1. Introduction: Rethinking Magnet Development for the AI Era

In an era where innovation cycles are shrinking, the demand for high-performance magnetic materials is rising faster than ever. Electric vehicles, robotics, aerospace, and renewable-energy systems all rely on stronger, lighter, and more stable magnets.

However, traditional magnet development depends heavily on empirical testing and trial-and-error formulation — a process that can take months or even years.

Magnetstek bridges this gap by integrating artificial intelligence (AI) and simulation-driven design to accelerate material discovery and magnetic assembly optimization. This approach enables rapid, data-driven customization, helping clients achieve faster time-to-market and higher performance reliability.

2. The Power of AI in Magnetic Material Discovery

AI is transforming how magnetic materials are identified, tested, and optimized. Instead of physically producing and testing every alloy composition, AI models can predict material performance using historical data, physical principles, and simulation results.

2.1 AI-Assisted Alloy Screening

- Machine learning algorithms analyze thousands of existing alloy datasets to predict coercivity (Hc), remanence (Br), and Curie temperature (Tc).

- This helps identify promising new compositions — such as low-dysprosium (Dy) or Dy-free NdFeB alternatives — without costly experiments.

2.2 Predictive Performance Modeling

- Neural network models simulate how grain size, crystal orientation, and dopant concentration affect overall magnetic behavior.

- The result: accelerated discovery of compositions with improved temperature resistance, corrosion stability, and magnetization uniformity.

2.3 Design Automation

- AI integrates with finite element analysis (FEA) to automate geometry optimization for assemblies — predicting how magnet shape, orientation, and gap tolerances affect magnetic field distribution.

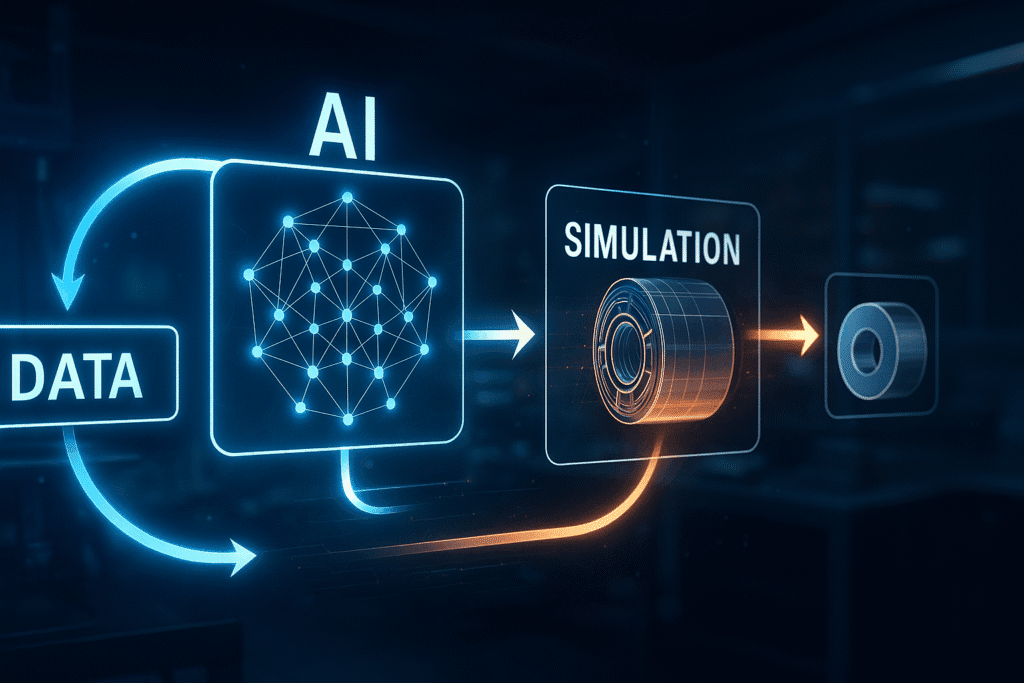

3. How Magnetstek Uses AI + Simulation to Accelerate Custom Magnet Development

At Magnetstek, AI is not just a research tool — it’s embedded throughout the product design workflow.

3.1 Data-Driven Material Selection

Using internal databases and machine learning models, Magnetstek predicts material behavior under specific customer conditions:

- Operating temperature range (−40 °C to 250 °C).

- Magnetic field strength and stability requirements.

- Environmental durability (humidity, vacuum, radiation).

