Introduction

Imagine a world where robots assemble themselves with precision and ease, creating sophisticated machines that revolutionize industries. At the heart of this technological marvel lies an often-overlooked component: the magnet. As robotics continues to advance, the role of magnets becomes increasingly pivotal. From enhancing precision to enabling complex movements, magnets are driving the future of robot manufacturing. This article explores ten innovative ways magnets are transforming the field, offering insights into their applications and the benefits they bring to the industry.

1. Magnetic Grippers in Assembly Lines

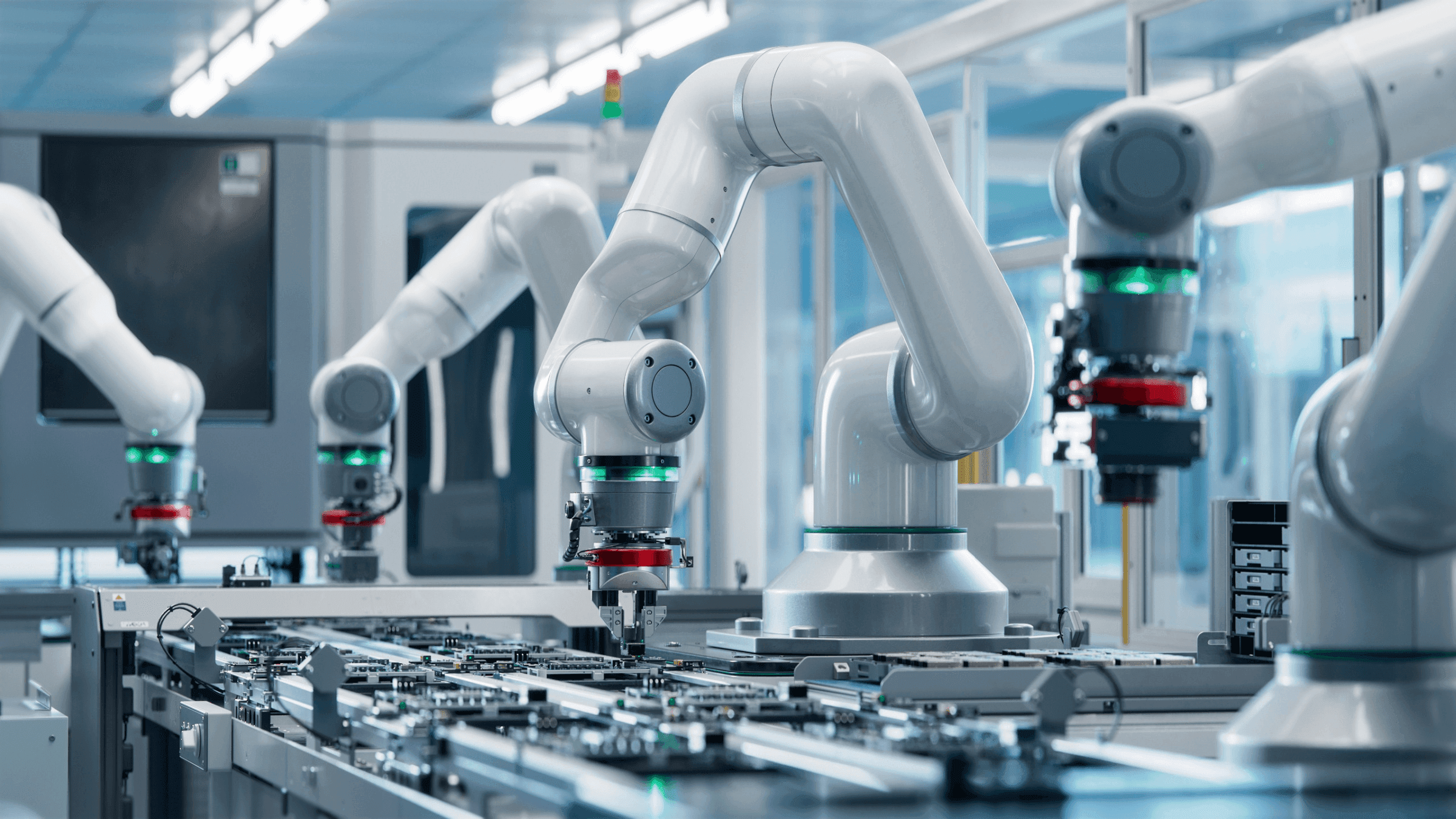

In the bustling environment of modern manufacturing, efficiency and precision are more than just desirable; they’re essential. Enter magnetic grippers—a technology that’s transforming assembly lines by leaps and bounds. Imagine a robotic arm seamlessly picking up and placing components with a dexterity that rivals human hands. This isn’t science fiction; it’s the reality magnetic grippers are creating.

