Introduction

In the world of magnetism, particularly in the realm of permanent magnets, two critical parameters determine their effectiveness and application suitability: coercivity and remanence. These properties are essential in understanding how magnets perform under different conditions and how they can be utilized in various applications. This article delves into the intricacies of coercivity and remanence, exploring their definitions, mechanisms, and relevance to custom neodymium magnets.

What is Coercivity?

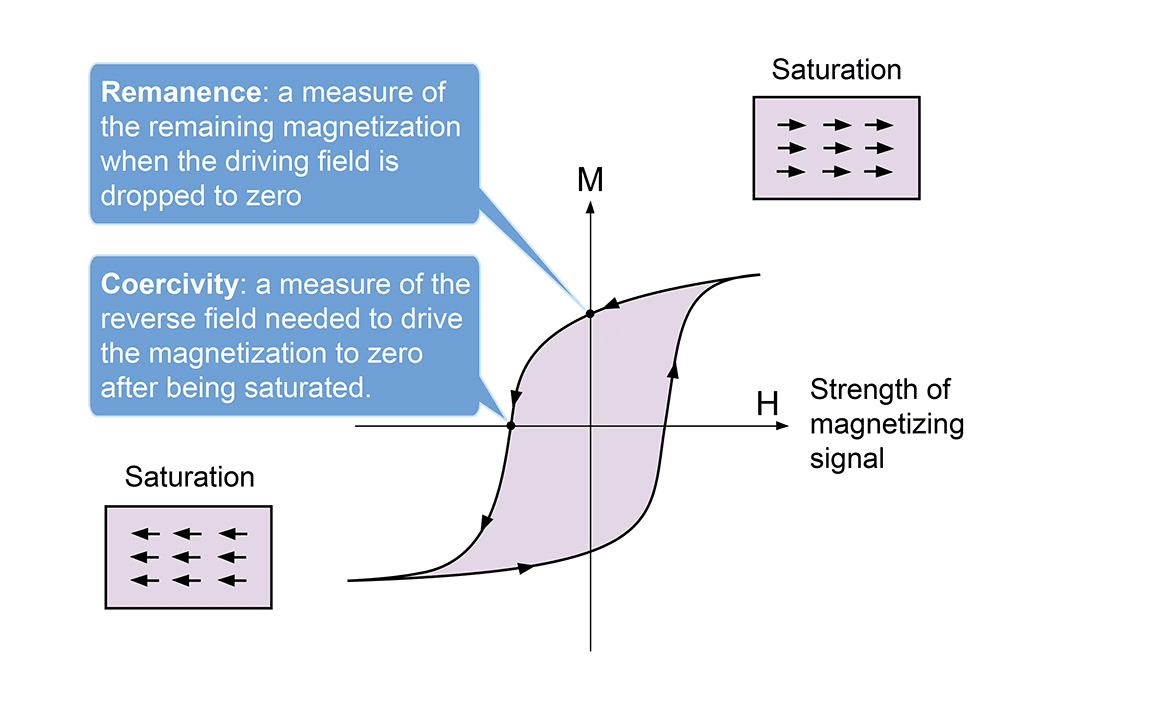

Coercivity is a measure of a magnet’s resistance to demagnetization. It reflects the amount of external magnetic field required to reduce the magnet’s magnetization to zero after it has been magnetized to saturation. Essentially, coercivity quantifies how resistant a material is to losing its magnetization.

Coercivity Mechanisms

Understanding coercivity involves examining the mechanisms that contribute to a magnet’s resistance to demagnetization. There are primarily two types of coercivity mechanisms in permanent magnets:

Intrinsic Coercivity: This type of coercivity is inherent to the material itself and is related to its magnetic properties at the atomic or molecular level. Intrinsic coercivity is influenced by factors such as the material’s crystal structure, magnetic anisotropy, and domain wall movement. Materials with high intrinsic coercivity are less susceptible to changes in their magnetic state under external magnetic fields.

