Introduction to Bonded Magnets

Bonded magnets are a class of magnets made from magnetic powders that are combined with a polymer binder to create a composite material. This innovative approach to magnet manufacturing offers unique properties that set bonded magnets apart from their sintered counterparts. With a growing demand in various industries due to their versatility, these magnets are becoming increasingly significant in applications ranging from consumer electronics to automotive and industrial machinery.

Understanding the manufacturing process of bonded magnets is crucial for engineers, designers, and manufacturers who seek to optimize the performance and functionality of their products. This article delves deep into the intricacies of the bonded magnet manufacturing process, providing insights into the materials, techniques, and technologies involved.

1. Understanding Bonded Magnets

Before exploring the manufacturing process, it’s important to understand what bonded magnets are and how they differ from traditional sintered magnets.

1.1 Definition

Bonded magnets are composed of magnetic powder, usually made from rare earth elements like neodymium, combined with a polymer matrix. This combination allows for flexible designs and the possibility of manufacturing magnets with complex shapes that would be difficult or impossible to achieve with sintered magnets.

1.2 Types of Bonded Magnets

There are two primary types of bonded magnets:

- Polymer-Bonded Magnets: These magnets use thermoplastic or thermosetting polymers as the binder. They can be produced in various shapes and sizes, making them suitable for numerous applications.

- Metal-Bonded Magnets: This type combines magnetic powders with metal binders, providing enhanced magnetic performance and thermal stability.

2. The Manufacturing Process

The manufacturing of bonded magnets involves several key stages, each critical to ensuring the final product meets the desired specifications. The process can generally be divided into the following steps:

2.1 Material Selection

The first step in the manufacturing process is selecting the appropriate materials. The magnetic powder is typically made from rare earth materials like neodymium-iron-boron (NdFeB) or samarium-cobalt (SmCo). The choice of binder material is also crucial, as it affects the magnet’s performance characteristics, including its thermal stability, mechanical strength, and magnetic properties.

2.2 Powder Preparation

Once the materials are selected, the magnetic powder must be prepared. This involves several sub-steps:

- Milling: The raw magnetic materials are milled into fine powders. This process enhances the magnetic properties by increasing the surface area of the powder particles.

- Sieving: The powdered materials are then sieved to ensure uniform particle size distribution. This is vital for achieving consistent magnetic performance in the final product.

- Magnetization: Depending on the application, the powder may be magnetized before being bonded, although this is often done after the shaping process.

2.3 Mixing

The prepared magnetic powder is then mixed with the chosen binder material. This mixing process is crucial, as it determines the uniformity and consistency of the final product.

- Equipment: The mixing can be done using different types of equipment, such as high-shear mixers or twin-screw extruders, depending on the material properties and the desired outcome.

- Parameters: The mixing time, temperature, and ratio of powder to binder are all carefully controlled to achieve the desired magnetic properties.

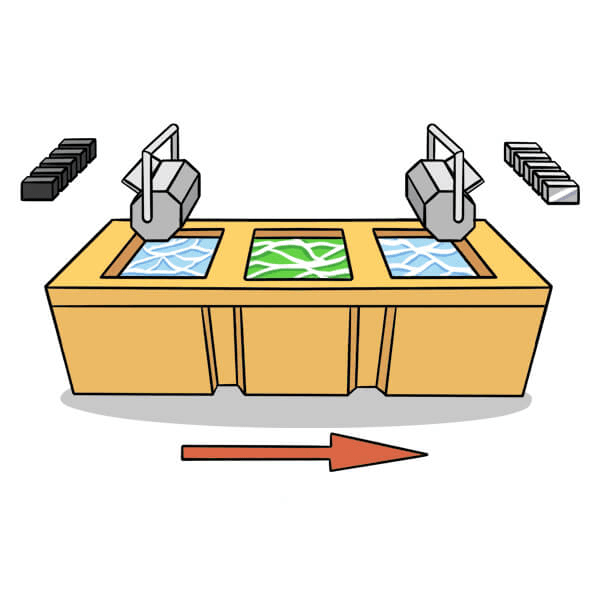

2.4 Shaping

Shaping is one of the most critical steps in the bonded magnet manufacturing process, as it defines the magnet’s final form and size. There are several methods of shaping bonded magnets:

- Injection Molding: This is the most common method for producing bonded magnets. The mixed material is heated and injected into a mold, where it cools and solidifies into the desired shape. Injection molding allows for complex geometries and high-volume production.

- Compression Molding: In this process, the mixture is placed into a mold and compressed under high pressure. This method is often used for producing larger or simpler shapes.

- 3D Printing: Emerging technologies like additive manufacturing are being explored for producing bonded magnets. This technique allows for intricate designs and custom shapes that traditional methods cannot achieve.

