1. Introduction

Imagine a world where skyscrapers couldn’t stand tall, electric vehicles couldn’t run, and wind turbines couldn’t generate power. This might be the reality without the robust power of heavy-duty industrial magnets. These unsung heroes of modern industry are vital to numerous applications, driving innovation and efficiency across various sectors. In this comprehensive review, we’ll dive deep into the realm of heavy-duty industrial magnets, examining their features, applications, and the top products on the market today.

2. What are Heavy-Duty Industrial Magnets?

Heavy-duty industrial magnets are a special class of magnets designed to perform under demanding conditions. These magnets are characterized by their high magnetic strength, durability, and the ability to maintain their magnetic properties under extreme conditions. They come in various types, including neodymium (NdFeB), samarium cobalt (SmCo), ferrite (ceramic), and alnico magnets, each with unique properties suited for specific industrial applications.

Neodymium magnets, known for their exceptional strength, are widely used in applications requiring powerful magnetic fields. Samarium cobalt magnets, though slightly less powerful, offer superior resistance to high temperatures and corrosion, making them ideal for harsh environments. Ferrite magnets are cost-effective and provide adequate magnetic strength for less demanding applications, while alnico magnets combine good magnetic strength with high temperature stability.

3. Key Features of Heavy-Duty Industrial Magnets

When evaluating heavy-duty industrial magnets, several key features stand out:

Strength and Durability: These magnets are engineered to deliver strong magnetic fields and withstand physical stress and environmental factors.

Temperature Resistance: Certain types, like samarium cobalt, can operate efficiently at high temperatures without losing their magnetic properties.

Corrosion Resistance: Coatings and materials that resist corrosion extend the life of the magnets in challenging environments.

Customizability: They can be manufactured in various shapes, sizes, and coatings to meet specific application needs, whether it’s a tiny component in an electronic device or a large assembly in an industrial machine.

4. Common Applications of Heavy-Duty Industrial Magnets

Heavy-duty industrial magnets play a critical role in a multitude of industries:

Automotive Industry: Used in electric motors, alternators, and various sensors.

Aerospace Industry: Essential for actuators, sensors, and electric propulsion systems.

