Magnetic induction control has emerged as a transformative technology in robotics, providing a non-contact, highly efficient means to manipulate, actuate, and control robotic systems. This article delves into the principles behind magnetic induction control, examines its integration into modern robotic systems, explores its diverse applications, and highlights how custom magnet solutions—such as those available from Magnetstek—can elevate the performance and reliability of these advanced systems.

Introduction

Robotics has witnessed rapid advancements over the past decades, driven by breakthroughs in materials science, control theory, and sensor technologies. Among these innovations, magnetic induction control has garnered significant attention for its ability to provide precise, wireless control of robotic systems. Unlike traditional mechanical or hydraulic actuators, magnetic control harnesses the forces generated by electromagnetic fields to manipulate objects without physical contact. This unique characteristic makes it especially suitable for applications where minimal interference, reduced wear, and high precision are critical—ranging from medical robotics and micro-manipulation to industrial automation and consumer electronics.

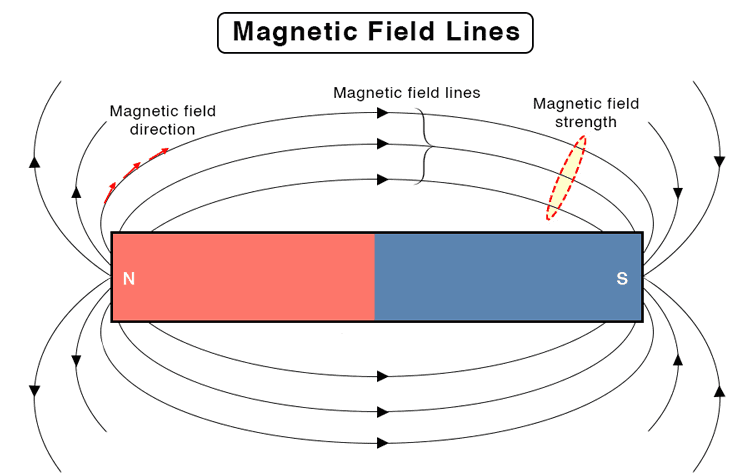

Magnetic induction operates on the fundamental principles of electromagnetic theory. When an electric current flows through a conductor, it generates a magnetic field. By varying this current or the configuration of the conductor, engineers can create complex magnetic field patterns capable of exerting forces and torques on nearby ferromagnetic or magnetically responsive materials. In robotics, this capability enables the precise actuation of components, efficient energy transfer, and real-time control over movement and orientation.

Fundamentals of Magnetic Induction Control

At its core, magnetic induction control relies on two key phenomena: electromagnetic induction and the Lorentz force. Electromagnetic induction, first discovered by Michael Faraday, is the process by which a changing magnetic field induces an electric current in a conductor. This principle is the foundation for many modern technologies, including transformers, electric motors, and wireless power transmission systems.

The Lorentz force, on the other hand, describes the force experienced by a charged particle moving in a magnetic field. In the context of robotics, the Lorentz force can be harnessed to generate motion. When a magnetic field interacts with the magnetic dipole moment of a permanent magnet or a magnetized material, a force is produced. This force can be finely tuned by adjusting the strength, orientation, and gradient of the magnetic field, enabling precise control over the movement of the robotic component.

An essential aspect of magnetic induction control is its non-contact nature. Since magnetic fields can penetrate non-magnetic materials, they allow for actuation without the need for physical interfaces. This attribute is particularly advantageous in environments where contamination, wear, or mechanical friction must be minimized.

Design and Integration of Magnetic Induction Control Systems

In modern robotic systems, magnetic induction control can be implemented in various configurations. Some systems use stationary electromagnets to generate controlled magnetic fields, while others integrate movable permanent magnets on robotic arms or mobile platforms. Hybrid systems combine the best features of both approaches, offering the flexibility of electromagnets with the high field strength and stability of permanent magnets.

