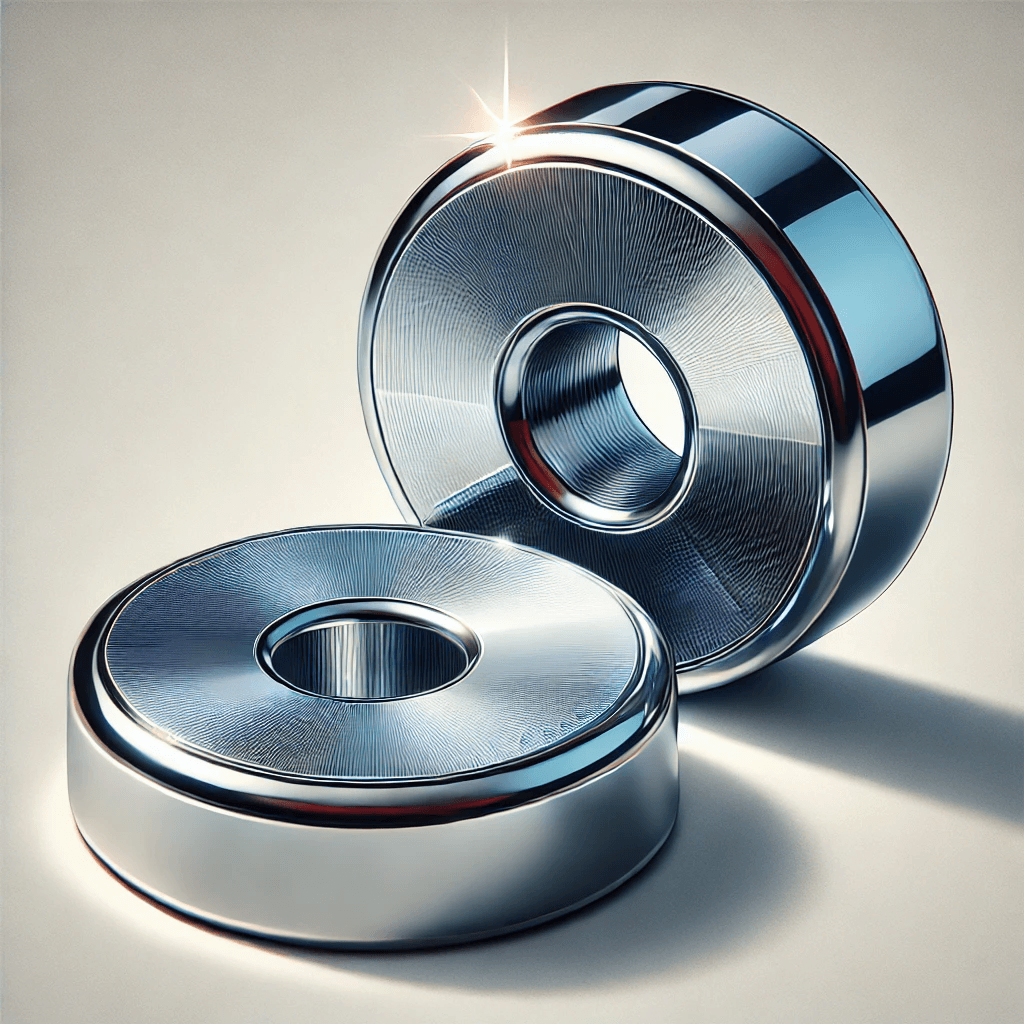

Imagine a small, unassuming component that can revolutionize everything from high-tech robotics to everyday household items, from sleek audio devices to the high-speed assembly lines of automotive factories. That’s the magic of countersunk magnets—a seemingly simple but incredibly powerful tool that plays a crucial role in countless applications across industries. These magnets, with their unique flush-mount design, offer a perfect blend of strength, precision, and subtlety, making them indispensable in modern engineering and manufacturing. Whether you’re securing a crucial component in a factory, enhancing the functionality of electronic devices, or creating innovative designs in home décor, countersunk magnets provide a silent but steadfast solution. In this article, we will explore six of the most compelling applications of countersunk magnets, highlighting their versatility and transformative impact on the world around us.

1. Countersunk Magnets in Industrial Manufacturing

A. Assembly and Component Fixing

Countersunk magnets play a crucial role in modern industrial manufacturing, where speed, precision, and space efficiency are essential. These magnets are widely used in the assembly of machinery, fixtures, and tools, enabling the secure fixation of components during the manufacturing process. The ability to install countersunk magnets with screws or bolts allows for quick and easy positioning of parts without the need for bulky clamps or other fasteners.

In industries such as electronics, automotive, and medical device manufacturing, countersunk magnets are embedded into jigs and fixtures to hold metal parts securely in place. This not only speeds up assembly times but also improves accuracy by ensuring that components remain fixed during processes such as welding, cutting, and machining. The flush mounting of countersunk magnets ensures that the fixtures do not interfere with the operation of automated machinery, further enhancing productivity.

For example, in the automotive industry, countersunk magnets can be used in robotic arms on production lines to hold parts steady as they are welded or assembled. These magnets are particularly beneficial in high-speed manufacturing processes where quick adjustments and part replacements are common.

