Introduction

Imagine a magnet so powerful and resistant to high temperatures that it has revolutionized industries ranging from aerospace to medical technology. Welcome to the world of Samarium-Cobalt (SmCo) magnets. These remarkable magnets have been a game-changer, providing unparalleled performance in extreme conditions where other materials would falter. As we delve into the intricacies of SmCo magnets, we will explore their manufacturing processes and the technological innovations that continue to push the boundaries of what these magnets can achieve.

Samarium-Cobalt magnets are crucial components in many advanced applications due to their unique properties, including high magnetic strength and excellent thermal stability. They are widely used in high-tech industries, such as aerospace, medical devices, and renewable energy systems. In this article, we will examine the history and development of SmCo magnets, their manufacturing processes, and the latest technological innovations driving their evolution. By understanding these aspects, we gain insight into why SmCo magnets remain at the forefront of magnetic technology.

History and Development of SmCo Magnets

Early Discoveries

The story of SmCo magnets begins in the early 1960s when researchers first explored the potential of rare earth elements in creating powerful magnets. The combination of Samarium, a rare earth element, and Cobalt, a transition metal, led to the development of a new class of magnets with exceptional magnetic properties. These early discoveries laid the foundation for the subsequent advancements in SmCo magnet technology.

Evolution Over Time

Throughout the 1970s and 1980s, significant progress was made in refining the manufacturing processes and improving the performance of SmCo magnets. Innovations in alloy compositions and production techniques resulted in magnets with higher magnetic strength and greater thermal stability. By the 1990s, SmCo magnets had established themselves as indispensable components in various high-performance applications.

Comparison with Other Magnets

Compared to other types of magnets, such as Neodymium (NdFeB) and Alnico, SmCo magnets offer unique advantages. While NdFeB magnets are known for their high magnetic strength, they are less stable at elevated temperatures. Alnico magnets, on the other hand, have good temperature stability but lower magnetic strength. SmCo magnets strike a balance, providing both high magnetic strength and excellent thermal stability, making them ideal for demanding applications.

Manufacturing Processes of SmCo Magnets

Raw Material Extraction and Preparation

The manufacturing of SmCo magnets begins with the extraction and preparation of raw materials. Samarium is typically sourced from mineral deposits containing rare earth elements, while Cobalt is obtained from various mining operations. These raw materials undergo purification processes to remove impurities, ensuring the highest quality inputs for magnet production.

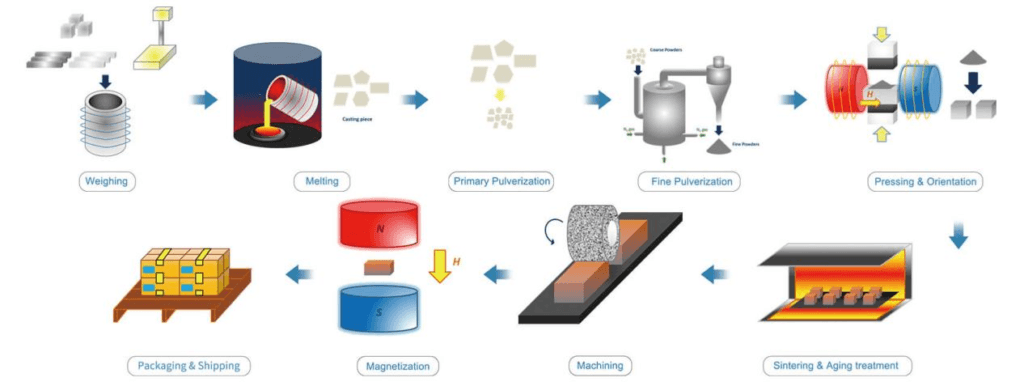

Powder Metallurgy Process

The primary method for manufacturing SmCo magnets is powder metallurgy. This process involves several key steps:

– Alloying: Samarium and Cobalt are alloyed in precise proportions to achieve the desired magnetic properties. The alloy is melted and cast into ingots.

– Milling: The ingots are then crushed and milled into a fine powder. This step is critical for achieving a uniform particle size, which is essential for the subsequent steps.

– Pressing: The powder is pressed into the desired shape using a die. This step involves compacting the powder under high pressure to form a solid, cohesive mass.

– Sintering: The pressed shapes are heated in a controlled atmosphere to a temperature below their melting point. Sintering causes the particles to bond together, resulting in a dense, solid magnet.

Sintering and Heat Treatment

Sintering is a crucial step in the production of SmCo magnets. During this process, the pressed shapes are heated to approximately 1100-1250°C. This high-temperature treatment allows the particles to fuse, enhancing the magnet’s density and strength. Additionally, specific heat treatments are applied to optimize the magnetic properties, such as coercivity and remanence.

