In today’s fast-paced industrial environments, ensuring worker safety is of utmost importance. The complexities of modern manufacturing, assembly lines, and even research laboratories demand meticulous attention to safety standards. One simple but highly effective solution to mitigate risks and improve operational safety is the use of mounting magnets. These magnets help secure tools, equipment, and materials in place, preventing accidents caused by shifting, falling, or dislodging objects. In this article, we will explore how mounting magnets contribute to workplace safety, their specific applications across various industries, and how Magnetstek designs these magnets to meet the demands of a wide range of safety-critical environments.

The Importance of Safety in Work Environments

In any industrial setting, the risk of accidents and injuries is ever-present. Many workplace incidents are caused by unsecured tools, materials, or machinery, which can result in workers being injured, equipment being damaged, or production being halted. Workplace hazards can include:

- Falling objects: Tools or materials can fall from overhead racks or workstations, causing serious injuries.

- Slip and trip accidents: Objects left on the floor can create obstacles that cause workers to trip and fall.

- Vibration-induced displacement: Machines or tools that move or shift during operation can lead to injuries or errors.

- Transport-related risks: Moving materials or goods that are improperly secured can lead to accidents during transit.

Mounting magnets help to address these risks by securely attaching tools, equipment, and materials to fixed surfaces, ensuring they remain in place during operations. These magnets offer a simple yet effective solution for enhancing safety in a variety of environments.

Types of Mounting Magnets

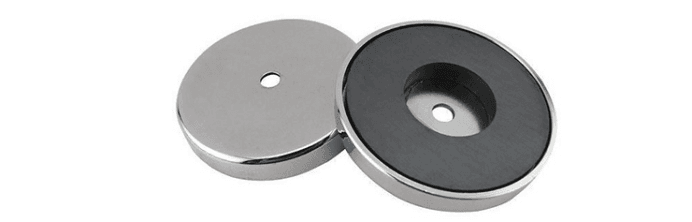

Mounting magnets come in various types, each designed for different applications. These magnets can range in strength, size, and functionality, depending on the intended use. Below are some common types of mounting magnets that are frequently used to enhance safety in the workplace:

1. Neodymium Magnets

Neodymium magnets, or NdFeB magnets, are made from an alloy of neodymium, iron, and boron. These rare-earth magnets are known for their exceptionally strong magnetic properties. Neodymium magnets are often used in applications where a compact but powerful magnet is required. They are especially useful in securing tools and equipment that must remain in place despite vibrations or forces from nearby machinery.

In industrial settings, Magnetstek provides high-performance neodymium-based mounting magnets that are perfect for securing heavy tools or larger machinery components. Their high pull force makes them ideal for environments such as automotive manufacturing or aerospace, where precision and safety are paramount.

2. Ferrite Magnets

Ferrite magnets are made from iron oxide and either barium or strontium. While they do not offer the same magnetic strength as neodymium magnets, they are highly durable and cost-effective. Ferrite magnets are frequently used for general-purpose applications and are well-suited for securing lighter materials or tools that do not require the intense holding force of rare-earth magnets.

Ferrite-based mounting magnets are commonly used in warehouses, retail displays, and other low-force applications. They offer an affordable and effective solution for preventing tools from falling or materials from shifting.

3. Samarium Cobalt Magnets

Samarium cobalt magnets, another form of rare-earth magnet, are known for their excellent resistance to high temperatures and corrosion. These magnets are typically used in more specialized applications where the environment may expose the magnets to extreme conditions, such as in high-temperature industrial or military settings.

Due to their superior temperature stability, samarium cobalt magnets are ideal for situations where mounting magnets need to function reliably in heat-intensive environments, such as in metalworking or certain laboratory settings.

4. Electromagnetic Mounting Systems

Electromagnetic mounting systems differ from permanent magnets in that they require an electrical current to create a magnetic field. These systems can adjust their magnetic strength based on the amount of electricity supplied. They are commonly used in applications that require temporary magnetism or in situations where the magnetic strength needs to be controlled dynamically.

These systems are often used in industries like steel manufacturing, where temporary but strong magnetic forces are needed to hold large, heavy objects in place during production processes.

How Mounting Magnets Enhance Safety in Work Environments

1. Preventing Tools and Equipment from Falling

One of the most prevalent safety hazards in industrial workplaces is the falling of tools or equipment. Tools left unsecured on elevated surfaces or workstations can easily be knocked over, potentially injuring workers below. In environments such as construction sites or high-rise factories, this is a significant concern.