Traditional mechanical grippers often rely on physical grasping mechanisms, which can be cumbersome and sometimes damaging to delicate parts. Magnetic grippers, however, leverage the invisible force of magnetism to hold and move objects. This non-contact method has several distinct advantages, especially in industries where precision and care are paramount.

For instance, take the electronics industry, where tiny, fragile components must be placed onto circuit boards with incredible accuracy. Magnetic grippers excel in this setting. They can handle minute parts without causing damage, ensuring each component is placed precisely where it needs to be. This not only speeds up the assembly process but also significantly reduces the risk of errors and rework. The efficiency gained here translates to lower costs and higher quality products, giving companies a competitive edge.

But the benefits of magnetic grippers aren’t confined to delicate tasks. In the automotive industry, where large and heavy parts need to be manipulated, magnetic grippers prove their versatility and strength. These grippers can securely hold heavy, irregularly shaped parts, making the assembly process smoother and more efficient. Picture a robotic arm swiftly moving a hefty car door into place with exacting precision—this is the power of magnetic grippers at work.

Moreover, magnetic grippers offer a high level of adaptability. They can easily switch between different types of components without the need for extensive reconfiguration, which is a common drawback of mechanical grippers. This flexibility is a game-changer on assembly lines, where products and components often vary. By integrating magnetic grippers, manufacturers can reduce downtime and increase productivity, leading to faster production cycles and greater output.

The advantages extend beyond just handling efficiency. Magnetic grippers are also more durable and require less maintenance than their mechanical counterparts. The absence of moving parts means there’s less wear and tear, which translates to longer operational life and lower maintenance costs. For manufacturers, this reliability is invaluable, as it ensures continuous production without frequent interruptions for repairs or part replacements.

Industries around the world are already reaping the benefits of magnetic grippers. Companies in sectors ranging from consumer electronics to automotive manufacturing are integrating this technology into their assembly lines, witnessing first-hand the improvements in speed, precision, and efficiency. By adopting magnetic grippers, they are not only enhancing their current production capabilities but also paving the way for future innovations.

In conclusion, magnetic grippers are a revolutionary technology in the realm of robot manufacturing. Their ability to handle components delicately yet securely, coupled with their adaptability and durability, makes them an indispensable tool on modern assembly lines. As industries continue to push the boundaries of what’s possible in manufacturing, magnetic grippers will undoubtedly play a crucial role in shaping the future.

2. Magnetic Encoders for Precision Control

Precision is a cornerstone of effective robotics, and magnetic encoders play a critical role in achieving it. These devices convert the position or motion of a shaft or axle to an analog or digital signal, providing crucial feedback for precise control of robotic movements. Unlike optical encoders, magnetic encoders are resistant to dust, dirt, and other contaminants, making them ideal for harsh industrial environments.

Magnetic encoders are extensively used in robotic arms, ensuring that each movement is accurately tracked and controlled. This is particularly important in applications such as welding, where precision is essential to ensure high-quality joints. By providing accurate position feedback, magnetic encoders help maintain consistency and quality in robotic operations.

3. Magnetic Sensors in Robotics

Magnetic sensors are indispensable in modern robotics, offering a range of functionalities that enhance performance and safety. These sensors detect changes in magnetic fields and convert them into electrical signals, which can be used to monitor positions, speed, and proximity. Different types of magnetic sensors, such as Hall effect sensors and magnetoresistive sensors, are employed based on specific requirements.

In autonomous robots, magnetic sensors are used for navigation and obstacle detection. They help robots understand their environment by detecting magnetic markers or changes in the magnetic field, allowing for precise movements and avoiding collisions. Magnetic sensors are also crucial in medical robots, where they assist in detecting and measuring magnetic fields generated by biological processes, aiding in diagnostics and treatment.

4. Magnetic Bearings for Reduced Friction

Friction is a common challenge in mechanical systems, and robots are no exception. Magnetic bearings offer a solution by providing non-contact support to rotating parts, significantly reducing friction and wear. These bearings use magnetic fields to levitate the rotating components, allowing for smooth and efficient movement.

Robots equipped with magnetic bearings experience less mechanical resistance, leading to improved energy efficiency and longer operational lifespans. This technology is particularly beneficial in high-speed applications, such as industrial robots used in manufacturing and assembly lines, where reduced friction translates to faster and more reliable performance.

