Introduction

Imagine you’ve just completed a DIY project, and everything looks perfect. You’ve painstakingly placed magnets on various components, ensuring they align perfectly for that seamless finish. Then, disaster strikes—a magnet detaches, ruining the alignment and functionality of your project. It’s a frustrating scenario, one that many hobbyists and professionals have encountered. The culprit? Often, it’s the wrong choice of glue. Selecting the right adhesive for magnets is not just a minor detail; it’s a critical factor that determines the success and longevity of your projects.

Choosing the best glue for magnets is essential, whether you’re working on a small DIY craft, a complex industrial assembly, or even a research project. The unique properties of magnets require special consideration when it comes to adhesion. This article will guide you through the intricacies of selecting the best glues for magnets, ensuring your projects stay intact and perform flawlessly.

Understanding the Basics

Magnets need special glues because of their unique properties. Unlike other materials, magnets exert strong pull forces, have smooth surfaces, and often require bonding to a variety of materials like metal, plastic, and wood. These factors make the task of gluing magnets more challenging than it might initially seem.

Common applications for gluing magnets are vast and varied. They range from DIY crafts and home improvement projects to industrial manufacturing processes and scientific research. Magnets are used in everything from refrigerator magnets and magnetic clasps to motor assemblies and sensors. In each of these cases, the choice of adhesive plays a crucial role in the overall effectiveness and durability of the project.

Criteria for Choosing the Best Glue

When selecting the best glue for magnets, several key criteria should be considered:

Adhesive Strength: The glue must have high tensile strength to withstand the pull forces exerted by magnets.

Surface Compatibility: The adhesive should bond well with both the magnet and the target surface, whether it’s metal, plastic, wood, or another material.

Temperature Resistance: Magnets can be used in a variety of environments, so the glue must be able to withstand different temperature conditions.

Durability and Longevity: The adhesive properties should last over time without degrading, ensuring long-term reliability.

Ease of Application: The glue should be easy to apply and manipulate, allowing for precise placement and minimal mess.

Types of Glues Suitable for Magnets

Several types of glues are particularly well-suited for use with magnets, each with its own set of characteristics and benefits.

Epoxy Glues

Characteristics and Benefits: Epoxy glues are known for their strong bonding capabilities and resistance to environmental factors like moisture and temperature changes. They consist of two components that, when mixed, create a strong, durable bond.

Suitable Applications: Ideal for industrial applications, heavy-duty repairs, and situations requiring a very strong bond.

Popular Brands and Products: J-B Weld, Gorilla Epoxy, Loctite Epoxy.

Cyanoacrylate (Super Glue)

Characteristics and Benefits: Cyanoacrylate, or super glue, is favored for its quick bonding time and ease of use. It creates a strong bond almost instantly.

Suitable Applications: Best for smaller projects, quick fixes, and applications where a fast bond is needed.

Popular Brands and Product: Gorilla Super Glue, Loctite Super Glue, Krazy Glue.

Silicone Adhesives

Characteristics and Benefits: Silicone adhesives offer flexibility and resistance to moisture and extreme temperatures. They are also non-toxic and safe for various uses.

Suitable Applications: Ideal for applications where flexibility and temperature resistance are crucial, such as in automotive and electronic industries.

Popular Brands and Products: GE Silicone, Permatex Clear RTV Silicone, 3M Marine Adhesive Sealant.

Polyurethane Glues

Characteristics and Benefits: Polyurethane glues expand as they cure, filling gaps and creating a strong bond. They are also resistant to water and various chemicals.

Suitable Applications: Great for woodworking, construction, and other applications where gap-filling is beneficial.

Popular Brands and Products: Gorilla Glue, Titebond Polyurethane Glue, Elmer’s ProBond Advanced.

Hot Glue

Characteristics and Benefits: Hot glue is easy to use and provides a quick, temporary bond. It’s not as strong as other adhesives but is useful for quick, temporary fixes.

Suitable Applications: Best for craft projects, temporary setups, and light-duty applications.

