In modern medical devices, particularly implantable or portable infusion pumps, rotary blood pumps, insulin delivery systems, and microfluidic medication modules, precision and reliability are non-negotiable. Magnetic components lie at the center of these systems, enabling contactless torque transfer, hermetic sealing, reduced wear, and consistent long-term performance. This case study examines the engineering, development, and real-world application of a custom multi-pole radial magnet ring designed for a next-generation miniature medical pump. The project highlights the challenges, design requirements, material selection, magnetic simulations, manufacturing considerations, and validation results, illustrating how tailored magnet solutions can significantly enhance device capability.

This study is based on an end-customer program in which engineering teams required a compact, high-efficiency magnetic rotor capable of high rotational precision, strong torque output in limited space, low energy consumption, and stable behavior across a wide temperature and humidity range. Their existing commercial magnet rings suffered from weak pole strength, insufficient radial uniformity, and suboptimal bonding reliability, which led to reduced pump consistency and higher rejection rates during assembly.

Our task was to engineer a custom radial-magnetized, multi-pole magnet ring, optimized specifically for their pump geometry and dynamic requirements. The development process covered magnet selection, magnetic orientation strategy, pole count optimization, geometric design, simulation-driven refinement, prototyping, and production validation. The final component demonstrated significantly improved torque density, smoother rotation, enhanced power efficiency, and reliable operation at high speeds—resulting in a robust upgrade to the medical pump’s functional performance.

Background and Application Context

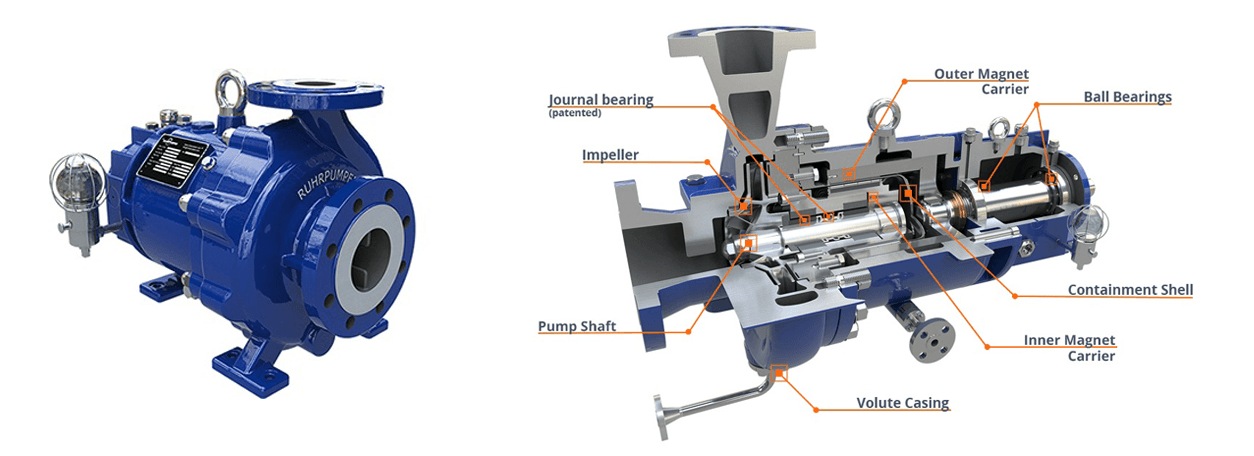

Small medical pumps rely on magnetic coupling to transfer torque from an external or internal motor to a fluid impeller while maintaining a sealed sterile environment. Unlike industrial pumps where size is less restrictive, medical pumps must be miniaturized, lightweight, and energy-efficient, often powered by small batteries that must last for years. Magnet performance therefore strongly influences the pump’s lifespan and reliability.

Traditional radial magnet rings are typically produced using segment assembly or sintered radial rings with limited pole count. While these methods are widely used in consumer products, they often fail to meet medical device expectations, particularly in:

- Torque ripple and rotational non-uniformity

- Noise and vibration

- Heat generation

- Pole-to-pole imbalance

- Demagnetization under high load or sterilization cycles

- Variability from magnet to magnet

The customer required a magnetic solution that would address these weaknesses without increasing pump size or compromising material biocompatibility.

Their product concept incorporated a brushless DC micro-motor driving a magnetic impeller inside a sealed chamber. The magnet ring needed to provide high coupling efficiency for rotation speeds up to 6,000–12,000 rpm, depending on pump mode, and withstand humidity, sterilization, and repeated thermal cycles. Additionally, the pump required exceptionally low audible noise and minimal vibration to enhance patient comfort.

