Magnets are integral components in a wide array of industries, from automotive to aerospace, electronics, and beyond. Among the different types of magnets available, FeCrCo magnets and Neodymium magnets (NdFeB) are two of the most commonly used. However, each of these magnets comes with its unique set of properties that make them suitable for specific applications. This article delves into the advantages of FeCrCo magnets, particularly in high-temperature environments, and contrasts them with the characteristics of Neodymium magnets.

1. Understanding FeCrCo Magnets

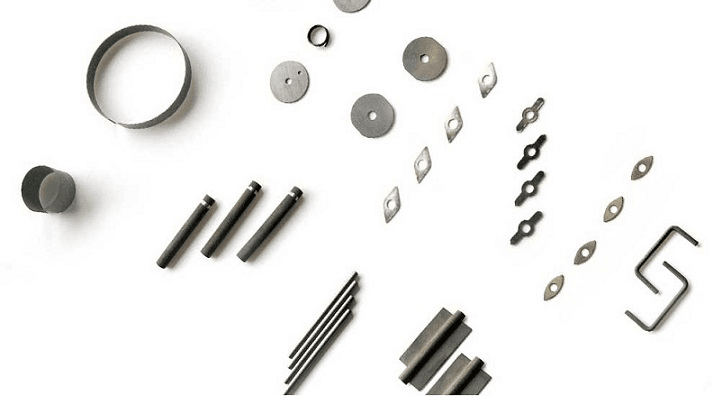

FeCrCo magnets are a type of permanent magnet composed of iron (Fe), chromium (Cr), and cobalt (Co). This combination creates a material that possesses excellent magnetic properties along with other critical features like high-temperature stability and corrosion resistance. The flexibility of FeCrCo magnets in terms of machining also adds to their versatility in various applications.

FeCrCo magnets are particularly noted for their ability to maintain magnetic properties at elevated temperatures, often reaching up to 400°C or higher without significant loss in performance. This makes them ideal for applications where other magnets, such as Neodymium magnets, might fail due to thermal constraints.

2. Introduction to Neodymium Magnets

Neodymium magnets, or NdFeB magnets, are among the strongest permanent magnets available. Comprising neodymium (Nd), iron (Fe), and boron (B), these magnets exhibit high magnetic strength, which makes them suitable for various applications requiring strong magnetic fields. However, this strength comes with some limitations, particularly when exposed to high temperatures or corrosive environments.

Despite their impressive magnetic force, Neodymium magnets generally start to lose their magnetic properties when exposed to temperatures above 150°C. To counteract this, NdFeB magnets often require protective coatings to prevent oxidation and degradation, which can further complicate their use in certain environments.

For custom applications involving Neodymium magnets, check out the options available through this link.

3. High-Temperature Performance: A Critical Comparison

One of the most significant differences between FeCrCo magnets and Neodymium magnets is their performance at high temperatures. This is crucial for industries such as aerospace, automotive, and heavy machinery, where components are often exposed to extreme conditions.

3.1 FeCrCo Magnets in High-Temperature Applications

FeCrCo magnets excel in high-temperature environments due to their unique material composition. These magnets can retain their magnetic properties at temperatures as high as 400°C, with some formulations even exceeding this threshold. This makes them the preferred choice in applications such as:

- Aerospace Components: Where magnets must endure high heat without losing effectiveness.

- Industrial Sensors: Which operate in high-temperature environments like furnaces or engines.

- Military Equipment: Where durability under extreme conditions is paramount.

Given their robust nature, FeCrCo magnets are often employed in applications where reliability at high temperatures is non-negotiable.

3.2 Neodymium Magnets and Temperature Limitations

In contrast, Neodymium magnets, despite their strong magnetic fields, suffer from thermal limitations. They generally lose their magnetic strength when the temperature exceeds 150°C, making them unsuitable for high-temperature environments without significant modifications. Even with special grades of NdFeB magnets designed to withstand higher temperatures (up to about 200-230°C), they still do not match the thermal resilience of FeCrCo magnets.

