mechanical fit, and environmental robustness in robot joints.

4. Magnet Assembly Engineering for Robot Joints

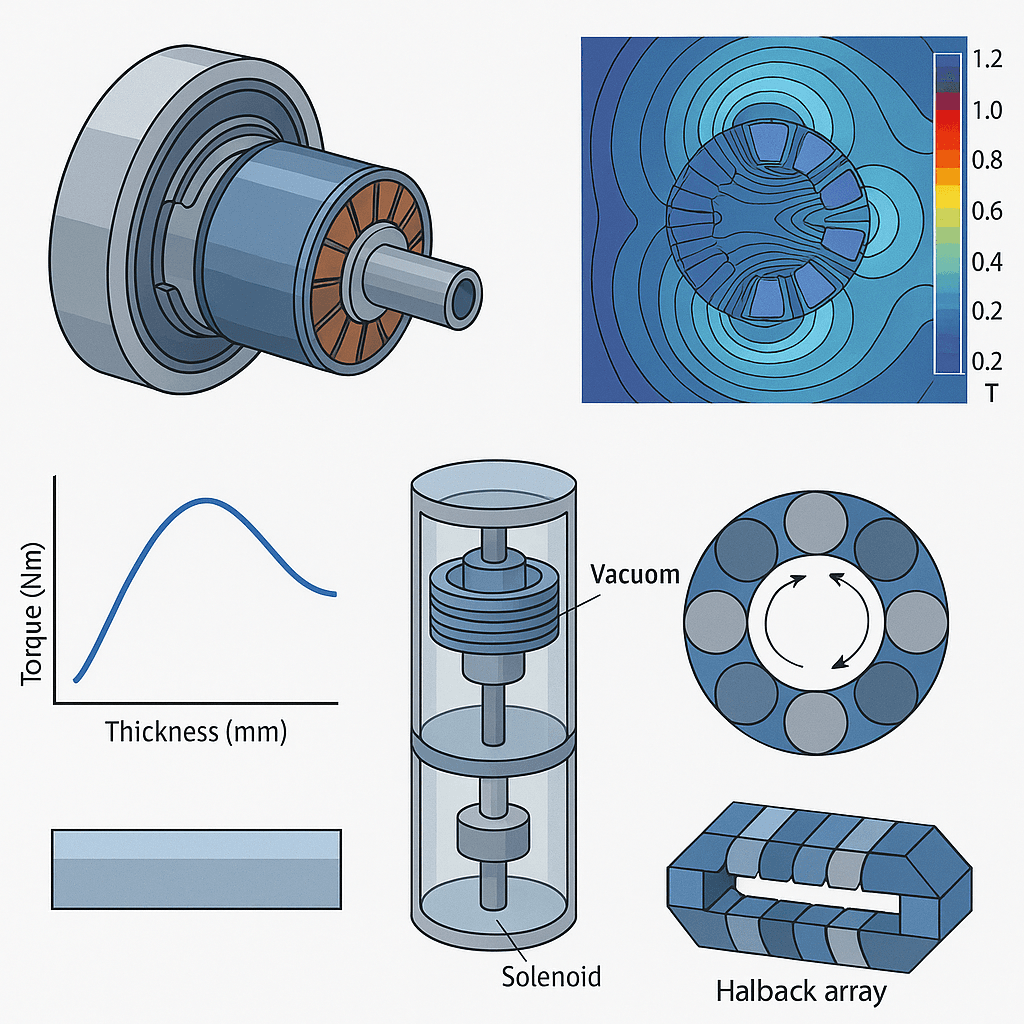

4.1 Rotor Magnet Assembly Design

The arrangement of thin disc magnets in a rotor is a critical determinant of motor performance. Key considerations include:

– **Magnetization Direction:** Axial or radial, depending on desired field geometry.

– **Pole Count:** More poles can improve torque smoothness but may reduce maximum speed.

– **Clearance and Fitting:** Ensuring tight tolerances to minimize air gaps, which reduce efficiency.

– **Adhesive and Mechanical Fixation:** Thin discs may be bonded with high-strength adhesives or encased in metal housings for added security at high RPM.

4.2 Balancing and Vibration Control

Precision balancing of the rotor is vital at high speeds. Even minute inconsistencies can induce vibration, leading to noise, wear, and potential demagnetization. Techniques include:

– **Dynamic balancing after assembly**

– **Use of lightweight, non-magnetic adhesives**

– **Integration of vibration-damping materials**

MagnetsTek’s expertise in assembly ensures that thin disc magnet rotors can achieve speeds of 40,000–60,000 RPM with minimal vibration and maximum reliability.