Design Requirements for the Magnet Ring

Before development began, the engineering team defined the following key parameters:

- Outer Diameter (OD): approximately 20–24 mm (compact medical form factor)

- Inner Diameter (ID): 10–12 mm to fit over a titanium or stainless-steel hub

- Height: 10–18 mm depending on coil design and impeller geometry

- Pole Count: 8–36 poles, depending on target torque and motor electronics

- Magnet Material: high-grade NdFeB, ideally N52 or equivalent high-remanence type

- Magnetization Mode: radial, multi-pole, all north-south alternating or unidirectional outward-facing polarity

- Temperature Range: 0°C to 60°C continuous operating range, with short-term exposure up to 90°C during sterilization

- Surface Coating: medical-grade epoxy, Parylene, or NiCuNi+epoxy hybrid for corrosion resistance

- Performance Goals:

- strong radial magnetic field

- high torque transfer

- reduced cogging

- quiet and smooth rotation

- stable performance across the entire lifetime of the pump

These requirements laid the foundation for a multi-stage engineering process.

Material Evaluation and Selection

NdFeB was the preferred material due to its high energy product, enabling substantial magnetic performance within limited dimensions. Several grades were evaluated:

- N35–N42: acceptable for low-cost consumer pumps but insufficient for medical torque density

- N48–N50: good balance of cost and strength but marginal for extreme efficiency requirements

- N52 grade: highest available remanence in commercial supply, maximizing torque in small geometries

- High-temperature grades (e.g., H, SH, UH): considered for sterilization cycles

Ultimately, a modified N52H grade was selected, combining strong magnetic flux with improved resistance to thermal demagnetization.

Given the humidity sensitivity of NdFeB, corrosion protection was essential. Parylene-C and medical-grade epoxy were both evaluated; epoxy provided better mechanical durability for press-fit assembly, while Parylene offered exceptional biocompatibility. The final choice was dual-layer NiCuNi + epoxy, optimized for strength and environmental durability.

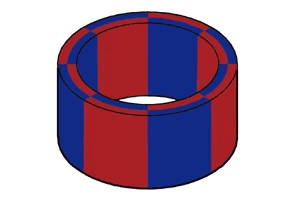

Magnetization Strategy and Pole Optimization

Unlike standard ring magnets, which often use 2, 4, or 8 poles, medical pumps benefit from higher pole counts to achieve smoother torque, quieter operation, and higher efficiency at lower electrical load.

Three magnetization schemes were evaluated:

- Alternating North-South (multi-pole) radial magnetization: ideal for BLDC motors, offering strong torque ripple reduction.

- All-south or all-north outward (unidirectional) magnetization: preferred for coupling applications where external pole concentration is required.

- Halbach-like radial patterns: combining strong outward flux with reduced inward flux.

Simulations revealed that a 12-pole and 18-pole design offered optimal balance for the customer’s drive electronics and impeller geometry. Higher pole counts such as 24- or 36-pole rings were tested but resulted in overly thin magnetic domains, reducing field strength and increasing complexity.

The selected configuration achieved:

- consistent magnetic flux density along the circumference

- low cogging torque

- strong rotational coupling

- improved energy efficiency by reducing motor current draw

Peak surface field measurements exceeded 6,000 Gauss across the pole transitions, meeting the customer’s torque requirement.

Mechanical Design Considerations

The magnet ring had to integrate seamlessly with the impeller shaft system while maintaining dimensional precision and robustness.

Key mechanical requirements included:

- Concentricity within 0.03 mm to avoid imbalance

- Flatness tolerance within 0.05 mm to minimize axial wobble

- Tight ID tolerance to ensure secure mounting on the titanium hub

- Controlled press-fit interface to avoid micro-cracking of sintered NdFeB

- Anti-chipping edges, achieved by chamfering and polishing critical zones

- Coating thickness uniformity to maintain magnetic gap accuracy

To further stabilize magnetic performance, an internal soft-magnetic sleeve was considered. A thin stainless-steel 430/434 ring (0.5–1.0 mm thickness) inside the magnet was modeled to determine whether flux return improvement would enhance torque. In this case, simulations showed a moderate but measurable improvement (~8–12%), but the customer preferred a non-metallic core for easier sterilization and reduced inertial mass, so the design remained magnet-only.

Manufacturing Processes and Challenges

Producing multi-pole radial magnet rings is more complex than manufacturing axially magnetized or simple segment-bonded rings. The process involved:

1. High-precision sintering

The magnet blank was sintered to near-net shape with tight control over crystal grain orientation to support radial magnetization. Variation in grain alignment would lead to inconsistent pole strengths.

