Introduction

Imagine a world where your electric car could travel further, your electronics were more efficient, and industrial processes became even more reliable and robust. This isn’t a future dream but a present reality made possible through the power of magnets. Specifically, Samarium Cobalt (SmCo) magnets are a key player in these advancements. Known for their exceptional magnetic strength, temperature stability, and resistance to demagnetization, SmCo magnets are crucial in numerous high-tech and industrial applications. Understanding the various shapes of these magnets and their specific uses can unlock a new level of innovation and efficiency in technology and manufacturing.

Overview of Samarium Cobalt Magnets

Samarium Cobalt magnets, a type of rare earth magnet, are composed of an alloy of samarium and cobalt. They are renowned for their high magnetic strength and exceptional resistance to temperature extremes, making them ideal for applications that require a reliable magnetic force under harsh conditions. Compared to other magnets, such as Neodymium (NdFeB), Alnico, and Ferrite, SmCo magnets stand out due to their stability at high temperatures and their ability to maintain magnetic properties over time.

Key properties of SmCo magnets include:

– High Magnetic Strength: SmCo magnets exhibit high coercivity and magnetic energy, providing strong and reliable magnetic fields.

– Temperature Stability: They can operate efficiently in temperatures up to 350°C (662°F) without losing their magnetic properties.

– Resistance to Demagnetization: SmCo magnets have high resistance to external demagnetizing influences.

– Corrosion Resistance: They are naturally resistant to oxidation and corrosion, unlike NdFeB magnets which require protective coatings.

Common Shapes of SmCo Magnets and Their Characteristics

SmCo magnets are manufactured in various shapes to suit different applications. Each shape has unique characteristics that make it ideal for specific uses:

– Round Discs: These are flat, circular magnets commonly used in sensors and electronic devices.

– Blocks/Cubes: Rectangular or square-shaped magnets that provide strong magnetic fields for industrial and mechanical applications.

– Rings: Circular magnets with a central hole, used in motors and rotating machinery.

– Tubes/Cylinders: Cylindrical magnets often utilized in medical devices and precision instruments.

– Balls: Spherical magnets used in research and development applications.

– Arc Segments: Curved magnets designed for use in electric motors and generators.

– Irregular Shapes: Custom shapes tailored to specific industrial needs and applications.

– Countersunk Magnets: Magnets with a hole designed for mounting and fixing solutions.

Applications of Round Disc SmCo Magnets

Round disc SmCo magnets are widely used in electronics, motors, and magnetic couplings due to their flat shape and high magnetic strength.

Electronics: In the electronics industry, these magnets are used in speakers, sensors, and MRI machines. Their ability to maintain stable magnetic properties under varying temperatures makes them ideal for sensitive and high-precision devices. For example, in MRI machines, SmCo magnets provide the stable magnetic fields necessary for accurate imaging.

Motors and Generators: These magnets are crucial components in motors and generators where high efficiency and reliability are required. Their strength and stability ensure consistent performance in demanding environments.

Magnetic Couplings: In magnetic couplings, round disc SmCo magnets are used to transfer torque without physical contact, reducing wear and increasing the lifespan of mechanical systems.

Case Study – High-Precision Sensors: A leading manufacturer of high-precision sensors integrates round disc SmCo magnets into their products to ensure accurate and stable readings in environments with fluctuating temperatures. This application highlights the magnets’ superior performance in maintaining sensitivity and reliability.

Applications of Block/Cube SmCo Magnets

Block and cube SmCo magnets are favored in industrial applications for their strong magnetic fields and structural stability.

Industrial Applications: These magnets are extensively used in magnetic separators, holding applications, and magnetic assemblies. In recycling industries, block magnets play a crucial role in separating ferrous materials from non-ferrous ones, improving the efficiency of recycling processes.

Wind Turbines: In the renewable energy sector, block SmCo magnets are used in wind turbines to convert kinetic energy into electrical energy efficiently. Their robustness and high magnetic strength make them suitable for such large-scale applications.

Aerospace: The aerospace industry relies on these magnets for various applications, including navigation systems and control mechanisms. Their ability to withstand extreme temperatures and high-altitude conditions ensures reliable performance.