5. Technological Advancements in Magnet Performance

5.1 Advances in Bonded and Composite Magnets

Recent years have seen significant innovation in bonded magnet technology. Bonded magnets, produced by embedding magnetic powder in a polymer or resin matrix, offer:

– **Complex Shapes:** Easily molded into intricate geometries, including thin discs with integrated features.

– **Enhanced Mechanical Strength:** Reduced brittleness compared to sintered magnets, improving durability in dynamic environments.

– **Lower Weight:** Polymer matrices are lighter than metal, supporting further miniaturization.

Ongoing research focuses on improving the magnetic energy product and thermal stability of bonded magnets, making them increasingly viable for demanding robotic applications.

5.2 Miniaturization and Micro-Magnet Integration

The push toward smaller, lighter robots—especially in fields like medical robotics and wearables—demands ever-smaller magnets. Micro-magnets, with sizes down to 0.1mm, maintain high energy efficiency and can be fully magnetized through their thickness, even at the micro-scale. This opens doors to:

– **MEMS integration**

– **Miniature actuators and sensors**

– **High-precision, low-inertia robot joints**

5.3 Surface Coatings and Environmental Protection

Thin disc magnets are susceptible to corrosion and mechanical wear. Advanced coatings are now standard, including:

– **Parylene:** For ultra-thin, conformal protection.

– **Rubber or TPR:** Adds impact resistance and slip prevention.

– **Epoxy or NiCuNi:** For robust environmental sealing.

Such coatings extend magnet lifespan and reliability, particularly in humid or chemically aggressive environments.

6. Integration with Robot Joint Motor Architectures

6.1 Types of Robot Joint Motors Utilizing Thin Disc Magnets

The primary architectures benefiting from thin disc magnets include:

– **Inner Rotor Motors:** Magnets are mounted on the rotor core, maximizing torque density.

– **Outer Rotor Motors:** Used in some collaborative robots for distributed torque and low-profile designs.

– **Coreless and Slotless Motors:** Thin discs enable the construction of coreless designs, reducing cogging and improving smoothness.

6.2 Sensor Integration and Feedback

Modern robot joints require precise position and velocity feedback. Thin disc magnets are often paired with magnetic sensors (Hall effect, magnetoresistive, etc.) for non-contact, high-resolution measurement. Custom assemblies can integrate both the magnet and sensor for compact, robust solutions.

6.3 Thermal Management and High-Speed Operation

High-performance robot motors generate significant heat. Thin disc magnets, particularly those made from high-grade NdFeB or SmCo, are optimized for thermal stability. Advanced assembly techniques, such as integrating thermal pathways or using high-temperature adhesives, further improve reliability.

7. Industrial Applications and Case Studies

7.1 Industrial Automation

In automated manufacturing and logistics, robot arms and pick-and-place machines rely on thin disc magnet motors for fast, precise motion. Levitation-based transport systems, enabled by magnetic bearings, are emerging as a contamination-free solution for moving delicate components.

7.2 Medical Robotics

Surgical robots and diagnostic equipment demand compact, sterilizable motors. Thin disc magnets, with their small size and customizable coatings, are ideal for integration into minimally invasive tools and MRI-compatible systems.

7.3 Aerospace and Defense

Space and defense robotics require motors that are lightweight, reliable, and resistant to extreme temperatures and radiation. SmCo thin disc magnets, with their superior thermal and corrosion resistance, are frequently used in such applications.

7.4 Energy Storage and Flywheels

Flywheel energy storage systems in robotics benefit from low-friction, magnetically levitated bearings. Thin disc magnets are used to minimize losses and ensure long-term performance.

8. Design Optimization: Key Considerations

8.1 Magnetic Circuit Design

Maximizing the effectiveness of thin disc magnets involves careful engineering of the magnetic circuit:

– **Minimize Air Gap:** Small air gaps between magnet and stator increase magnetic flux and torque.

– **Optimize Pole Shape and Layout:** Custom arc segments or Halbach arrays can be used for field concentration.

– **Simulation Tools:** Finite Element Analysis (FEA) enables designers to predict and optimize field distribution.