2. CNC machining

Post-sintering, the ring was machined to achieve precise OD/ID tolerances. However, NdFeB is brittle, so machining required specialized diamond tooling, slow feed speeds, and coolant control.

3. Multi-pole magnetizing fixture

A customized magnetizing fixture was developed to achieve uniform radial fields. Fixture design required simulation of:

- coil positioning

- flux concentration

- heat distribution during pulse magnetization

- pole uniformity tuning

4. Coating application

Dual-layer coating was applied with thickness controlled to ±5 μm. Coating adhesion was tested across thermal cycling, high humidity, and immersion environments.

5. Quality consistency across batches

Medical devices demand near-zero variability. Therefore, special control procedures were established:

- 100% pole-strength mapping

- circumferential field uniformity scans

- mechanical tolerance verification

- coating thickness testing

- dynamic balance testing

The most challenging step was ensuring all rings in the batch achieved identical pole shapes and amplitudes—critical for electronic commutation consistency. Fixture improvement and pulse waveform tuning ultimately solved the issue.

Simulation-Driven Optimization

Magnetic simulation (FEM) was used extensively to refine the design. Three major areas were explored:

Magnetic flux distribution

Field contours revealed how flux traveled across each pole. Adjustments were made to pole width, ring thickness, and material grade.

Torque output modeling

Using the customer’s BLDC motor parameters, torque curves were generated to compare pole scenarios. The final model matched the targeted torque output with a safety margin of ~18%.

Thermal-demagnetization safety

Simulations ensured that at the highest expected temperature (around 90°C), the magnet would retain >90% of its original flux density. This verified suitability for sterilization cycles.

Prototype Fabrication and Testing

Several prototypes were produced for evaluation:

- 12-pole version, 18 mm height

- 18-pole version, 16 mm height

- Halbach-enhanced variation

- Single-direction outward-pole version

Testing included:

1. Magnetic Field Measurements

Rotating Gaussmeter mapping confirmed pole count, amplitude uniformity, and transition sharpness. The best version achieved <4% peak-to-peak variation.

2. Torque Coupling and Efficiency Test

In the pump assembly, power consumption decreased by 6–9% compared to the original magnet ring, enabling longer device battery life.

3. Noise and Vibration Evaluation

Vibration amplitude dropped by ~22%, and audible noise decreased due to smoother torque ripple.

4. High-Speed Rotary Testing

The magnet maintained stability at speeds up to 7,000 rpm with no demagnetization or coating damage. Extended testing up to 12,000 rpm demonstrated excellent performance.

5. Thermal/Humidity Stress

After 120 thermal cycles and >500 hours at 95% humidity, there was no measurable degradation.

Customer Integration and Final Performance

After extensive evaluation, the customer selected the 18-pole radial magnetized ring, noting several improvements:

More stable pump output flow

Reduced motor current draw

Lower operating temperature of the motor

Quieter and smoother rotation

Higher reliability during prolonged continuous operation

A major advantage was the magnet ring’s excellent reproducibility across production batches. This solved a long-standing problem the customer faced with inconsistent magnet performance.

The magnet ring became a key enabler in the customer’s upgraded pump system, ultimately helping them achieve regulatory approvals and move into scaled manufacturing.

Lessons Learned and Engineering Insights

This case study highlights several insights relevant to magnet design for medical pumps:

- Pole count is critical for noise and efficiency, not merely torque.

- Material and coating selection strongly affect long-term reliability in humid or sterilized environments.

- Radial magnetization is highly sensitive to fixture design, requiring careful tuning.

- Simulations dramatically reduce development cycles, enabling rapid iteration.

- Balance between pole count and pole strength must be optimized to avoid magnetic domain thinning.

- Dimensional precision directly affects pump stability, particularly concentricity and ID tolerance.

- Manufacturing repeatability is essential for medical devices, where single defective magnets can cause system-level failures.

Conclusion

The development of this custom multi-pole radial magnet ring illustrates how tailored magnet engineering significantly improves the performance of miniaturized medical pump systems. By combining high-grade materials, precision machining, advanced magnetization methods, robust coatings, and simulation-driven optimization, we delivered a solution that surpassed the customer’s previous component in every measurable category.

The project underscores the importance of close integration between magnet engineers, motor designers, and pump developers. When properly executed, customized magnet assemblies can transform the efficiency, reliability, and user experience of medical devices—enabling quieter, safer, longer-lasting pumps that are essential in modern healthcare.