Electromagnets are pivotal components in a myriad of applications, ranging from simple devices like electric bells to complex systems in electric vehicles, MRI machines, and industrial machinery. Their effectiveness, efficiency, and reliability hinge significantly on their design, which involves optimizing various parameters to achieve desired performance characteristics. This article delves into the intricacies of electromagnet design optimization, exploring fundamental concepts, key design parameters, and advanced techniques to refine electromagnet performance.

1. Understanding Electromagnets

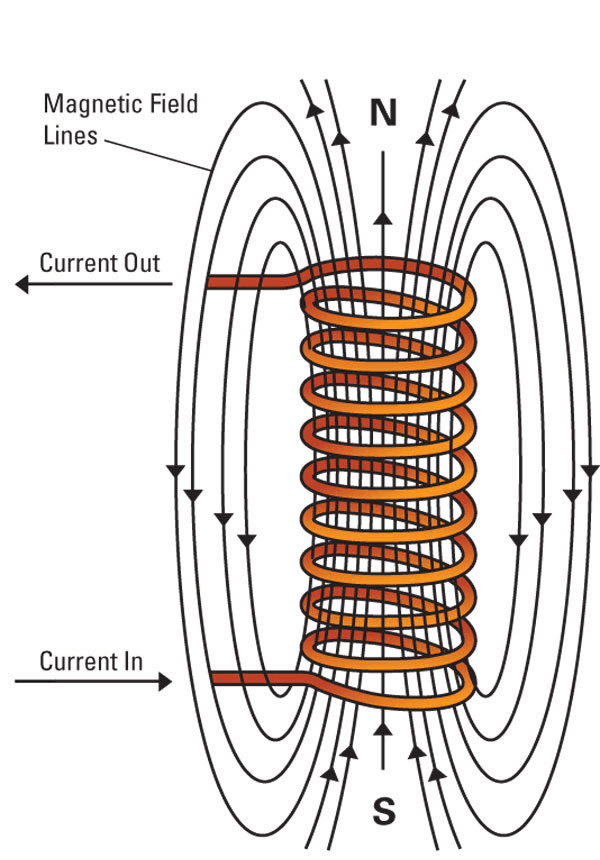

Before diving into optimization, it’s essential to grasp the fundamental principles of electromagnets. An electromagnet consists of a coil of wire, usually wound around a ferromagnetic core. When an electric current passes through the coil, it generates a magnetic field due to Ampère’s circuital law. This magnetic field can be controlled by adjusting the current flowing through the coil or modifying the coil’s physical attributes.

1.1 Basic Components

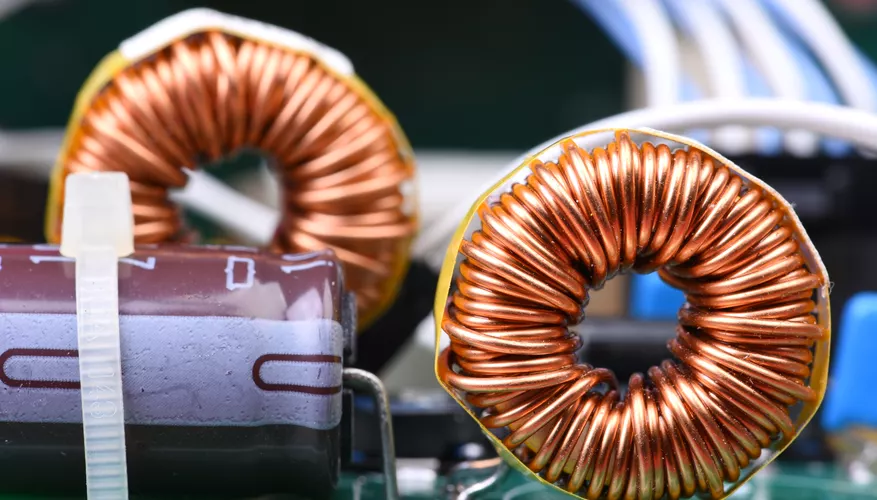

- Coil: The coil, typically made of copper or aluminum wire, generates the magnetic field when current flows through it. The coil’s geometry, including the number of turns and winding configuration, affects the magnetic field strength and distribution.

- Core: The core, usually made of materials like iron or steel, enhances the magnetic field generated by the coil. The core material’s magnetic permeability influences the electromagnet’s performance.

2. Design Parameters for Electromagnets

Optimizing an electromagnet involves careful consideration of several design parameters:

2.1 Coil Design

- Number of Turns: Increasing the number of turns in the coil amplifies the magnetic field strength, as described by Ampère’s Law. However, more turns also mean increased resistance and potentially higher power consumption. The number of turns must be balanced with the desired magnetic field strength and efficiency.

- Wire Gauge: The thickness of the wire affects its resistance and, consequently, the current carrying capacity. A thicker wire reduces resistance but occupies more space. Choosing the right gauge involves a trade-off between electrical resistance and physical constraints.

