Introduction

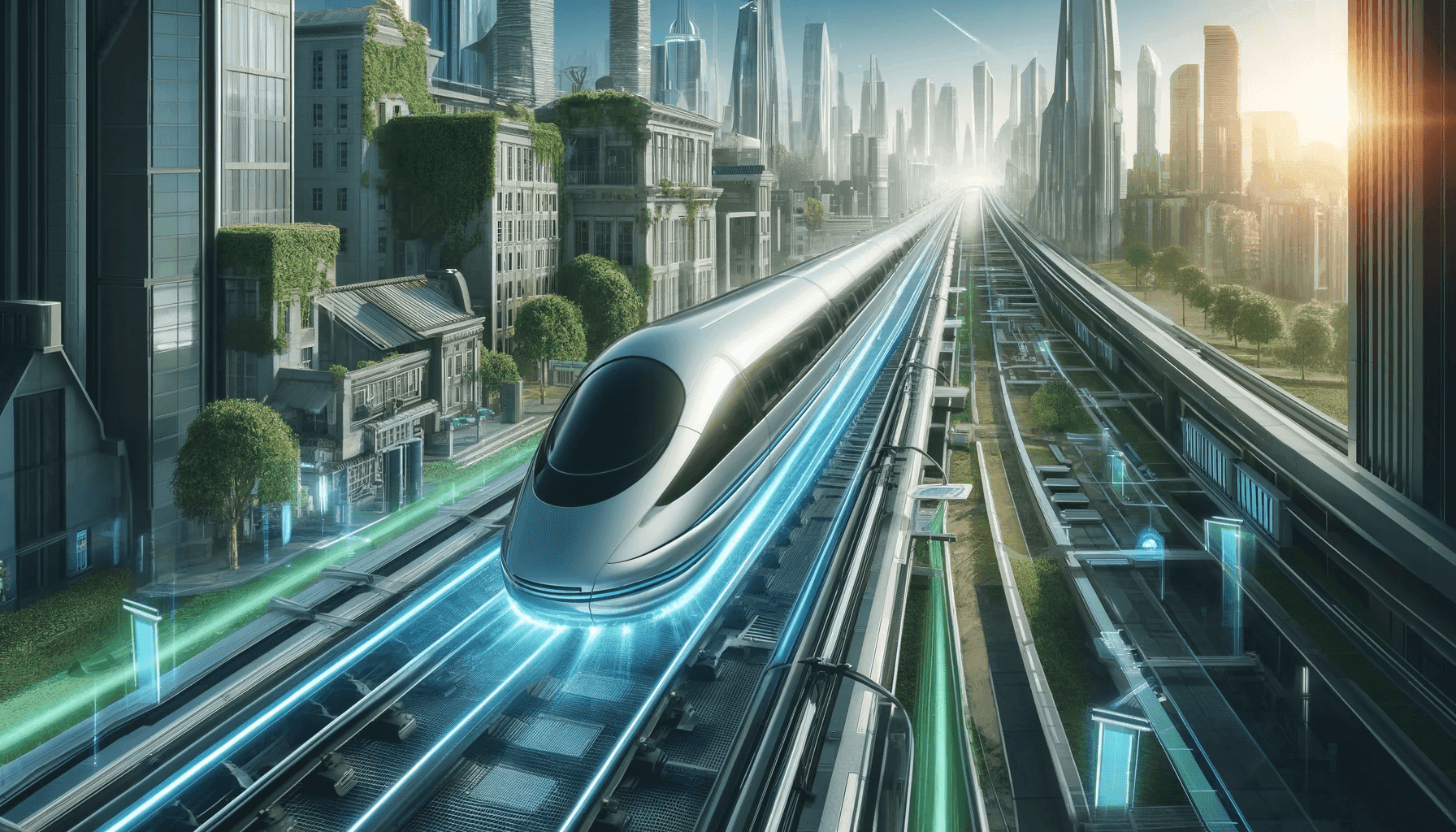

Imagine a world where transport systems glide silently over their tracks with no contact with the ground, where manufacturing processes are so streamlined that components float to their assembly points. This is not a scene from a futuristic movie but a reality made possible today through the wonders of magnetic levitation technology. Recent advancements have pushed maglev systems into the spotlight, not just as a novel gimmick but as a transformative force in various industries.