5. Magnetic Couplings for Smooth Power Transmission

Power transmission in robotics often involves the transfer of torque between different components. Magnetic couplings provide a contactless method of transmitting torque, using magnetic fields to connect and drive rotating parts. This eliminates the need for physical connections, reducing wear and maintenance requirements.

Magnetic couplings are ideal for applications where precision and reliability are critical. In robotic joints, for example, they enable smooth and precise movements without the backlash commonly associated with mechanical couplings. This results in more accurate and consistent robotic performance, essential for tasks such as assembly, welding, and material handling.

6. Electromagnets in Robotic Actuators

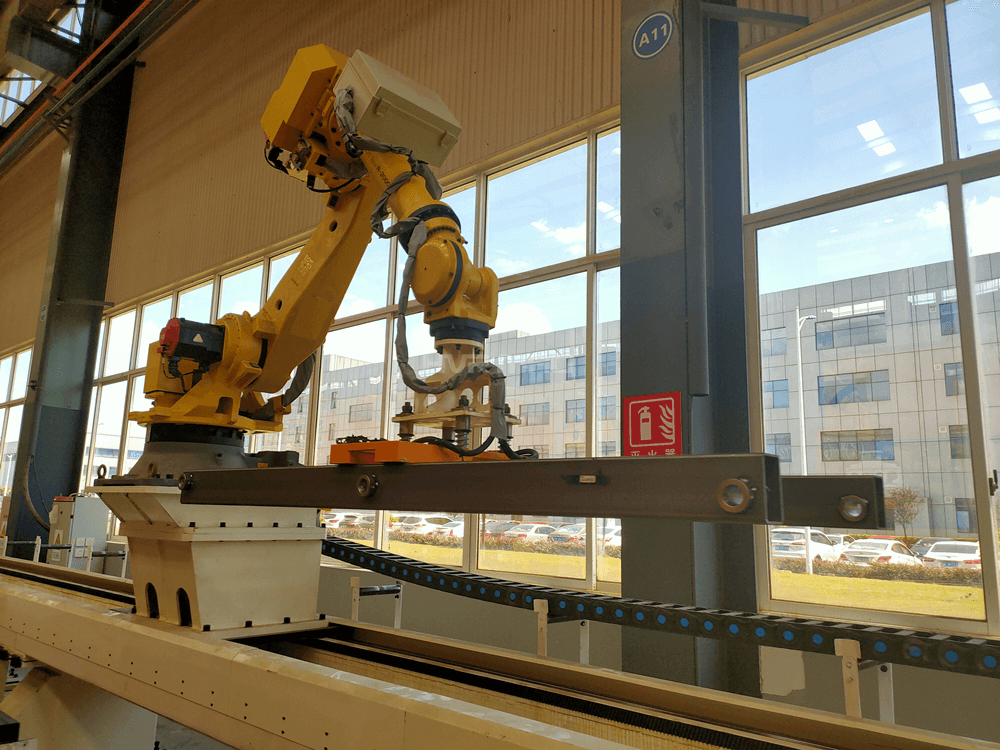

Actuators are the muscles of robots, responsible for movement and force generation. Electromagnets are widely used in actuators due to their ability to produce strong and controllable magnetic fields. These fields can be used to generate motion or exert force, making electromagnets ideal for a variety of robotic applications.

Electromagnetic actuators are found in robotic arms, grippers, and even locomotion systems. They offer precise control over movement and force, allowing robots to perform delicate tasks with high accuracy. In industrial settings, electromagnets enable robots to lift and manipulate heavy objects with ease, improving efficiency and safety in the workplace.

7. Magnetic Levitation for Advanced Movement

Magnetic levitation, or maglev, is a technology that uses magnetic fields to lift and propel objects without physical contact. In robotics, maglev offers the potential for highly advanced and precise movements, as it eliminates friction and allows for smooth, controlled motion.

Maglev technology is being explored in various robotic applications, from transportation systems to assembly lines. For instance, maglev robots can move quickly and accurately along production lines, handling tasks such as inspection, sorting, and assembly with unparalleled efficiency. The absence of friction also reduces wear and maintenance, further enhancing the benefits of maglev in robotics.

8. Magnetic Materials in Robot Construction

In the rapidly evolving world of robotics, the materials used in robot construction are just as crucial as the design and programming. One material group stands out for its unique properties and transformative impact: magnetic materials. These powerful and versatile materials are not only enhancing the functionality of robots but also opening up new possibilities in design and performance.

