Table of Contents

- 1. Understanding Magnetic Hook Weight Capacity

- 2. Why Weight Capacity Matters

- 3. Calculating Your Weight Requirements

- 4. Testing and Verifying Weight Capacity in Real-Life Conditions

- 5. Considering Different Application Scenarios

- 6. Choosing the Right Magnetic Hook for Your Needs

- 7. Other Factors Affecting Magnetic Hook Performance

- 8. Common Mistakes When Selecting Magnetic Hooks

- 9. Conclusion: Ensuring Your Magnetic Hook Meets Your Needs

Magnetic hooks are versatile and valuable in a wide range of applications, from organizing spaces at home to industrial setups. They offer convenience and flexibility, but ensuring that the magnetic hook has the appropriate weight capacity is critical to avoid accidents and ensure long-term reliability. This guide will explore everything you need to know to determine if a magnetic hook’s weight capacity aligns with your requirements, covering factors that impact magnetic strength, how to measure weight needs, and common mistakes to avoid.

1. Understanding Magnetic Hook Weight Capacity

- What Is Weight Capacity?

Weight capacity is the maximum load a magnetic hook can securely hold without detaching from the surface or losing its grip. It’s typically expressed in pounds or kilograms and depends on several factors including the magnet type, the hook’s construction, and the surface it’s attached to. - Factors Influencing Weight Capacity

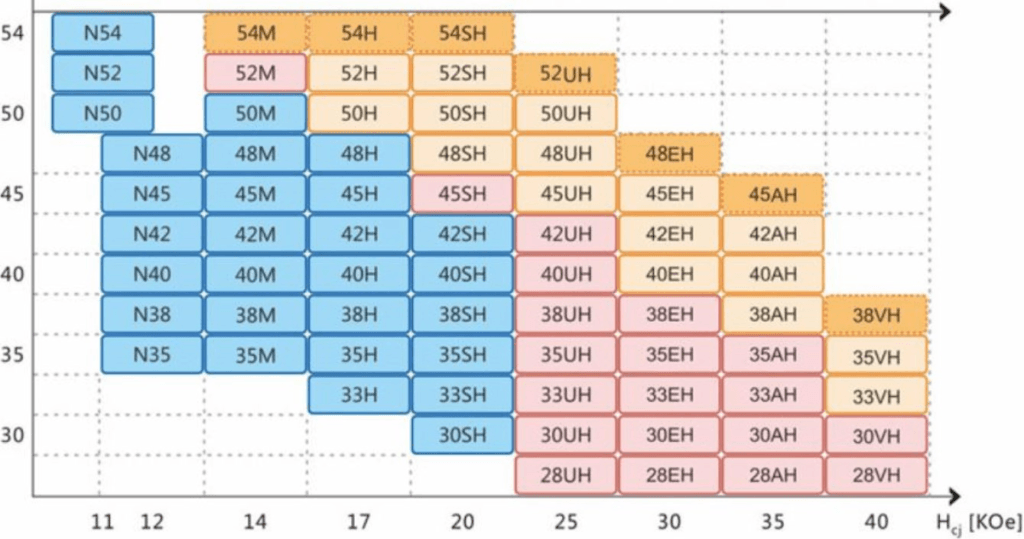

Not all magnetic hooks are the same, and various factors determine how much weight each can hold:- Magnet Type: Stronger magnets, like neodymium magnets, are often used in heavy-duty magnetic hooks because they can support a larger load for their size.

- Surface Type: The type and quality of the surface are crucial. Ferromagnetic surfaces like iron or steel provide the strongest attachment, while non-metallic surfaces or those with gaps or textures may reduce magnetic strength.

- Environmental Conditions: High or low temperatures, humidity, and exposure to corrosive substances can weaken a magnet’s holding capacity over time.

2. Why Weight Capacity Matters

- Safety and Reliability

Knowing the weight capacity of a magnetic hook is essential for safety, especially if the items being held are heavy, valuable, or potentially hazardous. Overloading a hook can lead to accidents, property damage, or injuries. - Purpose Matching

Different uses call for different weight capacities. Understanding the intended purpose, from light-duty uses in home settings to heavy-duty industrial applications, ensures that the hook will perform well and last over time.

