In the realm of modern technology, two powerful forces often converge in surprising ways: micro‑magnets and laser light. Micro‑magnets—tiny permanent magnets on the scale of micrometers—pack a remarkable magnetic punch despite their minuscule size. When paired with the precision and energy of lasers, they unlock cutting‑edge capabilities across medicine, microfabrication, optical communications, and beyond. In this article, we’ll explore how lasers shape, pattern, and drive micro‑magnets, and how those micro‑magnets, in turn, enhance laser systems. Along the way, we’ll introduce key Magnetstek products to help you bring these innovations to life.

1. What Are Micro‑Magnets?

Micro‑magnets are permanent magnets whose dimensions range from a few micrometers up to a millimeter. Made from advanced magnetic materials—often neodymium‑iron‑boron (NdFeB) or samarium‑cobalt (SmCo)—they deliver high magnetic flux in a tiny footprint. Their applications span:

- MEMS and micro‑motors, where space is at a premium

- Lab‑on‑a‑chip devices for biomedical analysis

- Optical components, such as magnetic actuators in fiber optics

- Data storage and sensing at micro‑ and nano‑scales

The challenge lies in manufacturing and manipulating these tiny magnets with the precision needed for such delicate applications. Enter the laser.

2. Laser Machining of Micro‑Magnets

Traditional magnet shaping techniques—stamping, cutting, grinding—struggle at micrometer scales. Ultrashort‑pulse laser machining has emerged as a powerful solution:

- Precision Ablation: Femtosecond or picosecond laser pulses remove material with minimal heat‑affected zones, avoiding damage to the magnet’s microstructure.

- Complex Geometries: Lasers can carve intricate shapes—micro‑gears, spiral poles, even Halbach‑array segments—directly into SmCo or NdFeB magnets.

- High Throughput: By raster‑scanning a focused beam, manufacturers can process many micro‑magnets in parallel.

For example, Sm₂Co₁₇ micromagnets—valued for their high temperature stability—have been laser‑machined into complex MEMS components with sub‑10 μm feature resolution. These micro‑magnets power micro‑actuators and micro‑rotors in next‑generation devices.

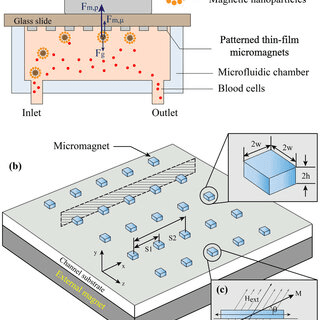

3. Laser Patterning for Magnetic Microchips

Beyond cutting, lasers can pattern magnetic materials on silicon or polymer substrates, creating magnetic microchips for biomedical and analytical applications:

- Magnetizable Films: A thin layer of magnetic composite (e.g., Fe₃O₄ nanoparticles in a polymer) is deposited on a wafer.

- Laser Writing: A focused laser beam selectively heats and cures the film, defining micromagnet arrays or magnetic traps.

- Functional Microchips: The patterned magnets guide or capture magnetic particles—such as magnetically tagged exosomes—for isolation and analysis.

This laser‑based microchip approach enables high‑density magnetic patterns with feature sizes down to a few microns, revolutionizing lab‑on‑a‑chip diagnostics and single‑cell manipulation.

4. Magnetically Actuated Fiber‑Coupled Lasers

In laser microsurgery and precision material processing, controlling the laser beam with micrometer accuracy is essential. One innovative solution attaches micro‑magnets to the tip of an optical fiber and uses external magnetic fields to steer the beam:

- Permanent Micro‑Magnets: Tiny NdFeB magnets (∼100 μm) are bonded to the fiber tip.

- Magnetic Actuators: Electromagnetic coils generate controlled fields that exert torque on the micro‑magnet, bending the fiber.

- Closed‑Loop Control: A photodetector monitors beam position and feeds back to the coil currents, achieving high‑speed, high‑precision laser scanning.

