I. Introduction

In an age where technology permeates every aspect of our lives, the invisible yet powerful force of magnetism plays a crucial role. From the smooth functioning of MRI machines in hospitals to the accurate readings of electronic sensors in smartphones, magnetic shielding is the unsung hero ensuring these devices work flawlessly. Imagine a world where your GPS malfunctions or medical imaging provides inaccurate results due to magnetic interference—such a scenario underscores the importance of effective magnetic shielding. This article delves into the fascinating world of magnetic shield materials, comparing their properties, uses, and performance to highlight the best options available.

II. Understanding Magnetic Shielding

Definition: Magnetic shielding involves the use of materials to protect sensitive electronic equipment from external magnetic fields that can cause interference or damage. This is achieved by redirecting or absorbing magnetic field lines, thereby minimizing their impact on the protected area.

Applications: Magnetic shielding is vital across various industries. In healthcare, MRI machines require extensive shielding to produce clear images. Consumer electronics, like smartphones and laptops, rely on shielding to prevent signal distortion. Aerospace and defense sectors use magnetic shielding to protect sensitive navigation and communication equipment. Additionally, scientific research often involves precise measurements that would be impossible without effective magnetic shielding.

Basic Principles: The principle behind magnetic shielding is based on the material’s ability to conduct magnetic flux. Materials with high magnetic permeability can attract and contain magnetic field lines, preventing them from penetrating the shielded area. This property is crucial for materials used in magnetic shielding, as it determines their effectiveness in different applications.

III. Common Materials Used in Magnetic Shielding

Mu-metal:

Composition and Properties: Mu-metal is an alloy primarily composed of nickel and iron, with small amounts of copper and molybdenum. It is known for its exceptionally high magnetic permeability, which allows it to efficiently redirect magnetic field lines.

Advantages and Disadvantages: The primary advantage of Mu-metal is its high efficiency in shielding low-frequency magnetic fields. However, it is expensive and challenging to work with, requiring careful handling and annealing processes.

Typical Applications: Mu-metal is commonly used in medical imaging equipment, such as MRI machines, and in scientific instruments where precision is critical.

Permalloy:

Composition and Properties: Permalloy is another nickel-iron alloy, with a higher percentage of nickel compared to Mu-metal. It offers high magnetic permeability and low coercivity.

Advantages and Disadvantages: Permalloy is easier to fabricate than Mu-metal and less expensive. However, its shielding effectiveness is slightly lower, making it suitable for applications where extreme precision is not as critical.

Typical Applications: Permalloy is used in magnetic sensors, transformers, and certain types of magnetic shielding enclosures.

Ferrites:

Composition and Properties: Ferrites are ceramic compounds made from iron oxides combined with metallic elements such as nickel, zinc, or manganese. They have moderate magnetic permeability and high electrical resistivity.

Advantages and Disadvantages: Ferrites are cost-effective and provide good high-frequency magnetic shielding. However, they are brittle and can be challenging to integrate into certain designs.

Typical Applications: Ferrites are commonly used in consumer electronics, power supplies, and communication devices.

Supermalloy:

Composition and Properties: Supermalloy is a nickel-iron alloy with even higher nickel content and additional elements such as molybdenum. It has extremely high magnetic permeability and very low coercivity.

Advantages and Disadvantages: Supermalloy offers superior shielding performance but is costly and difficult to manufacture.

Typical Applications: It is used in highly sensitive magnetic field detection equipment and in environments where maximum shielding efficiency is required.

Metglas:

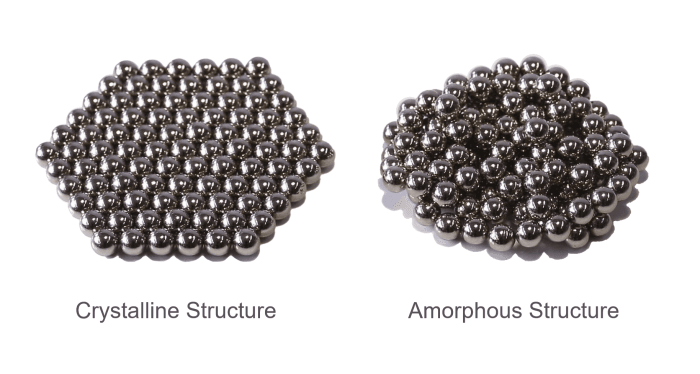

Composition and Properties: Metglas is an amorphous metal, meaning it lacks a crystalline structure. This unique structure provides high magnetic permeability and low coercivity.

Advantages and Disadvantages: Metglas is highly efficient in magnetic shielding and relatively easy to fabricate into thin films. However, it can be more expensive than other materials.

Typical Applications: Metglas is used in transformer cores, magnetic shielding for electronic devices, and in certain types of sensors.

Amorphous Metals:

Composition and Properties: Amorphous metals, like Metglas, are characterized by their non-crystalline structures. They exhibit high magnetic permeability and low coercivity.

