Manufacturing magnets is a precise and intricate process, especially when it comes to Alnico magnets. Renowned for their excellent temperature stability and high magnetic flux density, Alnico magnets are vital in various industrial applications. In this article, we’ll delve into the detailed manufacturing methods of Alnico magnets, providing a comprehensive look at how these powerful magnets are made.

Introduction to Alnico Magnets

Alnico magnets, an alloy composed primarily of aluminum (Al), nickel (Ni), and cobalt (Co), are among the oldest types of permanent magnets. Developed in the 1930s, Alnico magnets have been widely used due to their high coercivity (resistance to demagnetization), good thermal stability, and robust magnetic properties. These characteristics make them suitable for various applications, including electric motors, sensors, loudspeakers, and scientific instruments.

Historical Context and Development

The development of Alnico magnets marked a significant advancement in the field of magnetism. Before their introduction, the primary permanent magnets available were steel magnets, which had relatively low magnetic performance. The discovery of the Alnico alloy allowed for stronger and more reliable magnets, paving the way for numerous technological advancements.

Composition and Characteristics

Alnico magnets are typically composed of 8-12% aluminum, 15-26% nickel, 5-24% cobalt, with the remainder being iron. Additionally, small amounts of copper and titanium can be added to modify the magnetic properties. The exact composition of the alloy can be tailored to achieve specific magnetic characteristics, depending on the intended application.

Magnetic Properties

- High Magnetic Flux Density: Alnico magnets exhibit a high magnetic flux density, which means they can produce strong magnetic fields.

- Temperature Stability: One of the most significant advantages of Alnico magnets is their ability to retain their magnetic properties at high temperatures, up to 550°C (1022°F).

- Corrosion Resistance: Alnico magnets have good resistance to oxidation and corrosion, which enhances their durability in various environments.

Manufacturing Methods of Alnico Magnets

Alnico magnets are made using two primary methods: casting and sintering. Each method offers distinct advantages and is chosen based on the required properties and intended applications of the magnets.