B. Automation and Robotics

The rise of automation in manufacturing has led to a greater demand for precise and reliable components. Countersunk magnets are integral to this evolution, providing a robust solution for holding parts securely in place during automated processes. These magnets are widely used in robotics, where they ensure that robotic arms can precisely position parts for assembly or further processing.

In automotive production lines, countersunk magnets help secure parts during assembly, allowing robots to move components without misalignment or shifting. This ensures that every part is positioned correctly without the need for manual intervention, improving efficiency and reducing the chances of errors. The flush nature of countersunk magnets is particularly useful in applications where space is limited, allowing robots to work more efficiently in confined environments.

In addition to assembly robots, countersunk magnets are also used in automated sorting and packaging systems. The magnets help secure products on conveyor belts, preventing movement that could disrupt the sorting process. This is especially important in industries such as pharmaceuticals, electronics, and food processing, where precision and reliability are paramount.

2. Countersunk Magnets in Electronic Devices

A. Sensors and Actuators

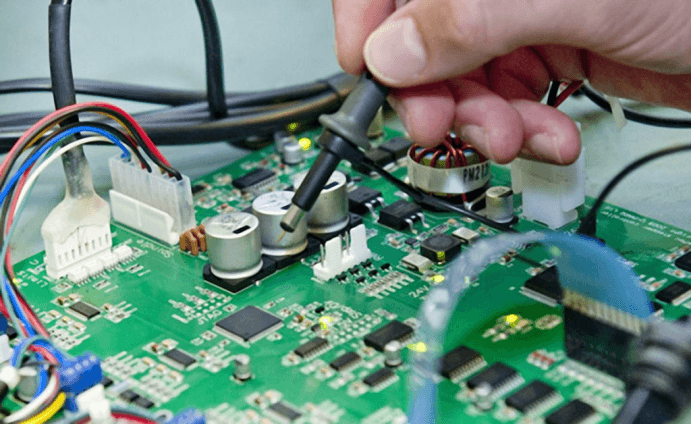

Countersunk magnets are widely used in the electronic industry, particularly in sensors and actuators. In electronic devices, magnets are used to detect the presence or absence of objects, triggering specific actions such as turning a device on or off, changing settings, or activating certain functions.

A common example of this is in smartphones, tablets, and laptops, where countersunk magnets are embedded into the device’s frame to interact with magnetic sensors. When the device’s cover or case is closed, the magnets trigger the sensor to turn off the display or lock the device, thereby conserving battery life and preventing accidental touches. These magnets are small, reliable, and unobtrusive, ensuring that the device’s functionality is not compromised while enhancing the user experience.

Additionally, countersunk magnets are used in the automotive and industrial sectors for controlling actuators and positioning systems. These magnets help ensure precise movement and positioning, making them integral to the functioning of various control mechanisms.

B. Speakers and Audio Equipment

In audio equipment such as headphones, loudspeakers, and microphones, countersunk magnets are essential components in the creation of sound. The magnet’s interaction with the voice coil produces vibrations that generate sound waves. The strength and stability of the magnet directly influence the audio quality, with stronger magnets typically leading to higher efficiency and better sound reproduction.

The design of countersunk magnets is particularly beneficial in the audio industry because they allow for a more compact speaker design without compromising performance. By embedding the magnet flush within the speaker’s housing, manufacturers can ensure a sleek and modern design while still maintaining optimal sound quality. The flush installation of countersunk magnets also prevents unwanted vibrations that could distort sound, improving the overall audio experience.

Moreover, these magnets are critical in maintaining the proper alignment of speaker components. In high-performance speakers, the precise positioning of the magnets ensures that the diaphragm and voice coil are properly aligned, allowing for more accurate sound reproduction. This makes countersunk magnets a valuable asset in both consumer audio devices and professional sound equipment.

3. Countersunk Magnets in the Automotive Industry

A. Vehicle Assembly and Part Positioning

The automotive industry is another key area where countersunk magnets are widely used. In vehicle assembly, these magnets are used to secure parts during manufacturing, ensuring that components remain in place while the vehicle is being built. Countersunk magnets are often embedded into metal components such as door frames, dashboards, and trim pieces, allowing them to be securely held in place during assembly without the need for traditional fasteners or mechanical locks.

One significant advantage of countersunk magnets in vehicle assembly is their ability to provide a secure hold without requiring additional space. This is particularly important in modern automotive manufacturing, where space efficiency is crucial. By using countersunk magnets, manufacturers can streamline their assembly lines, reducing the need for bulky clamps and improving overall production efficiency.

Furthermore, countersunk magnets are also used to secure electronic components inside vehicles, such as sensors, actuators, and control modules. These components often need to be precisely positioned and held in place to ensure proper functionality. Countersunk magnets provide a reliable solution for keeping these parts stable during installation and operation, contributing to the overall reliability and performance of the vehicle.

B. Magnetic Mounting for Automotive Accessories

In addition to their role in vehicle assembly, countersunk magnets are also used for mounting automotive accessories such as phone holders, GPS units, and cameras. The flush design of countersunk magnets allows for easy installation and removal of these accessories, making them ideal for use in vehicles where space is limited and aesthetics are important.

