Table of Contents

- Introduction to Magnetic Refrigeration

- Understanding the Principles of Magnetism

- The Magnetocaloric Effect: The Heart of Magnetic Refrigeration

- Permanent Magnets: Types and Properties

- Engineering Magnet Assemblies for Refrigeration

- Design Considerations and Magnetic Circuit Optimization

- Applications of Magnetic Refrigeration Technology

- Advantages and Challenges of Permanent Magnets in Refrigeration

- Material Innovations in Permanent Magnets

- Environmental and Sustainability Benefits

- Future Outlook and Market Trends

- Conclusion

- Related Products

1. Introduction to Magnetic Refrigeration

Magnetic refrigeration is an exciting and rapidly advancing technology offering a sustainable and efficient alternative to traditional vapor-compression refrigeration. At its core, magnetic refrigeration relies on the magnetocaloric effect—a phenomenon in which certain materials heat up or cool down when subjected to a changing magnetic field. Unlike conventional methods, which rely on greenhouse gases and mechanical compressors, magnetic refrigeration systems can offer higher energy efficiency, lower environmental impact, and quieter operation.

Permanent magnets are central to the practical realization of magnetic refrigeration. These powerful components provide the strong, stable magnetic fields required to induce the magnetocaloric effect in refrigerant materials. As such, understanding the principles, design, and application of permanent magnets is vital for engineers, researchers, and industries aiming to harness the full potential of magnetic refrigeration.

2. Understanding the Principles of Magnetism

2.1 What is Magnetism?

Magnetism is a fundamental force that arises from the motion and alignment of electrons within atoms. When the magnetic moments of electrons align in a material, a net magnetic field is produced. This alignment can occur naturally (as in ferromagnetic materials) or be induced by external fields.

2.2 Permanent vs. Electromagnets

Permanent magnets are materials that retain their magnetization without external power. Common examples include iron, nickel, cobalt, and rare-earth compounds such as neodymium-iron-boron (NdFeB) and samarium-cobalt (SmCo). In contrast, electromagnets require an electric current to generate a magnetic field, which ceases when the current stops.

2.3 Magnetic Assemblies and Circuit Optimization

Magnetic assemblies combine permanent magnets with other materials (such as steel or soft magnetic alloys) to concentrate or direct magnetic fields for specific applications. Optimizing these assemblies is essential for applications like magnetic refrigeration, where maximizing the field strength and uniformity directly impacts efficiency.

3. The Magnetocaloric Effect: The Heart of Magnetic Refrigeration

3.1 Fundamental Mechanism

The magnetocaloric effect (MCE) is the reversible temperature change in a magnetic material when exposed to a varying magnetic field. When a suitable magnetocaloric material is placed in a strong magnetic field, its magnetic domains align, decreasing magnetic entropy and releasing heat (heating up). When the field is removed, the domains randomize, increasing entropy and absorbing heat (cooling down).

3.2 Typical Magnetocaloric Materials

Materials with a strong MCE near room temperature are of the greatest interest. Gadolinium (Gd) and its alloys are classic examples, but research is ongoing into rare-earth and transition-metal-based compounds for improved performance, cost, and sustainability.

