Electromagnets have long played an essential role in various industries, powering technologies from simple electric motors to complex particle accelerators. As the demand for more efficient and specialized electromagnets grows, advancements in design and technology have led to the development of more refined solutions. Among these innovations is the TDCC (Trans-Directionally Controlled Current) electromagnet, which represents a significant step forward in electromagnet design. This article will explore the key differences between TDCC electromagnets and traditional electromagnets, including their design principles, operational efficiency, and applications.

Understanding Electromagnet Basics

Traditional Electromagnets

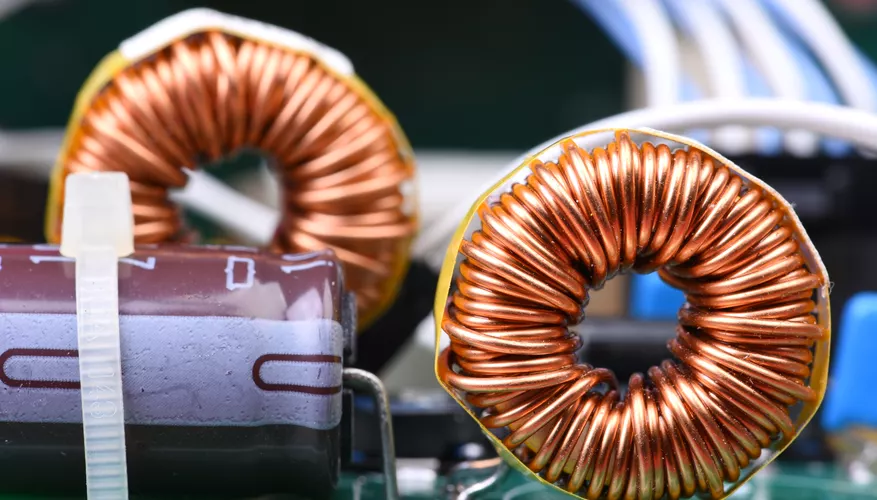

A traditional electromagnet is a device that generates a magnetic field when electric current flows through a coil of wire. The strength of the magnetic field can be controlled by adjusting the current, and it ceases when the current is turned off. Traditional electromagnets are widely used in various applications, including electric motors, magnetic levitation, industrial lifting magnets, and scientific research. They consist of a core material, usually iron or a similar ferromagnetic material, which enhances the magnetic field generated by the current-carrying coil.

TDCC Electromagnets

TDCC electromagnets, on the other hand, use a more sophisticated mechanism to control the magnetic field. Instead of simply relying on direct current (DC) or alternating current (AC) flowing through a wire, TDCC technology modulates the direction and intensity of the current in a much more precise and controlled manner. This allows the TDCC electromagnet to achieve higher levels of precision in magnetic field manipulation, making it ideal for applications where magnetic field control is critical. TDCC electromagnets can also operate more efficiently, reducing power consumption while maintaining high performance.

Key Differences Between TDCC Electromagnets and Traditional Electromagnets

1. Current Control and Directionality

Traditional electromagnets typically rely on a single-direction current flow through their coils to generate a magnetic field. The current may be DC for constant magnetic fields or AC for alternating magnetic fields. The magnetic field strength is primarily controlled by adjusting the current’s amplitude. While effective for many applications, this method lacks the fine control needed for more advanced technologies.

TDCC electromagnets, as the name suggests, offer a more advanced approach by controlling the current in multiple directions (trans-directionally). Instead of a single current flow, TDCC electromagnets can dynamically adjust the direction and intensity of the current at various points along the coil. This multi-directional current control allows for more sophisticated magnetic field manipulation. For instance, TDCC electromagnets can create highly localized magnetic fields or adjust the field’s direction and strength with extreme precision, something traditional electromagnets cannot achieve.

This advanced control opens up new possibilities in applications where precise magnetic field manipulation is essential, such as in medical imaging devices, quantum computing, and particle accelerators.

2. Magnetic Field Precision and Stability

In traditional electromagnets, the magnetic field strength and direction are directly tied to the current supplied to the coil. This can lead to some limitations in terms of precision, especially in applications that require constant magnetic fields over long periods or highly localized magnetic fields.

TDCC electromagnets, with their trans-directional current control, can maintain more stable and precise magnetic fields. The ability to adjust current flow in multiple directions and at multiple points along the coil allows for finer control over the magnetic field’s shape, intensity, and location. This results in a more stable magnetic field, which is crucial in applications like nuclear magnetic resonance (NMR) spectroscopy or magnetic confinement in fusion reactors.

Moreover, TDCC electromagnets can adjust their magnetic fields in real time without significant lag, enabling dynamic field modulation in rapidly changing environments, something traditional electromagnets struggle with due to their reliance on single-direction current flow.