3.2 Virtual Prototyping and Digital Twins

Before a physical sample is produced, Magnetstek creates a digital twin of the magnet or assembly.

Through 3D magnetic simulation, engineers evaluate:

- Flux density and uniformity.

- Torque response in rotating machinery.

- Magnetic coupling efficiency.

- Field leakage and demagnetization risk.

This enables virtual validation of hundreds of design variants overnight — eliminating costly trial-and-error fabrication.

3.3 Automated Geometry Optimization

AI-assisted topology algorithms adjust magnet dimensions, pole counts, and orientations automatically to reach desired torque or field output — ideal for:

- Halbach rotors.

- Linear actuator arrays.

- Precision sensors and medical instruments.

3.4 Rapid Iteration & Production Integration

Once the optimal design is confirmed through simulation, Magnetstek’s engineering team transitions directly to prototyping or pilot production.

Because field patterns and mechanical stresses are pre-validated, lead time from design to functional testing can drop by up to 70%.

4. Application Examples

4.1 Electric Vehicle Motors

AI-optimized NdFeB assemblies achieve higher efficiency and reduced rare-earth usage by refining pole geometry and flux paths.

→ Result: lighter rotors, less heat generation, and improved torque density.

4.2 Industrial Robotics

Simulation-driven design of thin disc magnets and multi-pole ring arrays enables smoother motion and more accurate feedback control.

→ Result: lower vibration and higher positional precision.

4.3 Aerospace and Space Systems

AI-guided selection of SmCo and FeCo alloys ensures magnetic stability in cryogenic and radiation-exposed conditions.

→ Result: reliable magnetic performance during long-term missions.

5. Benefits for Magnetstek’s Clients

| Customer Objective | Magnetstek Solution | Outcome |

|---|---|---|

| Faster R&D cycle | AI + digital twin simulation | Up to 70% faster prototyping |

| Lower development cost | Reduced experimental runs | 40–60% cost savings |

| Improved reliability | Virtual field validation | Consistent magnetic performance |

| Supply chain flexibility | Rare-earth substitution modeling | Material independence |

By combining AI with magnetic expertise, Magnetstek helps global customers shorten their innovation cycle while achieving high-precision results.

6. Future Outlook

The convergence of AI, simulation, and manufacturing data is leading to a new paradigm:

- Generative AI for Magnet Design: Automatically creates magnet geometries optimized for multiple performance parameters.

- AI-Driven Sustainability: Identifies recyclable alloy systems and energy-efficient production routes.

- Collaborative Design Platforms: Real-time cloud interfaces allowing clients to co-simulate with Magnetstek engineers before production.

This vision positions Magnetstek as a digital partner in the magnetics industry — merging advanced analytics with hands-on engineering.

7. You May Also Want to Know (FAQs)

1. How does AI accelerate magnet development?

AI predicts material and performance outcomes before physical testing, drastically shortening the R&D cycle.

2. What simulation tools does Magnetstek use?

Finite element modeling (FEA), multiphysics solvers, and proprietary AI-driven geometry optimization software.

3. Can this process be used for all magnet types?

Yes — including NdFeB, SmCo, AlNiCo, and soft magnetic assemblies.

4. How accurate are AI predictions?

Validated models typically achieve 90–95% correlation with experimental data.

5. Does AI help reduce rare-earth element dependency?

Absolutely. AI identifies alternative alloys with similar performance but lower critical element content.

6. How can customers collaborate with Magnetstek?

Clients can share CAD or magnetic field requirements; Magnetstek performs virtual simulations and delivers optimized designs.

7. What industries benefit most?

Automotive, robotics, aerospace, defense, renewable energy, and precision manufacturing.

8. Is AI also used in quality control?

Yes — AI analyzes magnetization and dimensional data to predict performance deviation early in production.

9. What is the typical project timeline?

From initial concept to validated prototype: 2–4 weeks depending on complexity.

10. Can AI handle multi-physics scenarios (thermal + magnetic)?

Yes — Magnetstek’s coupled simulation framework includes thermal, structural, and magnetic domains.

AI is revolutionizing magnetics — transforming what used to be a lengthy, experiment-driven process into a fast, intelligent, and predictive design workflow.

By combining artificial intelligence, digital simulation, and advanced manufacturing, Magnetstek delivers not only magnets, but complete engineering solutions that help clients move from concept to production with confidence and speed.

Magnetstek — Accelerating Innovation through Smart Magnet Design.