Adhesive magnets have become a versatile tool in countless industries—from advertising and retail to industrial applications and home décor. Their unique combination of magnetic properties with the ease of an adhesive backing makes them an attractive solution for many applications. However, with the broad range of adhesive magnets available on the market, choosing the right one for your specific needs can be a daunting task. This comprehensive guide is designed to walk you through everything you need to know—from understanding the basics of adhesive magnets to considering key factors such as magnetic strength, adhesive quality, environmental resistance, and customization options. Whether you are a business owner looking for promotional materials, an industrial engineer needing durable magnetic solutions, or a DIY enthusiast seeking creative projects, this article will provide valuable insights to help you make an informed decision.

What Are Adhesive Magnets?

At their core, adhesive magnets are products that combine a magnetic material with a self-adhesive backing. The magnetic component, which may be made of flexible rubberized materials or rigid metals, provides the power to stick to ferromagnetic surfaces, while the adhesive layer secures the magnet in place without the need for additional fastening tools.

Key Components

- Magnetic Material:

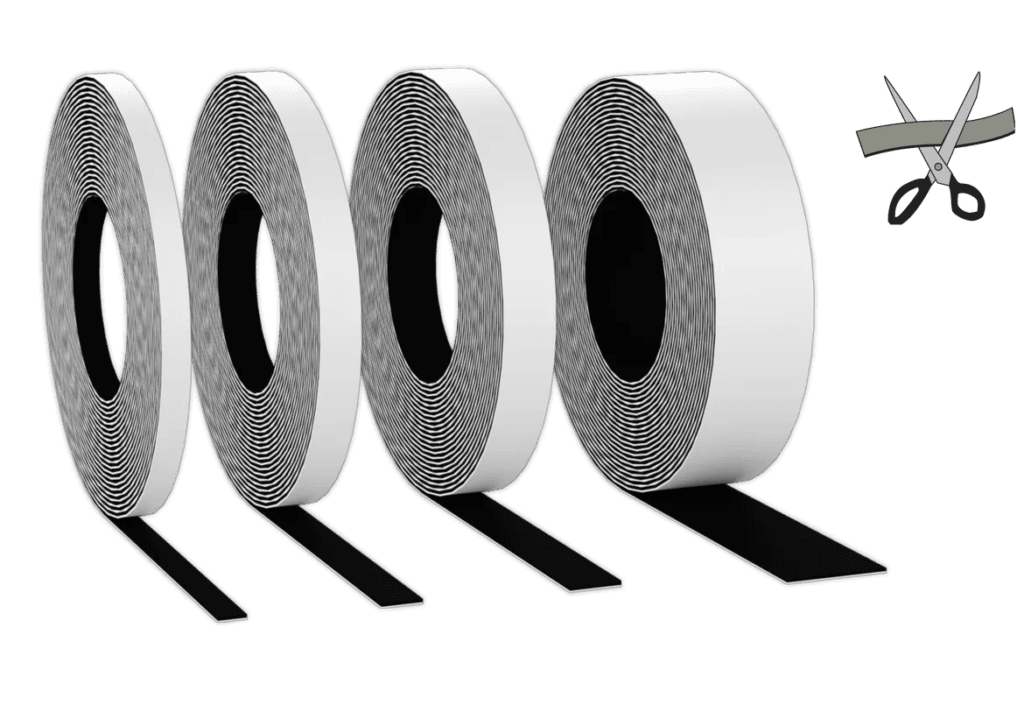

- Flexible Magnets: Often made from ferrite or a blend of magnetic powders with polymers, these magnets are bendable and can be cut into various shapes and sizes.

- Rigid Magnets: Typically composed of solid materials like neodymium, these magnets offer higher magnetic strength but usually lack the flexibility of their counterparts.

- Adhesive Backing:

- Permanent Adhesives: Provide a strong, long-lasting bond suitable for surfaces where the magnet will remain in place indefinitely.

- Repositionable Adhesives: Allow for temporary placement or repositioning, ideal for signage or applications where frequent adjustments are needed.

The simplicity of the design—integrating magnetism with adhesive qualities—makes these products easy to apply and highly effective across various applications.

Types of Adhesive Magnets

Adhesive magnets come in a variety of forms to suit different requirements. Understanding the distinctions between the types available will help you determine which one best fits your needs.