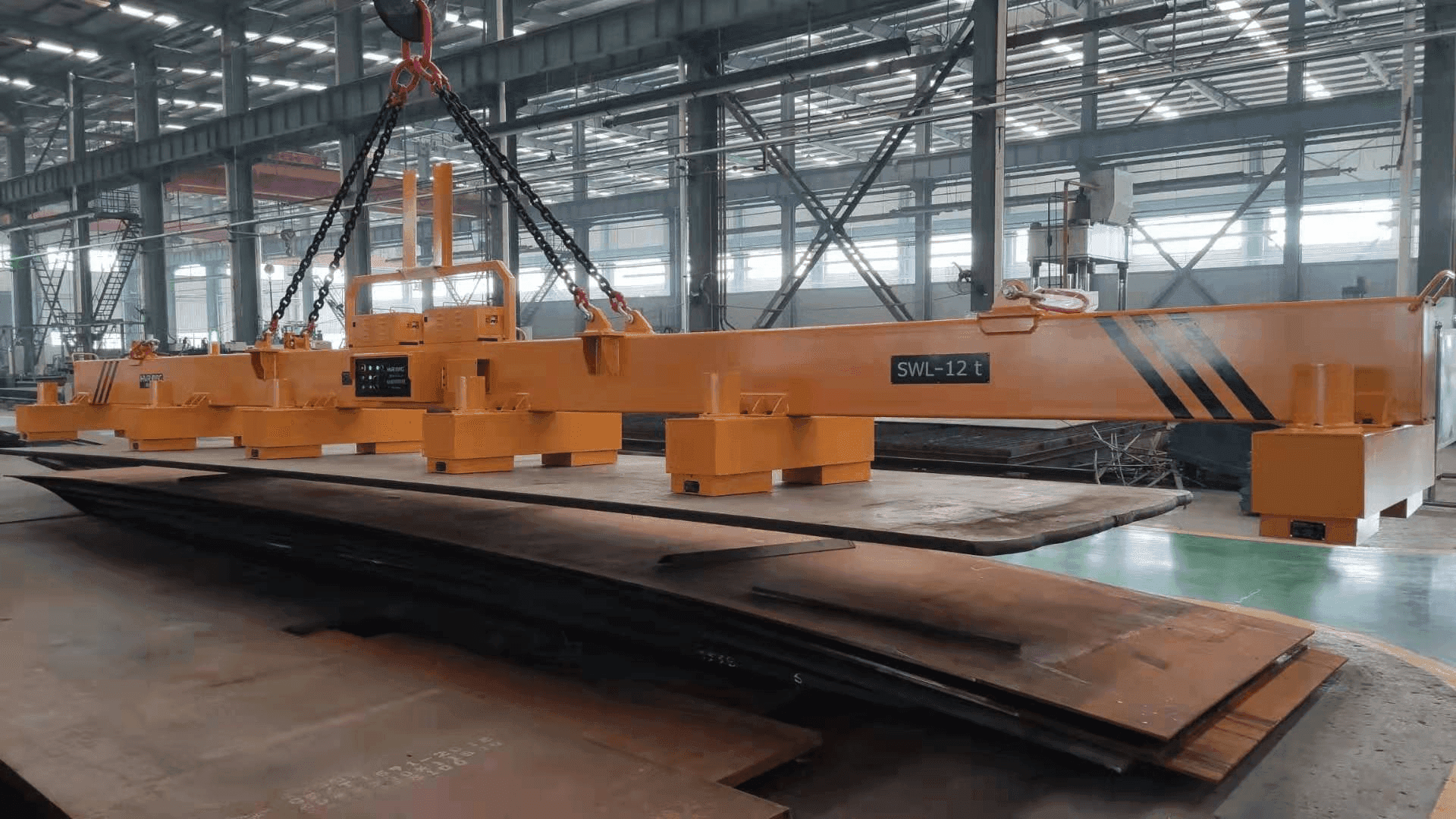

Manufacturing and Assembly Lines: Employed in conveyor belts, magnetic separators, and robotic arms.

Medical Devices and MRI Machines: Provide the magnetic fields necessary for imaging and diagnostic equipment.

Electronics and Telecommunications: Integral in speakers, microphones, and data storage devices.

Renewable Energy: Used in the generation of power from wind turbines and other green technologies.

5. How to Choose the Right Heavy-Duty Industrial Magnet

Selecting the appropriate magnet for your needs involves several considerations:

Application-Specific Requirements: Determine the magnetic strength, size, and shape needed for your specific use case.

Environmental Factors: Consider temperature, exposure to chemicals, and potential for corrosion.

Performance Evaluation: Assess the magnet’s strength, durability, and consistency in performance.

Cost Considerations: Balance the magnet’s features with your budget constraints, ensuring you get the best value for your investment.

6. Top Heavy-Duty Industrial Magnets Reviewed

In this section, we review some of the top heavy-duty industrial magnets available, based on performance, durability, cost-effectiveness, and customer feedback.

Product A: Neodymium Magnet

Description: A high-strength neodymium magnet, ideal for applications requiring maximum magnetic force.

Features: Exceptional magnetic strength, high durability, corrosion-resistant coating.

Pros: Extremely powerful, versatile, long-lasting.

Cons: Can be brittle, expensive compared to other types.

Customer Reviews: Highly rated for performance and reliability, but noted for higher cost.

Product B: Samarium Cobalt Magnet

– **Description**: A high-performance magnet suitable for high-temperature environments.

– **Features**: Excellent temperature resistance, corrosion-resistant, strong magnetic field.

– **Pros**: Stable at high temperatures, durable.

– **Cons**: More costly than ferrite magnets, less magnetic strength than neodymium.

– **Customer Reviews**: Praised for high-temperature applications, reliable but more expensive.

Product C: Ferrite Magnet

– **Description**: A cost-effective magnet suitable for general industrial applications.

– **Features**: Good magnetic strength, affordable, resistant to demagnetization.

– **Pros**: Cost-effective, widely available, decent performance.

– **Cons**: Lower magnetic strength, heavier than other types.

– **Customer Reviews**: Valued for cost-effectiveness and reliability in less demanding applications.

Comparison Table

| Product | Strength | Temperature Resistance | Durability | Cost | Customer Rating |

| Neodymium Magnet | Excellent | Good | High | High | 4.8/5 |

| Samarium Cobalt | Very Good | Excellent | High | High | 4.7/5 |

| Ferrite Magnet | Good | Fair | Fair | Low | 4.2/5 |

7. Innovations and Trends in Industrial Magnets

The field of industrial magnets is continually evolving. Recent advancements include:

– **Improved Materials**: Development of new magnetic alloys and composites that enhance performance and reduce costs.

– **Advanced Manufacturing Techniques**: Techniques such as additive manufacturing (3D printing) to produce complex magnet shapes with precise specifications.

– **Sustainability**: Efforts to develop magnets from more abundant and environmentally friendly materials.

– **Miniaturization**: Trends toward smaller, more powerful magnets to meet the needs of compact electronic devices and advanced technologies.

8. Case Studies and Success Stories

Case Study 1: Automotive Industry

A leading electric vehicle manufacturer incorporated neodymium magnets in their motors, resulting in a 20% increase in motor efficiency and a 15% reduction in production costs due to the magnets’ durability and performance.

Case Study 2: Renewable Energy

A wind turbine company adopted samarium cobalt magnets in their generators, which led to significant improvements in energy output and operational reliability, even under extreme weather conditions.

9. Tips for Maintaining and Extending the Life of Industrial Magnets

To ensure longevity and optimal performance of your industrial magnets:

– **Proper Handling and Storage**: Avoid dropping or striking magnets, and store them in a dry, room-temperature environment.

– **Regular Maintenance and Inspection**: Periodically check for signs of wear or damage and clean the magnets to remove any debris.

– **Best Practices for Usage**: Use magnets within their specified operational limits and avoid exposing them to conditions that could cause demagnetization or physical damage.

10. Conclusion

Heavy-duty industrial magnets are indispensable components in many modern technologies and industries. Choosing the right magnet involves understanding your specific needs and the various options available. By considering the factors discussed and reviewing top products, you can make an informed decision that enhances your application’s performance and efficiency. Whether you’re in automotive, aerospace, or renewable energy, the right heavy-duty industrial magnet can make all the difference. Take a step today to evaluate your magnet needs and consider the top-rated products reviewed here for reliable and powerful solutions.