Case Study – Magnetic Separators for Recycling Industries: A major recycling company uses block SmCo magnets in their magnetic separators to improve the efficiency of sorting and recycling processes. These magnets provide strong and stable magnetic fields that effectively separate ferrous materials, enhancing the overall productivity and sustainability of the recycling operations.

Applications of Ring SmCo Magnets

Ring-shaped SmCo magnets are particularly useful in rotors, stators, and medical devices due to their unique shape and magnetic properties.

Rotors and Stators in Motors: In motor applications, ring SmCo magnets are used in rotors and stators to create efficient and powerful motors. Their circular shape and high magnetic strength ensure smooth and consistent rotational motion.

Magnetic Bearings: These magnets are also used in magnetic bearings, providing a contact-free solution that reduces friction and wear. This application is critical in high-speed machinery and precision instruments.

Medical Devices: In the medical field, ring SmCo magnets are used in devices such as MRI machines and surgical instruments. Their stability and strength ensure accurate and reliable performance in critical medical applications.

Case Study – High-Speed Motor Applications: A leading manufacturer of high-speed motors incorporates ring SmCo magnets into their designs to achieve higher efficiency and performance. These magnets provide the necessary magnetic fields to support rapid and precise motor operation, showcasing their importance in advanced motor technology.

Applications of Tube/Cylinder SmCo Magnets

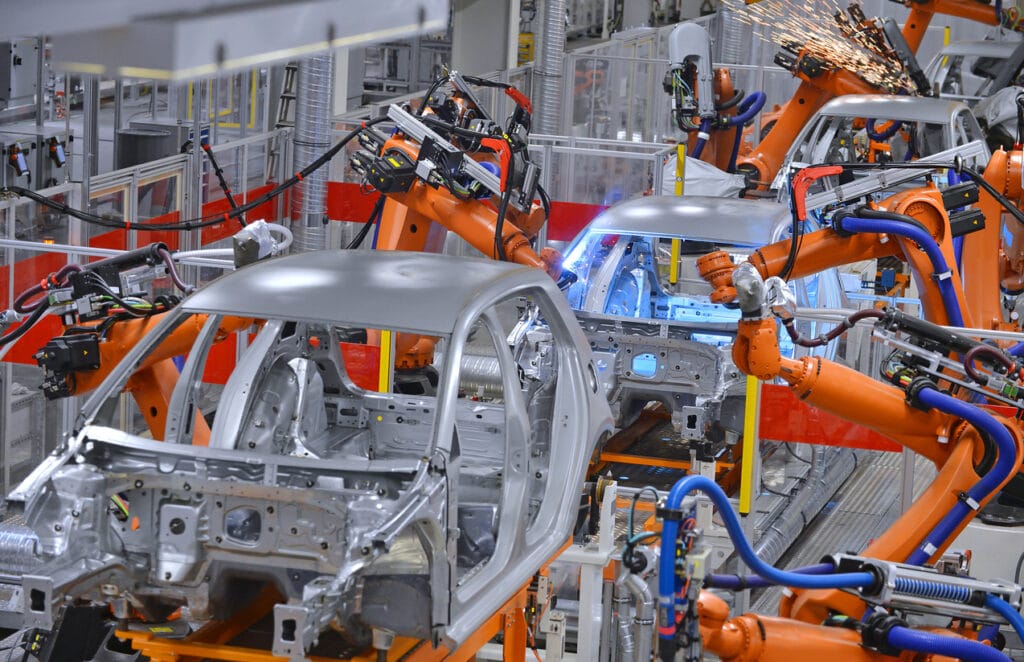

Tube and cylinder SmCo magnets are versatile and used in various industries, including automotive and robotics.

Automotive Industry: In the automotive sector, these magnets are used in fuel injection systems and electric vehicle (EV) motors. Their cylindrical shape and magnetic properties enhance the efficiency and performance of these systems.

Robotics: In robotics, tube SmCo magnets are used for precision control and movement. Their high magnetic strength and stability enable precise and reliable operation of robotic arms and sensors.