1. Flexible Adhesive Magnets

Flexible adhesive magnets are perhaps the most common type used in everyday applications such as refrigerator magnets, promotional signage, and temporary displays. Their main advantages include:

- Versatility: Easily cut or printed on, allowing for customization in shape, color, and size.

- Lightweight Construction: Suitable for applications where weight is a concern.

- Ease of Application: Their flexibility makes them easy to apply on both flat and slightly curved surfaces.

Common Applications:

- Retail promotions and point-of-purchase displays

- Temporary signage and event marketing

- Decorative home items

2. Rigid Adhesive Magnets

Rigid adhesive magnets are designed for situations that demand higher magnetic strength and durability. These magnets are less flexible but can offer significant holding power, making them ideal for industrial applications and heavy-duty uses.

Common Applications:

- Industrial equipment mounting

- Secure attachments in automotive applications

- Situations requiring long-term durability under challenging conditions

3. Specialty Adhesive Magnets

There are also specialty adhesive magnets designed to meet unique industry requirements. These might include magnets with enhanced environmental resistance (e.g., high temperature or UV resistance), magnets with a protective coating for chemical resistance, or magnets with customized adhesive formulas tailored to specific surfaces like glass or painted walls.

Key Features:

- Environmental Resistance: Suitable for outdoor or harsh industrial settings.

- Custom Adhesives: Formulated for optimal performance on difficult substrates such as oily or wet surfaces.

Key Considerations When Choosing Adhesive Magnets

Choosing the right adhesive magnet involves several factors beyond simply the strength of the magnet. Here are some essential considerations to ensure that your chosen product meets your needs.

Magnetic Strength and Pull Force

The effectiveness of an adhesive magnet largely depends on its magnetic strength, often quantified as the pull force. When evaluating magnetic strength, consider the following:

- Material Composition: The type of magnetic material—whether it is ferrite, neodymium, or a blend—affects the pull force. For heavy-duty applications, stronger materials like neodymium may be necessary.

- Size and Shape: Larger magnets generally offer greater surface area for adhesion and magnetic pull. However, the shape of the magnet (circular, rectangular, custom shapes) can also influence performance, particularly on curved or irregular surfaces.

- Thickness: A thicker magnetic layer may provide additional holding power but could also affect the flexibility of the magnet.

Adhesive Quality

The adhesive backing is as important as the magnetic component since it ensures the magnet stays in place. When assessing adhesive quality, consider:

- Bonding Strength: Ensure the adhesive is strong enough for the intended surface—whether it’s metal, glass, plastic, or painted surfaces.

- Surface Compatibility: Some adhesives are formulated to work best on smooth, non-porous surfaces, while others are designed for more challenging substrates.

- Durability and Longevity: Depending on whether the application is temporary or permanent, the adhesive’s resistance to temperature changes, moisture, and UV light will be crucial.

Environmental Conditions

The environment in which the adhesive magnet will be used plays a significant role in product selection:

- Temperature: For outdoor or industrial applications, consider magnets and adhesives that can withstand extreme temperatures.

- Humidity and Moisture: Environments with high humidity or exposure to water require adhesives that maintain their bonding properties even in moist conditions.

- UV Exposure: For outdoor applications, UV-resistant adhesives and magnet materials can help prevent degradation over time.

- Chemical Exposure: In industrial settings, exposure to chemicals or solvents is common. Ensure that the adhesive is resistant to any chemicals it might encounter.

Application-Specific Requirements

Different applications may have unique requirements:

- Temporary vs. Permanent Applications: If the magnet needs to be repositionable, opt for adhesives that allow for removal without leaving residue. For permanent installations, a stronger, more durable adhesive is preferred.

- Load and Stress Factors: Consider the weight or stress that will be placed on the magnet. Heavy signage or equipment may require magnets with higher pull force and robust adhesives.

- Aesthetic Considerations: In retail or decorative applications, the visual appeal of the magnet may be important. Custom printing, colors, and finishes can be crucial factors.

Customization Options

Many suppliers offer customization options for adhesive magnets, including:

- Custom Shapes and Sizes: Tailor the magnet to fit specific design requirements or application constraints.

- Printed Graphics: Ideal for marketing materials, promotional magnets can be printed with logos, images, and messages.

- Variable Adhesive Properties: Some suppliers allow you to choose between permanent and repositionable adhesives based on your project needs.

Economic Considerations

While quality and performance are critical, cost is also an important factor:

- Budget Constraints: Determine your budget early in the process. Higher-strength magnets and specialized adhesives may come at a premium.

