Magnetization direction is a critical aspect when working with magnets, especially sintered neodymium magnets. It determines the position of the north and south poles of a magnet and plays a crucial role in its performance and application. Understanding the magnetization direction of magnets helps ensure that the product functions efficiently and effectively in its intended application. In this article, we will discuss various magnetization directions, including how to identify and select the appropriate direction for different shapes of magnets.

What Is Magnetization Direction?

Magnetization direction refers to the orientation of the magnetic poles (north and south) in a magnet. It is established during the magnetization process, which is the first step in making sintered neodymium magnets magnetic. For neodymium magnets, the strength is at its highest when one pole is in direct contact with an opposite surface. However, the effectiveness depends largely on the alignment of the magnetization with the application requirements.

Key Characteristics:

- North Pole in Red, South Pole in Gray: In diagrams, the north pole is typically represented in red, while the south pole is depicted in gray.

- Maximizing Efficiency: Magnets are most effective when their magnetization direction aligns with their application.

Let’s explore the common magnetization directions in various magnet shapes.

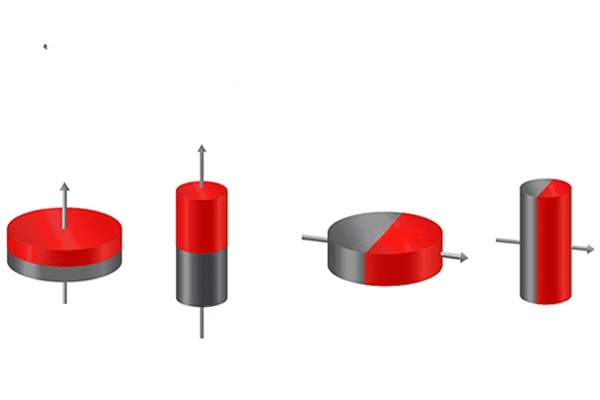

1. Magnetization Directions in Circular and Cylindrical Magnets

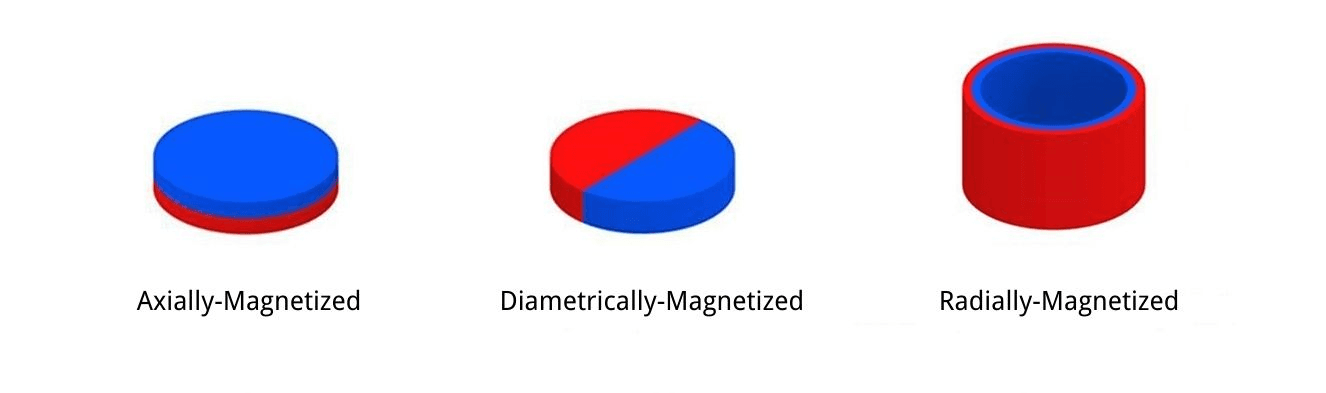

Circular magnets, including cylindrical shapes, can have either axial magnetization or radial magnetization.

Axial Magnetization

- Description: The north and south poles are located on the flat surfaces of the magnet.

- Applications: Ideal for applications where the flat sides interact with opposite surfaces.

- Effectiveness: Best when the flat surface of the magnet contacts an opposing surface.

Radial Magnetization

- Description: The north and south poles are located on the curved side of the magnet.

- Applications: Commonly used in specialized engineering or industrial applications requiring radial fields.

- Performance: Magnetic force is strongest on the curved side, though weaker compared to axial when used on flat surfaces.