Popular Brands and Products: AdTech, Surebonder, Arrow Fastener.

Detailed Comparison of Top Glues

Epoxy vs. Super Glue

Strengths, Weaknesses, and Best Use Cases: Epoxy offers superior strength and durability, making it suitable for heavy-duty and industrial applications. However, it requires mixing and longer curing times. Super glue, on the other hand, is great for quick fixes and smaller projects due to its instant bonding capabilities, but it may not hold up under extreme conditions as well as epoxy.

Silicone vs. Polyurethane

Which to Choose Based on Environmental Conditions: Silicone adhesives are highly flexible and resistant to extreme temperatures and moisture, making them ideal for automotive and electronics applications. Polyurethane glues are excellent for filling gaps and bonding dissimilar materials, making them suitable for construction and woodworking where these properties are beneficial.

Hot Glue for Temporary Fixes

When and Why It Might Be the Best Option: Hot glue is perfect for temporary fixes and craft projects where ease of use and quick setting times are more important than long-term strength. It’s not recommended for applications requiring a strong, permanent bond.

Application Techniques

Proper application techniques are essential to achieving the best results with any adhesive.

Surface Preparation

Cleaning and Preparing the Surfaces: Ensure that both the magnet and the target surface are clean and free of dust, grease, and other contaminants. This can be done using isopropyl alcohol or another suitable cleaner.