Mounting magnets provide a simple and effective way to secure tools and equipment in place. With the help of powerful neodymium mounting magnets or ferrite-based tool holders, tools like drills, wrenches, and other handheld devices can be attached securely to walls, workstations, or machinery. This prevents the tools from falling, even when subjected to vibration or mechanical movement.

In industries like automotive manufacturing, where tools are frequently in use and subject to vibrations from machinery, using magnetic tool holders can significantly reduce the risk of accidents due to falling equipment.

2. Reducing Slip and Trip Hazards

Slips and trips caused by objects left on the floor or in high-traffic areas are common causes of workplace injuries. These accidents can be costly and disruptive, especially in fast-paced environments like warehouses, distribution centers, and construction sites.

By securely mounting tools, parts, and materials on magnetic racks or magnetic tool holders, companies can significantly reduce clutter and keep the workplace safer. With Magnetstek’s magnetic mounting systems, businesses can keep workspaces organized and free from potential hazards. For example, instead of leaving tools on the floor, workers can store them on magnetic panels mounted to the walls or sides of workbenches.

These magnetic storage systems help ensure that there is a designated and safe place for every tool, preventing them from becoming tripping hazards.

3. Securing Equipment During Operations

Vibrations, machine movement, and even sudden jolts during industrial operations can cause tools, equipment, or materials to shift unexpectedly. This can lead to misalignment, mechanical failure, or injury. To prevent such occurrences, mounting magnets are used to hold tools, workpieces, and components firmly in place during operations.

In industries like welding and machining, securing parts or materials with magnetic clamps ensures they stay in position while workers complete their tasks. Magnetic welding holders, for instance, are specifically designed to hold metal pieces at precise angles, reducing the risk of injury from misalignment or equipment shifting.

In automated manufacturing lines, magnetic clamps can hold workpieces or molds steady during processes like drilling, milling, or grinding, ensuring safety and precision throughout the operation.

4. Preventing Material Shifting During Transport

Materials that are improperly secured during transport pose a significant risk, particularly in large warehouses or manufacturing facilities. Improperly secured pallets, tools, or materials can shift or even fall off forklifts or conveyor belts, creating potential safety hazards.

Magnetic transport fixtures, such as magnetic pallet holders, can help securely hold materials in place during transport. These magnets are designed to attach to metal surfaces on conveyors or pallet racks, ensuring that materials stay in place during movement.

In high-speed environments, such as food processing or electronics assembly, securing materials with magnetic systems reduces the risk of accidents or product damage during transport. The magnets help stabilize the load and minimize shifting, making the transport process smoother and safer.

5. Enhancing Safety in Hazardous Environments

In hazardous work environments such as chemical plants, oil rigs, and mining operations, safety is a top priority due to the presence of flammable substances, high-pressure systems, or dangerous machinery. Mounting magnets play a crucial role in preventing equipment from shifting or becoming dislodged, which could lead to catastrophic accidents in these environments.

Explosion-proof magnets are designed to work safely in environments where sparks or electrical discharges could lead to fires or explosions. These magnets securely hold tools and equipment in place while ensuring that no electrical or magnetic interference occurs. In these high-risk environments, mounting magnets act as an extra layer of protection, ensuring that all equipment remains in place without causing harm to the workplace.

6. Magnetic Mounting for First Aid and Emergency Equipment

In emergency situations, it is vital that safety equipment is quickly accessible. First aid kits, fire extinguishers, and emergency tools must be readily available in case of an accident or injury. Magnetic mounts can be used to securely attach these safety items to walls, vehicles, or workstations, ensuring they are easy to access in emergencies.

For example, magnetic fire extinguisher mounts can be installed in areas where fire safety equipment needs to be easily accessible. Similarly, magnetic first aid kits can be placed in central locations, ensuring that workers can access them quickly in the event of an injury.

Conclusion

Mounting magnets are a cost-effective, reliable, and highly versatile solution for improving safety in the workplace. Whether it’s preventing tools from falling, reducing trip hazards, stabilizing machinery, or securing materials during transport, these magnets provide practical solutions to a wide range of safety concerns. By using Magnetstek’s mounting magnets, companies can significantly reduce the risks associated with unsecured equipment, creating safer and more efficient working environments.

As industries continue to evolve and demand greater safety standards, the use of mounting magnets will become an even more integral part of workplace safety protocols, helping businesses minimize accidents, enhance operational efficiency, and ensure the well-being of their employees.