8.2 Mechanical Integration

– **Precision Assembly:** Automated assembly lines ensure repeatable, accurate placement of thin discs.

– **Balancing:** Essential for high-RPM operation, as discussed earlier.

– **Mounting Methods:** Rubber coatings, adhesives, or mechanical fixtures should be selected based on the application’s load and environmental conditions.

8.3 Electrical Considerations

– **Back-EMF Optimization:** The magnet’s strength and geometry should be matched to the winding design to maximize efficiency.

– **Thermal Management:** Adequate heat sinking and airflow must be provided to prevent demagnetization.

9. Challenges and Solutions in Thin Disc Magnet Applications

9.1 Handling and Assembly Challenges

Thin disc magnets are brittle and can be difficult to handle, especially at micro scales. Solutions include:

– **Automated Pick-and-Place Systems:** Reduce breakage and improve precision.

– **Protective Coatings:** Rubber or polymer layers protect against chipping.

– **Custom Jigs and Fixtures:** Aid in alignment and placement during assembly.

9.2 Sustainability and Supply Chain Considerations

The reliance on rare earth elements like neodymium and samarium presents supply chain and environmental challenges. Ongoing research focuses on:

– **Recycling:** Recovering magnets from end-of-life products.

– **Alternative Materials:** Development of high-performance ferrites or rare-earth-free alloys.

– **Magnet-Free Motor Technologies:** Emerging designs using electromagnetic or superconducting coils are being explored, though not yet mainstream for robotics.

9.3 Cost and Scalability

High-grade thin disc magnets are expensive to produce, especially in small batches or custom shapes. MagnetsTek Engineering addresses this with:

– **Efficient Production Lines:** Capable of tolerances down to 0.005mm and turnaround times as fast as 2 weeks for NdFeB and 4 days for SmCo.

– **Standardization:** Offering a wide range of off-the-shelf sizes and shapes to reduce customization costs.

10. Maximizing Performance and Lifespan: Practical Tips

10.1 Handling and Storage

– **Handle with Care:** Thin disc neodymium magnets are powerful yet brittle; use non-magnetic tweezers and avoid stacking without spacers.

– **Keep Away from Electronics:** Strong magnetic fields can damage sensitive components and data.

– **Maintain Dry Conditions:** Store in dry, temperature-stable environments to prevent corrosion.

10.2 Maintenance and Inspection

– **Regular Inspection:** Check for coating wear, chipping, or changes in magnetic performance.

– **Re-magnetization:** Some applications allow for periodic re-magnetization if field strength drops.

10.3 Assembly and Mounting

– **Use High-Grade Adhesives:** For secure, vibration-resistant mounting.

– **Verify Alignment:** Misalignment can cause uneven wear or reduced efficiency.

10.4 Environmental Protection

– **Select Appropriate Coatings:** Match the operating environment (humidity, chemicals, temperature) to the best available coating.

– **Encapsulation:** In especially harsh conditions, fully encapsulate magnets in protective housings.

11. Future Trends and Innovations

11.1 Rare-Earth-Free and Hybrid Magnets

Research into rare-earth-free magnets is gaining traction, aiming to reduce reliance on critical elements and improve sustainability. Hybrid magnets, combining different materials, may offer a balance of strength, stability, and cost.

11.2 Smart Magnetic Assemblies

Integration with embedded sensors and IoT connectivity enables real-time monitoring of magnet health, temperature, and performance, paving the way for predictive maintenance in robotics.

11.3 Advanced Manufacturing: Additive & Microfabrication

Additive manufacturing and microfabrication techniques are enabling the production of highly customized, integrated magnetic components at unprecedented scales, supporting the next generation of miniaturized, high-precision robot joints.

12. Conclusion

Thin disc magnets are a cornerstone of modern robot joint motor technology. Their unmatched strength-to-size ratio, customizability, and machinability allow for unprecedented levels of precision, power density, and efficiency in robotics. As the technology advances—through material innovations, manufacturing breakthroughs, and smarter integration—the potential for further miniaturization, sustainability, and performance optimization grows.

MagnetsTek Engineering stands at the forefront of this field, offering both off-the-shelf and fully customized thin disc magnet solutions, supported by deep expertise in materials science, manufacturing, and assembly design. For engineers and designers aiming to push the boundaries of robotic performance, the careful optimization of thin disc magnets is not just valuable—it is essential.

Related Products

Rotor Magnetic Assemblies for Motors