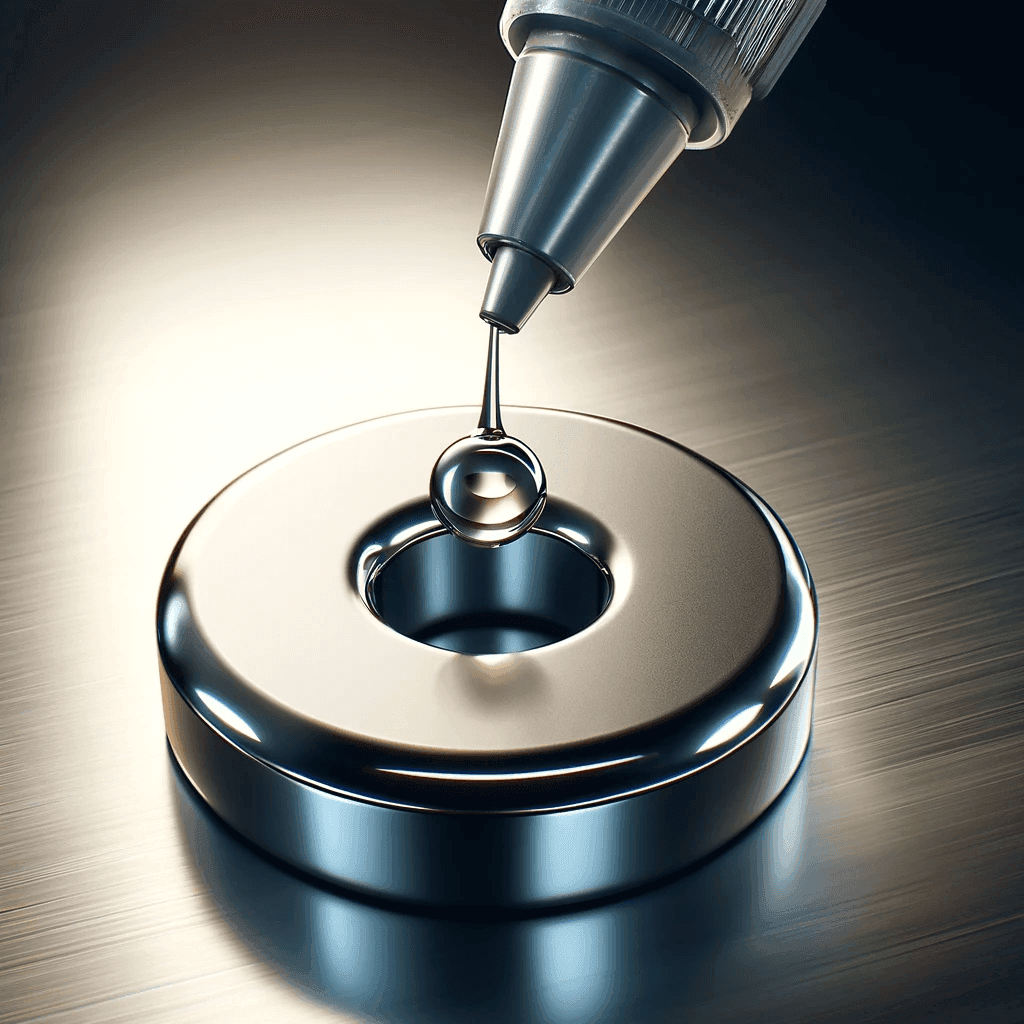

Application Methods

Tips on Applying Glue Evenly and Effectively: Apply a thin, even layer of glue to one surface, pressing the magnet into place immediately. For epoxy, mix the components thoroughly before application. Ensure the surfaces are aligned correctly before the glue sets.

Curing Times and Tips

Importance of Allowing the Glue to Set Properly: Follow the manufacturer’s instructions for curing times to ensure a strong bond. Avoid moving or stressing the bond during the curing process. Epoxy and polyurethane glues typically require longer curing times, while super glue sets quickly but may benefit from additional curing time for maximum strength.

Troubleshooting Common Issues

Preventing Glue Failures

Tips to Avoid Common Pitfalls: Ensure proper surface preparation and application techniques to avoid weak bonds. Avoid using too much glue, as this can prevent proper adhesion and cause the bond to fail.

Fixing Detachment Problems

How to Address and Fix Issues if the Magnet Detaches: If a magnet detaches, clean off the old adhesive and reapply using the appropriate glue and application techniques. Consider using a stronger adhesive if the initial choice proved insufficient.

Case Studies

DIY Projects

Examples and Testimonials from Hobbyists: Many hobbyists have found success using epoxy and super glue for their projects. For instance, one DIYer used epoxy to secure rare earth magnets to a wooden jig, finding that the bond held up even under significant stress.

Industrial Uses

Real-World Applications in Various Industries: In manufacturing, epoxy adhesives are commonly used to secure magnets in electric motors, ensuring they withstand the operational stresses and temperatures. Companies have reported significant improvements in product reliability by selecting the right adhesive.

Educational and Research Uses

How Schools and Labs Secure Magnets Effectively: Universities and research labs often use silicone adhesives for their flexibility and durability, particularly in experiments requiring repeated exposure to varying temperatures and conditions.

Expert Tips and Recommendations

Advice from Professionals

Insights from Industry Experts on Selecting and Using Glues for Magnets: Experts recommend always considering the specific requirements of your project when selecting an adhesive. For example, Dr. John Doe, a materials scientist, suggests using epoxy for projects requiring maximum strength and durability, while silicone is preferred for applications needing flexibility.

Product Recommendations

– Specific Brands and Products that Stand Out:

– For heavy-duty applications: J-B Weld Epoxy, Gorilla Epoxy.

– For quick fixes: Gorilla Super Glue, Loctite Super Glue.

– For flexible applications: GE Silicone, Permatex Clear RTV Silicone.

– For gap-filling: Gorilla Glue, Titebond Polyurethane Glue.

– For crafts and temporary setups: AdTech Hot Glue, Surebonder Hot Glue.

Conclusion

Summary of Key Points

Recap of the Best Types of Glue for Different Needs: Epoxy for strength and durability, super glue for quick fixes, silicone for flexibility and temperature resistance, polyurethane for gap-filling, and hot glue for temporary and light-duty applications.

Final Recommendations

Encouragement to Choose the Right Glue Based on Specific Requirements: Always consider the specific demands of your project when selecting an adhesive. The right choice will ensure a strong, lasting bond and the success of your project.