Extrinsic Coercivity: This mechanism arises from external factors such as the shape and size of the magnet and the presence of any impurities or defects within the material. Extrinsic coercivity is typically influenced by factors like the distribution of magnetic domains and the interaction between domain walls and structural features of the magnet.

What is Remanence?

Remanence, also known as residual magnetization, is the magnetization left in a material after an external magnetic field is removed. It represents the ability of a magnet to retain its magnetization once the magnetizing force is withdrawn. Remanence is a crucial parameter for permanent magnets because it determines how well they can maintain their magnetic properties over time.

Should a Permanent Magnet Have High Remanence?

The answer depends on the intended application of the magnet. For many applications, especially those requiring strong and stable magnetic fields, a high remanence is desirable. High remanence ensures that the magnet remains highly magnetic even after the external field is removed, which is crucial for maintaining performance in various devices.

For instance, in applications such as motors, sensors, and magnetic separators, a high remanence is beneficial as it enhances the efficiency and effectiveness of these devices. Custom Neodymium Magnets, which are known for their high remanence, are particularly valuable in these contexts due to their strong and stable magnetic fields. If you’re interested in learning more about Custom Neodymium Magnets, you can explore more details here.

However, in certain applications where the magnet’s performance needs to be altered or where the magnet will be exposed to varying external fields, a lower remanence might be advantageous. For example, in some types of data storage devices, a lower remanence can help in reducing the risk of residual magnetization affecting data integrity.

The Relationship Between Magnetization and Coercivity

Magnetization refers to the extent to which a material becomes magnetized when exposed to an external magnetic field. The relationship between magnetization and coercivity is crucial in determining a magnet’s overall performance. Typically, materials with high magnetization tend to have higher coercivity, as they can maintain a strong magnetic field even when subjected to opposing forces.

In practical terms, this relationship means that a magnet with high magnetization will generally have a higher coercivity, allowing it to resist demagnetization more effectively. Custom Neodymium Magnets, for example, are renowned for their high magnetization and coercivity, making them suitable for applications that demand both strong and stable magnetic fields.

Coercivity and Remanence in Custom Neodymium Magnets

Custom Neodymium Magnets are specifically engineered to meet the precise needs of various applications. Their high coercivity and remanence make them ideal for a wide range of uses, from industrial machinery to consumer electronics. These magnets are crafted to ensure optimal performance and durability, with their coercivity and remanence tailored to specific requirements.

For instance, in applications requiring strong magnetic fields with minimal loss of magnetization over time, custom neodymium magnets are designed to provide the necessary characteristics. If you’re looking for magnets that offer exceptional performance and reliability, exploring Custom Neodymium Magnets can provide valuable insights into how these magnets can be customized to meet your needs.

Applications and Implications

Understanding coercivity and remanence is crucial in selecting the right permanent magnets for various applications. The choice of magnet depends on the specific requirements of the application, including factors like magnetic field strength, stability, and resistance to demagnetization.

For example:

- Electronics and Sensors: High remanence is essential in electronic devices and sensors to ensure consistent and reliable performance.

- Motors and Generators: Coercivity plays a critical role in motors and generators, where resistance to demagnetization is crucial for maintaining efficiency and functionality.

- Magnetic Separators: In magnetic separation applications, both high coercivity and high remanence are desirable to effectively separate magnetic materials from non-magnetic ones.

Conclusion

Coercivity and remanence are fundamental properties that determine the performance and suitability of permanent magnets for various applications. Understanding these properties allows for better selection and utilization of magnets in different contexts. Custom Neodymium Magnets, with their high coercivity and remanence, offer exceptional performance for a wide range of applications, ensuring that they meet specific needs effectively. For those interested in exploring the potential of custom neodymium magnets, further information is available here.

By grasping the concepts of coercivity and remanence, you can make informed decisions about the type of magnet required for your application, optimizing performance and reliability in your magnetic solutions.