This magnetically actuated fiber‑coupled laser can perform intricate microsurgical cuts, 3D micro‑printing, or surface texturing—all without bulky mechanical stages.

5. Halbach Arrays and Free‑Electron Lasers

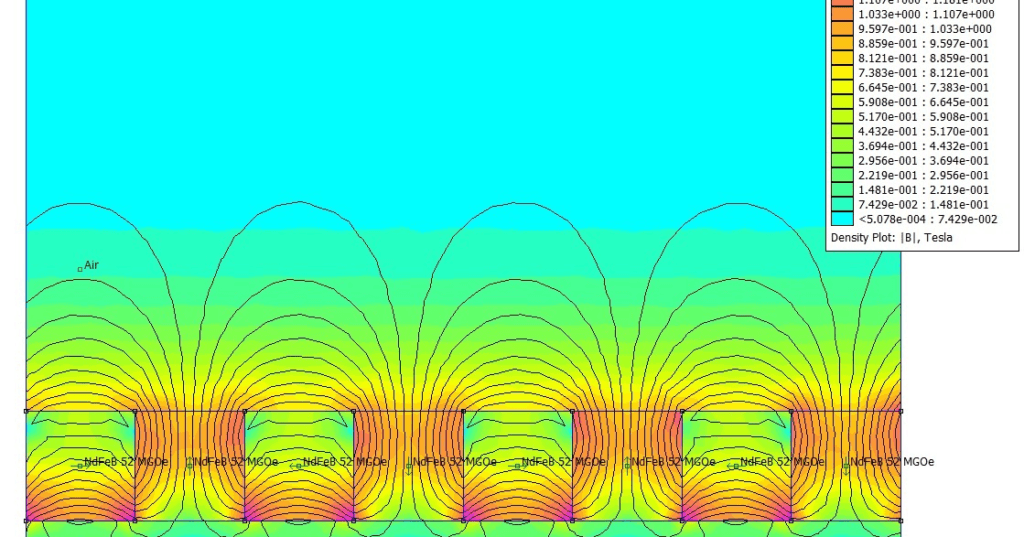

On a larger scale, Halbach arrays—linear arrangements of micro‑magnet segments with rotating magnetization—create one‑sided, high‑flux magnetic fields. In free‑electron lasers (FELs), these arrays serve as the “wiggler” magnets:

- Electron Beam Oscillation: As high‑speed electrons pass through the alternating field of the Halbach array, they oscillate and emit coherent, high‑intensity laser light.

- Tunable Wavelength: By adjusting the array period and field strength, FELs can produce wavelengths from infrared to X‑rays.

- Compact Design: Micro‑fabricated magnet segments reduce size and cost compared to conventional electromagnets.

While FELs are large‑scale research instruments, the underlying principle demonstrates the power of micro‑magnet arrays in laser generation.

6. Laser Cutting and Welding for Micro‑Rotor Assembly

Micro‑rotors—tiny spinning devices used in micro‑fluidics and miniature generators—often rely on micro‑magnets for magnetic bearings or drive:

- Laser Cutting: Thin NdFeB foils are laser‑cut into rotor magnets with precise pole counts and shapes.

- Laser Welding: Micro‑magnets can be laser‑welded onto stainless steel or ceramic shafts without adhesives, ensuring alignment and high rotational speeds.

This laser‑based assembly yields robust micro‑rotors for applications in cooling, sensing, and micro‑power generation.

7. Micro Magnets in Laser Printers and Optical Isolators

Everyday devices also benefit from laser‑machined micro‑magnets:

- Magnetic Rollers: In laser printers, micro‑magnets embedded in rollers help control toner distribution and improve print quality.

- Optical Isolator Magnets: In fiber‑optic communication, micro magnets bias Faraday rotators to ensure unidirectional light flow, protecting sensitive laser sources from back‑reflections.

These applications highlight how micro magnets, shaped and positioned by lasers, enhance the performance and reliability of common laser systems.

