Introduction

Stainless steel, a ubiquitous material found in countless everyday objects, is often associated with its remarkable corrosion resistance and sleek, modern appearance. However, one aspect of stainless steel that frequently puzzles people is its magnetic properties – or lack thereof. Do magnets actually stick to stainless steel, or is this a common misconception?

In this comprehensive article, we will delve into the intriguing relationship between magnets and stainless steel, exploring the science behind their interactions, the various types of stainless steel and their unique magnetic behaviors, and the practical implications of these properties in real-world applications. By the end of this journey, you’ll have a deeper understanding of the magnetic mysteries that surround this versatile material.

Do Magnets Stick to Stainless Steel?

Stainless steel is a popular material used in many products, from kitchen appliances to industrial equipment, due to its durability and corrosion resistance. However, many people are often curious about whether a magnet will stick to stainless steel. The answer is not straightforward, as it depends on the type of stainless steel and the strength of the magnet.

Stainless steel is an alloy made up of iron, chromium, and other elements. The exact composition of the alloy determines its magnetic properties. Austenitic stainless steels, which are commonly used in household appliances, contain nickel and are generally non-magnetic. Ferritic and martensitic stainless steels, on the other hand, contain higher amounts of iron and are magnetic.

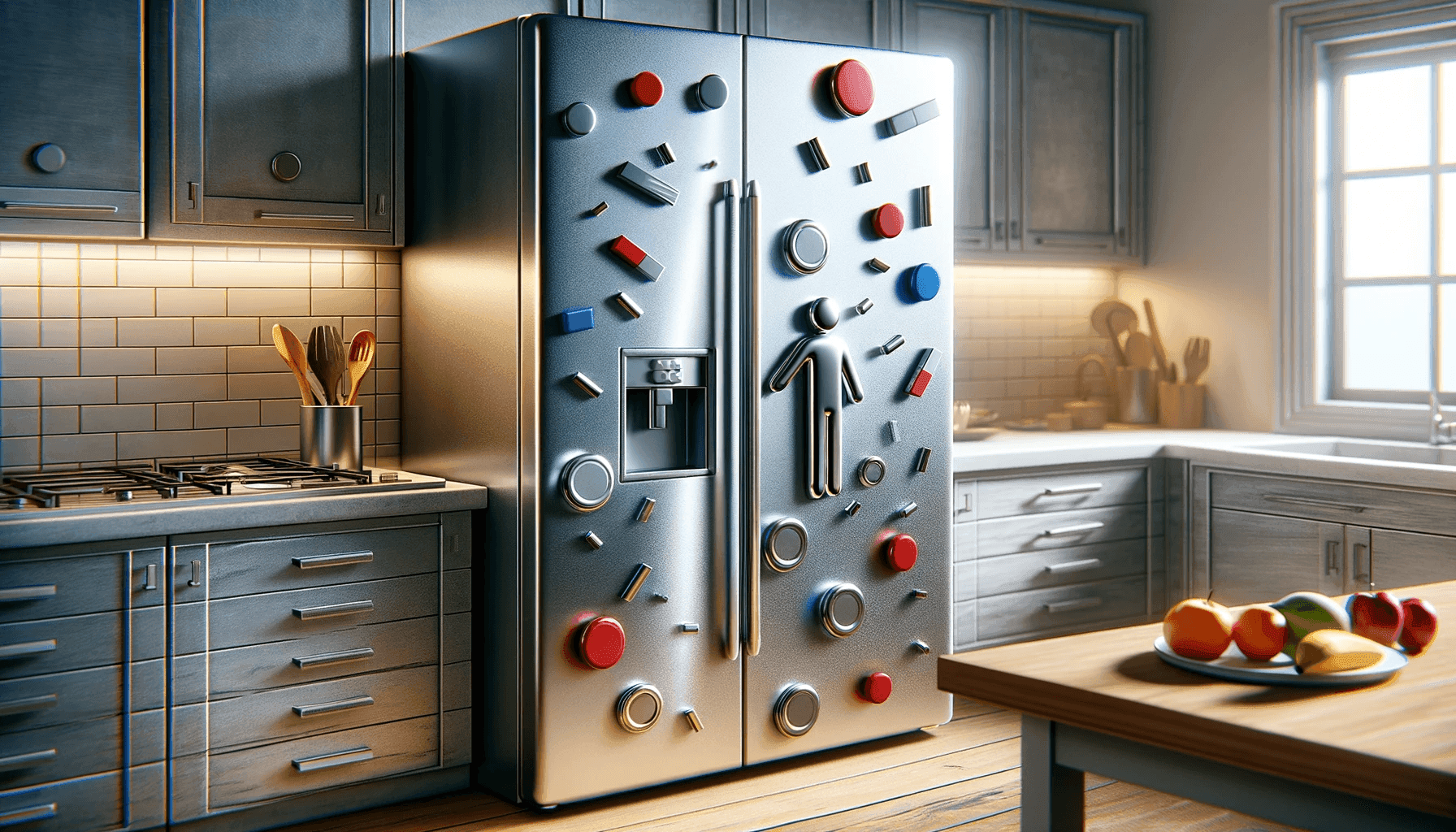

To determine if a magnet will stick to a stainless-steel surface, you need to know the type of stainless steel used. One easy way to tell is to use a refrigerator magnet. If the magnet sticks, it is likely ferritic or martensitic stainless steel. If it doesn’t stick, it is likely austenitic stainless steel.

It’s worth noting that even if a magnet does not stick to an austenitic stainless-steel surface, there may still be some magnetic attraction due to the presence of impurities or surface contaminants. In general, the higher the nickel content in the alloy, the less magnetic it will be.

The Science Behind Magnetism and Metals

To understand the magnetic properties of stainless steel, it’s essential to first explore the concept of magnetism itself. Magnetism is a fundamental force in nature, arising from the behavior of electrons within materials. Ferromagnetic materials, such as iron, nickel, and cobalt, have a unique atomic structure that allows their magnetic domains to align, creating a strong magnetic field.

In contrast, paramagnetic materials, like aluminum and titanium, have a more random arrangement of magnetic domains, resulting in a weaker magnetic response. Diamagnetic materials, such as copper and gold, have no unpaired electrons and are not attracted to magnets.

Stainless Steel Varieties and Their Magnetic Properties

The magnetic behavior of stainless steel is primarily determined by its alloy composition, specifically the ratio of iron, chromium, and nickel. There are three main types of stainless steel grades that exhibit different magnetic properties:

1. Ferritic Stainless Steel: Ferritic stainless steels, such as grades 430 and 434, contain a higher proportion of iron and are generally magnetic. These steels have a body-centered cubic (BCC) crystal structure, which allows the magnetic domains to align and create a magnetic field.

2. Martensitic Stainless Steel: Martensitic stainless steels, including some knife blades, also contain a higher iron content and are magnetic. Like ferritic steels, they have a BCC crystal structure that enables magnetic properties.

3. Austenitic Stainless Steel: Austenitic stainless steels, such as grades 304 and 316, are the most common variety used in household and commercial applications. These steels contain a higher percentage of nickel and have a face-centered cubic (FCC) crystal structure, which makes them generally non-magnetic.

Factors Influencing Magnetism in Stainless Steel

The magnetic properties of stainless steel can be influenced by various factors beyond the alloy composition, including:

1. Manufacturing Processes: The manufacturing processes used to create stainless steel can impact its magnetic properties. For example, cold working can induce magnetic properties in austenitic stainless steels due to strain-induced martensite formation.

2. Heat Treatment: Heat treatment can also alter the magnetic characteristics of stainless steel, either enhancing or reducing the material’s magnetic traits through changes in its chemical composition and microstructure.

3. Environmental Factors: External factors such as temperature and the presence of a magnetic field can also affect the magnetic state of stainless steel, highlighting the need for careful consideration in its application and handling.

Practical Applications and Considerations

The magnetic properties of stainless steel can have significant implications in various applications:

1. Household Appliances: For household appliances like refrigerators, the magnetic properties of the stainless steel can determine whether standard refrigerator magnets will adhere to the surface. Ferritic and martensitic stainless steels are more likely to allow magnets to stick, while austenitic grades are generally non-magnetic.

2. Industrial Applications: In industrial settings, the magnetic properties of stainless steel can be crucial, particularly in applications where magnetic neutrality is required, such as in magnetic resonance imaging (MRI) equipment. Austenitic stainless steels are often preferred for these non-magnetic applications.

3. Fastener Selection: When selecting stainless steel fasteners, such as screws, the magnetic properties can be an important consideration. Ferritic and martensitic stainless steel fasteners are magnetic and may be preferred in certain applications, while austenitic fasteners are non-magnetic.

Testing Stainless Steel for Magnetic Properties

For those interested in testing the magnetic properties of stainless steel, a simple and effective method is to use a refrigerator magnet. If the magnet sticks to the surface, the stainless steel is likely of the ferritic or martensitic variety. If the magnet does not adhere, the steel is most likely austenitic.

More advanced testing techniques, such as permeability measurements and magnetic saturation analysis, can be employed by professionals to accurately determine the magnetic characteristics of stainless steel.