- Cost vs. Performance: Sometimes, paying a little extra for higher quality can result in long-term savings by reducing maintenance or replacement costs.

- Volume Discounts: If you need a large quantity, many suppliers offer bulk pricing that can reduce the per-unit cost.

Understanding Magnetic Strength and Adhesion

A key part of selecting the right adhesive magnet is understanding how magnetic strength and adhesion work together. Here are some in-depth considerations:

Testing Magnetic Pull Force

- Laboratory Testing: Manufacturers often test the pull force of their magnets under controlled conditions. Understanding these ratings can help you compare products effectively.

- Real-World Conditions: Keep in mind that the rated pull force might differ in real-world applications due to factors such as surface irregularities and environmental conditions.

- Edge Effects: The magnetic pull can diminish near the edges of the magnet. For applications that require uniform holding power, consider magnets with a design that minimizes edge effects.

Evaluating Adhesive Performance

- Bonding Tests: Look for adhesives that have undergone rigorous testing to ensure they bond effectively with a range of substrates.

- Longevity Studies: Some products are tested for long-term performance to determine how the adhesive holds up over time, especially under stress or environmental exposure.

- Ease of Removal: For repositionable applications, consider adhesives that allow for clean removal without damaging the surface or leaving residue.

Integrating Magnetic Strength and Adhesive Bonding

The overall effectiveness of an adhesive magnet is a synergy between its magnetic strength and the adhesive quality. Even a powerful magnet can fail if the adhesive doesn’t hold up, and a strong adhesive is of little use if the magnet itself cannot generate enough pull force. Striking the right balance is crucial:

- Matching Adhesive to Magnet Strength: For high-strength magnets, ensure that the adhesive can support the load. This is particularly important in industrial applications where safety and reliability are paramount.

- Tailoring to Application Demands: Consider the specific demands of your application—whether you need a robust permanent bond or a flexible, repositionable solution.

Environmental Factors and Their Impact

When selecting an adhesive magnet, the environmental conditions in which it will be used are vital considerations. Different environments demand different properties from both the magnetic material and the adhesive backing.

Temperature Considerations

- High-Temperature Applications: In industrial settings or outdoor applications where temperatures can soar, select magnets and adhesives that can maintain their properties without degradation. Certain adhesives are designed to remain strong at elevated temperatures.

- Cold Environments: Conversely, in freezing conditions, some adhesives may become brittle or lose their bonding power. Verify that the product specifications match your environmental needs.

Humidity and Moisture Resistance

- Indoor vs. Outdoor: Indoor environments generally present fewer challenges than outdoor settings, where exposure to rain, snow, or high humidity can weaken the adhesive bond.

- Waterproof Adhesives: For applications exposed to moisture, look for adhesives that are specifically formulated to be waterproof or water-resistant, ensuring that the magnet remains securely attached.

UV and Weather Resistance

- Outdoor Exposure: Ultraviolet (UV) radiation can degrade both the magnetic material and the adhesive over time. Opt for UV-resistant coatings and adhesives for products destined for prolonged outdoor use.

- Weather Extremes: In areas prone to rapid weather changes, choose adhesives that have been tested for performance under fluctuating conditions.

Chemical and Solvent Exposure

- Industrial Settings: In industries where exposure to chemicals or solvents is a risk, ensure that the adhesive is resistant to these substances. This is particularly important for applications in manufacturing, automotive, or chemical processing facilities.

- Household Uses: Even in less harsh environments, household cleaners and other chemicals can affect the longevity of the adhesive. Choosing a product with chemical resistance can extend the life of your installation.

Application-Specific Considerations

Every application is unique, and your choice of adhesive magnet should reflect your specific needs. Here are some common application areas and the considerations for each:

Retail and Promotional Uses

- Visibility and Aesthetics: Promotional adhesive magnets often serve a dual purpose as both functional and advertising tools. Custom printing and vibrant colors are critical.

- Temporary Installations: For events, trade shows, or seasonal promotions, repositionable adhesives may be preferable, allowing for easy removal and reapplication without damaging surfaces.

- Lightweight Design: Since these magnets are often used on storefront windows or doors, a lightweight, flexible design is ideal.