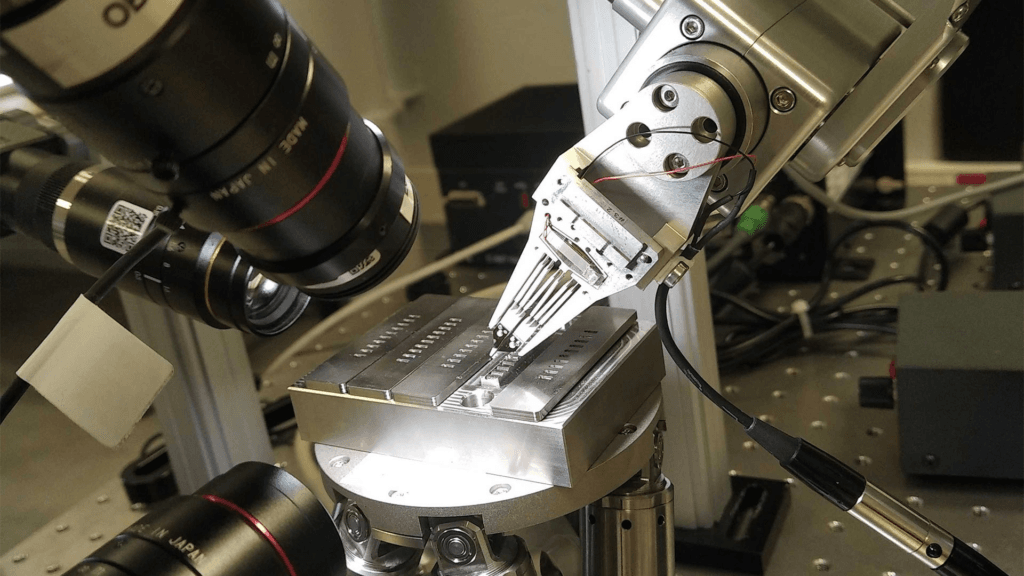

One popular configuration is to use electromagnetic coils arranged around a workspace. By modulating the current through these coils, engineers can generate dynamic magnetic fields with precise spatial and temporal characteristics. This setup is particularly useful in applications such as magnetic resonance imaging (MRI)–guided surgery, where the robotic tools must be controlled with sub-millimeter accuracy within a human body.

In addition, the integration of magnetic sensors and feedback control systems has enabled closed-loop control of robotic systems. Magnetic sensors, such as Hall-effect sensors, provide real-time information about the magnetic field distribution and the position of magnetically actuated components. This data is then processed by advanced control algorithms to adjust the magnetic field in real time, ensuring that the robotic system follows the desired trajectory with high precision.

For engineers looking to build or enhance a magnetic induction control system, the quality of the magnets used is of paramount importance. Custom magnet solutions can significantly improve system performance. For instance, high-performance neodymium magnets are renowned for their strong magnetic fields and durability. If your project demands reliable and efficient actuation, consider exploring Magnetstek’s offerings. Their Custom Neodymium Magnets are designed to deliver exceptional strength and versatility, making them ideal for a variety of robotic applications.

Magnetic Induction Control in Medical Robotics

One of the most exciting applications of magnetic induction control is in the field of medical robotics. In minimally invasive surgery, for example, magnetic fields are used to guide and control tiny robotic instruments inside the human body. These instruments can be steered through complex anatomical pathways with minimal trauma to surrounding tissues.

Magnetic actuation offers several distinct advantages in the medical field:

- Precision and Minimal Invasiveness: Magnetic fields can penetrate biological tissues without causing harm, enabling surgeons to control microrobots with sub-millimeter precision. This is particularly beneficial in procedures such as capsule endoscopy or targeted drug delivery, where traditional instruments may be too large or rigid.

- Wireless Control: The non-contact nature of magnetic induction eliminates the need for wires or cables, reducing the risk of infection and mechanical interference. Wireless control also allows for more flexible and adaptable surgical procedures.

- Real-Time Feedback: Integration with magnetic sensors allows for continuous monitoring of the robotic instrument’s position and orientation. This real-time feedback is crucial for adapting to dynamic surgical environments.

A prime example of magnetic induction control in medical robotics is the use of magnetic endoscopes. These devices are equipped with tiny magnets at their tips, which respond to externally applied magnetic fields. By precisely controlling the magnetic field, surgeons can navigate the endoscope through the gastrointestinal tract, reaching areas that would otherwise be difficult or impossible to access. Custom magnetic assemblies, such as those available from Magnetstek’s Magnetic Assemblies, can be used to enhance the performance of these devices, ensuring that the magnetic fields are strong, uniform, and precisely controlled.

Applications in Industrial Automation and Micro-Manipulation

Beyond the medical field, magnetic induction control has significant applications in industrial automation and micro-manipulation. In manufacturing processes, for instance, magnetic actuators can be used to move and position small components with high precision. This is particularly valuable in the assembly of electronics, where even a slight misalignment can lead to product failure.

Magnetic control systems are also being employed in the development of micro-robots that can operate in confined or hazardous environments. These micro-robots can perform tasks such as inspection, maintenance, and repair in environments where traditional robots might be too large or cumbersome. Their small size and wireless control make them ideal for applications in semiconductor manufacturing, chemical processing, and even space exploration.

In micro-manipulation, magnetic induction control offers the ability to handle delicate objects without direct physical contact. This is especially useful in the fields of biotechnology and materials science, where the precise handling of cells, molecules, or nanoparticles is critical. By using magnetic fields to gently move and position these tiny objects, researchers can perform experiments and processes with minimal disruption to the sample.

For such applications, the choice of magnetic components is again crucial. Magnetstek provides a range of custom solutions, including Mounting Magnets that are designed for secure attachment and stability in various industrial settings. These products ensure that your magnetic control system maintains optimal performance even in challenging environments.