This temperature sensitivity can limit the use of Neodymium magnets in applications like:

- High-Power Motors: Where consistent performance at elevated temperatures is required.

- Magnetic Couplings: In systems that operate under significant thermal stress.

- Electronics: That must endure high operating temperatures.

Thus, while Neodymium magnets are powerful, their thermal limitations necessitate careful consideration in high-temperature applications, often leading to the preference for FeCrCo magnets.

4. Corrosion Resistance: A Vital Factor in Material Selection

Another crucial difference between FeCrCo magnets and Neodymium magnets is their resistance to corrosion, particularly in harsh environments.

4.1 FeCrCo Magnets’ Superior Corrosion Resistance

FeCrCo magnets naturally possess excellent corrosion resistance due to the presence of chromium in their composition. This makes them well-suited for use in environments where they may be exposed to moisture, chemicals, or saltwater. Their ability to withstand such conditions without the need for additional protective coatings adds to their appeal in industries such as:

- Marine Engineering: Where exposure to saltwater is a constant challenge.

- Chemical Processing: Where magnets are exposed to corrosive substances.

- Outdoor Applications: Such as in wind turbines or other exposed equipment.

The inherent corrosion resistance of FeCrCo magnets makes them a low-maintenance and reliable option in such applications.

4.2 The Need for Protective Coatings in Neodymium Magnets

Neodymium magnets, on the other hand, are prone to oxidation and corrosion. Without protective coatings (such as nickel, zinc, or epoxy), these magnets can degrade quickly, especially in humid or corrosive environments. While these coatings can help prolong the lifespan of Neodymium magnets, they add another layer of complexity and potential points of failure, especially if the coating is damaged or wears away over time.

This need for additional protection limits the use of Neodymium magnets in environments where they might be exposed to moisture or corrosive elements, despite their superior magnetic strength.

5. Machinability and Design Flexibility

When it comes to machining and design flexibility, FeCrCo magnets again demonstrate notable advantages over Neodymium magnets.

5.1 FeCrCo Magnets’ Machining Ease

FeCrCo magnets can be easily machined into various shapes and sizes, making them ideal for custom applications where precise dimensions are required. Their machinability is superior to that of Neodymium magnets, which are more brittle and prone to chipping or cracking during the manufacturing process. This ease of machining allows FeCrCo magnets to be tailored for specific applications without compromising their structural integrity.

This flexibility in manufacturing makes FeCrCo magnets suitable for:

- Custom Sensor Designs: Where specific shapes and sizes are needed.

- Precision Instruments: That require exact magnetic configurations.

- Complex Assemblies: Where the magnet must be integrated into a larger system with tight tolerances.

5.2 Neodymium Magnets’ Limitations in Machining

In contrast, Neodymium magnets are notoriously difficult to machine due to their brittleness. Special care must be taken during the manufacturing process to avoid damaging the magnet, which can increase production costs and time. Additionally, the need for protective coatings further complicates the machining process, as these coatings must be applied after the magnet has been shaped, adding additional steps and potential points of failure.

Therefore, while Neodymium magnets offer powerful magnetic properties, their limitations in machining and the need for protective measures make them less versatile in custom applications where precise dimensions and durability are required.

6. Magnetic Stability Over Time

The long-term stability of magnetic properties is another important factor to consider when choosing between FeCrCo and Neodymium magnets.

6.1 FeCrCo Magnets’ Long-Term Stability

FeCrCo magnets are known for their stable magnetic properties over time, even when exposed to varying environmental conditions. This stability is crucial in applications where consistent performance is required over long periods, such as in aerospace, military, and high-precision instruments.

The magnetic stability of FeCrCo magnets ensures that they maintain their performance without significant degradation, reducing the need for frequent replacements or recalibrations. This reliability makes them a cost-effective choice in applications where long-term performance is critical.

6.2 Neodymium Magnets’ Potential for Magnetic Degradation

While Neodymium magnets initially offer higher magnetic strength, they are more susceptible to degradation over time, especially when exposed to high temperatures, humidity, or corrosive environments. This potential for magnetic loss can lead to decreased performance in applications where long-term reliability is essential.