Magnetic materials, such as neodymium, samarium-cobalt, and ferrite, are increasingly being used to build various parts of robots, from motors and sensors to structural components. What makes these materials so special? Their ability to generate and manipulate magnetic fields, which can be harnessed in multiple innovative ways.

For starters, let’s delve into the realm of motors. Traditional motors are the workhorses of many robotic systems, but when magnetic materials are used, the efficiency and power output can be significantly enhanced. Neodymium magnets, for instance, are renowned for their strength and stability. Incorporating these magnets into motors means higher torque and greater efficiency, which translates to more powerful and responsive robots. Whether it’s in industrial robots that need to lift heavy objects or precision robots used in medical applications, the enhanced performance of magnetic motors is a game-changer.

But the advantages don’t stop at motors. Magnetic materials are also pivotal in the development of advanced sensors, which are the eyes and ears of robotic systems. Sensors made with magnetic materials, such as magnetoresistive sensors, can detect changes in magnetic fields with high accuracy. This capability is essential for tasks requiring precise positioning and movement. For example, in automated guided vehicles (AGVs) used in warehouses, magnetic sensors ensure accurate navigation and collision avoidance, thereby improving safety and efficiency.

Structural components of robots also benefit immensely from magnetic materials. Imagine building a robot with joints that can be easily assembled and disassembled using magnetic connectors. This not only simplifies the assembly process but also allows for quick repairs and modifications. Magnetic joints provide a level of flexibility and convenience that traditional mechanical fasteners can’t match. This is particularly advantageous in modular robots, where components are frequently swapped out based on the task at hand.

Moreover, the use of magnetic materials can lead to more compact and lightweight robot designs. Magnetic components, being both strong and light, contribute to reducing the overall weight of the robot without compromising on strength or durability. This is critical in applications like drones or robotic arms, where weight reduction can enhance mobility and extend operational time.

The adaptability of magnetic materials also shines in custom applications. Custom magnets can be tailored to meet specific requirements, solving unique challenges that standard components might not address. For instance, in the field of medical robotics, custom magnetic materials can be designed to interact safely with the human body, enabling non-invasive surgical procedures or precise drug delivery systems.

Industries across the globe are already embracing the benefits of magnetic materials in robot construction. Automotive manufacturers are incorporating these materials to build more efficient assembly robots. Electronics companies use them to create delicate handling systems for tiny components. Even the aerospace sector is exploring magnetic materials for developing advanced robotic systems for space exploration.

In summary, magnetic materials are revolutionizing robot construction in multiple profound ways. From boosting motor performance and sensor accuracy to enabling innovative structural designs and custom solutions, these materials are at the forefront of robotic advancements. As technology continues to evolve, the integration of magnetic materials will undoubtedly lead to even more exciting and groundbreaking developments in robotics. Embracing these materials not only enhances current capabilities but also sets the stage for a future where robots are more powerful, efficient, and versatile than ever before.

9. Magnetic Separation in Manufacturing Processes

During the manufacturing of robotic components, ensuring the purity and quality of materials is essential. Magnetic separation is a technique used to remove magnetic impurities from raw materials, improving the quality and performance of the final products. This process involves using magnets to attract and separate magnetic particles from non-magnetic ones.

Magnetic separation is widely used in industries such as electronics and automotive, where high-quality materials are crucial for reliable performance. By incorporating magnetic separation into the manufacturing process, companies can produce higher quality robotic components, resulting in more efficient and durable robots.

10. Custom Magnets for Specialized Robotic Applications

One of the most exciting aspects of magnet technology in robotics is the ability to design and produce custom magnets for specific applications. Custom magnets are tailored to meet unique requirements, solving challenges that standard magnets cannot address. This flexibility allows for the creation of highly specialized robotic systems that excel in their intended roles.

For example, in medical robotics, custom magnets are designed to interact with magnetic fields generated by the human body, enabling precise and non-invasive procedures. In industrial robotics, custom magnets can be optimized for specific tasks, such as high-speed assembly or delicate material handling, enhancing the overall efficiency and effectiveness of robotic systems.

Conclusion

Magnets are undeniably at the forefront of innovations in robot manufacturing, providing solutions that enhance precision, efficiency, and functionality. From magnetic grippers and sensors to advanced applications like maglev technology, magnets are revolutionizing the way robots are designed, built, and operated. As technology continues to advance, the role of magnets in robotics is set to grow even further, driving new possibilities and innovations in the industry. Embracing these magnetic technologies will be key to unlocking the full potential of robotics, paving the way for a future where robots are more capable, efficient, and versatile than ever before.