Introduction

In the ever-evolving landscape of modern technology and innovation, permanent magnets have emerged as indispensable components, playing crucial roles in a wide array of applications. From consumer electronics and renewable energy systems to medical devices and transportation, these magnetic marvels have become an integral part of our daily lives. Among the various types of permanent magnets, neodymium magnets, or NdFeB magnets, stand out as one of the most powerful and versatile options available. However, within this category, there exists a fundamental distinction between bonded and sintered neodymium magnets, each with its unique characteristics and applications.

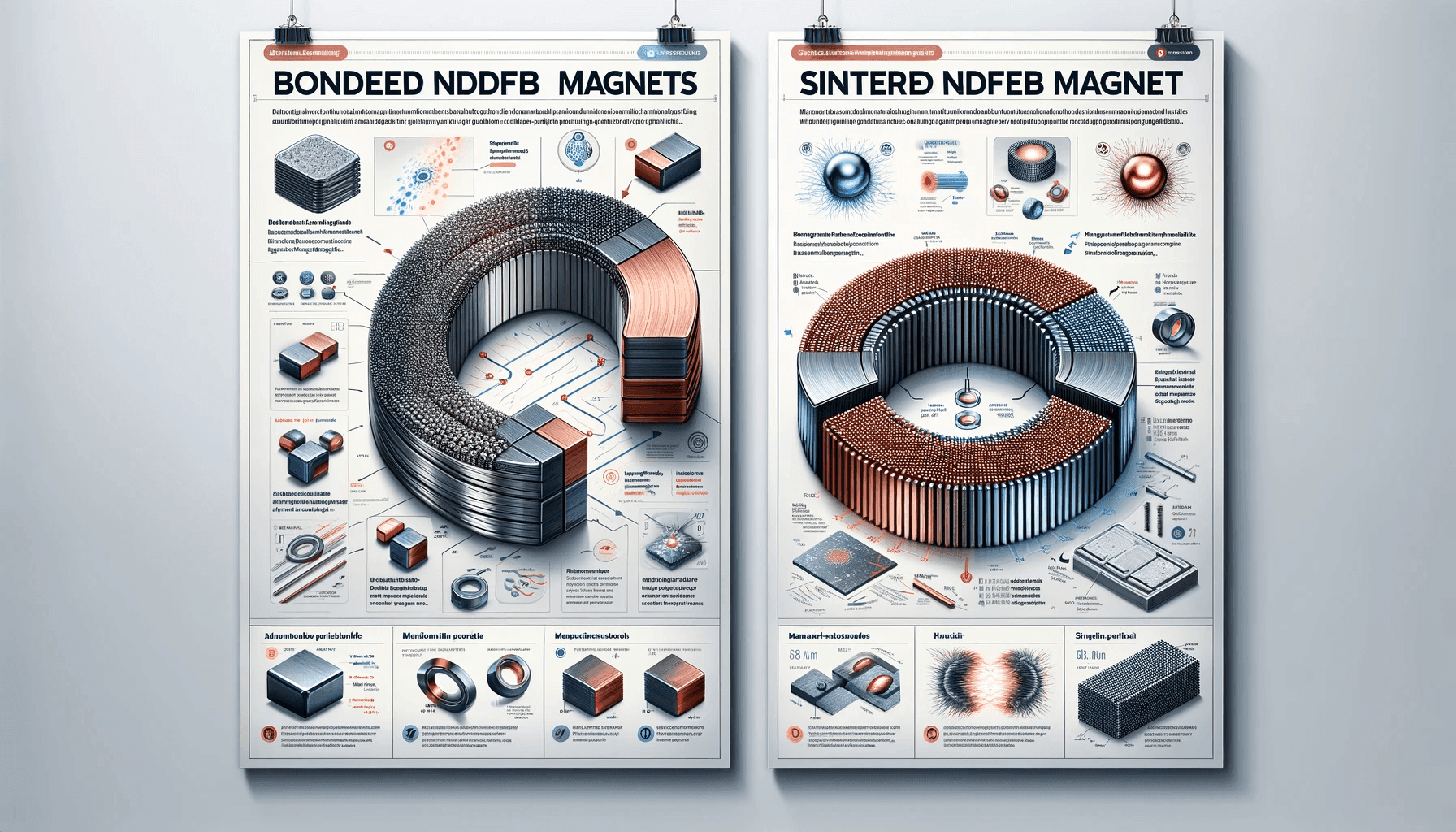

What is the difference between bonded and sintered neodymium magnets?

Bonded neodymium magnets, also known as NdFeB polymer magnets, are composite materials consisting of neodymium-iron-boron magnetic powder particles embedded in a polymer or resin matrix. These magnets are formed through an injection molding process, where the magnetic powder and polymer are combined and then molded into the desired shape.

On the other hand, sintered neodymium magnets are produced through a powder metallurgy process, where neodymium-iron-boron magnetic powder is compacted under high pressure and then sintered (heated) in a controlled atmosphere. This process results in a dense, solid magnet without the need for a polymer binder.

The primary difference between these two types of neodymium magnets lies in their manufacturing processes, composition, structure, magnetic properties, and applications.

Manufacturing Process Differences

Bonded neodymium magnets are manufactured through an injection molding process, similar to that used for plastic products. The magnetic powder and polymer binder are mixed together and then injected into a mold under high pressure and temperature. This process allows for the production of complex shapes and intricate designs, making bonded magnets suitable for applications where precise geometries are required.