Casting Method

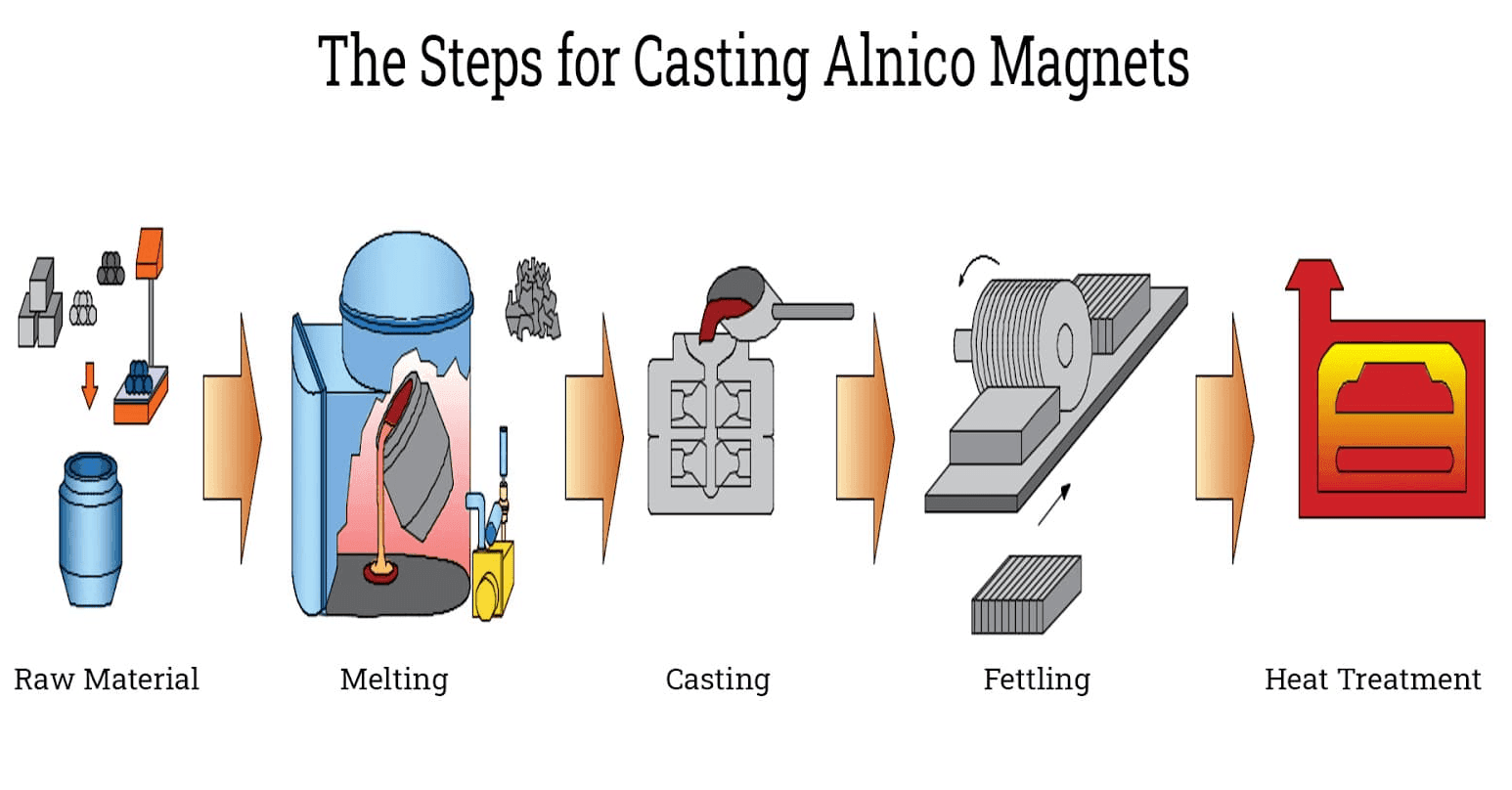

The casting method is the most common manufacturing technique for Alnico magnets. This process involves several key steps:

Melting and Alloying: The raw materials (aluminum, nickel, cobalt, iron, and other elements) are melted together in a furnace at temperatures exceeding 1750°C. The precise composition of the alloy can be adjusted to achieve specific magnetic properties.

Casting: The molten alloy is poured into sand molds to create the desired shape of the magnet. These molds are designed to produce various shapes, such as cylinders, rings, or blocks.

Cooling and Solidification: The cast molds are allowed to cool gradually. Slow cooling is essential to ensure the proper formation of the alloy’s crystalline structure, which is critical for the magnetic properties.

Heat Treatment: The solidified magnets undergo heat treatment, which involves heating them to around 900°C and then cooling them at a controlled rate. This process enhances the magnetic characteristics by optimizing the crystal alignment within the alloy.

Machining: The heat-treated magnets are then machined to their final dimensions. This step is crucial for achieving the precise size and shape required for specific applications.

Magnetization: Finally, the machined magnets are magnetized by exposing them to a strong magnetic field, aligning the magnetic domains within the material to produce a powerful magnet.

Sintering Method

While less common than casting, the sintering method is used for producing smaller Alnico magnets with high precision. The sintering process involves the following steps:

Powder Preparation: The raw materials are finely ground into a powder. This powder is then mixed to ensure a uniform composition.

Compaction: The powder mixture is compacted into a desired shape using a press. This step forms a “green” magnet, which is fragile and not yet fully dense.

Sintering: The compacted shape is placed in a sintering furnace, where it is heated to temperatures around 1200°C in a controlled atmosphere. During sintering, the powder particles fuse together, forming a solid and dense magnet.

Cooling and Machining: The sintered magnets are slowly cooled and then machined to the required dimensions, similar to the casting method.

Magnetization: The final step is magnetizing the sintered magnets by exposing them to a strong magnetic field.

Advantages and Disadvantages of Manufacturing Methods

Both casting and sintering methods have their own set of advantages and disadvantages, which influence the choice of method based on the application’s specific needs.

Casting Method: Advantages

·Large and Complex Shapes: The casting method is suitable for producing large and complex shapes that would be difficult to achieve through sintering.

·High Magnetic Performance: Cast Alnico magnets typically exhibit superior magnetic performance compared to sintered magnets.

Casting Method: Disadvantages

·Material Waste: The casting process can result in a significant amount of material waste, as excess material needs to be machined away to achieve the final shape.

·Longer Production Time: The cooling and heat treatment steps in the casting process can be time-consuming, leading to longer production times.

Sintering Method: Advantages

·High Precision: The sintering method allows for the production of smaller magnets with high precision and uniformity.

·Efficient Material Use: Sintering minimizes material waste, as the powder is compacted into the desired shape with little excess.

Sintering Method: Disadvantages

·Limited Size and Shape: Sintered Alnico magnets are generally smaller and less complex in shape compared to cast magnets.

·Lower Magnetic Performance: Sintered magnets may have slightly lower magnetic performance compared to cast magnets.

Custom Alnico Magnets

At MagnetsTek, we specialize in producing Custom AlNiCo Magnets tailored to specific requirements. Our extensive experience allows us to deliver magnets with precise dimensions, shapes, and magnetic properties. Whether you need magnets for scientific instruments, electric motors, or other industrial applications, our custom Alnico magnets are designed to meet your exact specifications.

In addition to Alnico magnets, we also offer Custom SmCo Magnets. Samarium Cobalt (SmCo) magnets are known for their high magnetic strength and excellent temperature stability, making them ideal for demanding applications.

Applications of Alnico Magnets

The versatility and robust properties of Alnico magnets make them suitable for a wide range of applications across various industries. Some of the most common uses include:

Electric Motors and Generators: Alnico magnets are commonly used in electric motors and generators due to their high magnetic flux density and thermal stability. They help in converting electrical energy to mechanical energy and vice versa efficiently.