Case Study – Robotics for Precision Control: A robotics company utilizes tube SmCo magnets in their robotic arms to achieve precise and controlled movements. These magnets provide the stability and strength needed for high-precision tasks, highlighting their critical role in advanced robotics.

Applications of Ball SmCo Magnets

Ball-shaped SmCo magnets are primarily used in research and development, as well as in magnetic levitation applications.

Research and Development: In R&D, these magnets are used in experimental setups to study magnetic properties and interactions. Their spherical shape allows for unique and varied magnetic field applications.

Magnetic Levitation: In magnetic levitation applications, ball SmCo magnets are used to create stable and efficient levitation systems. This technology is utilized in maglev trains and other advanced transportation systems.

Case Study – Experimental Setups in Universities: A university research lab uses ball SmCo magnets in their experimental setups to study advanced magnetic properties and applications. These magnets provide the necessary flexibility and strength for various experimental designs, showcasing their importance in scientific research.

Applications of Arc Segment SmCo Magnets

Arc segment SmCo magnets are essential in electric motors, particularly in electric vehicles (EVs), and wind turbines.

Electric Motors: In electric motors, arc segment SmCo magnets provide the necessary magnetic fields for efficient operation. Their curved shape fits perfectly into motor designs, enhancing performance and reliability.

Wind Turbines: In wind turbines, these magnets are used to convert kinetic energy into electrical energy efficiently. Their high magnetic strength and stability make them ideal for this large-scale application.

Case Study – Electric Vehicle Motor Production: An electric vehicle manufacturer uses arc segment SmCo magnets in their motor production to achieve higher efficiency and performance. These magnets provide the necessary magnetic fields for powerful and reliable EV motors, showcasing their importance in the automotive industry.

Applications of Irregular Shaped SmCo Magnets

Irregular shaped SmCo magnets are custom-designed for specific industrial needs and applications, providing tailored solutions for unique challenges.

Custom Industrial Solutions: These magnets are used in custom industrial solutions where standard shapes are not suitable. They are designed to meet specific requirements and provide optimal performance.

Prototype Development: In prototype development, irregular shaped SmCo magnets are used to test new designs and applications. Their custom shapes allow for innovative and flexible solutions.

Case Study – Custom Solutions for Unique Industrial Applications: A manufacturing company uses irregular shaped SmCo magnets in their custom solutions to meet unique industrial challenges. These magnets provide the flexibility and strength needed for specific applications, highlighting their importance in industrial innovation.

Applications of Countersunk SmCo Magnets

Countersunk SmCo magnets are designed for mounting and fixing solutions, providing structural stability and secure attachment.

Mounting and Fixing Solutions: These magnets are used in various mounting and fixing applications, providing a secure and stable attachment. Their countersunk holes allow for easy installation and reliable performance.

Structural Applications: In structural applications, countersunk SmCo magnets provide the necessary magnetic force for secure and stable construction. They are used in various engineering and construction projects.

Case Study – Construction and Engineering Projects: An engineering firm uses countersunk SmCo magnets in their construction projects to achieve secure and stable structures. These magnets provide the necessary magnetic force for reliable and efficient construction, showcasing their importance in the engineering industry.

Advantages of Using Custom Shaped SmCo Magnets

Custom shaped SmCo magnets offer several advantages, including enhanced performance for specific applications, cost-effectiveness in the long term, and tailored solutions for

unique challenges.

Enhanced Performance: Custom shapes provide optimal performance for specific applications, ensuring efficiency and reliability.

Cost-Effectiveness: While custom magnets may have a higher initial cost, their long-term benefits and efficiency can result in overall cost savings.

Tailored Solutions: Custom magnets are designed to meet unique requirements, providing tailored solutions for specific industrial needs.

Conclusion

Selecting the right shape of SmCo magnet for specific applications is crucial for achieving optimal performance and efficiency. The versatility and unique properties of SmCo magnets make them essential in advancing technology and industry. By understanding the different shapes and their applications, businesses can unlock new levels of innovation and productivity, ensuring a brighter and more efficient future.

One Reply to “Magnetic Mastery: How Different Shapes of SmCo Magnets Enhance Technology”

I like this.