2.5 Curing

Once the magnets are shaped, they undergo a curing process. Curing involves applying heat to solidify the binder and enhance the magnet’s mechanical and magnetic properties.

- Heat Treatment: The shaped magnets are placed in an oven or furnace where they are heated to a specific temperature for a set duration. This process can significantly improve the magnet’s strength and stability.

- Cooling: After curing, the magnets are allowed to cool gradually to prevent cracking or warping.

2.6 Surface Treatment

The final step in the manufacturing process is surface treatment, which enhances the durability and corrosion resistance of the magnets. Common surface treatments include:

- Coating: Magnets can be coated with various materials, such as nickel, zinc, or epoxy, to protect against oxidation and wear.

- Polishing: For applications where aesthetics are important, polishing can be applied to achieve a smooth, shiny finish.

2.7 Quality Control

Quality control is critical at every stage of the manufacturing process. Various tests and inspections ensure that the magnets meet the required specifications, including:

- Magnetic Testing: Measuring the magnetic strength and characteristics using gaussmeters or fluxmeters.

- Dimensional Inspection: Ensuring that the magnets conform to the specified dimensions and tolerances.

- Mechanical Testing: Evaluating the strength and durability of the magnets through various stress tests.

3. Advantages of Bonded Magnets

Bonded magnets offer several advantages over traditional sintered magnets, making them an attractive choice for many applications:

3.1 Design Flexibility

One of the most significant advantages of bonded magnets is their design flexibility. The ability to create complex shapes and sizes allows manufacturers to optimize their designs for specific applications, resulting in improved performance and efficiency.

3.2 Lightweight

Bonded magnets are generally lighter than sintered magnets, making them ideal for applications where weight is a critical factor, such as in aerospace and automotive industries.

3.3 Cost-Effectiveness

The manufacturing process of bonded magnets can be more cost-effective for large production runs, as the techniques used allow for high-speed production and less waste.

3.4 Enhanced Magnetic Properties

The combination of high-quality magnetic powders with polymer binders can result in superior magnetic properties, including high coercivity and energy product, which is crucial for high-performance applications.

3.5 Resistance to Corrosion

With proper surface treatment, bonded magnets can exhibit excellent resistance to corrosion and environmental factors, making them suitable for harsh environments.

4. Applications of Bonded Magnets

The unique properties of bonded magnets make them suitable for a wide range of applications across various industries:

4.1 Consumer Electronics

Bonded magnets are extensively used in consumer electronics, including speakers, headphones, and magnetic sensors. Their lightweight and compact design allows for integration into small devices without compromising performance.

4.2 Automotive

In the automotive industry, bonded magnets are used in electric motors, sensors, and actuators. Their high energy density and reliability contribute to the efficiency and performance of electric vehicles.

4.3 Medical Devices

Bonded magnets play a crucial role in medical devices such as MRI machines, hearing aids, and various imaging equipment. Their biocompatibility and stability are essential in these applications.

4.4 Renewable Energy

With the rise of renewable energy technologies, bonded magnets are increasingly used in wind turbines and solar panel systems. Their efficiency and durability are vital for optimizing energy conversion.

4.5 Industrial Equipment

In industrial settings, bonded magnets are utilized in automation systems, conveyor belts, and various manufacturing processes. Their versatility and strength enhance productivity and reliability.

5. Future Trends in Bonded Magnet Manufacturing

As technology advances, the manufacturing process of bonded magnets continues to evolve. Here are some trends to watch for in the future:

5.1 Advanced Materials

Researchers are exploring new materials and composites that could further enhance the performance of bonded magnets. Innovations in polymer science and magnetic materials are likely to yield even more efficient and effective magnets.

5.2 Additive Manufacturing

The adoption of additive manufacturing (3D printing) in bonded magnet production is set to grow. This technology allows for rapid prototyping and the production of complex geometries, enabling manufacturers to meet specific customer needs more effectively.

5.3 Sustainability

As sustainability becomes a central focus for industries worldwide, the development of eco-friendly materials and processes for producing bonded magnets will be essential. This includes exploring recycling methods for used magnets and reducing waste during manufacturing.

5.4 Automation and Industry 4.0

The integration of automation and Industry 4.0 principles in the manufacturing process of bonded magnets will enhance efficiency and precision. Smart factories equipped with advanced monitoring systems can ensure optimal production conditions and real-time quality control.

Conclusion

The manufacturing process of bonded magnets is a fascinating interplay of materials science, engineering, and innovative manufacturing techniques. As demand continues to grow across various sectors, understanding this process is crucial for anyone involved in the design and production of magnetic components.

Bonded magnets offer significant advantages in terms of design flexibility, weight, and performance, making them an invaluable resource in modern applications. With ongoing advancements in technology and materials, the future of bonded magnets looks bright, promising even more exciting developments in the years to come.