- Winding Pattern: The configuration of wire winding influences the uniformity of the magnetic field. Common patterns include solenoidal (cylindrical) and toroidal (doughnut-shaped). Each pattern has specific applications and advantages based on the required field distribution.

2.2 Core Design

- Material: The core material significantly impacts the electromagnet’s performance. Materials with high magnetic permeability, such as silicon steel or ferrites, are preferred for their ability to concentrate and enhance the magnetic field.

- Shape and Size: The core’s shape and size affect the magnetic field distribution and strength. For instance, a U-shaped core might be used for applications requiring concentrated magnetic fields, while a cylindrical core is often employed for more uniform fields.

2.3 Power Supply

- Current: The amount of current flowing through the coil directly influences the magnetic field strength. A higher current generates a stronger magnetic field but also increases power consumption and heat dissipation.

- Voltage: The voltage applied to the coil determines the current flow according to Ohm’s Law. Proper voltage control ensures efficient operation and prevents overheating.

3. Optimization Techniques

Optimization of electromagnets involves fine-tuning these design parameters to achieve the best performance. Several techniques and methodologies can be employed to optimize electromagnet design:

3.1 Analytical Methods

- Mathematical Modeling: Mathematical models can predict the performance of electromagnets based on design parameters. Models like the Biot-Savart Law and Ampère’s Law provide a theoretical foundation for predicting magnetic field strength and distribution.

- Finite Element Analysis (FEA): FEA is a computational technique used to simulate the electromagnetic fields within an electromagnet. It allows designers to visualize field distribution, identify potential issues, and optimize design parameters before physical prototyping.

3.2 Experimental Methods

- Prototyping and Testing: Building prototypes and conducting experiments help validate theoretical models and optimize design parameters. Testing allows designers to measure actual performance, identify discrepancies from the theoretical model, and make necessary adjustments.

- Field Mapping: Field mapping involves measuring the magnetic field at various points around the electromagnet. This data helps in assessing the uniformity of the magnetic field and identifying areas where design improvements are needed.

3.3 Advanced Techniques

- Optimization Algorithms: Advanced optimization algorithms, such as genetic algorithms and simulated annealing, can systematically explore design parameter space to find optimal configurations. These algorithms are particularly useful for complex design problems with multiple conflicting objectives.

- Machine Learning: Machine learning techniques can analyze large datasets generated from experiments and simulations to identify patterns and optimize design parameters. Machine learning models can predict performance based on various design choices, accelerating the optimization process.

4. Applications and Practical Considerations

Understanding the specific requirements of an application is crucial for optimizing electromagnets. Different applications demand different performance characteristics:

4.1 Industrial Applications

- Electromagnetic Actuators: In industrial automation, electromagnets are used as actuators to control mechanical movements. Design optimization focuses on achieving precise control, high reliability, and durability under varying operational conditions.

- Magnetic Separators: Electromagnets are employed in magnetic separators to extract ferromagnetic materials from non-magnetic materials. Optimization emphasizes achieving strong and uniform magnetic fields to ensure effective separation.

4.2 Medical Applications

- MRI Machines: In medical imaging, electromagnets are integral to MRI machines. Optimization focuses on achieving high magnetic field strength and uniformity to produce clear and accurate images while ensuring patient safety and comfort.

- Magnetic Therapy: Electromagnets used in magnetic therapy devices must be optimized for specific field strengths and frequencies to achieve therapeutic effects without causing harm.

4.3 Consumer Electronics

- Speakers and Headphones: Electromagnets in speakers and headphones are designed to produce sound by converting electrical signals into acoustic waves. Optimization involves balancing magnetic field strength with efficiency and sound quality.

- Electric Motors: In electric motors, electromagnets are used to generate rotational motion. Optimization focuses on achieving high torque and efficiency while minimizing energy losses and heat generation.

5. Challenges and Future Directions

Design optimization of electromagnets presents several challenges, and ongoing research aims to address these issues:

5.1 Material Limitations

- Core Materials: Developing advanced core materials with higher magnetic permeability and lower hysteresis losses is a key area of research. Novel materials like nanocrystalline alloys and soft magnetic composites are being explored for improved performance.

- Wire Materials: Innovations in wire materials, such as superconductors, could enable more efficient electromagnets with reduced power consumption and heat dissipation.

5.2 Thermal Management

Effective thermal management is critical for maintaining electromagnet performance and preventing overheating. Advanced cooling techniques, such as active cooling systems and heat sinks, are being investigated to enhance thermal management.

5.3 Integration with Emerging Technologies

The integration of electromagnets with emerging technologies, such as smart materials and Internet of Things (IoT) systems, presents opportunities for innovative applications. Research is focusing on developing adaptive electromagnets that can respond to real-time data and environmental changes.

6. Conclusion

The optimization of electromagnets is a multifaceted endeavor that requires a deep understanding of design parameters, advanced techniques, and application-specific requirements. By leveraging analytical, experimental, and advanced optimization methods, designers can enhance the performance, efficiency, and reliability of electromagnets across various applications. As technology continues to advance, ongoing research and development will drive further innovations, addressing existing challenges and unlocking new possibilities for electromagnet design.