Defining Magnetic Levitation and Magnetic Floatation

Magnetic levitation, or maglev, is a method by which an object is suspended in the air without any support other than magnetic fields. The magnetic forces used to counteract the effects of gravitational and any other accelerations. Magnetic floatation, on the other hand, specifically refers to the use of magnetic forces to levitate objects above a liquid or solid surface without solid mechanical support. These technologies harness the principles of electromagnetism to achieve what was once deemed impossible—levitating mass in stable equilibrium. Maglev technology finds its utility in various sectors, fundamentally altering how processes are approached by eliminating the need for physical contact or traditional propulsion systems.

Historical Development and Key Innovations

The concept of magnetic levitation has been around since the mid-20th century, with significant theoretical contributions by renowned scientists like James Clerk Maxwell. The first practical applications began in earnest with transportation—where the technology promised faster, more efficient travel—and have since expanded. Innovations such as the Inductrack system, which uses passive magnetic levitation, or the Japanese SCMaglev, which boasts some of the fastest trains in the world, highlight the progressive steps taken to bring this technology into mainstream applications.

Current Technologies and How They Work

Maglev systems primarily utilize two types of technologies: Electromagnetic Suspension (EMS) and Electrodynamic Suspension (EDS). EMS involves electromagnets attracting the vehicle to a ferromagnetic track, stabilizing it as it moves. In contrast, EDS uses superconducting magnets to create a magnetic field that induces currents in the track, which in turn produce magnetic fields strong enough to levitate the train. Each technology offers unique advantages and challenges, particularly in terms of energy consumption, operational stability, and maintenance requirements.

Business Applications of Magnetic Levitation

Beyond the high-speed trains that have become the poster children of maglev technology, businesses in manufacturing, product display, and even furniture are finding innovative uses for magnetic levitation. In manufacturing, for instance, maglev conveyor systems can transport parts smoothly and without friction, reducing wear and tear and maintenance costs. Levitating displays in retail environments create eye-catching setups that enhance customer engagement and product appeal.

Benefits of Magnetic Levitation in Business

The adoption of maglev technology offers numerous benefits to businesses. The most significant is the drastic reduction in friction, leading to lower energy requirements and less mechanical failure. This technology also allows for faster operations and increased safety, as the lack of contact eliminates many traditional causes of malfunctions and accidents. Furthermore, maglev systems are remarkably energy efficient and can contribute to a business’s sustainability goals by reducing carbon emissions.

Challenges and Limitations

Despite its advantages, maglev technology faces considerable challenges. The initial investment for maglev infrastructure can be prohibitively high, discouraging some industries from adopting it. Technical challenges, such as the need for precise control systems and the complexities associated with magnetic field management, also pose significant hurdles. Additionally, regulatory and safety standards have yet to fully catch up with the new technology, creating a potential barrier for widespread deployment.

Case Studies: Successful Maglev Implementations

The Shanghai Maglev Train, operational since 2004, serves as a prominent example of successful commercial maglev application, connecting Shanghai Pudong Airport with the city center at speeds reaching 430 km/h. On a smaller scale, companies like Crealev have developed levitation technology for commercial product displays, showing that maglev can be scaled down effectively for retail and promotional purposes.

The Future of Magnetic Levitation

The future of magnetic levitation looks promising, with ongoing research aimed at reducing costs and improving efficiency. Innovations in materials science, such as the development of cheaper, more powerful superconductors, could further enhance the feasibility of maglev systems. Looking forward, maglev technology could play a crucial role in sustainable urban development, revolutionizing everything from public transport to logistics.

Conclusion

Magnetic levitation technology, once an esoteric scientific endeavor, has evolved into a substantial commercial force with the potential to redefine traditional business operations. Its ability to minimize friction, increase efficiency, and reduce environmental impact makes it a compelling choice for forward-thinking businesses. As the technology matures and becomes more accessible, it could very well become a cornerstone of modern industry, transforming our approach to transport, manufacturing, and beyond.