Advantages of Magnetic Induction Control

The adoption of magnetic induction control in robotics comes with a host of advantages:

- Contactless Operation: Since magnetic fields can act at a distance, there is no physical contact between the actuator and the object. This minimizes wear and tear, reduces maintenance costs, and is ideal for sterile or hazardous environments.

- High Precision: Magnetic control systems can be finely tuned to provide sub-millimeter accuracy. This is essential in applications where even the slightest error can have significant consequences, such as in neurosurgery or semiconductor manufacturing.

- Versatility: Magnetic induction can be applied across a wide range of scales—from large industrial robots to microscale devices. This versatility makes it a valuable tool in many different sectors.

- Scalability: The principles of magnetic induction remain the same regardless of the size of the system. Whether you are building a robotic arm for industrial applications or a microrobot for targeted drug delivery, magnetic control can be scaled to meet your needs.

- Wireless Control: The absence of physical connections allows for greater freedom of movement and more flexible system design. Wireless magnetic control is particularly beneficial in environments where wiring is impractical or poses a risk, such as in medical or underwater applications.

Challenges and Future Directions

Despite its many advantages, magnetic induction control is not without challenges. One of the primary hurdles is the accurate modeling and control of magnetic fields in complex environments. The strength and direction of a magnetic field can be influenced by various factors, including nearby ferromagnetic materials, temperature fluctuations, and electrical interference. These factors can lead to discrepancies between the intended and actual magnetic field, affecting the precision of robotic control.

To overcome these challenges, ongoing research is focusing on advanced control algorithms, sensor fusion techniques, and adaptive systems that can dynamically compensate for environmental variations. Integration with real-time imaging and sensor feedback is also being explored to enhance the accuracy and reliability of magnetic control systems.

In the future, we can expect to see further advancements in magnetic materials and actuator design. Improvements in the quality and performance of custom magnets—such as those provided by Magnetstek’s extensive product range—will play a crucial role in pushing the boundaries of what is possible with magnetic induction control. Innovations in magnetic assemblies, for instance, will enable even more precise and powerful control systems, opening up new possibilities in robotics, medical devices, and industrial automation.

Furthermore, the convergence of magnetic control with other emerging technologies, such as artificial intelligence and machine learning, holds great promise. By leveraging data-driven approaches, future systems could autonomously adapt to changing conditions, optimize performance in real time, and even predict and compensate for potential errors before they occur.

How Magnetstek Enhances Magnetic Control Systems

For robotics engineers and researchers, the quality of the magnets used is a critical factor in the overall performance of a magnetic induction control system. Magnetstek offers a range of custom magnet solutions that are designed to meet the stringent requirements of modern robotics. Their products include:

- Custom Neodymium Magnets: Known for their exceptional magnetic strength and durability, these magnets are ideal for high-performance applications. For more details, visit Magnetstek Custom Neodymium Magnets.

- Magnetic Assemblies: Carefully engineered assemblies ensure that magnetic fields are uniform and precisely directed, which is crucial for achieving accurate control. Explore Magnetstek Magnetic Assemblies for more information.

- Mounting Magnets: Secure and reliable, these magnets are designed to maintain stability under various conditions, making them perfect for both industrial and medical applications. Check out Magnetstek Mounting Magnets.

By utilizing these high-quality magnet solutions, engineers can significantly improve the performance and reliability of their magnetic control systems. The customizability of Magnetstek’s products means that magnets can be tailored to the specific needs of any application, whether it’s a micro-robot navigating the human body or an industrial arm handling delicate components.

Conclusion

Magnetic induction control represents a powerful and versatile technology in the realm of robotics. Its ability to provide wireless, contactless, and precise control over robotic systems makes it an invaluable tool in various fields—from medical robotics and industrial automation to micro-manipulation and beyond. As advances in materials science and control theory continue to evolve, the potential applications of magnetic control are set to expand even further.

Custom magnet solutions, such as those offered by Magnetstek, are at the forefront of these innovations. With products ranging from high-performance neodymium magnets to carefully engineered magnetic assemblies and mounting magnets, Magnetstek provides the essential building blocks for next-generation magnetic control systems. By integrating these products into your designs, you can achieve higher precision, improved reliability, and greater overall performance in your robotic systems.

As research continues and new technologies emerge, the integration of magnetic induction control in robotics will undoubtedly lead to groundbreaking applications and solutions. Whether you are developing a minimally invasive surgical robot, an industrial micro-manipulator, or a cutting-edge automated assembly system, magnetic induction control offers the precision, flexibility, and efficiency needed to succeed in today’s competitive technological landscape.

In summary, magnetic induction control is not just a niche technology—it is a fundamental enabler of modern robotics, driving innovation and opening new frontiers in control and actuation. By leveraging advanced magnetic materials and integrating them with sophisticated control systems, engineers and researchers are shaping the future of robotics. For those seeking to push the limits of what is possible, exploring custom solutions from providers like Magnetstek is a critical step towards achieving excellence in robotic performance.