3.3 Magnetic Refrigeration Cycle

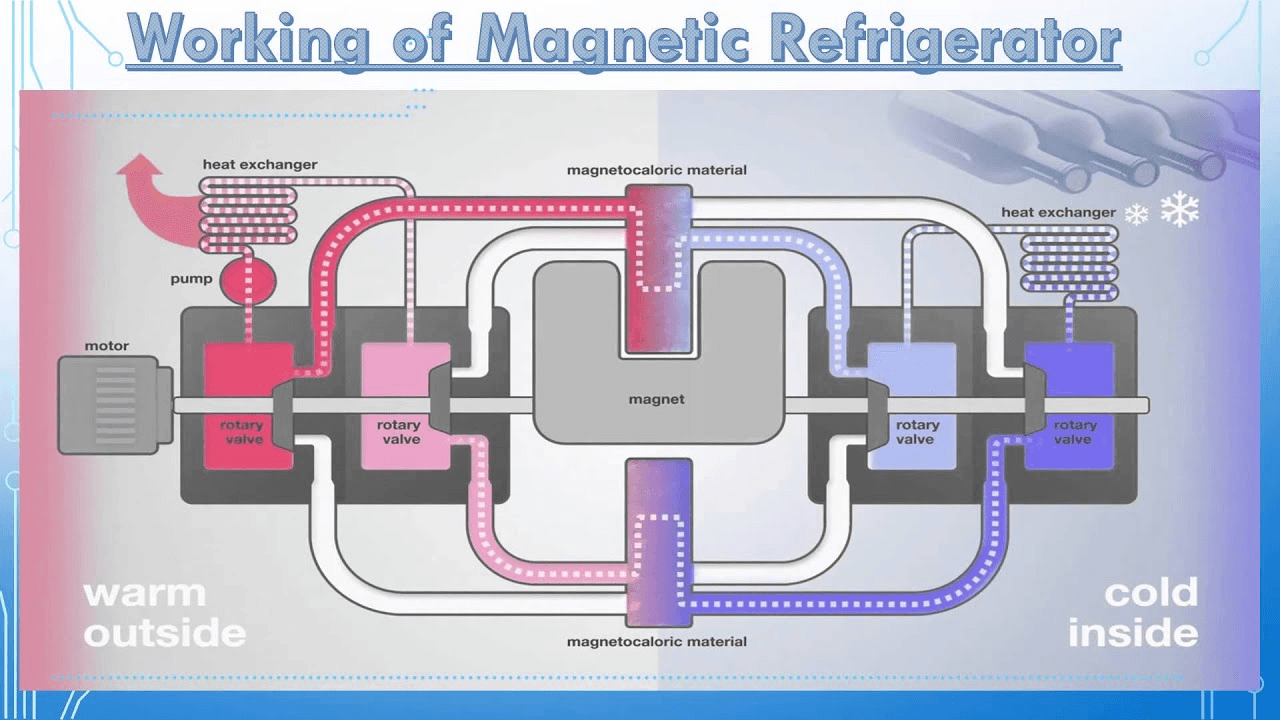

The basic magnetic refrigeration cycle consists of four steps:

- Adiabatic magnetization (material heats up).

- Isomagnetic enthalpy transfer (heat is expelled to a sink).

- Adiabatic demagnetization (material cools down).

- Isomagnetic entropy transfer (material absorbs heat from the load).

Permanent magnets are used to supply the strong, controllable magnetic fields required for step 1 and 3.

4. Permanent Magnets: Types and Properties

4.1 Types of Permanent Magnets

The choice of permanent magnet material is dictated by required field strength, thermal stability, cost, and corrosion resistance. Common types include:

- Ferrite (Ceramic) Magnets: Low cost, good corrosion resistance, moderate strength.

- Alnico Magnets: Excellent temperature stability, moderate strength, but easily demagnetized.

- Samarium-Cobalt (SmCo) Magnets: High strength, exceptional thermal stability, corrosion resistance, but expensive.

- Neodymium-Iron-Boron (NdFeB) Magnets: Highest magnetic strength, compact size, but sensitive to corrosion and temperature.

4.2 Key Properties for Magnetic Refrigeration

Magnetic refrigeration demands magnets with:

- High remanence (Br): For strong, lasting magnetic fields.

- High coercivity (Hc): To resist demagnetization.

- Thermal stability: Stable performance across the refrigeration cycle temperature range.

- Corrosion resistance: Especially for applications prone to moisture or chemical exposure.

4.3 Grades and Manufacturing

Permanent magnets are manufactured in various grades, reflecting their maximum energy product (BHmax), temperature stability, and other properties. Advances in powder metallurgy, sintering, and bonding processes have enabled the production of magnets tailored for demanding applications like magnetic refrigeration.

