I. Introduction

Have you ever wondered if magnets can rust? It’s a common question, often rooted in the broader understanding that many metals are prone to rusting. From household items to industrial machinery, the effects of rust can be detrimental, causing deterioration and malfunction. But how do magnets fare when it comes to rusting? This is particularly crucial given the diverse applications of magnets, from high-tech medical devices to everyday household objects. Understanding whether magnets rust and how to protect them is essential for maintaining their performance and longevity.

II. Understanding Rust and Corrosion

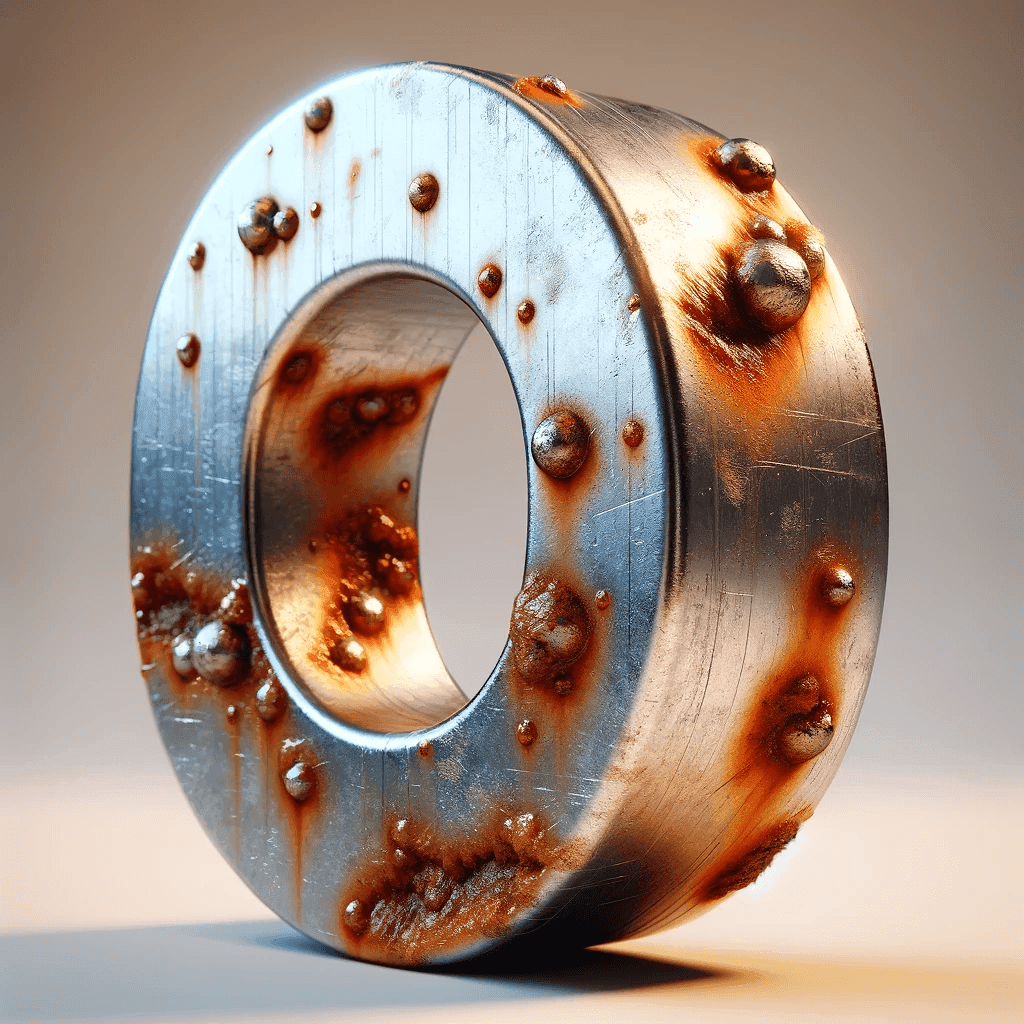

Before delving into whether magnets rust, it’s important to understand what rust and corrosion are. Rust specifically refers to the oxidation of iron, resulting in iron oxide. Corrosion, on the other hand, is a broader term encompassing the degradation of metals due to chemical reactions with their environment. This can include rust but also covers other forms of oxidation and chemical interactions. The primary conditions that lead to rusting include exposure to moisture and oxygen. Without these elements, rusting cannot occur. This is why metals left outdoors or in humid environments tend to rust more quickly.

Rust not only affects the appearance of metal objects but also compromises their structural integrity and functionality. For magnets, rust can interfere with their magnetic properties, making them less effective or even unusable in some cases. This makes understanding and preventing rust critical for anyone using magnets in their applications.

III. Types of Magnets

Magnets come in various types, each with its unique composition and properties. The main types of magnets include Neodymium (NdFeB) magnets, Samarium Cobalt (SmCo) magnets, Alnico magnets, Ferrite (Ceramic) magnets, and Bonded magnets. Each type is made from different materials, which influence their susceptibility to rust and corrosion.

– Neodymium (NdFeB) Magnets: Composed of neodymium, iron, and boron, these are the strongest commercially available magnets.

– Samarium Cobalt (SmCo) Magnets: Made from samarium and cobalt, they are known for their high temperature and corrosion resistance.

– Alnico Magnets: Consist of aluminum, nickel, and cobalt. They are known for their temperature stability.