In contrast, sintered neodymium magnets are produced through a powder metallurgy process. The neodymium-iron-boron magnetic powder is first compacted under high pressure, forming a dense, solid shape. This compacted shape is then sintered (heated) in a controlled atmosphere, typically at temperatures exceeding 1,000°C (1,832°F). During the sintering process, the magnetic particles fuse together, creating a strong, dense magnet without the need for a polymer binder.

Composition and Structure Differences

Bonded neodymium magnets are composite materials, consisting of neodymium-iron-boron magnetic powder particles dispersed within a polymer or resin matrix. The polymer binder acts as a binding agent, holding the magnetic particles together and allowing the magnet to maintain its shape. The resulting structure is non-crystalline or amorphous, with the magnetic particles randomly oriented within the polymer matrix.

In contrast, sintered neodymium magnets are composed solely of neodymium-iron-boron magnetic material, without the presence of a polymer binder. The sintering process fuses the magnetic particles together, creating a dense, crystalline structure. This crystalline structure, with its highly aligned magnetic domains, contributes to the superior magnetic properties of sintered neodymium magnets.

Magnetic Properties and Density Differences

Due to their composition and manufacturing processes, bonded and sintered neodymium magnets exhibit distinct magnetic properties and densities.

Sintered neodymium magnets typically possess higher magnetic energy density and higher maximum energy product (BHmax) values compared to bonded magnets. This means that sintered magnets can generate stronger magnetic fields and store more magnetic energy per unit volume, making them ideal for applications that require high magnetic performance.

Additionally, sintered neodymium magnets have a higher density, typically ranging from 7.4 to 7.6 g/cm³, while bonded magnets have a lower density, typically around 3.5 to 5.5 g/cm³, due to the presence of the polymer binder.

The higher magnetic performance and density of sintered neodymium magnets can be attributed to their crystalline structure and the absence of a non-magnetic polymer binder, which allows for better alignment and interaction of the magnetic domains within the material.

Application Differences

The unique properties of bonded and sintered neodymium magnets make them suitable for different applications:

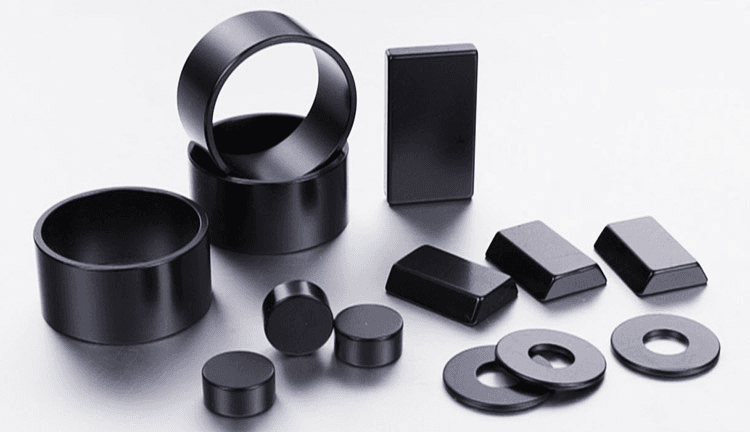

Bonded neodymium magnets are widely used in applications where complex shapes, intricate designs, or specific geometries are required. They are commonly found in consumer electronics, such as speakers, motors, and sensors, as well as in various industrial applications, including magnetic separators, magnetic couplings, and magnetic assemblies.

Sintered neodymium magnets, on the other hand, are preferred in applications that demand high magnetic performance and energy density. They are extensively used in high-end applications such as wind turbines, electric vehicles, medical imaging equipment (MRI machines), and high-performance motors and generators.

Advantages and Disadvantages

Both bonded and sintered neodymium magnets have their own advantages and disadvantages:

Bonded neodymium magnets offer several advantages, including:

– Ability to produce complex shapes and intricate designs

– Lower manufacturing costs compared to sintered magnets

– Resistance to corrosion and oxidation due to the polymer binder

– Flexibility and impact resistance, making them suitable for applications where vibration or shock is a concern

However, bonded magnets also have some disadvantages, such as:

– Lower magnetic performance compared to sintered magnets

– Lower maximum operating temperature due to the polymer binder

– Potential for demagnetization at high temperatures or in strong opposing magnetic fields

Sintered neodymium magnets, on the other hand, offer superior magnetic performance and energy density, making them ideal for high-end applications. However, they also have some drawbacks:

– Higher manufacturing costs due to the complex powder metallurgy process

– Brittleness and susceptibility to chipping or cracking

– Potential for corrosion or oxidation without proper coatings or protective measures

– Limited ability to produce complex shapes or intricate designs

Conclusion

The choice between bonded and sintered neodymium magnets ultimately depends on the specific requirements of the application. Bonded magnets offer versatility in shape, lower manufacturing costs, and resistance to corrosion and impact, making them suitable for a wide range of consumer and industrial applications. Sintered magnets, on the other hand, provide superior magnetic performance and energy density, making them the preferred choice for high-end applications that demand exceptional magnetic strength and efficiency.

As technology continues to evolve, the demand for powerful and versatile magnetic materials will only increase. By understanding the differences between bonded and sintered neodymium magnets, engineers, designers, and manufacturers can make informed decisions and select the most appropriate magnetic solution for their specific needs, driving innovation and advancing the boundaries of what is possible in various industries.