5. Engineering Magnet Assemblies for Refrigeration

5.1 Magnet Assembly Principles

Individual magnets are rarely used alone in high-performance applications. Instead, assemblies (such as Halbach arrays, pot magnets, or custom magnetic circuits) are designed to concentrate, shape, and direct magnetic fields for maximum efficiency.

5.2 Halbach Arrays

A Halbach array is a special arrangement of permanent magnets that amplifies the magnetic field on one side while nearly cancelling it on the other. This property is especially useful in magnetic refrigeration, where maximizing the field in the working region (while reducing stray fields) boosts efficiency and safety.

5.3 Pot Magnets and Protective Design

Pot magnets consist of a permanent magnet encased in a steel cup, focusing the field on one side. This design offers enhanced pull force, protection from mechanical damage, and reduced demagnetization risk—a vital consideration for long-term reliability in refrigeration systems.

5.4 Custom Magnet Assemblies

Companies like MagnetsTek Engineering specialize in delivering high-performance assemblies tailored for specific applications, including aerospace, defense, automotive, and industrial refrigeration. Customization optimizes field strength, geometry, and mounting for integration into magnetic refrigeration devices.

6. Design Considerations and Magnetic Circuit Optimization

6.1 Simulation and Modeling

Advanced finite element modeling (FEM) tools are used to simulate magnetic fields, optimize magnet placement, and predict performance for assemblies in refrigeration systems. This ensures the required field strength and homogeneity where the magnetocaloric material is located.

6.2 Thermal Management

Permanent magnets can lose strength at elevated temperatures. For magnetic refrigeration, careful attention must be paid to:

- Magnet material selection (e.g., SmCo for high-temperature stability).

- Physical separation or insulation between magnet and hot components.

- Active cooling of the magnet assembly if necessary.

6.3 Corrosion Protection

NdFeB magnets, while strong, are prone to corrosion. Protective coatings (nickel, epoxy, parylene) or encapsulation are often used, especially in humid or chemically aggressive environments.

6.4 Mechanical Integration

Magnet assemblies must be mechanically robust to withstand cycling, vibration, and potential impact. Pot magnets, bonded assemblies, and precision mounting systems are employed to ensure longevity and safety.

7. Applications of Magnetic Refrigeration Technology

7.1 Domestic and Commercial Refrigeration

Magnetic refrigeration is being developed for home refrigerators, freezers, and beverage coolers. The potential for quieter operation, reduced maintenance, and higher efficiency is particularly appealing for the consumer market.

7.2 Industrial and Scientific Cooling

Laboratory chillers, process cooling, and temperature control for sensitive electronics or lasers are prime candidates for magnetic refrigeration. The technology’s ability to achieve low temperatures without harmful refrigerants is a major advantage.

7.3 Automotive and Aerospace

Electric vehicles and aircraft can benefit from compact, efficient, and environmentally friendly cooling systems based on magnetic refrigeration, reducing reliance on traditional compressors and refrigerants.

7.4 Medical Applications

Magnetic refrigeration offers precise, vibration-free cooling for sensitive medical equipment (such as MRI systems) and vaccine storage, improving reliability and reducing noise.

8. Advantages and Challenges of Permanent Magnets in Refrigeration

8.1 Advantages

- Energy Efficiency: Permanent magnets enable highly efficient, low-loss magnetic field generation, reducing energy consumption compared to electromagnetic systems.

- Environmental Friendliness: No need for greenhouse gas refrigerants; reduced carbon footprint.

- Reliability and Durability: No moving parts or electrical losses in the magnet assembly; long operational life.

- Compactness: High energy product magnets (NdFeB, SmCo) allow for smaller, lighter refrigeration units.

8.2 Challenges

- Material Cost and Availability: Rare earth elements (Nd, Sm, Co) are expensive and subject to supply risks.

- Thermal Sensitivity: Some permanent magnets (notably NdFeB) lose strength at higher temperatures.

- Corrosion Susceptibility: NdFeB is prone to corrosion without protective coatings.

