Introduction to Magnets

Magnets play a crucial role in various applications, from everyday household items to advanced technological systems. Traditional magnets, such as permanent magnets made from materials like neodymium, ferrite, and samarium-cobalt, exhibit magnetic properties based on their composition and structure. These magnets have been widely used in various applications, including electric motors, magnetic storage devices, and magnetic resonance imaging (MRI).

However, the need for more efficient and powerful magnetic systems has led to the development of innovative designs, one of which is the Halbach array. This article will delve into the differences between Halbach arrays and traditional magnets, exploring their structures, properties, applications, and advantages.

What is a Halbach Array?

A Halbach array is a specific arrangement of permanent magnets that enhances the magnetic field on one side while canceling the field on the opposite side. Named after physicist Klaus Halbach, who first described this configuration in the 1980s, the Halbach array has gained prominence in various fields due to its unique properties.

Structure of a Halbach Array

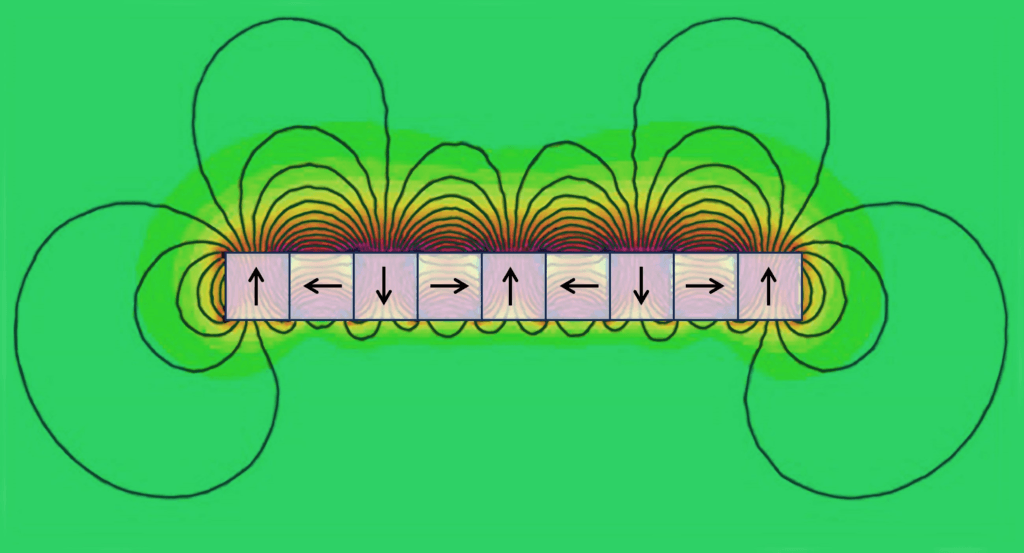

Halbach arrays consist of a series of permanent magnets arranged in a specific pattern. The magnets are typically oriented such that the direction of magnetization rotates around the array. This unique configuration produces a strong magnetic field on one side and a significantly weaker field on the other.

There are several common configurations for Halbach arrays, including:

- Planar Halbach Array: This two-dimensional array consists of permanent magnets arranged in a flat pattern, commonly used in applications requiring a strong magnetic field on one side.

- Cylindrical Halbach Array: This three-dimensional configuration wraps the magnets around a cylindrical shape, often used in applications such as magnetic bearings and rotating machinery.

- Linear Halbach Array: This arrangement consists of magnets aligned in a straight line, typically used in linear motor applications.

Traditional Magnets: An Overview

Traditional magnets are classified into two main categories: permanent magnets and temporary magnets. Permanent magnets retain their magnetic properties even after the external magnetic field is removed, while temporary magnets exhibit magnetism only in the presence of an external field.

Common Types of Traditional Magnets:

- Neodymium Magnets: Made from an alloy of neodymium, iron, and boron, these are among the strongest permanent magnets available. They are widely used in various applications due to their high magnetic strength and compact size.

- Ferrite Magnets: Composed of ceramic materials, ferrite magnets are less expensive than neodymium magnets and are commonly used in everyday applications like refrigerator magnets and loudspeakers.

- Samarium-Cobalt Magnets: These magnets are known for their high resistance to demagnetization and high-temperature performance. They are often used in applications where stability is critical, such as in aerospace and military applications.

Key Differences Between Halbach Arrays and Traditional Magnets

1. Magnetic Field Distribution

One of the most significant differences between Halbach arrays and traditional magnets lies in their magnetic field distribution.

- Halbach Arrays: The design of a Halbach array allows for a highly concentrated magnetic field on one side while effectively canceling it on the opposite side. This unique characteristic makes Halbach arrays particularly advantageous in applications where a focused magnetic field is required, such as in magnetic levitation systems and electric motors.