Advantages and Disadvantages: These materials offer excellent magnetic shielding properties and are easier to produce in thin layers. They are, however, relatively expensive.

Typical Applications: Amorphous metals are used in advanced electronic devices, aerospace applications, and precision instruments.

IV. Comparative Analysis of Magnetic Shield Materials

Performance Metrics:

Permeability: The ability of a material to conduct magnetic flux is a critical factor. Mu-metal and Supermalloy lead in this category, offering the highest permeability. Ferrites and amorphous metals also perform well but are more suitable for different frequency ranges.

Saturation Magnetization: This metric indicates the maximum magnetization a material can achieve. Materials like Mu-metal and Permalloy have high saturation magnetization, making them effective in high-intensity fields.

Coercivity: Low coercivity is desirable for magnetic shielding materials, as it indicates they can easily align with external magnetic fields. Supermalloy and Metglas excel in this aspect.

Temperature Stability: Materials must maintain their shielding properties across a range of temperatures. Ferrites and amorphous metals generally offer better thermal stability compared to nickel-iron alloys.

Cost Analysis:

Manufacturing Costs: Ferrites and Permalloy are more cost-effective to produce compared to Mu-metal and Supermalloy. Metglas, despite its high performance, also incurs higher manufacturing costs.

Maintenance and Longevity: Materials like Supermalloy and Metglas, though initially more expensive, often provide longer service life and lower maintenance costs, justifying their higher upfront investment.

Ease of Fabrication:

Machinability: Ferrites are difficult to machine due to their brittleness, whereas Permalloy and amorphous metals are easier to work with. Mu-metal and Supermalloy require specialized processing techniques.

Flexibility in Design: Amorphous metals and Metglas offer high flexibility in terms of shape and application, making them suitable for complex designs. Ferrites, while effective, are limited by their rigid structure.

Environmental Impact:

Sustainability: Ferrites, being ceramic-based, have a lower environmental impact during production. Nickel-iron alloys like Mu-metal and Supermalloy involve more intensive mining and processing.

Recycling and Disposal: Amorphous metals and Metglas are relatively easy to recycle, whereas the disposal of nickel-based alloys requires careful handling to avoid environmental contamination.

V. Case Studies and Real-World Applications

Case Study 1: Use of Mu-metal in MRI Machines

Mu-metal’s high permeability and low coercivity make it ideal for shielding the sensitive components of MRI machines from external magnetic fields, ensuring accurate imaging and patient safety.

Case Study 2: Ferrites in Consumer Electronics

Ferrites are extensively used in smartphones and laptops to minimize electromagnetic interference from other components and external sources, providing clear signals and efficient device performance. Their cost-effectiveness and high-frequency shielding capabilities make them a staple in the electronics industry.

Case Study 3: Amorphous Metals in Aerospace Engineering

In aerospace engineering, the use of amorphous metals for magnetic shielding ensures the protection of critical navigation and communication systems from magnetic interference. Their lightweight nature and high performance under varying temperatures are particularly beneficial in this demanding field.

Case Study 4: Supermalloy in Scientific Research Equipment

Supermalloy’s exceptional shielding properties are employed in scientific research environments, such as particle accelerators and sensitive magnetic field detection instruments. These applications require the highest level of precision, which Supermalloy can reliably provide.

VI. Future Trends in Magnetic Shielding Materials

Innovations in Material Science:

Development of New Alloys: Continuous research is leading to the development of new alloys that offer improved magnetic shielding properties while reducing costs. Hybrid materials that combine the best attributes of existing alloys are particularly promising.

Nanotechnology and Magnetic Shielding: Advances in nanotechnology are paving the way for the development of nanocomposite materials with superior magnetic shielding capabilities. These materials can offer enhanced performance at a fraction of the thickness and weight of traditional materials.

Challenges and Opportunities:

Addressing Limitations of Current Materials: While existing materials provide effective shielding, there is always room for improvement in terms of efficiency, cost, and ease of fabrication. Overcoming these challenges will expand the application range of magnetic shielding materials.

Potential for Cost Reduction and Efficiency Improvement: Innovations in manufacturing processes and material science can lead to significant cost reductions and performance enhancements. This could make high-performance magnetic shielding materials more accessible for a broader range of applications.

VII. Conclusion

Summary: Magnetic shielding is an essential aspect of modern technology, protecting sensitive electronic components from external magnetic fields that can cause interference or damage. A variety of materials are used for magnetic shielding, each with its own set of properties, advantages, and disadvantages. Understanding these materials’ performance metrics, cost implications, and environmental impact is crucial for selecting the right material for specific applications.

Final Thoughts: Choosing the appropriate magnetic shield material depends on the specific requirements of the application, including the strength of the magnetic field, environmental conditions, and budget constraints. Materials like Mu-metal and Supermalloy offer exceptional shielding performance but at a higher cost and complexity. In contrast, ferrites and amorphous metals provide a balance of cost-effectiveness and performance for various industrial and consumer applications.