8. Emerging Frontiers: Smart Micro‑Magnetic Optics

Research is pushing the envelope further, integrating micro‑magnets into smart optical components:

- Magnetostrictive Lenses: Coating a micro‑lens with magnetostrictive material and applying a magnetic field changes its curvature, enabling focus tuning without moving parts.

- Reconfigurable Photonic Circuits: Arrays of micro‑magnets can shift the position of magnetic nanoparticles in a waveguide, modulating light paths on‑the‑fly.

- Micro‑LiDAR Scanners: Magnetically driven micro‑mirror arrays, fabricated via laser micromachining, steer laser beams for compact 3D scanning in autonomous vehicles.

These innovations promise smaller, faster, and more energy‑efficient laser‑based systems.

9. Integrating Magnetstek Products

To build and optimize laser‑micro‑magnet systems, Magnetstek offers a range of products:

- Neodymium Magnets

Ultra‑strong permanent magnets in grades up to N52, available in custom micro‑sized shapes for beam steering and actuation. - Ferrite Magnets

Cost‑effective, corrosion‑resistant magnets ideal for high‑volume applications like magnetic rollers and optical isolators. - Magnetic Assemblies

Pre‑assembled magnet‑pole configurations—Halbach arrays, ring magnets, or custom stacks—ready for integration into laser modules. - Magnetic Sensors

Hall‑effect and flux‑gate sensors to monitor field strength, enabling closed‑loop control in magnetically actuated laser systems. - Custom Magnetic Solutions

From micro‑magnet machining to complete magnetic sub‑assemblies, our engineers tailor designs to your laser application requirements.

10. Challenges and Considerations

While laser‑enabled micro‑magnets open exciting possibilities, they also present challenges:

- Thermal Management: Laser machining can introduce heat‑affected zones; optimizing pulse duration and energy is critical to preserve magnetic properties.

- Material Selection: NdFeB offers high remanence but lower temperature tolerance; SmCo excels at high temperatures but is more brittle.

- Alignment Precision: Micro‑magnet placement must be accurate to micrometer tolerances to ensure predictable magnetic fields and beam control.

- Surface Quality: Laser cutting can leave recast layers; post‑processing (polishing or chemical etching) may be needed for optical applications.

Addressing these factors early in design ensures reliable performance in demanding laser environments.

11. Future Directions

The synergy of lasers and micro‑magnets is still unfolding. Key trends include:

- Hybrid Laser‑Magnet Fabrication: Combining additive (laser deposition) and subtractive (laser ablation) processes to build 3D micro‑magnet structures in situ.

- Room‑Temperature Magnetoelectric Devices: Integrating magnetostrictive micro‑magnets with piezoelectric layers, controlled by laser‑induced heating, for novel light modulation.

- AI‑Driven Process Control: Using machine learning to optimize laser parameters in real time, achieving sub‑micron magnet features with minimal defects.

- Biocompatible Magnetic Lasers: Developing micro‑magnet‑driven fiber lasers for implantable medical devices, enabling localized therapy with magnetic steering.

As these technologies mature, we can expect ever more compact, precise, and versatile laser systems powered by micro‑magnets.

Conclusion

From ultrashort‑pulse laser machining of SmCo micro‑magnets to laser‑patterned magnetic microchips, from magnetically actuated fiber lasers in microsurgery to Halbach arrays in free‑electron lasers, the marriage of lasers and micro‑magnets is driving remarkable innovations. Micro‑magnets sculpted, patterned, and manipulated by laser light are enabling new frontiers in optics, medicine, manufacturing, and communications.

At Magnetstek, we provide the building blocks—Neodymium Magnets, Ferrite Magnets, Magnetic Assemblies, Magnetic Sensors, and Custom Magnetic Solutions—to turn your laser‑micro‑magnet concepts into reality. Whether you’re developing a next‑generation laser scanner, a lab‑on‑a‑chip diagnostic, or a high‑power FEL, our expertise and products will help you harness the invisible force of magnetism at the micro scale.

Explore our product pages today and discover how Magnetstek can power your laser‑driven micro‑magnet innovations.