3. Calculating Your Weight Requirements

- Assessing the Combined Weight of Items

Start by determining the combined weight of the items you plan to hang on the hook. This includes the primary item and any attachments, accessories, or containers. - Incorporating a Safety Margin

To ensure the hook can handle potential shifts in weight or slight changes in load, add a safety margin of 25–30%. This extra allowance helps account for any unexpected stresses or variations in how weight is distributed.

4. Testing and Verifying Weight Capacity in Real-Life Conditions

- Testing the Magnetic Hook in Various Orientations

Magnetic hooks may perform differently depending on whether they are attached vertically or horizontally. Testing in the actual intended environment—whether the hook will be on a vertical wall or under a shelf—can help verify that it holds well under those conditions. - Using a Scale for Accurate Measurements

To ensure you don’t exceed the hook’s weight capacity, use a scale to weigh items you intend to hang. For high-value or heavy objects, weighing and testing are especially important.

5. Considering Different Application Scenarios

- Home Use

Lighter magnetic hooks with capacities between 5–10 pounds are typically sufficient for home use, such as hanging kitchen utensils, keys, or light decor. - Industrial Use

In industrial settings, magnetic hooks are often needed for tools, equipment, or cables, requiring hooks with higher weight capacities (20 pounds or more). - Outdoor and Camping Applications

For outdoor scenarios, magnetic hooks should have durable materials and coatings to withstand elements like rain, sunlight, and temperature changes, while also offering reliable weight capacity for holding items like gear, lights, or tents.

6. Choosing the Right Magnetic Hook for Your Needs

- Evaluating Magnet Material and Grade

The strength of a magnet largely depends on its material. Neodymium magnets, for example, are among the strongest available for their size, making them ideal for hooks that need to hold a significant amount of weight. - Reviewing Manufacturer Specifications

Carefully review manufacturer specifications, as they provide insights into the hook’s tested weight capacity, often under optimal conditions. Note that capacity might vary slightly in real-world applications depending on environmental factors. - Considering the Size and Design of the Hook

Hooks with larger magnets and wider bases generally have a higher holding capacity due to the increased surface contact area.

7. Other Factors Affecting Magnetic Hook Performance

- Surface Compatibility

Magnetic hooks require a ferromagnetic surface, such as steel, to work effectively. Non-metal surfaces or certain types of metal (like aluminum) are not magnetic, making the hook ineffective. - Surface Cleanliness and Smoothness

Dirt, rust, or rough textures can reduce the holding strength of a magnetic hook. Before using the hook, make sure the surface is clean and smooth for maximum effectiveness. - Temperature and Environmental Impact

High temperatures can weaken the magnetic strength of many magnets, especially neodymium magnets. Similarly, exposure to moisture or corrosive substances may degrade the hook and the magnet over time, impacting holding power.

8. Common Mistakes When Selecting Magnetic Hooks

- Assuming All Surfaces Are Suitable

Not every metal surface is suitable for a magnetic hook. Always verify that the surface is compatible with magnets, especially for high-stakes applications where a secure hold is crucial. - Ignoring the Safety Margin

Many users overlook the importance of a safety margin, which can lead to accidents if the magnet gradually weakens or if items are added over time. Planning with a margin is essential for long-term reliability. - Not Testing Under Real-World Conditions

It’s easy to assume that a hook’s listed capacity is universally applicable. However, testing the hook in the actual location and orientation where it will be used helps reveal any weaknesses or limitations.

9. Conclusion: Ensuring Your Magnetic Hook Meets Your Needs

Selecting a magnetic hook with the right weight capacity involves understanding the hook’s specifications, testing it in practical scenarios, and factoring in safety margins and environmental influences. By thoroughly assessing your needs, considering the surface type, and accounting for external conditions, you can confidently choose a magnetic hook that will safely support your items for years to come.