These magnets provide a strong and secure hold for automotive accessories, preventing them from shifting or falling while the vehicle is in motion. Their magnetic force is strong enough to hold heavier devices, such as dash cams and portable GPS units, without damaging the vehicle’s interior. Moreover, the sleek design of countersunk magnets ensures that they blend seamlessly into the vehicle’s interior, maintaining a clean and modern appearance.

In electric vehicles (EVs), countersunk magnets also play a key role in the electric motor’s rotor assembly. High-performance neodymium magnets are often used in the rotor, helping to generate the necessary magnetic fields for motor operation. The efficiency of the motor is highly dependent on the quality of these magnets, and the precise installation enabled by countersunk magnets ensures that the motor performs optimally.

4. Countersunk Magnets in Home and DIY Projects

A. Magnetic Latches for Doors and Cabinets

Countersunk magnets are commonly used in home and DIY projects, particularly in the design of magnetic latches for doors and cabinets. These latches provide an elegant and functional solution for keeping doors and drawers securely closed without the need for traditional locks, bolts, or hinges. The flush-mount design of countersunk magnets ensures that they do not protrude from the surface, maintaining a clean and modern appearance.

Magnetic latches are used in a variety of home applications, such as in kitchen cabinets, storage chests, and toolboxes. The magnets provide a strong yet discreet hold, keeping doors and drawers closed even when subjected to vibrations or slight impacts. This makes them ideal for use in homes where safety, convenience, and aesthetics are important considerations.

B. Furniture Assembly and Magnetic Hinges

Countersunk magnets are also used in furniture assembly, particularly in magnetic hinges. These hinges provide a smooth, continuous movement for doors and panels, making them ideal for furniture such as bookcases, entertainment centers, and wardrobes. The flush-mount design ensures that the hinges are unobtrusive, contributing to the overall aesthetic of the furniture while providing reliable functionality.

Magnetic hinges offer several advantages over traditional mechanical hinges, including quieter operation, smoother movement, and more flexible design options. By using countersunk magnets, furniture manufacturers can create high-quality, durable products that meet the demands of modern consumers.

5. Countersunk Magnets in Security Systems

A. Magnetic Door and Window Contacts

Countersunk magnets are a critical component in security systems, where they are used as part of magnetic door and window contact sensors. These sensors are essential for detecting unauthorized entry into buildings, triggering alarms or other security measures when doors or windows are opened. The magnets are embedded in the doorframe or window, and when the door or window opens, the magnetic field is disrupted, signaling a breach.

The flush installation of countersunk magnets ensures that the sensors are discreet and do not interfere with the normal operation of doors or windows. This makes them ideal for use in residential, commercial, and industrial security systems, where both security and aesthetics are important considerations. These magnets are also used in access control systems, where they help secure doors or gates by triggering magnetic locks.

B. Automated Security Systems

Countersunk magnets are also used in automated security systems that rely on magnetic fields to detect movement or changes in the environment. These systems use the principles of magnetism to activate alarms, cameras, or other surveillance devices when an intruder is detected. For example, countersunk magnets can be used to trigger an automated locking mechanism when a door is opened

, or to activate a security camera when a sensor detects movement.

The ability of countersunk magnets to operate reliably and discreetly makes them a valuable asset in modern security systems. By incorporating these magnets, security companies can offer more efficient, accurate, and less intrusive security solutions for homes and businesses alike.

6. Countersunk Magnets in Marine Applications

A. Magnetic Anchoring Systems

Countersunk magnets are increasingly being used in marine applications, particularly in magnetic anchoring systems. These systems use powerful magnets to secure vessels in place when docked or anchored. The magnets’ flush design ensures that they can be installed in confined spaces without taking up valuable room on the vessel, making them ideal for use in boats and ships where space is at a premium.

Marine environments present numerous challenges, such as exposure to saltwater, corrosion, and extreme weather conditions. Countersunk magnets are typically made from corrosion-resistant materials such as neodymium or rare-earth alloys, making them perfect for use in these harsh conditions.

B. Navigation and Positioning Systems

Countersunk magnets also play a role in marine navigation and positioning systems. In some applications, magnets are used to create stable magnetic fields for compasses, helping to determine the vessel’s heading. The magnets’ flush design allows them to be integrated seamlessly into the compass housing, contributing to both the functionality and appearance of the system.

In addition, countersunk magnets are used in various other marine equipment, such as radar systems, sonar devices, and communication tools, where they help secure components in place or provide precise alignment.

Conclusion

Countersunk magnets are versatile and reliable components used across a wide range of applications. Their unique design, which allows for flush mounting, makes them ideal for situations where space efficiency, aesthetics, and strong magnetic force are crucial. From industrial manufacturing and robotics to consumer electronics, automotive design, home applications, security systems, and marine technology, countersunk magnets continue to provide innovative solutions that enhance functionality and improve efficiency. As technology advances and industries evolve, the role of countersunk magnets in shaping the future of manufacturing, design, and security will only continue to grow.