For applications that require consistent magnetic performance over an extended period, FeCrCo magnets are often the preferred choice due to their superior stability.

7. Cost Considerations and Application Suitability

Cost is always a factor when selecting materials for industrial applications. While Neodymium magnets are often chosen for their strong magnetic properties, the additional costs associated with protective coatings, specialized machining, and potential replacements due to degradation can add up over time.

7.1 FeCrCo Magnets: Cost-Effective in the Long Run

Although FeCrCo magnets may have a higher initial cost compared to some grades of Neodymium magnets, their durability, long-term stability, and resistance to environmental factors often make them more cost-effective in the long run. The reduced need for additional protective measures and lower risk of degradation mean that FeCrCo magnets can offer better value in applications where long-term performance is critical.

7.2 Neodymium Magnets: Balancing Cost and Performance

Neodymium magnets can be more cost-effective in applications where extreme magnetic strength is required, and the operating conditions do not involve high temperatures or corrosive environments. However, the need for protective coatings and the potential for performance degradation must be factored into the overall cost of using these magnets.

For applications that require a balance between cost and performance, custom Neodymium magnets with appropriate coatings can be an effective solution. More details on custom Neodymium magnet solutions can be found through this link.

8. Environmental Impact and Sustainability

As industries increasingly focus on sustainability, the environmental impact of the materials used becomes a key consideration.

8.1 FeCrCo Magnets and Sustainability

FeCrCo magnets are generally more sustainable in the long term due to their durability and reduced need for replacement. Their resistance to corrosion and degradation means that they have a longer lifespan, reducing the frequency of replacements and the associated environmental impact.

Additionally, the ability to machine FeCrCo magnets into precise shapes without significant waste further enhances their sustainability profile.

8.2 The Environmental Challenges of Neodymium Magnets

Neodymium magnets, while powerful, pose some environmental challenges. The mining and processing of rare earth elements like neodymium have significant environmental impacts, including habitat destruction and pollution. Furthermore, the need for protective coatings and the potential for magnet degradation over time contribute to additional waste and environmental concerns.

In applications where sustainability is a priority, FeCrCo magnets may be the more environmentally friendly choice due to their longer lifespan and reduced need for additional protective measures.

9. Application-Specific Considerations

When choosing between FeCrCo and Neodymium magnets, it’s essential to consider the specific requirements of the application, including operating conditions, desired lifespan, and cost constraints.

9.1 When to Choose FeCrCo Magnets

FeCrCo magnets are the ideal choice for applications that involve high temperatures, corrosive environments, or require long-term magnetic stability. They are particularly well-suited for:

- Aerospace and Military Applications: Where reliability under extreme conditions is critical.

- Industrial Equipment: That operates in high-temperature or corrosive environments.

- Precision Instruments: Where long-term magnetic stability is essential.

9.2 When to Opt for Neodymium Magnets

Neodymium magnets are the best choice when maximum magnetic strength is required, and the operating conditions are within the magnet’s thermal and environmental limits. They are ideal for:

- High-Power Motors and Generators: Where strong magnetic fields are necessary.

- Consumer Electronics: Such as headphones and speakers, where compact and powerful magnets are needed.

- Magnetic Assemblies: That require strong magnetic forces in confined spaces.

10. Conclusion: Choosing the Right Magnet for Your Needs

The choice between FeCrCo magnets and Neodymium magnets ultimately depends on the specific requirements of the application. While Neodymium magnets offer unmatched magnetic strength, their limitations in high-temperature and corrosive environments can be a drawback in certain situations. FeCrCo magnets, on the other hand, provide superior performance in challenging conditions, with excellent high-temperature stability, corrosion resistance, and long-term reliability.

By carefully considering the operating environment, desired lifespan, and overall cost, you can select the magnet that best meets your needs. Whether it’s the durable and stable FeCrCo magnets or the powerful Neodymium magnets, understanding the strengths and limitations of each will ensure optimal performance in your application.