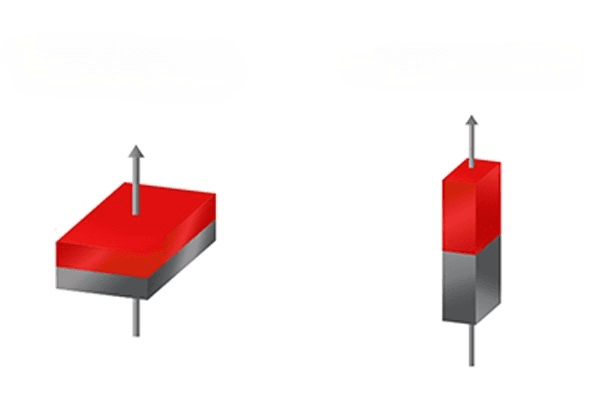

2. Magnetization in Rectangular and Square Magnets

Rectangular and square magnets are defined by their length × width × height dimensions. The magnetization direction is determined by the face through which magnetization occurs, typically the thickness.

Identifying Magnetization in Rectangular Magnets

- Example 1: For a magnet labeled as F20×15×10 mm, the magnetization direction is along the 10 mm thickness.

- Example 2: For a magnet labeled as F20×10×15 mm, the magnetization occurs along the 15 mm dimension.

Practical Applications

- High-Performance Uses: Rectangular magnets are often used in motors, sensors, and actuators, where precise magnetization alignment is crucial.

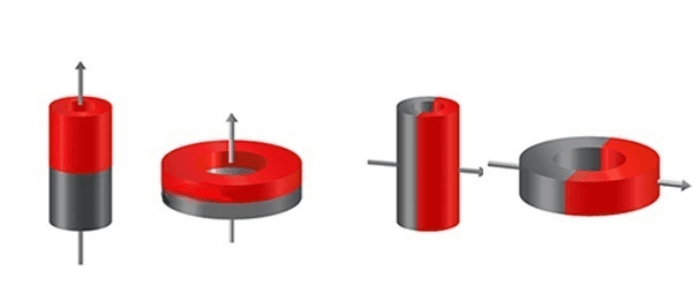

3. Magnetization Directions in Ring Magnets

Ring magnets, with their donut-like shape, can also have either axial or radial magnetization.

Axial Magnetization

- Poles Location: The north and south poles are on the flat faces of the ring.

- Best Use: Works effectively in assemblies where flat surfaces interact with opposing polarities.

Radial Magnetization

- Poles Location: North and south poles are on the inner and outer circular surfaces.

- Common Uses: Often employed in rotary machinery and specialized magnetic field setups.

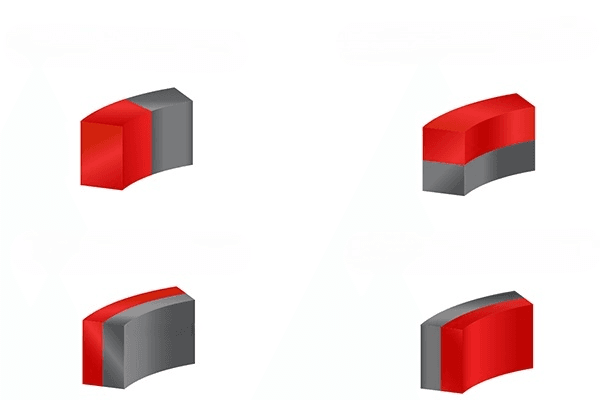

4. Magnetization in Arc Magnets

Arc magnets, also known as segment or curved magnets, are typically used in motors and generators. They have four common magnetization directions.

Common Magnetization Patterns

- Through Thickness: The poles are located on the inner and outer curved surfaces.

- Through Length: The poles extend along the length of the arc.

- Through Width: The poles are across the width of the arc.

- Custom Patterns: Some arcs feature tailored patterns for specific applications.

Key Considerations

- Motor Applications: Arc magnets with through-thickness magnetization are widely used in motors, providing consistent rotational force.

- Generators: Radial magnetization is essential in generators for efficient magnetic field production.

Why Is Magnetization Direction Important?

Choosing the correct magnetization direction ensures optimal performance in applications. Here’s why:

- Enhanced Magnetic Force: Proper alignment maximizes the magnetic field strength.

- Minimized Energy Loss: Inappropriate magnetization can reduce efficiency.

- Application-Specific Requirements: Motors, sensors, and magnetic assemblies rely heavily on precise magnetization alignment for functionality.

Additional Magnetization Directions

Although less common, some magnets may feature complex magnetization directions, including:

- Multi-pole Magnetization: Alternating north and south poles on the same surface.

- Custom Magnetization: Designed for unique applications requiring non-standard magnetic fields.

Conclusion

Understanding the magnetization direction of magnets is crucial for selecting the right magnet for any application. Whether working with circular, rectangular, ring, or arc magnets, identifying the poles and aligning the magnetization direction with the product’s requirements ensures optimal performance.

By mastering the various magnetization directions, you can maximize the efficiency and effectiveness of your magnets in industrial, engineering, or commercial applications.