- Magnet Demagnetization: Incorrect handling or exposure to adverse fields can reduce performance.

- Design Complexity: Optimizing magnetic circuits for high field strength and uniformity requires advanced engineering.

9. Material Innovations in Permanent Magnets

9.1 Reducing Rare Earth Content

To address cost and supply chain risks, research focuses on developing magnets with less reliance on scarce rare earths. Ferrite magnets, though less powerful, are being engineered for higher performance. Alternative alloys and hybrid magnet systems are also under investigation.

9.2 Advanced Manufacturing Techniques

Hot pressing, additive manufacturing (3D printing), and novel bonding techniques enable the creation of complex magnet geometries and composite structures, opening new possibilities for tailored refrigeration assemblies.

9.3 Improved Coatings and Surface Treatments

Innovations in protective coatings (ceramics, polymers, multi-layer systems) extend magnet life, especially in harsh refrigeration environments.

9.4 Magnet Recycling and Circular Economy

Recycling technologies for end-of-life magnets are advancing, allowing recovery and reuse of rare earth elements. This reduces environmental impact and enhances sustainability for magnetic refrigeration supply chains.

10. Environmental and Sustainability Benefits

10.1 Elimination of Harmful Refrigerants

Traditional vapor-compression systems use hydrofluorocarbons (HFCs) and other greenhouse gases, which are being phased out due to their environmental impact. Magnetic refrigeration operates with solid-state magnetocaloric materials—no emissions, no ozone depletion.

10.2 Lower Energy Consumption

Magnetic refrigeration’s higher theoretical efficiency (Carnot efficiency) translates to real-world energy savings, especially when paired with high-performance permanent magnets.

10.3 Reduced Noise and Maintenance

With no moving compressors or pumps, magnetic refrigeration systems are quieter and require less maintenance, reducing lifecycle costs and environmental impact.

10.4 Sustainable Magnet Sourcing

Efforts to recycle magnets and develop alternative materials further minimize the ecological footprint of this technology.

11. Future Outlook and Market Trends

11.1 Growing Market Adoption

As efficiency regulations tighten and environmental awareness grows, magnetic refrigeration is gaining traction in commercial, domestic, and specialty markets. Pilot products are already on the market, with broader adoption expected as costs fall.

11.2 Integration with Renewable Energy

Magnetic refrigeration pairs well with renewable energy systems. For example, solar-powered refrigerators benefit from high efficiency and reliability, especially in off-grid or remote locations.

11.3 Smart System Integration

The rise of the Internet of Things (IoT) and smart appliances opens new opportunities for intelligent, sensor-driven control of magnetic refrigeration systems, optimizing energy use and performance.

11.4 Research and Development Directions

Key areas of ongoing research include:

- New magnetocaloric materials with larger MCE near room temperature.

- Advanced magnet designs for improved field uniformity and gradient control.

- Reducing rare earth dependence and improving recyclability.

- Miniaturization for portable and niche applications.

12. Conclusion

Permanent magnets are at the heart of magnetic refrigeration technology, providing the strong, stable fields required to unlock the magnetocaloric effect. Advances in magnet materials, assembly techniques, and engineering design are rapidly driving this technology from the laboratory to the marketplace.

By enabling high-efficiency, environmentally friendly, and reliable cooling, permanent magnets offer a compelling solution to the challenges posed by traditional refrigeration. As research and innovation continue, magnetic refrigeration will play an increasingly vital role in the global transition to sustainable energy and reduced environmental impact.

Whether for home appliances, medical equipment, or industrial process cooling, the power of permanent magnets is key to realizing the promise of magnetic refrigeration. Their versatility, efficiency, and adaptability ensure they will remain central to this field for decades to come.

13. Related Products

—

This comprehensive guide has explored the principles, engineering, and applications of permanent magnets in the context of magnetic refrigeration technology. By understanding the underlying science and technological innovations, engineers and industry leaders can harness the full potential of this transformative technology for a greener, more efficient future.