Industrial and Heavy-Duty Applications

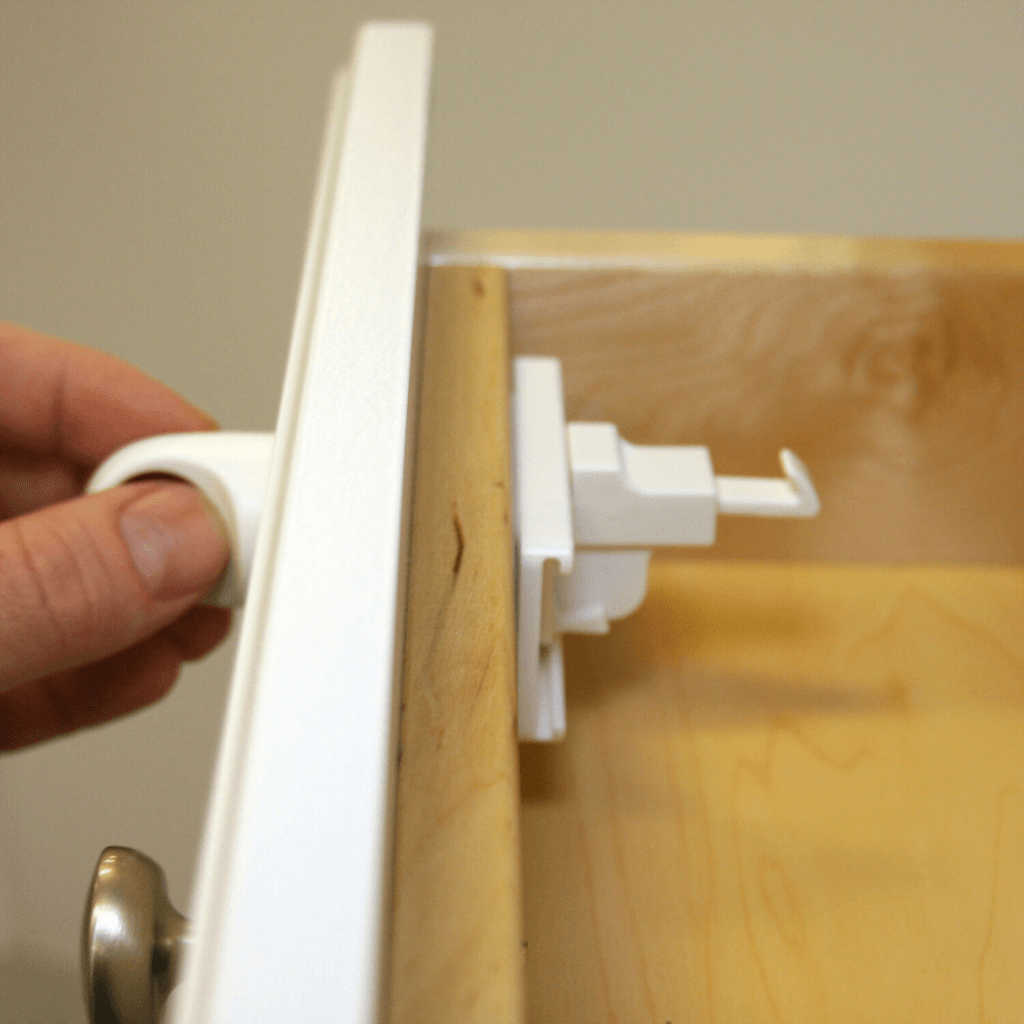

- High Pull Force: In industrial settings, the adhesive magnet must have a high pull force to hold up heavy machinery, panels, or equipment.

- Durability: These magnets must withstand harsh conditions, including extreme temperatures, vibration, and chemical exposure.

- Permanent Bonding: A permanent adhesive is often necessary for applications where safety is a concern, such as in automotive or aerospace industries.

Home and Office Decor

- Aesthetic Flexibility: Home décor magnets, such as those used on refrigerators or bulletin boards, often need to be visually appealing as well as functional.

- Easy Removal: In environments where the design may change over time, repositionable adhesives that do not damage surfaces are preferable.

- Variety of Sizes: From small decorative pieces to larger organizational tools, the range of sizes and shapes should match the intended use.

Custom and Niche Applications

- Unique Substrate Requirements: Some applications may involve surfaces that are challenging for standard adhesives—such as textured walls or uneven metal surfaces. Custom adhesive formulations may be necessary.

- Specialized Environmental Needs: For applications in extremely harsh or unique environments (e.g., marine applications, high-altitude installations), ensure that both the magnetic material and the adhesive are tailored to withstand these conditions.

