Permanent magnets—especially high-performance NdFeB (Neodymium-Iron-Boron)—are central to modern motors, robotics, automation, aerospace, renewable energy, medical devices, and sensing systems. However, sintered NdFeB suffers from inherent vulnerabilities: chemical reactivity, moisture sensitivity, structural brittleness, and weak grain-boundary strength. These weak points make protective coatings an essential part of any magnet engineering or application design.

Coatings determine whether a magnet lasts for years or fails within months, especially in environments involving humidity, abrasion, salt, chemicals, or thermal cycling. This guide provides a deep engineering analysis of how to choose the best coating for corrosion protection, mechanical wear resistance, high-humidity stability, and application-specific reliability.

1. Why NdFeB Magnets Require Coatings

1.1 Structural and chemical vulnerability of NdFeB

NdFeB magnets are produced via powder metallurgy, resulting in a microstructure with:

- Iron-rich grain boundaries

- High porosity

- Electrochemical reactivity

- Poor ductility and tensile strength

- Low fracture toughness

Moisture and oxygen attack grain boundaries first, leading to structural swelling, surface blistering, and rapid degradation.

1.2 Corrosion begins at edges, cracks, and defects

Coating failure rarely begins at smooth surfaces. Instead, it is triggered at:

- Sharp corners

- Thinly coated edges

- Machined surfaces

- Handling scratches

- Pinholes in plating

- Micro-cracks from assembly impact

Once initiated, corrosion propagates beneath the coating, often expanding unseen until catastrophic failure occurs.

1.3 Coatings provide more than corrosion protection

Coatings also contribute:

- Increased surface hardness

- Enhanced wear resistance

- Chemical shielding

- Electrical insulation

- Biocompatibility

- Improved thermal cycling tolerance

- Reduced friction (in PTFE-type coatings)

- Dampening of mechanical shock

Therefore, coating selection must consider both environmental conditions and mechanical interface requirements.

2. Engineering Overview of Magnet Coating Options

This section analyzes each coating’s behavior, mechanical performance, chemical stability, failure mechanisms, and industrial suitability.

2.1 NiCuNi (Nickel–Copper–Nickel)

Corrosion behavior

NiCuNi provides moderate corrosion resistance but is vulnerable in:

- High humidity

- Salt spray

- Chloride environments

- Repetitive condensation cycles

Moisture penetrates through pinholes or compromised edges, leading to copper layer corrosion and coating lift.

Mechanical performance

- High surface hardness

- Excellent abrasion resistance

- Uniform thin coating (~12–25 μm)

- Best option for tight air-gap motors

Failure modes

- Edge cracking under impact

- Delamination due to poor substrate preparation

- Sub-film corrosion initiated at defects

- Surface blistering under hydrogen accumulation

Best for

Motors, rotors, robotic actuators, high-speed applications, magnetic rings, Halbach arrays, and environments where mechanical strength matters most.