Machining and Finishing

After sintering, the magnets may require further machining to achieve the precise dimensions and shapes needed for their intended applications. Techniques such as grinding and cutting are used to achieve the desired specifications. Surface treatments and coatings, such as nickel or epoxy, are often applied to protect the magnets from corrosion and mechanical damage.

Quality Control

Quality control is a critical aspect of SmCo magnet production. Various testing and inspection methods are employed to ensure that the magnets meet stringent performance and reliability standards. Magnetic properties, dimensional accuracy, and surface integrity are thoroughly evaluated to guarantee consistency and performance across all manufactured units.

Technological Innovations in SmCo Magnets

Advanced Manufacturing Techniques

Recent advancements in manufacturing techniques have significantly enhanced the performance and capabilities of SmCo magnets. One such innovation is additive manufacturing, commonly known as 3D printing. This technology allows for the creation of complex shapes and structures that were previously difficult or impossible to achieve with traditional methods. Improved sintering technologies have also led to more efficient production processes and higher quality magnets.

Material Innovations

Material scientists have made significant strides in developing high-performance SmCo alloys. These new alloys offer enhanced magnetic properties, such as higher magnetic strength and improved resistance to demagnetization. Additionally, efforts are being made to reduce the dependency on rare earth elements by exploring alternative materials and alloy compositions.

Nanotechnology Applications

Nanotechnology has opened up new possibilities for SmCo magnets. By manipulating materials at the nanoscale, researchers have been able to create nanostructured SmCo magnets with superior magnetic properties. These advancements have led to the development of magnets with higher energy densities and improved performance in various applications.

Sustainability and Environmental Impact

As environmental concerns become increasingly important, the SmCo magnet industry is adopting more eco-friendly manufacturing practices. Efforts are being made to minimize waste and reduce the environmental impact of production processes. Additionally, recycling and reusing SmCo materials are being explored to ensure a sustainable supply chain.

Applications of SmCo Magnets

Aerospace and Defense

SmCo magnets play a vital role in the aerospace and defense industries. Their ability to maintain stable magnetic properties at high temperatures makes them ideal for applications in aircraft engines, missile guidance systems, and satellite communications. The reliability and performance of SmCo magnets in extreme conditions are critical for the success of these advanced technologies.

Medical Technology

In the medical field, SmCo magnets are widely used in Magnetic Resonance Imaging (MRI) machines and other medical devices. Their high magnetic strength and stability ensure accurate imaging and diagnostics. Additionally, SmCo magnets are used in various medical sensors and actuators, contributing to the advancement of medical technology.

Automotive Industry

The automotive industry benefits significantly from SmCo magnets, particularly in the development of electric and hybrid vehicles. These magnets are used in motors and generators, providing the necessary performance and efficiency for modern automotive technologies. The durability and thermal stability of SmCo magnets are crucial for the demanding conditions of automotive applications.

Consumer Electronics

High-performance audio and electronic devices rely on the superior magnetic properties of SmCo magnets. These magnets are used in speakers, headphones, and other audio equipment to deliver high-quality sound. Additionally, SmCo magnets are found in various electronic components, enhancing the performance and reliability of consumer electronics.

Renewable Energy

The renewable energy sector is another area where SmCo magnets make a significant impact. They are used in wind turbines and other renewable energy systems, contributing to the efficient generation of clean energy. The high performance and durability of SmCo magnets ensure the long-term reliability of these critical technologies.

Future Trends and Developments

Emerging Technologies

The future of SmCo magnets is bright, with emerging technologies poised to unlock new applications and capabilities. Advanced robotics, quantum computing, and space exploration are just a few areas where SmCo magnets are expected to play a pivotal role. As these technologies evolve, the demand for high-performance magnets will continue to grow.

Research and Development

Ongoing research and development efforts are focused on further enhancing the performance and capabilities of SmCo magnets. Scientists and engineers are exploring new alloy compositions, manufacturing techniques, and applications to push the boundaries of what these magnets can achieve. Collaboration between academia, industry, and government organizations is driving innovation in this field.

Market Trends

The market for SmCo magnets is projected to experience steady growth in the coming years. Factors such as increasing demand for high-performance materials, advancements in technology, and the expansion of renewable energy projects are driving this growth. Economic considerations, such as the availability of raw materials and geopolitical factors, will also influence the market dynamics.

Conclusion

Samarium-Cobalt magnets have established themselves as essential components in a wide range of advanced applications, thanks to their unique properties and exceptional performance. The manufacturing processes and technological innovations discussed in this article highlight the continuous efforts to enhance the capabilities of SmCo magnets. As industries evolve and new technologies emerge, the importance of SmCo magnets will only grow. Continued research, development, and innovation are crucial to unlocking the full potential of these remarkable magnets, ensuring they remain at the forefront of magnetic technology.

Understanding the intricate processes and cutting-edge advancements behind SmCo magnets gives us a deeper appreciation for their role in shaping the future of various industries. As we look ahead, the future of Samarium-Cobalt magnets is not just promising; it’s magnetic.