Sensors and Actuators: Alnico magnets are employed in sensors and actuators for precise and reliable performance. Their stability over a wide temperature range ensures consistent operation in varying environmental conditions.

Loudspeakers: The strong magnetic fields generated by Alnico magnets make them ideal for use in loudspeakers, where they help in converting electrical signals into sound.

Scientific Instruments: The stability and reliability of Alnico magnets make them suitable for use in various scientific instruments, including MRI machines and other diagnostic equipment.

Holding and Lifting Applications: Alnico magnets are used in holding and lifting applications due to their strong magnetic fields and durability. They can securely hold or lift heavy objects in industrial settings.

Automotive Industry: Alnico magnets are used in various automotive components, such as sensors, motors, and actuators, contributing to the efficiency and performance of vehicles.

Quality Control in Alnico Magnet Manufacturing

Ensuring the quality and performance of Alnico magnets is critical, given their use in demanding applications. At MagnetsTek, we implement rigorous quality control measures throughout the manufacturing process to deliver high-quality magnets that meet our customers’ expectations.

Material Testing

·Chemical Composition Analysis: The raw materials are tested to ensure they meet the required chemical composition specifications. This step is crucial for achieving the desired magnetic properties in the final product.

·Mechanical Properties Testing: The mechanical properties of the alloy, such as tensile strength and hardness, are tested to ensure they meet the required standards.

Process Control

·Temperature Monitoring: The temperatures in the melting, casting, and heat treatment stages are closely monitored and controlled to ensure the proper formation of the alloy’s crystalline structure.

·Dimensional Accuracy: The dimensions of the cast or sintered magnets are measured at various stages to ensure they meet the specified tolerances.

Final Inspection

- Magnetic Performance Testing: The magnetic properties of the finished magnets, such as magnetic flux density and coercivity, are tested to ensure they meet the required specifications.

- Visual Inspection: The magnets are visually inspected for any defects, such as cracks or surface irregularities, that could affect their performance.

Customization and Flexibility

One of the key advantages of working with MagnetsTek is our ability to provide customized solutions for our clients. We understand that each application has unique requirements, and we are committed to delivering magnets that meet those specific needs.

Custom Shapes and Sizes

Whether you need a standard shape or a custom design, we can produce Alnico magnets in a wide range of shapes and sizes. Our advanced manufacturing capabilities allow us to create magnets that fit precisely into your application.

Tailored Magnetic Properties

By adjusting the composition of the alloy and the manufacturing process, we can tailor the magnetic properties of the magnets to meet your specific requirements. This customization ensures that you get the optimal performance for your application.

Fast Production and Delivery

We understand the importance of timely delivery, especially for industrial applications. Our efficient production processes and streamlined supply chain enable us to deliver custom Alnico magnets with short lead times, ensuring that you receive your products when you need them.

Environmental Considerations

As with any manufacturing process, the production of Alnico magnets involves various environmental considerations. At MagnetsTek, we are committed to minimizing our environmental impact through responsible manufacturing practices.

Recycling and Waste Reduction

We implement recycling programs for the raw materials used in our manufacturing process. Any excess material generated during casting or machining is collected and recycled, reducing waste and conserving resources.

Energy Efficiency

Our production facilities are designed to optimize energy efficiency. By using advanced technologies and energy management systems, we minimize energy consumption and reduce our carbon footprint.

Environmental Compliance

We adhere to all relevant environmental regulations and standards in our manufacturing processes. This commitment ensures that our operations are environmentally responsible and sustainable.

Future Trends and Innovations in Alnico Magnet Manufacturing

The field of magnet manufacturing is continuously evolving, with ongoing research and development aimed at improving the performance and efficiency of magnets. Several trends and innovations are shaping the future of Alnico magnet manufacturing:

Advanced Alloy Compositions

Researchers are exploring new alloy compositions to enhance the magnetic properties of Alnico magnets. By experimenting with different combinations of elements, they aim to create magnets with even higher magnetic flux density and thermal stability.

Improved Manufacturing Techniques

Advancements in manufacturing techniques, such as additive manufacturing (3D printing), are opening new possibilities for producing complex and precise magnet shapes. These techniques can potentially reduce material waste and production time while increasing design flexibility.

Integration with Smart Technologies

The integration of smart technologies, such as sensors and IoT (Internet of Things) devices, is transforming various industries. Alnico magnets, with their robust properties, are expected to play a crucial role in these smart applications, driving further innovation in their manufacturing and use.

Conclusion

Understanding the manufacturing methods of Alnico magnets provides insight into their superior performance and versatility. Whether through casting or sintering, the precision involved in producing these magnets ensures their reliability and efficiency in various applications. For customized solutions, MagnetsTek remains a trusted partner, offering high-quality Custom AlNiCo Magnets and Custom SmCo Magnets to meet your unique needs.

By appreciating the craftsmanship and technology behind Alnico magnet manufacturing, we can better understand the value and capabilities these magnets bring to modern industries. As technology continues to advance, Alnico magnets will undoubtedly remain a critical component in various applications, driving innovation and improving performance across multiple fields.