- Bespoke Designs: Many suppliers offer custom shapes, sizes, and printing options to meet specific branding or functional requirements. This flexibility is invaluable for niche markets.

Tips on Installation and Maintenance

Even the best adhesive magnet will underperform if not installed and maintained correctly. Here are some tips to ensure longevity and optimal performance:

Installation Best Practices

- Surface Preparation:

- Clean the target surface thoroughly to remove dust, oils, and any residues that could compromise adhesion.

- For surfaces with irregular textures, consider using a primer or adhesive enhancer if recommended by the manufacturer.

- Temperature Considerations:

- Apply the magnet in a controlled environment where the temperature is within the recommended range. Extreme cold or heat during installation can affect the adhesive’s curing process.

- Pressure Application:

- After placing the magnet, apply firm, even pressure to ensure that the adhesive makes full contact with the surface.

- For larger magnets, using a roller or a flat tool can help distribute the pressure evenly.

Maintenance Guidelines

- Regular Inspection:

- Check the magnet periodically to ensure that it remains securely attached, especially in high-traffic or outdoor areas.

- Look for signs of adhesive degradation, such as peeling or discoloration.

- Cleaning:

- Gently clean the magnet and the surface with a mild detergent and water solution. Avoid harsh chemicals that could weaken the adhesive.

- Ensure the magnet is completely dry after cleaning to prevent moisture accumulation, which might compromise adhesion over time.

- Environmental Monitoring:

- In applications subject to fluctuating environmental conditions, monitor the magnet’s performance. If you notice any weakening of the bond, consider reapplying or replacing the magnet with one that is better suited to the new conditions.

Sourcing and Vendor Considerations

Selecting a reputable supplier is as important as choosing the right adhesive magnet for your application. Here are some guidelines for working with vendors:

Evaluate Supplier Credentials

- Quality Assurance:

- Look for suppliers who adhere to recognized quality standards and have certifications that guarantee the performance and safety of their products.

- Customer Reviews and Testimonials:

- Research customer feedback to gauge satisfaction levels and the reliability of the supplier’s products and services.

Custom vs. Off-the-Shelf Products

- Customization Options:

- Determine whether you need a bespoke solution or if an off-the-shelf product will suffice. Custom adhesive magnets can be tailored to exact specifications but may require longer lead times and higher costs.

- Sample Testing:

- If possible, request samples to test the magnetic strength and adhesive quality under your specific conditions before committing to a large order.

Cost and Lead Times

- Budget Alignment:

- Balance your need for quality and performance with your budget constraints. Consider not just the upfront cost, but also the long-term reliability and potential maintenance costs.

- Delivery and Support:

- Ensure that the vendor can meet your delivery timelines and provides robust customer support for any technical queries or issues that may arise.

Future Trends and Innovations in Adhesive Magnets

The field of adhesive magnets is continually evolving, driven by advancements in materials science and manufacturing technology. Here are some trends to watch:

Sustainable Materials

- Eco-Friendly Adhesives:

- Manufacturers are increasingly developing adhesives that are both high-performance and environmentally friendly, reducing the reliance on volatile organic compounds (VOCs).

- Recyclable Magnets:

- Research into recyclable magnetic materials is gaining momentum, catering to a growing demand for sustainable products in both industrial and consumer markets.

Enhanced Performance

- Smart Adhesive Magnets:

- Future developments may include magnets with integrated sensors that monitor adhesion performance or environmental conditions, providing real-time feedback for maintenance.

- Improved Durability:

- Advances in polymer chemistry and magnetic materials are leading to products that can withstand harsher environments and offer longer service lives.

Customization and Digital Printing

- On-Demand Customization:

- Digital printing technologies now allow for rapid customization of adhesive magnets, making it easier for businesses to create bespoke promotional materials that align with their brand identity.

- Flexible Manufacturing:

- Innovations in flexible manufacturing processes are enabling shorter lead times and more cost-effective production of custom adhesive magnets, making them accessible even for small businesses.

Conclusion

Choosing the right adhesive magnet for your needs is a multifaceted decision that requires careful consideration of several factors. By understanding the various types of adhesive magnets—from flexible and rigid to specialty applications—and by evaluating key aspects such as magnetic strength, adhesive quality, environmental resistance, and customization options, you can ensure that you select a product that meets both your functional and aesthetic requirements.