- Traditional Magnets: Traditional magnets produce a magnetic field that is relatively uniform around their surface. While they can be effective in many applications, they do not provide the same level of control over field distribution as Halbach arrays. This limitation can be a drawback in situations where precise magnetic field manipulation is essential.

2. Efficiency and Power

The efficiency of magnetic systems is critical, particularly in energy-related applications.

- Halbach Arrays: Due to their unique arrangement, Halbach arrays can generate a stronger magnetic field with less material than traditional magnets. This increased efficiency can lead to lighter and more compact designs in applications such as motors and generators.

- Traditional Magnets: While traditional magnets can be powerful, they often require larger volumes of material to achieve similar magnetic strength. This can lead to bulkier designs and increased material costs.

3. Application Versatility

The versatility of magnetic systems is essential for a wide range of industries.

- Halbach Arrays: These arrays find applications in various fields, including:

- Magnetic Levitation: Halbach arrays are used in maglev trains, where the efficient magnetic field allows for smooth and high-speed travel.

- Electric Motors: Halbach arrays enhance motor performance by providing increased torque and efficiency, making them ideal for electric vehicles and industrial applications.

- Magnetic Resonance Imaging (MRI): The focused magnetic fields produced by Halbach arrays can improve image quality and reduce scan times in medical imaging applications.

- Traditional Magnets: Traditional magnets are commonly used in everyday applications, including:

- Home Appliances: Ferrite magnets are often found in refrigerator doors and microwave ovens.

- Speakers: Neodymium magnets are used in high-performance speakers due to their strong magnetic fields and compact size.

- Magnetic Tools: Various tools and devices use traditional magnets for holding or fastening components.

4. Demagnetization Resistance

Demagnetization resistance is a critical factor for many applications, particularly those exposed to high temperatures or strong external magnetic fields.

- Halbach Arrays: These arrays can be designed to enhance their resistance to demagnetization, making them suitable for high-performance applications. The arrangement of magnets allows for better stability under varying conditions.

- Traditional Magnets: Different types of traditional magnets have varying degrees of resistance to demagnetization. For example, samarium-cobalt magnets exhibit high resistance, while ferrite magnets are less robust in this regard.

5. Manufacturing Complexity

The complexity of manufacturing processes can impact the cost and scalability of magnetic solutions.

- Halbach Arrays: The design and assembly of Halbach arrays can be more complex than traditional magnets. The precise orientation and arrangement of magnets require careful engineering and manufacturing techniques, which may increase production costs.

- Traditional Magnets: Traditional magnets are generally easier to manufacture, making them more accessible for mass production. The simplicity of their design allows for cost-effective production methods.

Advantages of Halbach Arrays Over Traditional Magnets

1. Enhanced Magnetic Performance

Halbach arrays provide superior magnetic performance compared to traditional magnets. Their unique design allows for stronger magnetic fields in specific directions, making them ideal for applications that require high efficiency and power.

2. Compact Design

The ability to generate strong magnetic fields with less material enables Halbach arrays to achieve compact designs. This feature is particularly advantageous in applications where space is limited, such as in small electric motors and compact electronic devices.

3. Reduced Weight

The increased efficiency of Halbach arrays allows for weight reduction in magnetic systems. This advantage is crucial for applications like electric vehicles and aerospace, where every gram counts towards overall performance.

4. Improved Efficiency

Halbach arrays can significantly enhance the efficiency of magnetic systems. Their ability to focus magnetic fields reduces energy losses, leading to better overall performance in applications like magnetic bearings and electric motors.

5. Versatile Applications

The unique properties of Halbach arrays enable them to be used in a wide range of applications, from transportation systems to medical imaging. Their versatility makes them an attractive choice for industries seeking innovative solutions to complex challenges.

Disadvantages of Halbach Arrays Compared to Traditional Magnets

1. Manufacturing Complexity and Cost

The manufacturing process for Halbach arrays can be more complex and costly than for traditional magnets. The need for precise arrangement and orientation of magnets may limit their scalability for certain applications.

2. Limited Availability of Materials

The materials used in Halbach arrays, such as high-performance permanent magnets, may not be as widely available as those used in traditional magnets. This limitation could impact production timelines and costs.

3. Design Constraints

Designing Halbach arrays requires careful consideration of the intended application. While they offer unique advantages, the specific requirements for orientation and arrangement may limit their use in some scenarios.

Conclusion

Halbach arrays represent a significant advancement in magnet technology, offering enhanced performance, efficiency, and versatility compared to traditional magnets. While they may come with increased manufacturing complexity and costs, their unique properties make them an attractive option for various applications in industries ranging from transportation to healthcare. As technology continues to evolve, the use of Halbach arrays is likely to grow, further transforming the landscape of magnetic systems and their applications.

Understanding the differences between Halbach arrays and traditional magnets is essential for making informed decisions in engineering and design, ultimately leading to more efficient and innovative solutions across various fields.