3. Energy Efficiency and Heat Management

Traditional electromagnets are generally less energy-efficient, particularly when maintaining high magnetic field strengths over extended periods. The core material in traditional electromagnets often experiences energy losses due to eddy currents and hysteresis, especially in AC-driven systems. Additionally, the heat generated by resistive losses in the coil can be substantial, necessitating cooling systems to prevent overheating, which further increases energy consumption.

TDCC electromagnets offer significant improvements in energy efficiency. By controlling the current more precisely and distributing it in multiple directions, TDCC electromagnets can generate stronger magnetic fields with less power. This results in lower resistive losses and reduced heat generation. Additionally, TDCC technology allows for better heat management, as the system can dynamically adjust current distribution to avoid hot spots, reducing the need for extensive cooling systems.

These energy efficiency improvements make TDCC electromagnets ideal for applications requiring sustained magnetic fields, such as in industrial processes or scientific research, where traditional electromagnets would require significant energy input and cooling to maintain performance.

4. Size and Scalability

Traditional electromagnets, particularly those designed for high-strength applications, tend to be large and bulky. This is due to the need for large coils and cores to generate strong magnetic fields. While miniaturized traditional electromagnets exist for smaller-scale applications, their performance is often limited by the same factors that affect larger electromagnets: heat generation, energy consumption, and precision.

TDCC electromagnets, due to their advanced current control mechanisms, can achieve similar or better performance in a smaller form factor. The ability to control current in multiple directions and distribute the magnetic field more efficiently means that TDCC electromagnets can be more compact without sacrificing power or precision. This makes them more suitable for applications where space is limited, such as in medical devices or portable scientific instruments.

Moreover, TDCC electromagnets are more scalable than traditional electromagnets. The modular nature of the TDCC design allows for easy expansion or customization to meet specific application requirements, whether for small-scale precision devices or large-scale industrial systems.

5. Applications and Use Cases

Traditional electromagnets have a wide range of applications, including electric motors, generators, industrial lifting magnets, magnetic separation, and scientific equipment like mass spectrometers and NMR machines. They are well-suited for applications where simple magnetic field generation is required, and precision is not a critical factor.

TDCC electromagnets, with their enhanced precision and control, open up new possibilities in high-tech fields. In medical imaging, for example, TDCC electromagnets can provide more accurate magnetic fields for MRI machines, resulting in clearer images and faster scans. In quantum computing, the ability to control magnetic fields at the quantum level is essential for manipulating qubits, and TDCC electromagnets offer the necessary precision for these operations.

Other potential applications for TDCC electromagnets include advanced manufacturing processes, where precise magnetic fields can improve the accuracy and efficiency of processes like additive manufacturing or materials deposition. In particle accelerators, TDCC electromagnets can offer better beam control and stability, improving the performance of these cutting-edge scientific tools.

6. Cost and Complexity

One of the main advantages of traditional electromagnets is their relative simplicity and low cost. The materials and manufacturing processes involved in producing traditional electromagnets are well-established, making them a cost-effective solution for many applications.

TDCC electromagnets, while offering significant performance improvements, are more complex and therefore more expensive to produce. The advanced electronics required to control the trans-directional currents add to the cost, and the manufacturing process is more intricate. However, the increased performance, energy efficiency, and precision offered by TDCC electromagnets can justify the higher cost in applications where these factors are critical.

In fields where performance is more important than cost, such as medical imaging, quantum computing, or scientific research, the benefits of TDCC electromagnets far outweigh their higher price. However, for simpler applications where cost is a primary concern, traditional electromagnets remain a viable and effective solution.

7. Magnetic Field Configuration Flexibility

In traditional electromagnets, the magnetic field configuration is largely determined by the physical arrangement of the coil and core. Adjusting the magnetic field typically requires physical changes to the system, such as modifying the number of coils, changing the core material, or altering the current.

TDCC electromagnets, thanks to their advanced current control mechanisms, offer much greater flexibility in magnetic field configuration without the need for physical alterations. By adjusting the trans-directional currents, TDCC electromagnets can reconfigure their magnetic fields dynamically, allowing for more complex field shapes and patterns. This flexibility is particularly useful in applications like plasma confinement in fusion reactors, where precise control over the magnetic field configuration is essential.

Conclusion

TDCC electromagnets represent a significant advancement over traditional electromagnets, offering superior precision, efficiency, and flexibility. While traditional electromagnets remain suitable for many applications, TDCC electromagnets provide the enhanced control and performance needed for more advanced technologies. As industries continue to demand higher levels of precision and efficiency, the adoption of TDCC electromagnets is likely to grow, particularly in fields like medical imaging, quantum computing, and advanced manufacturing.

The differences between TDCC electromagnets and traditional electromagnets are not just incremental improvements but represent a shift in how magnetic fields can be generated and controlled. By leveraging trans-directional current control, TDCC electromagnets offer new possibilities for innovation across a wide range of industries.