– Ferrite (Ceramic) Magnets: Made from iron oxide and ceramic materials, they are cost-effective and highly resistant to rust.

– Bonded Magnets: Composed of magnetic powders mixed with a binding agent, they offer flexibility in shapes and sizes but vary in rust resistance depending on the materials used.

IV. Rusting Potential of Various Magnets

Let’s explore the rusting potential of each type of magnet in more detail.

Neodymium (NdFeB) Magnets

Neodymium magnets are extremely powerful but also highly susceptible to rust because of their iron content. When exposed to moisture and oxygen, these magnets can quickly corrode, which can degrade their magnetic properties and structural integrity. To prevent rust, neodymium magnets are often coated with protective layers such as nickel, zinc, or epoxy. These coatings provide a barrier that protects the magnets from the elements, significantly extending their lifespan and reliability.

Samarium Cobalt (SmCo) Magnets

Samarium cobalt magnets are less prone to rust compared to neodymium magnets. Their composition of samarium and cobalt makes them naturally resistant to oxidation and corrosion. This makes SmCo magnets ideal for applications in harsh environments, including high temperatures and corrosive conditions. However, they are more expensive than other types of magnets, which can be a consideration for some users.

Alnico Magnets

Alnico magnets, made from aluminum, nickel, and cobalt, exhibit excellent temperature stability and are resistant to oxidation. However, in the presence of aggressive chemicals or prolonged exposure to moisture, they can corrode. Alnico magnets are often used in applications where temperature fluctuations are significant, such as in sensors and automotive components. Protective coatings can be applied to further enhance their rust resistance.

Ferrite (Ceramic) Magnets

Ferrite magnets are composed of iron oxide and ceramic materials, making them highly resistant to rust. Their natural resistance to corrosion, coupled with their affordability, makes them a popular choice for many applications, including motors, loudspeakers, and magnetic separators. Ferrite magnets can withstand outdoor environments and do not require additional coatings for rust protection.

Bonded Magnets

Bonded magnets are created by mixing magnetic powders with a binding agent. The rust resistance of bonded magnets depends on the materials used in the magnetic powders and the binder. If the powders include iron, the magnets may be prone to rust unless properly coated or sealed. Bonded magnets offer flexibility in design and are used in various applications where custom shapes and sizes are required.

V. Prevention and Protection

Protecting magnets from rust involves several strategies, including coating and plating methods, environmental controls, and maintenance practices.

Coating and Plating Methods

Applying protective coatings is one of the most effective ways to prevent rust on magnets. Common coatings include nickel, zinc, and epoxy. Nickel plating provides a durable, corrosion-resistant layer that is often used for neodymium magnets. Zinc coatings offer good corrosion resistance and are cost-effective. Epoxy coatings provide excellent protection against moisture and chemicals, making them ideal for harsh environments.

Environmental Controls

Controlling the environment in which magnets are stored and used can significantly reduce the risk of rust. This includes keeping magnets in dry, low-humidity conditions and avoiding exposure to corrosive chemicals. In industrial settings, using climate-controlled storage areas can help maintain the integrity of magnets.

Maintenance Practices

Regular inspection and maintenance are crucial for preventing rust. This includes periodically checking for signs of corrosion and cleaning magnets to remove any contaminants that could lead to rust. Using appropriate cleaning methods and materials ensures that the magnets’ surfaces remain intact and protected.

VI. Real-world Applications and Case Studies

The potential for rust and the need for protection varies significantly across different industries and applications.

Industry-specific Concerns

In the medical field, for example, magnets are used in MRI machines and other diagnostic equipment. The presence of rust can compromise the performance and safety of these devices. Therefore, medical magnets often undergo stringent protective measures, including advanced coatings and rigorous quality control.

In the automotive industry, magnets are essential components in electric motors and sensors. Exposure to moisture and road salts can accelerate rusting. Automotive manufacturers often use specially coated magnets to ensure long-term reliability and performance.

Case Studies

One notable case involves the use of neodymium magnets in wind turbines. These magnets are exposed to harsh environmental conditions, including moisture and temperature fluctuations. To prevent rust, manufacturers use high-grade coatings and robust environmental controls. Lessons learned from early turbine designs have led to improvements in magnet protection, enhancing the turbines’ efficiency and lifespan.

#### VII. Choosing the Right Magnet for Your Needs

When selecting magnets for specific applications, several factors should be considered, including environmental exposure, required durability, and cost considerations.

Factors to Consider

– Environmental Exposure: Determine whether the magnets will be exposed to moisture, chemicals, or extreme temperatures.

– Required Durability: Consider the lifespan and reliability needed for the application.

– Cost Considerations: Balance the cost of the magnets with their performance and protective measures.

Expert Advice

Consulting with experts and working closely with suppliers can help identify the best magnet solutions for your needs. Customized solutions, such as tailored coatings and specific magnet compositions, can provide optimal performance and protection.

VIII. Conclusion

Understanding whether magnets rust and how to prevent it is crucial for maintaining their performance and longevity. Different types of magnets have varying susceptibility to rust, influenced by their composition and environmental exposure. Implementing protective measures, such as coatings, environmental controls, and regular maintenance, can significantly enhance the durability of magnets. By choosing the right type of magnet and taking appropriate preventive steps, you can ensure that your magnets remain effective and reliable in any application.