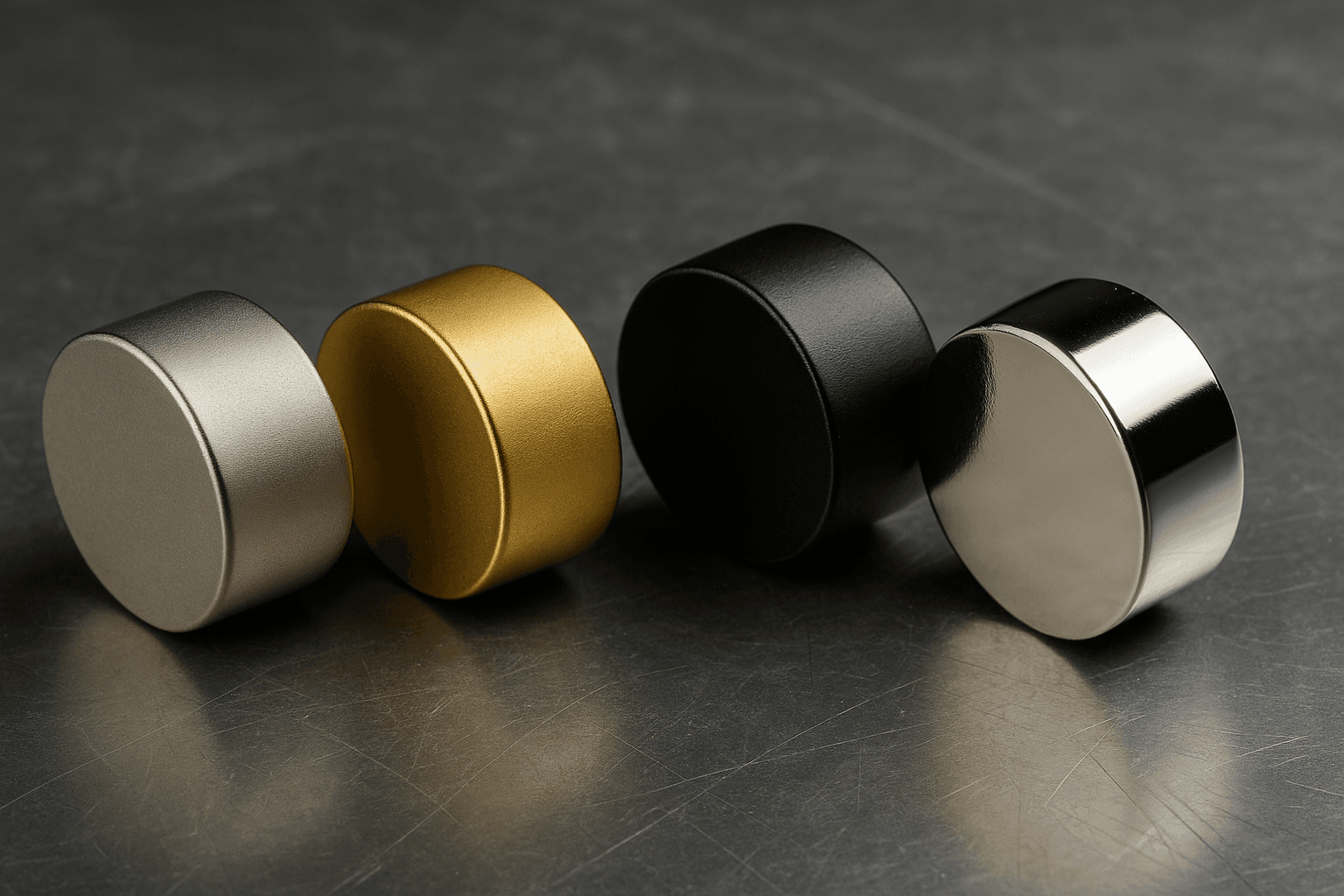

2.2 Epoxy Coating (Black, Grey, and Custom Colors)

Corrosion behavior

Outstanding moisture protection due to organic polymer barrier:

- Excellent salt spray resistance

- Excellent humidity cycling stability

- Strong chemical resistance

Epoxy is ideal for environments where NiCuNi alone fails.

Mechanical performance

- Softer coating

- High impact cushioning

- Poor abrasion resistance

- Sensitive to sharp metal contact

- Scratches expose porous NdFeB immediately

Failure modes

- Surface scratching → rapid under-film corrosion

- UV-induced aging

- Thermal embrittlement above ~120°C

- Thin corners due to flow characteristics during coating

Best for

Outdoor devices, security equipment, marine sensors, renewable energy components, HVAC controls, and devices requiring long-term corrosion durability.

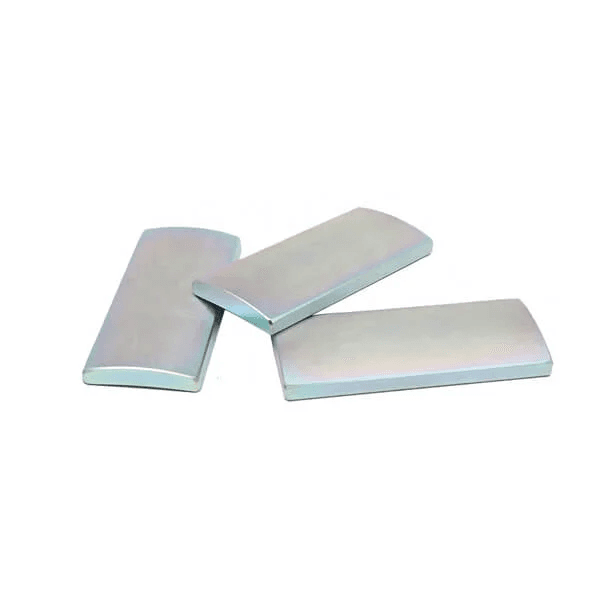

2.3 Zinc Coating

Corrosion behavior

Provides short-term, sacrificial protection.

However:

- White rust forms quickly

- Weak under high humidity

- Not suitable for long-term outdoor use

Mechanical performance

Soft, easily scratched, not recommended for wear-intensive applications.

Best for

Low-cost consumer electronics and temporary applications.

2.4 Phosphate Coating

Performance

Phosphate is not a corrosion coating; it is an interface treatment used for:

- Enhancing adhesive bonding

- Improving resin wetting

- Promoting adhesion in overmolding

- Reducing friction during assembly

Best for

Bonded NdFeB magnets, ferrite magnets, and components that will be embedded in resin or polymer matrices.

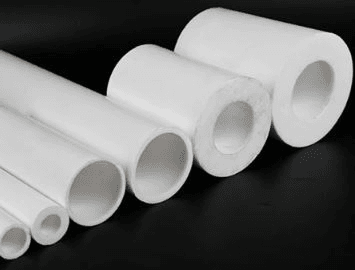

2.5 PTFE / Everlube / Teflon Coating

Corrosion behavior

Moderate. PTFE itself is chemically inert, but the underlying bond layers determine long-term corrosion resistance.

Mechanical performance

- Extremely low coefficient of friction

- Excellent sliding wear resistance

- Good chemical stability

- Not suitable for impact or abrasion

Best for

Linear motion stages, valves, robotics, dynamic applications where friction reduction is critical.

2.6 Gold Coating

Corrosion behavior

Gold is fully inert against oxidation and most chemical environments.

Mechanical performance

- Very thin (~0.5–1 μm)

- Soft and easily scratched

- Requires Ni underlayer for adhesion

Best for

Bio-sensing devices, medical instruments, wearables, cleanroom systems, and miniaturized precision magnets.

2.7 Parylene (C / N / F)

Corrosion behavior

Parylene is a CVD-applied, completely conformal, pinhole-free barrier with:

- Extremely low moisture permeability

- Uniform thickness even on complex geometries

- Excellent chemical resistance

Mechanical performance

- Flexible

- Electrically insulating

- Not abrasion-resistant unless enclosed in housings

Best for

Underwater sensors, hermetically sealed assemblies, medical systems, aerospace components, and long-lifecycle high-reliability devices.

3. Understanding Magnet Failure Mechanisms

Coating choice must be informed by the most common field failures.

3.1 Edge-initiated corrosion

Edges have the thinnest coating and the highest mechanical stress.

Mitigation

- Chamfer edges

- Thicker epoxy formulations

- Parylene conformal coverage

- Multi-layer systems (NiCuNi + Epoxy)

3.2 Sub-film corrosion spreading

Once corrosion penetrates coating defects, it spreads laterally.

Mitigation

- Epoxy (slows diffusion)

- Parylene (blocks moisture)

- Hybrid systems for redundancy

3.3 Mechanical cracking and chipping

NdFeB cracks easily under:

- Press-fit assembly

- Rotor installation

- Impact

- Vibration

Mitigation

- NiCuNi for mechanical stiffness

- Epoxy for impact cushioning

- Protective housings

3.4 Chemical degradation

Lubricants, coolants, acids, or solvents degrade certain coatings.

Mitigation

- PTFE for chemical resistance

- Parylene for high-purity chemical shielding

- Epoxy for mild chemical exposure

3.5 Thermal cycling fatigue

Different thermal expansion rates cause coating stress.

Mitigation

- Parylene (best flexibility)

- Epoxy for moderate conditions

- NiCuNi only for stable temperature environments

4. Selection Framework for Corrosion, Wear, and Humidity Conditions

Here is a practical engineering-based method for choosing the correct coating.

4.1 High-Humidity or Condensation-Prone Environments

Recommended coatings

- Epoxy

- NiCuNi + Epoxy

- Parylene C

Rationale

Epoxy and Parylene dramatically reduce moisture diffusion and eliminate pinhole-driven failure.

4.2 Marine or Salt-Spray Environments

Recommended coatings

- Epoxy (economical)

- Parylene C (premium)

- Hybrid NiCuNi + Epoxy

Rationale

Nickel alone fails quickly in chloride environments.

4.3 Wear, Abrasion, or Sliding Interfaces

Recommended

- NiCuNi

- PTFE

- Hard nickel

Avoid

Epoxy in dynamic interfaces due to poor abrasion resistance.

4.4 Medical, Wearable, or Biocompatible Applications

Recommended coatings

- Parylene C

- Gold plating

- Medical-grade epoxy

Rationale

These coatings provide biocompatibility, chemical inertness, and low irritation.

4.5 High-Temperature Applications

Material first, coating second

Use:

- High-temperature NdFeB (SH–EH grades)

- SmCo magnets for >200°C

Coatings

- NiCuNi

- Phosphate (for bonded magnets)

5. Validation Methods for Coating Quality

5.1 Salt Spray Testing (ASTM B117)

Tests the onset and progression of:

- Pitting

- Sub-film corrosion

- Blistering

- Edge degradation

5.2 Adhesion Tests

- Cross-hatch adhesion

- Pull-off tests

- Impact and chipping tests

- Centrifugal adhesion tests for rotors

5.3 Coating Thickness Measurement

Using:

- XRF

- Eddy current gauges

- SEM cross-sections

Tight thickness control is essential for high-speed motors.

5.4 Environmental Cycling

- Temperature cycling

- Humidity cycling

- UV exposure

- Chemical compatibility tests

- Abrasion resistance tests

6. Final Selection Summary

If corrosion resistance is top priority:

→ Epoxy or Parylene C

If mechanical wear resistance is essential:

→ NiCuNi or PTFE

If both corrosion and wear matter:

→ NiCuNi + Epoxy hybrid

If biocompatibility is required:

→ Parylene C or Gold

If exposed to salt spray:

→ Avoid NiCuNi alone → use Epoxy or Parylene

If for high-speed rotors:

→ NiCuNi